Best Gummy Making Machine for Premium Candy & Nutraceutical Production

From small batches to high-volume lines, customizable machines

engineered for consistency, quality, and food safety

AIPAK Gummy Making Machine

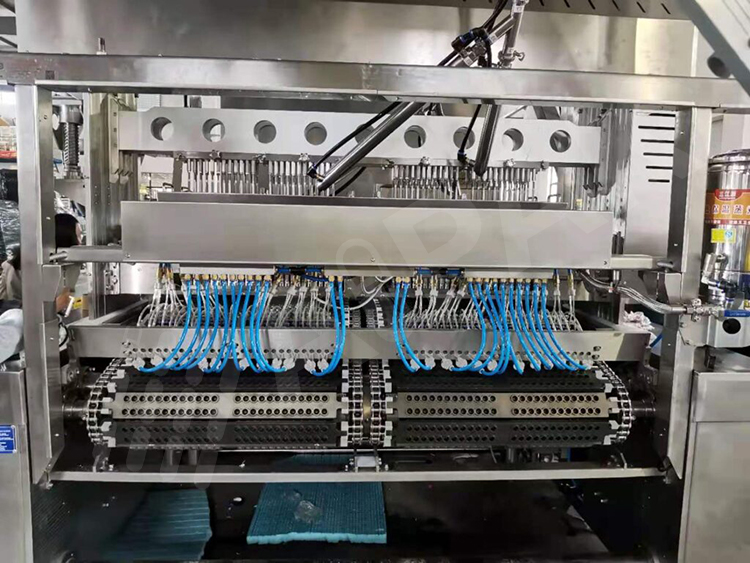

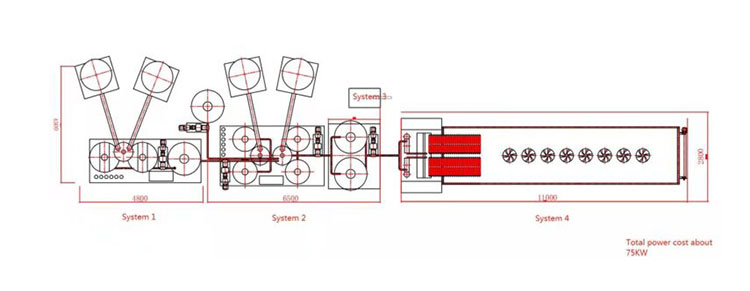

AIPAK Gummy Making machine is an advanced and continuous production line for making different sizes of gummy candies.It is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied. This depositing line consists of jacket dissolving cooker, gear pump, storage strainer, storage tank, discharging pump, color & flavor jigger, color & flavor mixer, depositor, cooling tunnel, electric control cabinet, etc.

AIPAK Gummy Making Machine Main Technical Parameters

| Model | APK-GM80Q | APK-GM150 | APK-GM300 | APK-GM450 | APK-GM600 |

| Capacity | 80 kg/h | 150kg/h | 300kg/h | 450kg/h | 600kg/h |

| Candy weight | As per the candy size | ||||

| Depositing Speed | 25~35 n/min | 25-45n/min | |||

| Steam requirement | 80kg/h,

0.4-0.6MPa |

250kg/h,

0.5-0.8MPa |

300kg/h,

0.8-1.2MPa |

400kg/h, 1.2-1.6MPa | 500kg/h, 1.6-1.8MPa |

| Compressed air requirement | 0.2m3/min,

0.4-0.6MPa |

0.2m3/min,0.4-0.6MPa | 0.2m3/min,0.4-0.6MPa | 0.25m3/mi,0.4-0.6MPa | 0.3m3/min,

0.4-0.6MPa |

| Working condition | Temperature 20℃-25℃;Humidity45-55% | ||||

| Electric power needed | 55kw/380V | 65kW/380V | 75kW/380V | 80kW/380V | 85kW/380V |

| Total Length | 8m | 16m | 18m | 18m | 20m |

| Weight of machine | 2500kg | 3500kg | 4000kg | 4500kg | 5000kg |

AIPAK Gummy Making Machine Product Samples

How to Choose the Right Gummy Machine

To select the best machine for your needs, consider:

Your production volume: small artisanal batches vs large factory output

Formulation: vegan / gelatin / pectin / sugar-free / medicinal gummies

Shape & texture: soft, chewy, sugar-coated, layered, etc.

Hygienic & regulatory standards required for your market (FDA, HACCP, ISO etc.)

Space & power constraints in your facility

Desired automation level vs labor cost

AIPAK Gummy Making Machine Production Process & Ingredients Compatibility

Ingredient mixing & cooking: heating gelatin or pectin with sugars, syrups, flavors

Molding / depositing: pouring into molds; multi-color layering possibly supported

Setting / Cooling / De-molding: precise temperature and timing essential

Drying / Curing: to achieve desired chewiness or shelf life; residual moisture adjustment

Coating / Sugar-dusting (if applicable): finishing touches for texture / appearance

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Gummy Making Machine FAQ

1: What types of gummy machines do you offer?

AIPAK offers a range of machines – from manual or bench-top models for small batches to fully automatic lines suited for industrial scale. Each model supports varied mold shapes, numbers of molds, and degrees of automation.

2: Can I use vegan or gelatin alternatives like pectin or agar?

Yes, our gummy making machines are compatible with multiple gummy formulations, including gelatin, pectin, agar, or mixed formulations. For vegan or specialized formulations, we can customize heating profiles and molds.

3: What is the typical batch size or capacity?

Depending on the model, capacity ranges from 5-50 kg/hr for small-scale machines to 1,000+ kg/hr for industrial machines. AIPAK also offers intermediate models to suit medium volume producers.

4: How do humidity and moisture impact gummy texture?

Moisture content and drying time are critical. Excess humidity can cause gummies to remain too soft or sticky; too little can make them brittle. Our gummy making machines include drying tunnels / controlled environment options to achieve optimal texture.

5: What are the power requirements and energy consumption?

Power depends on the machine size and features (number of heating zones, drying oven, etc.). Our gummy making machines are designed for efficiency. Typical power ranges from 5 kW for small models to 30-40 kW+ for large volume lines.

6: How do I clean and sanitize the machine?

We design for ease of cleaning: food-grade stainless contact surfaces, removable mold trays, CIP / washdown compatible parts. Always follow manufacturer guidelines for sanitation to maintain food safety.

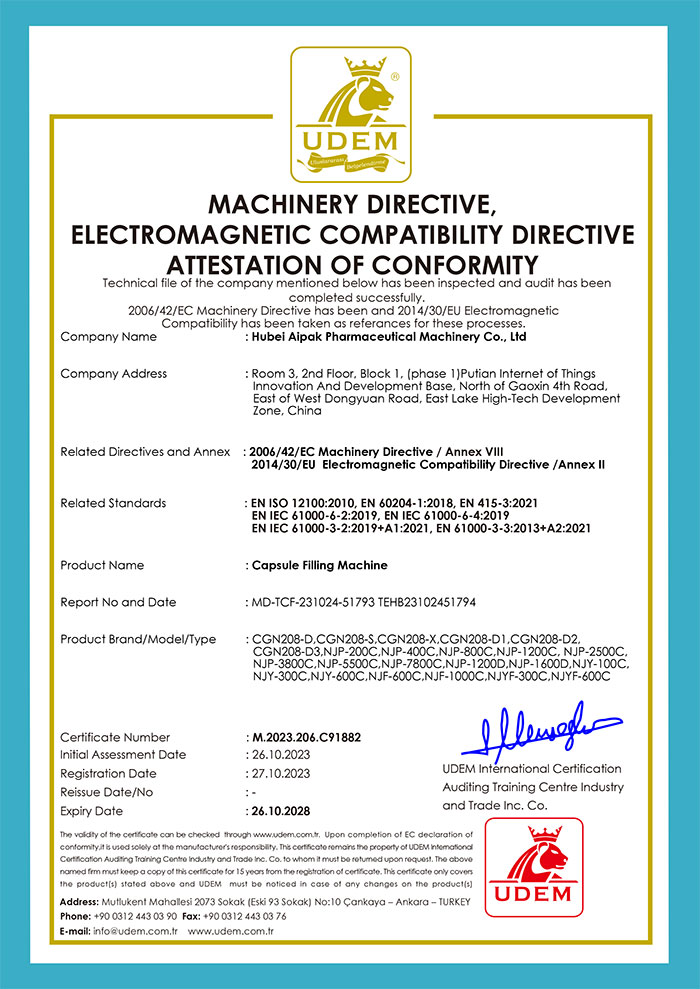

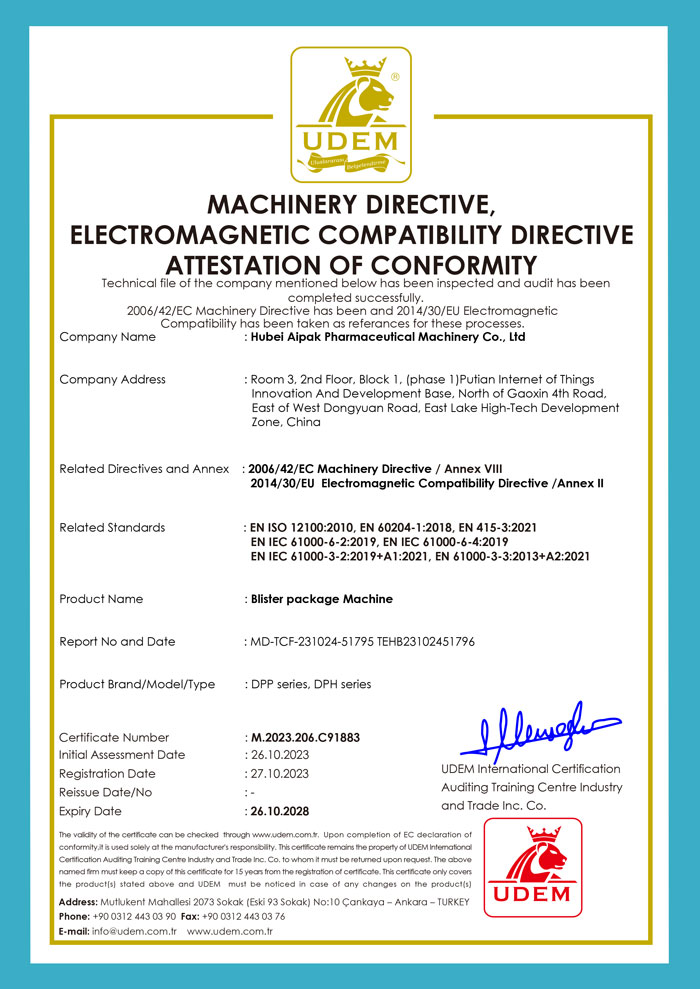

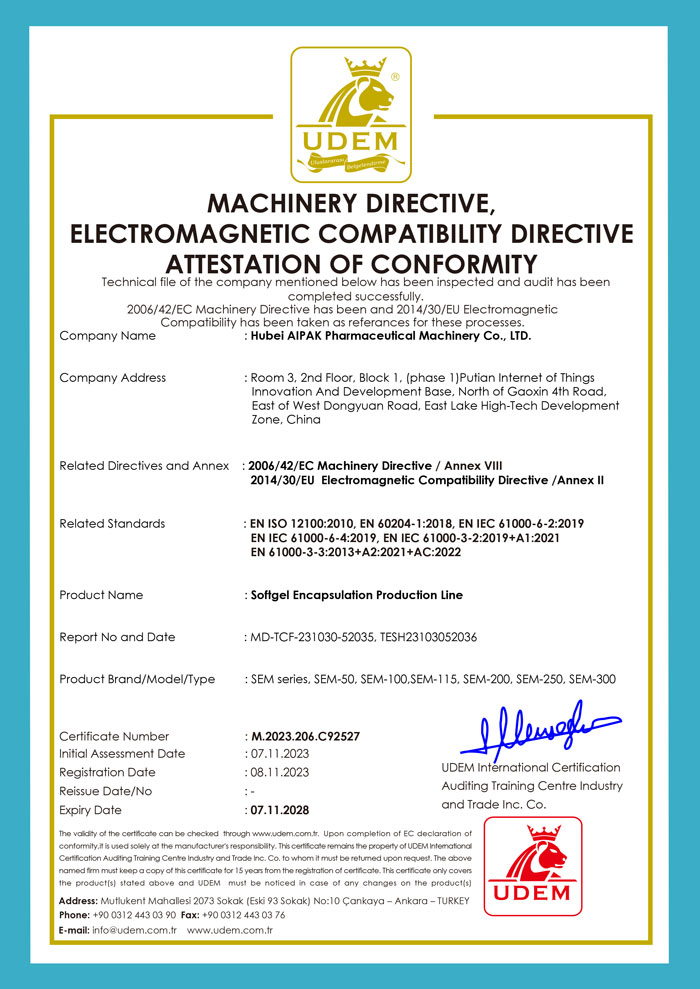

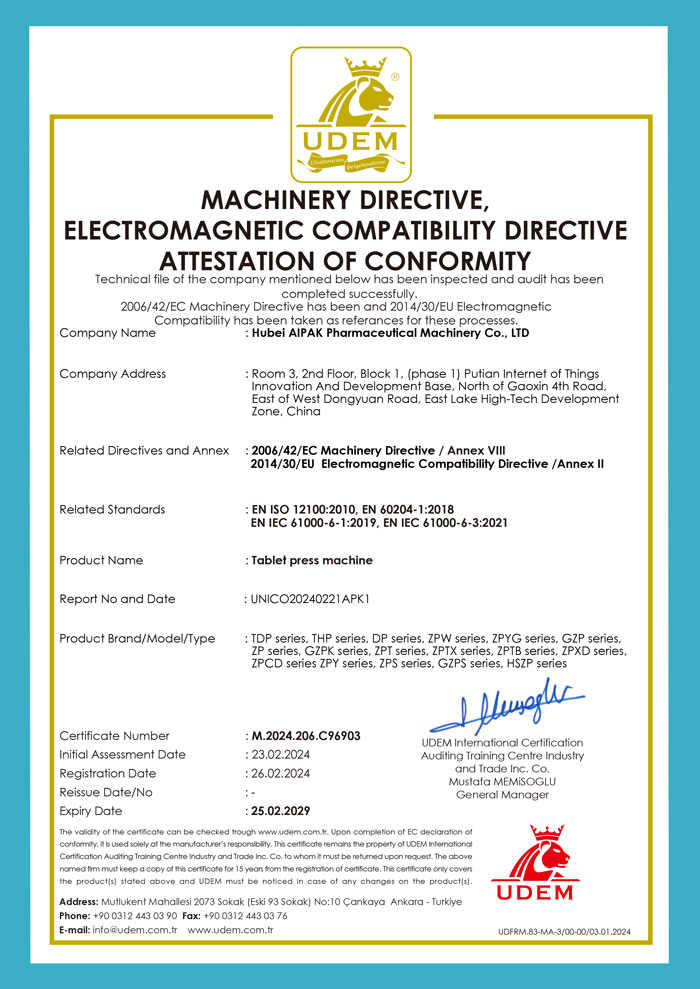

7: What certifications do these machines and/or your factory have?

Our manufacturing facilities are ISO, CE, and HACCP certified. The machine materials used are FDA / food-grade compliant; we can also assist with GMP compliance if required for the end product.

8: What is the lead time for delivery and do you provide spare parts?

Typical lead time is 4-8 weeks depending on customization. We supply spare part kits and provide technical support for maintenance.

9: Can you provide free samples or demos?

Yes, for qualified clients we offer sample batches or demos so you can test mold design, texture, flavor and ensure the machine meets your requirements.

10: What is your minimum order quantity (MOQ) or minimum purchase for custom molds?

MOQ for standard machine purchase is typically one unit. Custom molds may have MOQ (e.g. 1-5 mold sets depending on shape / material) due to tooling costs. We’ll discuss specifics based on your design.

The Buyer's Guide

Gummy Making Machine: The Ultimate Buying Guide in 2025

Have you ever heard of adding beneficial ingredients to gummies is the future?

It is why to swallow a pill if you can eat a sweet candy containing functional ingredients.

Gummies, nowadays, are specifically formulated to promote health benefits like immune support, bone health, sleep, and stress support.

Today, I will use this article to introduce the greatest invention: gummy making machine that makes the production of these gummies possible.

Reading through, you will get every detail you want to know about the gummy making machine that is a piece of confectionary equipment to manufacture all kinds of gummy bear candies.

Let’s get started directly.

1.Brief History of Gummy Making

It's consistently superb in the event that you begin something with history. There you go.

History of Gummy Bears

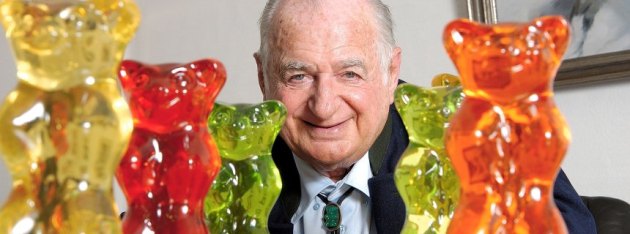

Hans Riegel, Billionaire Maker of Gummy Bears

Previously, the Gummy candies production measure conveyed Gummy resembling a bear. Making Gummy bear sweets seems as though bears were a consequence of a street jubilee.

The reason for the gummy candies production measure comes to the mid-1920s. The maker of the Gummy bear measure passes by the name Hans Riegel.

The maker saw bears acting in the festival and decided to make it in a comparable structure. The name Gummy comes from the primary fixing which was gum Arabic.

- 1920 Haribo is set up by Hans Riegel in Bonn. According to legend, the main association's capital joined a sack of sugar, a marble piece, a broiler, and a kettle.

- 1922 Riegel creates a bear-shaped common item upgraded gelatin, which he calls Tanzbär or moving bear.

- It wasn't until 1982 that Haribo had an action in the U.S. besides, the sweets ended up being immediately available to all Americans under the name Gold-Bears.

The move towards worldwide business was a victory and now gummy bears are acknowledged everywhere on the planet.

The commonness of the gummy bears has delivered different pantomimes and competitors, most conspicuously the Black Forest brand of Gummy bears started by the Ferarra bears Company, who presently moreover has Trolli makers of the fundamental gummy worm in 1981.

Everyone has their main image, yet the primary Haribo remains the best by far mostly due to its uniqueness.

2.What is a Gummy Making Machine?

A gummy bear production machine is a machine that you can use to make various types of the gummies.

AIPAK Gummy Making Machine

Gummy bears are basically a pleasant treat and having a sugar elective offers everyone an opportunity to experience the elevating delight that comes when you pop a little bundle of Gummy bears in your mouth.

A gummy making machine is a robotized gummy production machine line constrained by PLC, you can use it to make various sizes of Gummy bears, and other molded Gummy bears or Jellies.

A typical mark including a cooking unit bears speculator, bears styles, treats cooling machine and its association pumps, and so on.

3.Are there any Differences between the Gummy Making Machine and the ordinary Candy Making Machine?

The Gummy making machine and the bear production machine are both useful for making jellies and bears.

The two machines are available in both semi-automatic and automation version to suit your necessities.

Regardless of the likenesses, the two machines contrast in the working principle similarly as the trimmings being utilized. The Gummy making machine makes Gummy bears light and allows you to bite.

You also can use the machine to make Gummy bears of various animal shapes depending upon the structure.

Bears gummy maker machines, of course, make hard bears of various shapes and sizes. To an extent, the Gummy making machine is more noteworthy than the sweets producer machine.

4.Which Industries uses the Gummy Making Machine?

Following industries can use gummy bear in one way or another:

Food Processing Industry

You will utilize the gummy making machine in the food handling industry to make sticky bear sweets.

It is fit for delivering various sorts of gummies as indicated by the necessities of the client.

Nutraceutical Industry

Nutraceutical gummy candies

You will utilize the gummy production machine to make nutraceutical items to enhance various weight control plans.

The nutraceutical items aid the counteraction just as treatment of various sicknesses.

Healthcare Industry

Gummy bears normally contain generally void calories, yet as of late gummy bears containing nutrient C, created by producers, for example, these are being advertised to guardians of small kids. Multivitamins have likewise been delivered as gummi bears for youth who don't like eating sour things.

Crime Industry

Gummi Bears contain the best material for tricking unique mark scanners.

Food Decor Industry

Gummy Bears are candy which is brilliant for adorning cakes, and taste preferable with icing over those cheddar seasoned fish.

Gummy Bear Decorated Food

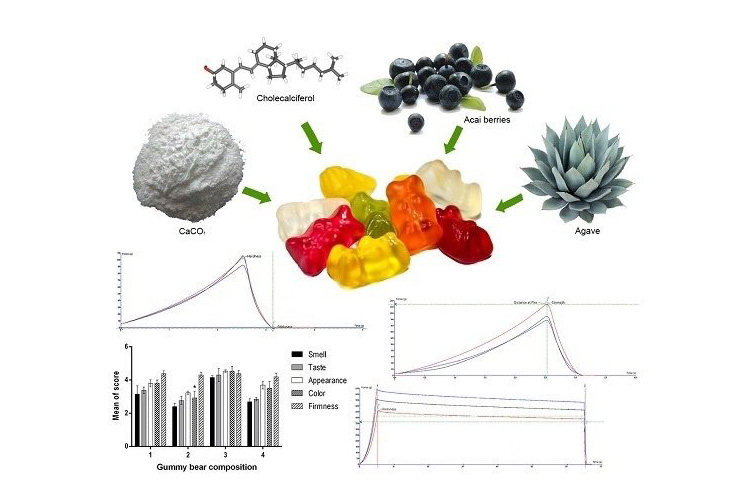

5.What is the Gummy Making Ingredients?

This will help you make the decision if you know about the ingredients of a product.

You can make Gummy bears by using various types of ingredients depending upon the objective market.

Gummy bears' plans are consistently grown by experienced food technologists and logical specialists.

By combining various ingredients, they can control the various characteristics of gummy candies, for instance, surface, taste, and appearance. The fundamental ingredients join water, gelatin, sugars, flavors, and shadings.

Ingredients of Gummy Bear

Here is the listing of the ingredients that you will need for making gummy bear:

WATER

This is an all-inclusive and the principle dissolvable that you will use in blending all the ingredients for making gummy jelly candies.

You will, although, need to follow the extents of water that you add to the blend for an ideal mixture.

It is additionally the principle saturating fixing that helps with making the gummy bear milder.

Water Used for the Recipe

Edible Gelatin

These is the essential ingredients that you need for the making of Gummy bears.

Gelatin is a sort of protein that you can get from animal tissues by heating up an animal's skin, horns, and bones.

It will outline a gel-like, thick course of action when you mix it properly with the ideal proportion of ingredients including water.

The adaptable thought of gelatin will similarly allow you to think about the semi-solid twist for the gummy desserts.

Mixing gelatin properly in the right conditions will provoke the game plan of a chewy Gummy surface of the gummy desserts.

Sweeteners

Gelatin, in itself, is impartial and has no taste. You ought to have added sugars in the blend to improve the kind of gummy bear sweets.

A part of the sugars that you will add to the blend is different sorts of sugars depending upon the gummy desserts.

The guideline sugar that you can use comes from sugar sticks or beets. Besides that, you can use substitute sucrose with fructose as the rule sugar.

Colors

You can create gummy bears in a range of tones & shades reliant upon your prerequisites. To attain this, you will combine food tone with the recipe in understanding the condition of Gummy bears.

Different Colors

Citric Acid

To protect the bears and growth in the time frame of realistic usability, you can add citric acid to the recipe of gummy bears materials.

Citric Acid

Citric acid has a little PH which makes it incredible for tiny bacteria to flourish in quite a low pH climate.

Starch

By adding the starch to the mixture of materials, you can enlarge the main part of the gummy bears.

Starch what is more develops the health fulfillment of the gummy bear. In any case, you should, remind that the necessities may change depending on the objective market. As an example, The elements for Gummy bears that target vegans is distinctive as it has substitute base ingredients.

Flavor

You need to add different kinds of flavors to give Gummy bears different likable types of tastes. You can likewise make different sorts of Gummy bears flavors including orange, raspberry, strawberry, pineapple, and lemon among others. The sort of the gummy bears is likewise an inconceivable determinant of the screening you will utilize.

Corn Syrup

To add the balance in the material of bears to help in the maintenance of the wetness in bears, you will require corn syrup. Apart from that, corn syrup or glucose syrup constructs the volume of gummy bears and makes them softer.

Furthermore, corn syrup aids the anticipation of sugar representation and expands the overall taste of the bears. You will likewise enhance a few added kinds of stuff close by the corn syrup to help in the precaution of microbial growth.

Corn Syrup

For Instance

- The red color derives from raspberry

- Orange taste arises in an orange color

- Strawberries are frequently in bottle green.

- Pineapple originate in a neutral shade

- Lemon commonly adopts the yellow tint

6.Why should you invest in a Gummy Making Machine?

Fast Lower Cost Production

The cycle utilizes a faster setting in the formulation of the gummies. To guarantee quick changeover between production process runs, the shaping framework utilizes another plan, with cut-in molds that permit fast, ease item change by replacing simply the molds instead of the total carriage framework.

Effective for Cost

The exactness and cleanliness of current cooking and keeping methods guarantee that items made utilizing the best method. Gummy cycle profits by uncommon weight and dimensional precision, with no shrinkage, and improved definition for unpredictable item shapes.

Multiple Range of Innovation:

You have a range of innovative things that you can look at in an expanding collection of the gummy bears. A gummy bear settling on the apparatus is a decent decision for your Gummy bears business. Increase your competitive power by decreasing investment for a new shaped gummy can.

AIPAK Gummy Making Machine

Gummy Bear Machine is Multi Tasker

Spontaneous manufacture track, only two-three machinists needed in the entire gummy handing outline. The machine is needed for business use as it speeds up the process and subsequently more significant yields.

Efficiency Makes it Unique

The bears store market is quickly rising, Gummy making machine fit gummy supplements or vitamins, THC gummy bears, liquid gummies, tonic gummy and handy gummy. The starch business and gummy making machine are clean, easy and spares work power. The Profit-Making gummy making machine creation range from flexible little cluster cooking to high yield nonstop cooking lines, the gummy bear yield from 50kgs/h to 600kgs/h.

Variety of Production

You can make a variety of gummy bears with one gummy making machine. Focus filling, many-colors, twofold layer, and other eye-getting bids to the sweetmeat market. Lower investment when you modernize your gummy bear to other designed gummy candies.

7.Is there any limitation of the Gummy Making Machine?

As you utilize the gummy making machine, you may encounter a couple of difficulties that must not stop your machine.

Possible Limitations

Here are a few of the things that may restrict or deter you from utilizing the gummy making machine.

- The first expense of buying the machine may compel you to dive further into your pockets. As it is a bit cost machine after all.

- You may likewise need to enlist experts to introduce the machine which will require more cash.

- You might need to train the team that will be using the machine after all which also gonna cost in one way or another.

- Because of the weight and size of the machine, you won't appreciate the advantage of moving it all around.

- The machine will also demand more space at the premises as well.

8.How many types of Gummy Making Machines are there in the Market?

One huge factor that you should see when buying the gummy making machine is what sort of machine you want to buy.

Here are the fundamental types of the gummy making machine that you can use for your production.

AIPAK Fully Automatic Gummy Making Machine

Fully Automatic Gummy Making Machine

For this situation, you will require not many workers if any since the machine is completely programmed.

You should simply program and design the machine as per your production details.

The completely programmed nature of the machine likewise expands the production limit of the gummy making material.

Semi-Automatic Gummy Making Machine

You can settle on a semi-auto gummy machine for production only when you have some employees.

You will require the staff to help you in playing out a portion of the exercises in the gummy production cycle.

The machine is additionally equipped for playing out a few of the activities of the gummy making activities all alone.

9.What are the Main Components of Gummy Making Machine?

Making gummy candy is neither easy nor takes just a few steps.

Parts of Gummy Making Machine

The gummy making machine has many parts and they are well defined here.

Freezing System

This specific part of this gummy making machine is used for the managing of the temperature. Most of the time it decreases the already increased temperature in the machine.

It utilizes exceptional hardware that can blow chilling air and condition the cooling zone at lower temperatures.

As it removes the warmth, It results in giving a better shape to a gummy bear that remains intact and later good for chewing.

Electrical Unit

Normally this unit is put to maintain the balance of the electricity.

Since the electrical unit is the primary piece of the machine that gives it the force it needs to work the machine.

It has different control frameworks that direct the amount of electricity to control the activities of the machine.

Pneumatic System

You know why it is mandatory to have this system in the machine. Since the gummy production machine relies upon the pressure of the air to play out specific capacities, it has a pneumatic framework to help.

The pneumatic framework gives the pressure of the air while controlling the sum as per the working setups of the machine.

Transport System

The vehicle framework controls and moves the gummy bears fixings and completed items starting with one spot then onto the next.

It comprises transport frameworks among other vehicle components that move the material starting with one station then onto the next.

Mixing and Melting Tank

The dissolving tank is where you will warm the gelatin and different fixings to a fluid state.

The gelatin is a fluid state is anything but difficult to blend in with different fixings and furthermore simple to move to start with one unit then onto the next.

This is where you will blend all the fixings that you require to make gummy bears.

It has a progression of blenders that homogenously blend all the fixings to shape one uniform combination.

Control Panel for Controlling

Most of the time gummy making machine comes with a control panel system that allows you many of the functionalities.

The PLC control board has a machine and human connection that permits you to effectively work with the machine.

You will likewise monitor, setup controls all the working systems of the gummy making machine from the control board.

The touch screen control panel of the gummy making machines gives access to running the process from the machine and also allows you to keep the things under your hands.

Greasing System

The oil framework apples enough oil or ointments on the gummy sweets.

Aside from that, the machine likewise has parts that keep on moving that require regular oiling to lessen erosion.

Items Hopper

Hopper for the products is the piece of the machine where you will put all the items that you require.

By using the hopper, all the fixings move to the dissolving and blending tank for additional processes.

Magnate or Candy Molding Station

That is the area where you will form the candy into various shapes and sizes as per the details of the production.

Sieve

Do you have any idea how we remove starch from the gummy bears? It is a Sieve. Sieve comprises of a progression of metals that vibrate and help with eliminating overabundance of starch from the sticky sweets.

Oscillating Brushes

As its name suggests the oscillator gave a to and fro motion.

The brushes pivot and clean away an abundance of starch from the gummy bears batches.

Sensors

This is the piece of the machine that will sensor all the abnormalities inside the machine's working cycle.

It can naturally prevent the machine from working if there should arise an occurrence of any issues with the machine.

Aside from that, the sensors additionally aid the appropriate adjustment of the machine.

It will help with advising the levels you need to hold fast to while working the machine.

Dust Assortment Unit

At the residue assortment unit, you will have the option to gather the abundance of starch tidy and dispose of it likewise.

Aside from that, you can reuse the starch dust as needs be in the wake of guaranteeing it is fine for use.

10.How to Make Gummy Bears?

In the gummy bear production, we have to use a specific kind of machine whose name is a starch mogul.

The assembling cycle happens in different phases, and the large scale manufacturing of gummy candies has enlisted huge upgrades to improve the effectiveness and speed of the cycle.

Let's dig into further information about how these gummy candies are being made?

Blending of the materials: Due to their production at a very large scale, gummy bears are mostly produced on a heavy level.

To begin with, the fixings are combined in a huge vat.

The most common type ingredients are sound like syrup, corn, pure water, edible colors, gelatin, and lastly flavors.

Most of the time citric acid and fruit juices are the essence of the flavor.

Gummy Making Parts

Cooking: Once the fixings or required items are blended, the subsequent fluid is cooked until it thickens into what producers call a slurry.

Covering of molds: Prior to putting the slurry in molds, the molds for gummy bears are fixed with corn starch, which keeps the gummy bear from adhering to molds.

Molding

The slurries at that point filled molds for forming. Gummy bears would be filled bear-formed molds, obviously. There are so various kinds of shapes for sticky confections, however of which bear formed is generally well known.

Cooling Down and Setting

Turnover Tray

Just after putting the slurries of candy bear into the mold, it needs to cool down to 65º F and permitted to settle down for 24 to 26 hours to permit the slurry to set and cool down.

Unmolding

Like almost after one day in mold, the sticky bears confections are eliminated and set in a huge drum tumbler.

Oil Tumbling

Oil Srayer

Within the tumbler, the sticky bears confections are tumbled in a light food-grade oil that retains any excess corn starch and keeps the sticky bears confections delicate and new.

Bundling

Once they are done tumbling in oil, it is all down with the making and now ready to be delivered to the people who crave this like you.

11.What is the Working Principle of Gummy Making Machine?

The more you know about machines the better you have a grip on everything.

These are some of the primary working standards of the gummy making machines which is likewise the way toward making candies of gummy.

To make the gummy jellies there is a bit of a tricky process that is holding of the starch in the process.

Whenever you making candies of gummies for yourself, you will experience the accompanying advances:

Stage of Preparation

To begin with, you will put all the fixings that you require to dewel in the hooper of the gummy making machine.

Prior to that, you need to affirm that the machine is an inappropriate working environment by doing an intensive review.

Never forget one thing that you will put the ingredients in the item hopper as indicated by the correct amount.

From that point onward, you will turn the power on the machine and set this up prior to beginning the process by starting the button.

Compounding of Bears

Compounding

The fixings will move from the items container and into the blending and softening tank in proper amounts.

The blending and melting tanks have blending, warming, and cooling capacities and are accessible in various sizes.

Relying upon the amount of the ingredients, it can take very near to three hours to complete the gummy candy process of compounding.

Once the compounding cycle will be completed, you will take an example of the group to the quality control research center.

Now, you will run a test if everything is as pre-planned and it does have the production requirements.

Formation of Gummy Candy

In the wake of affirming that the chunk of the specific product is finished with the correct determinations, you will move it from the blending tank.

It will stream to the station of or to one more holding machine which you without much of a stretch can recognize as Mogul.

Now it is the time, you will blend the liquid bunch in with starch which plays out the accompanying capacities:

- Be aware that your molten batch never sticks to the wall of the molden machine.

- It will likewise hold gummy candies in the correct spot during the setting, drying, and cooling measure.

- It likewise retains enough dampness out of candies, hence keeping the texture the proper level.

It likewise has a plate that has various shapes or forms that will shape the group appropriately.

The plate or forms may accept the state of various shapes, for example, the fish, bear, dolphin, bottle, or many other possible shapes.

The molds are as of now in a strong state because of the conditions inside the holding station.

From that point forward, you will move the cluster on transporting belt lines as the machine right to the starch buck.

In this final section of the Gummy making machine, gummy bear will be interlacing as it moves along the belt on the plate or tray.

Final Stage

At the starch back, the bunch falls onto vibrating metal screens which you can recognize as sifters.

The vibration of the sifter along with activity from wavering brushes will eliminate the overabundance of starch from the bunch.

Now the chunk is consists of gummy candy with the sort of shape that you do demand.

You can likewise pass the group of sticky candy through the embellishment stage to give it the correct improvements.

You have to investigate the candy as per the requirement of the production and wipe out the ones that have issues.

From that point forward, you will permit the sticky candy to continue to the bundling stage for additional preparation.

12.What is the General Specification of a Gummy Making Machine?

You can pick electrical warming or steam warming for the cookers, based on your market circumstances.

Think about the electrical expense and steam cost and pick the financially better one for you.

The Output of gummy bears per hour

Each gummy making machine should plan with maximum capacity, the final capacity will rely upon your gummy bear size and weight.

For example: If the gummy bear production line can make max 400kgs/h.

In the experience that your need to make a gummy bears like Haribo gummy bears just about 0.2 meters (0.8 in) long, weigh around 0.5 tsp, here, your last yield will be 2.5g x 50strokes/min x 10 x 2cavities x 60min=150kgs/h.

If you furthermore need to make five grams gummy bears, at that moment your final product will be 5g x 50strokes/min x 10 x 2cavities x 60min=300kgs/h.

Gummy Making Machine Dimensions

In view of various limits, the components of the entire gummy bear production line will be different. The greater size, the more space required.

You can discover superb machines, plan your line with straight kind if your factory rent is high, U sort, or L sort dependent on your restricted space.

Production Condition

Normally for gummy bear putting machine necessities

Brilliance: 50Lux, temperature 20~30℃, stickiness 45~50%, kindly check with your suppliers, and make the coordinated production condition in like manner.

Consumption of energy

You need to keep in mind the following features realted to the consumption.

Electrons, the greater capacity, the high the electrical energy needed. Steam consumption (if warmed by a steam kettle), the steam pressure ranges from 0.2~0.6Mpa.

Worker needs, usually for the line, are constrained by PLC, so the total gummy bear production line can be viewed by 2 to 3 workers.

Compacted air required for remodeling and wrapping machine, the steam prerequisite: 200000 ~ 600000pascals, packed air utilization range from 0.2~0.6 m3/min (in kiloliter per moment).

13.What other Equipment are Needed to Cooperate with the Gummy Making Machine for Gummy Making Process?

Production Line

As the process is a bit hard to run gummy making machine needs some supporting parts to support them as well.

The below mentioned are some of the key parts of the gummy making machine which includes;

Jacketed Cooker

This part of the machine is specifically used to ripen the material poured in like maltose and sugar for example and partly do it quite fastly.

It comes in different limits relying upon the machine that you are utilizing.

Holding Tank

That is the place that stores the solution fixings you have for doing.

It is likewise accessible in various limits relying upon the style and size of the gummy making machine.

Gummy Bear Depositing

Gummy/Jelly depositing and cooling tunnel unit

You can utilize this help gear to help with keeping various sums and amounts of sticky treats.

Cooling Tunnel

The cooling burrow disposes of extra warmness from the sticky treats.

You can handle the cooling hotness in the tunnels of cooling as indicated by the specifications of the production.

Weigher Gummy Making Machine

This is the part of the machine that you will use for the arrangement of the fixings or gummy bear pre-mixing.

It works by measuring all the vital fixings both in fluid and strong structure.

This is where you mix them thoroughly in the tank after putting all the ingredients used in one place.

It relies upon the pump and vacuum to move on the blend to the following phase of the sweet bear machine.

The request for put on the more ingredients just as blending time will rely upon the formula for doing gummy bear.

Loop Cooker Gummy Making Machine

You may utilize the machine to play out the accompanying capacities:

- Dissolving the elements for making sticky sweets, for example, sugar, water, and glucose slurry.

- Pre-cooking just as the cooking of sugar, water, glucose-slurry.

The machine has an exceptionally high limit and can cook a huge amount of starch.

Aside from that, it is not difficult to clean and keep up with an ongoing cooking framework.

Tanis Jet Cooker

You will utilize the machine to cook the starch jam fixings that you will require for doing gummy bears.

It additionally has an exceptionally high limit with regards to performing the good capacities.

Added Substance Blending System

You can utilize this machine to different added substances to the mass that has already gone through the cooking cycle.

A portion of the advantages of utilizing the machine include:

- It offers precise dosing of the added substances to the blend.

- It additionally has an appropriate framework for the inclusion of nutrients.

- You can likewise control the shadings that you add to the combination utilizing this machine.

This incorporates up to 6 distinct flavors and shadings.

Gel Molding Starch 800 R-HC

You can utilize this machine during the gum masses and molding of the jellies.

A portion of the benefits of utilizing this machine include:

- It is effectively open as you can approach the basic components of the machine without any problem.

- It additionally stores the items to the molding gummy cycle as it works at a moderate speed.

- It has an ergonomic plan which makes it simple to clean and decreases the odds of starch defilement.

- It is fit for working at various statures and adds starch to the combination during the trim cycle.

T-Gel Starch Conditioning

You will utilize this machine to aid the molding of starch.

A portion of the focal points you will insight by utilizing this machine include:

- The machine is energy proficient as it saves a great deal of energy subsequently lessing the expense of the process.

- It has an appropriate equilibrium of stream as it moves the fixings or ingredients starting with one point then onto the next for additional preparation.

- It comprises a triple sifter framework which guarantees that the starch is perfect enough before the move.

- The machine is protected and you can be certain that there will be no blast during the time spent utilizing it.

Candy Cleaner

You will utilize this sort of machine to cleansing the gummy bear by using the process of molding.

A portion of the highlights and points of interest of the gummy bear consists of the following;

- It utilizes the standard of compacted air to clean the gummy bear effectively.

- It is about cleaning the gummy bear mostly sterile manner without including the utilization of brushes.

- It additionally includes a residue assortment framework incorporated inside the machine that gathers any type of residue.

- You can without much of a stretch dismantle it for legitimate cleaning and examination.

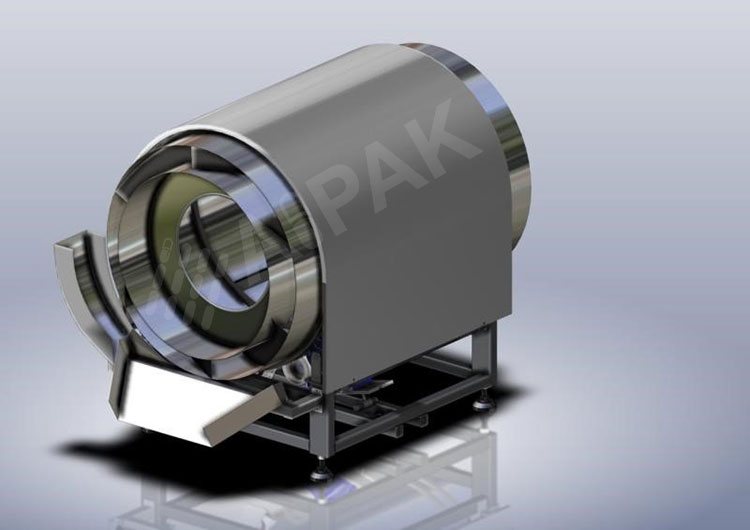

Oiling Drum

Sugar Coater

You can utilize the oiling drum to consequently add a cleaning specialist layer on jam or gumming treats.

Oil drummer can be in the small, medium, just as enormous limits.

The highlights, just as favorable circumstances of the machine, include:

- The principle machine making material is treated steel consequently guaranteeing sturdiness and disinfection.

- Hardened steel likewise guarantees that the execution of oil on the sticky candy is clean.

- It takes into consideration variable increments of dosing specialists.

- It likewise has a control board where it demonstrates time and permits you to change the settings.

- You can either pick between the little or the enormous limits relying upon your creation necessities.

Sander

This is a programmed machine that you may utilize for persistent glossing over of starch formed delicate bubbled sticky confections.

You can utilize the machine on little, medium just as enormous limits.

The primary focal points of utilizing the sander include:

- Sterile execution of the whole cycle consequently encouraging no pollution.

- You can change the machine to slant at various points relying upon the creation details.

- It comprises of a solid twofold drive framework and a tempered steel body.

- It has a liner with a unique fumes framework for appropriate dampness decrease.

- Aside from that, it has radiators for air and sugar drying.

Gel Conditioning Room

This is the machine that might be utilized for conditioning purposes effectively.

The upsides of utilizing this sort of machine include:

- The machine has simple and less exorbitant to buy and keep up.

- The machine has a legitimate guideline of the wind stream control framework that diminishes cooling and heating loops.

- The machine has elective units that uphold each other when any of the units is down.

- The machine has more modest ventilations with greater rooms which burn-through insignificant energy.

14.What Quality Standards Gummy Making Machine Meet?

There are always some standards to follow by any machine. In the case of the gummy making machine, you need to guarantee that the gummy making machine consents to explicit quality standards.

These quality necessities guarantee that the gummy making machine is fine for you and also make sure the long life of the machine.

Few of the quality prerequisites that the gummy making machine holds are these;

International Standards Organization is also known as ISO confirmation in agreement to the worldwide assembling norms and it also makes sure that everything is being made on the given set standards.

cGMP is related to the current assembling rehearses which guarantees the machine is in agreement to legitimate assembling rehearses.

It ensures that the machine has the most recent types of demonstrated innovation for making gummy bears.

CE which guarantees that all the electrical necessities are best in class and is fine for use.

This will, nonetheless, fluctuate with the location with which the machine will be as the force prerequisites differ.

FDA and well known as Food and Drug Administration which guarantees the machine is protected and reasonable for use in gummy making machine production.

The quality organization body will likewise differ as per the area the machine will be working.

Aside from the above details, you need to play out thorough quality control of the element or ingredients.

You need to play out an intensive assessment of the fixings at the Quality Control research center guaranteeing they adjust to determinations.

A portion of the tactile attributes that you have to make sure incorporate shading, appearance, smell just as flavor.

You need to play out a quality control inspection that will guarantee that the fixings or indigents produce quality and predictable bear candies.

15.How to Install Gummy Making Machine?

Gummy Making Machine Installation Steps

- First thing first, always clean the place where you want to put your machines.

- Set out the gummy bear hardware as per the design.

- Link up the gummy making machine and change it to the level position.

- Link up the heat protection water gulf and source pipe.

- Link up the compacted air to the changing chamber.

- Also make sure that you link up compacted air to projecting lifting and finding chamber.

- Gummy making machine utilizes a switch that is three-phase, five-wire framework, including ground wires and zero lines. If it's not too much trouble guarantee that the force isn't associated prior to wiring.

At that point, the provider engineer begins to troubleshooting steps.

16.What is the Cost of Buying a Gummy Making Machine?

The cost will be between from:

- l Small-scale gummy making machine: US$10,000-30,000

- l Automatic gummy bear production: US60,000-160,000

- l Fully automatic gummy bear production: US$120,000-280,000

17.What is the Factor you Should Keep in Mind When Buying a Gummy Making Machine?

Having a look at something is always better they say. But, not in the case of when you want to buy a machine like the Gummy making machine. There is no way you can just have and look and not deep insights before buying a machine.

To get yourself an appropriate gummy making machine you have to have some key factors in your mind. Out of them, these are some of the common specifications:

- A segment of sticky treats creation framework

- Part of sticky treats creation hardware

Attributes of the machine

The elements of the attributes of the gummy making machine incorporate the size and weight of the machine Edith, length, and height.

How much production do you want with your machine decides the size of the machine.

Other than that The dimension of your Gummy making machine is also decided by the size of your premises.

Production's Capacity

The greater the production limit, the greater the machine.

You should get a gummy making machine that will accommodate your requirements of the production.

The limit of production likewise will decide the degree of computerization of the machine.

For example, you will require a completely auto gummy making machine in the event that you have an extraordinary plant for the production.

Electricity needs of Machine

Various machines have changing force prerequisites relying upon the method of production.

You ought to consider the sort of work the machine will perform and decide the electric prerequisites.

Operational Condition and Requirements

For this situation, you will take a look at other operational prerequisite points, for example, coldness and warmth ness and humidness.

You can decide the most noteworthy temperature necessities in centi grades, for example, 550 C.

You ought to likewise decide the dampness of activity in rate to 100%, for example, 55% dampness.

Depositing Time

Knowing the specification about the deposition time in a gummy making machine is another factor to keep in mind.

This is an important factor to consider because this is where a gummy making machine assures that how much of the amount is being deposited. If it is right it is good otherwise, not.

For example, you can have a gummy bear making machine with a depositing rate of 30 to 45 n per minute.

18.How to Maintain Gummy Making Machine?

You need to maintain and clean up the gummy making machine routinely to enhance its duration of usability and rate of the input to output.

Maintain Gummy Making Machine

The following below written details about the gummy making machine can help you one way or another.

Stage One: Disconnect the Machine

First, you will detach the machine from the electric connection and afterward permit it to chill off.

You will permit the machine to chill off for some time as it would cause some fire in the event that you contact and use it right away.

Stage Two: Disassemble the Machine

From that point onward, you will cautiously dismantle the principal parts of the machine utilizing the correct gear.

As a rule, the machine provider frequently feeds you up with the manual of disassembling and assembling the gummy making machine.

You ought to follow the manual carefully to try not to alter the frameworks of the machine.

Stage Three: Cleansing Process

Utilizing distinctive cleaning materials, for example, a bit of fabric, brushes, exceptional cleansers, and water, start the cleaning cycle.

Ensure that you utilize the correct mix of cleaning cleansers that won't cause any problem with the machine.

Dispose of the difficult stains by absorbing water for some time and cleaning with a brush.

From that point onward, a dry cloth piece can be used for cleaning purposes.

Stage Four: Replacing the old Parts

Make sure to dispose of the exhausted or erosion parts and supplant them with new parts for better production methodology.

You ought to likewise oil the moving parts with oil to decrease rubbing during the activity cycle.

Stage Five: Again Assembling the Parts

At last, after careful cleaning, you will join the parts all together and proceed with the process of production.

19.How to Troubleshoot the Common Problems of the Gummy Making Machine?

Much the same as some other machine a gummy making machine can have issues because of some issues.

Here are few of the issues that you may insight while working with a gummy making machine

Some of the issues why the fixings probably won't stream because are;

- A more slow speed of the machine in this manner restricting the stockpile of ingredients at the correct time.

- You can correct this by guaranteeing that the speed of a stream of the gummy making machine is at par with the needs of the production.

- Stoppage of the sources of the ingredients as the gummy bear may hinder or stop the entry.

You can tackle this by handling the ingredients by unclogging entries to permit them to stream openly.

Too jelly like gummy bears

At times, Bear candy might be a lot like jelly.

This can be because of less proper mixing of the ingredients with shifting extents of ingredients.

Aside from that, the blending cycle may not be completely adequate neglecting to meet the correct blending limits.

You can settle this by noticing appropriate measurements of ingredients just as the blending limit.

Gummy bear candy might damage

You may encounter issues with the extra harms of the gummy bear jellies.

This can be because of erroneous arrangements of the critical boundaries of the gummy making machine.

20.What is the Future Prospects of the Gummy Making Machine?

There is always something to change in this 21st century. As they say, there is always room for more and you cannot afford any procrastination.

Expanding the speed, safety, and proficiency of the making cycle are the significant enhancements being examined for the upcoming time of the gummy making machine.

If you have a look at any of the starch making process of holding, your health and safety is a top thing to bear in mind since starch dryers can be extremely dangerous.

Presently the government around every corner of the world suggests limiting these risks by utilizing switches that are spark-free, impact dividers, and other such systems.

The later version of the starch drying machines relates themselves to a diminished blast risk and improved microbiological murdering. Furthermore, the mogul has been created in such a way that works quicker and all the more proficiently.

As you know new items are the help of any organization or you in the bear business, the latest flavor of gummies and shadings is continually being added to the basic formula. Likewise, interesting shapes are being formed, making plenty of new gummies.

So, you need all these latest machines to stay in the competition.

Otherwise, you might be disappearing from the market as Samsung and Apple did with the Nokia and Blackberry.

21.Why should you Trust AIPAK Gummy Making Machine?

- Machine helps you in eliminating the residues as it is clean and meet the hygiene condition.

- AIPAK do install as well offer the best possible services.

- Consultation is being offer at any point whenever you can ask for that.

- Customization is also offered by our certified Engineers.

- Are you worried about training. Don’t be so we also offer that too.

Gummy Making Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586