Why Cheap Gummy Machines Fail: Scaling to 150kg/h with Servo & Steam (Case Study)

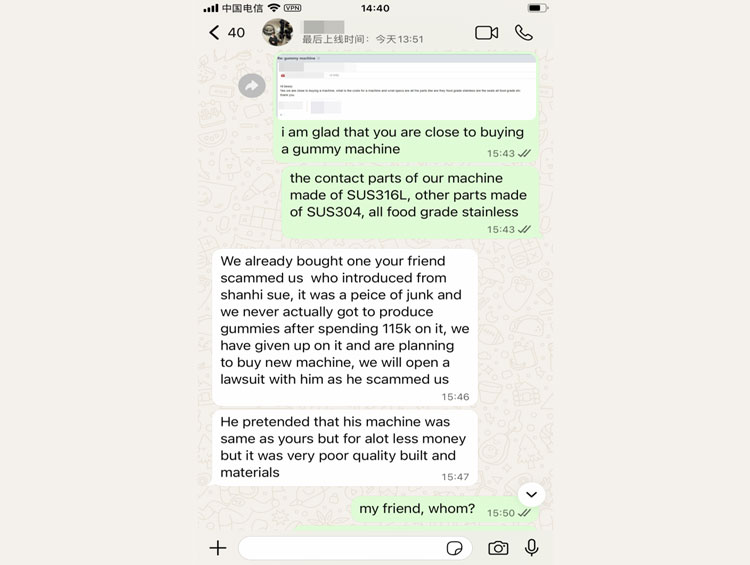

One year ago, a client asked me for a quote on a gummy production line. I gave him a fair price, but he chose a cheaper supplier.

Last month, he came back to me. He told me the cheap machine was a disaster. It could not run continuously. It broke down often. The supplier promised 150kg per hour, but he could barely get 40kg. He lost money and time. He needed a real solution.

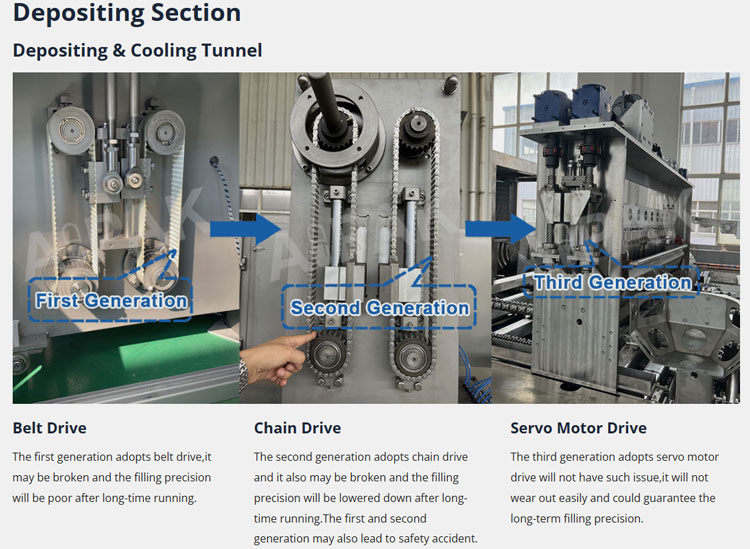

To achieve a true 150kg/h gummy production rate, you need a servo-driven depositing system and a stable heating source. We replaced the client's inconsistent mechanical system with a servo-controlled depositor that hits 35-45 strokes per minute. We also switched from electric to steam heating to lower energy costs and speed up the cooking process.

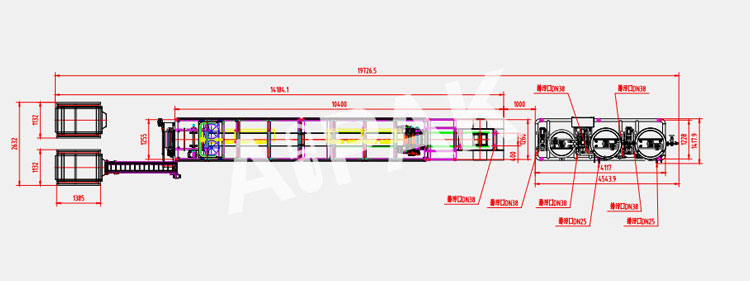

150kg gummy production line overview

This client was very careful this time. He was afraid of making another mistake. He had a specific goal: 150kg output per hour, 6 sets of molds, and gummies weighing 4-5 grams. My price was still higher than his old machine, but I had to show him why price reflects value. I guided him through every technical detail to rebuild his trust.

1.Why Did the Previous "150kg/h" Machine Fail to Deliver?

The client showed me videos of his old machine. It stopped frequently. The gummies were not uniform. He thought he bought a high-capacity line, but the engineering was weak.

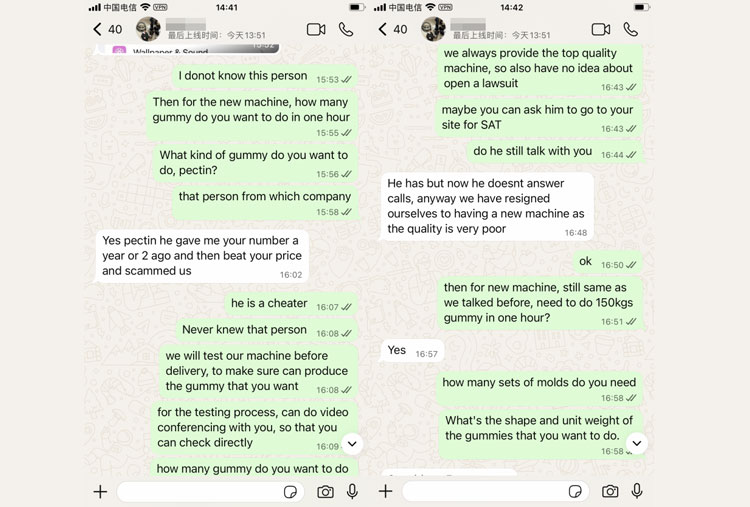

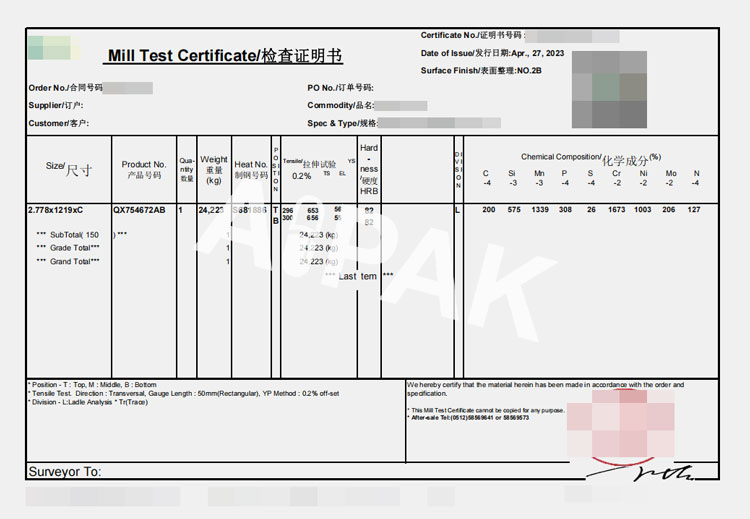

The main reason cheap machines fail is poor material quality and outdated control systems. A machine might run fast for five minutes, but if it jams or overheats, your daily output drops. We use SUS316L stainless steel for all contact parts and SUS304 for the frame. This ensures the machine is strong, hygienic, and runs without stopping.

Comparison of SUS316L vs standard steel parts

Based on my analysis of the client's old machine video, I found several critical flaws that are common in low-cost equipment. First, the control system was likely mechanical or used low-end motors. These cannot maintain a steady speed when the gummy slurry becomes thick. This causes the machine to stop or fill the molds unevenly.

Second, the material quality matters for speed. The client worried about hygiene and durability. I sent him our material certificates.

We use SUS316L for parts that touch the gummy. This is the highest standard for food and pharma. It resists corrosion from acid and sugar. The non-contact parts are SUS304. This makes the machine heavy and stable. A light, cheap machine shakes when it runs fast. This vibration causes errors in filling.

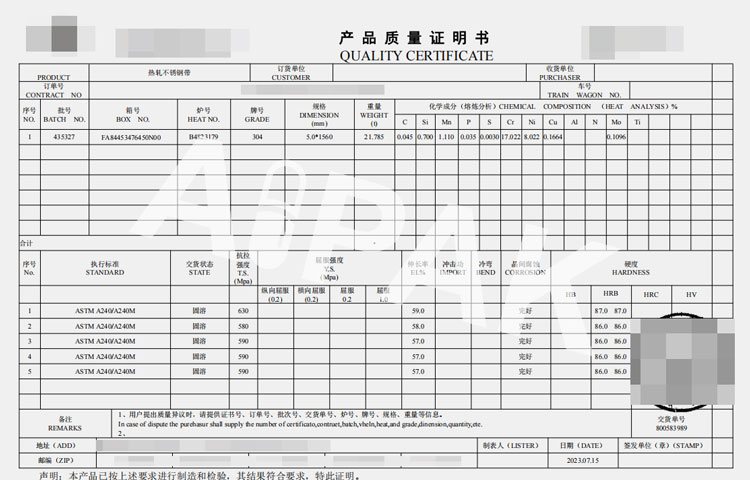

We also discussed the difference between "theoretical speed" and "actual production." Many suppliers test with water. Water flows easily. But gummy syrup is sticky and thick. A machine that pumps water at 150kg/h might only pump syrup at 40kg/h. We do not just sell a machine; we sell a process. I showed him videos of our machines running in the US.

Emails with the US customer

I also told him about a Turkish client currently running our 150kg line.

I invited him to see our factory. We prove our quality with real production, not just promises.

2.How Do We Prove True Capacity Before You Buy?

The client challenged me on the math. He asked, "How do I know your machine will actually do 150kg?" I did not just say "trust me." I used simple calculation and logic.

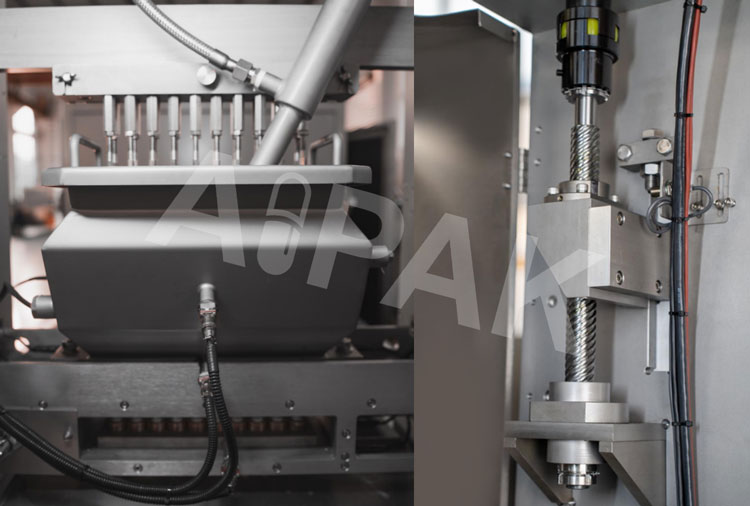

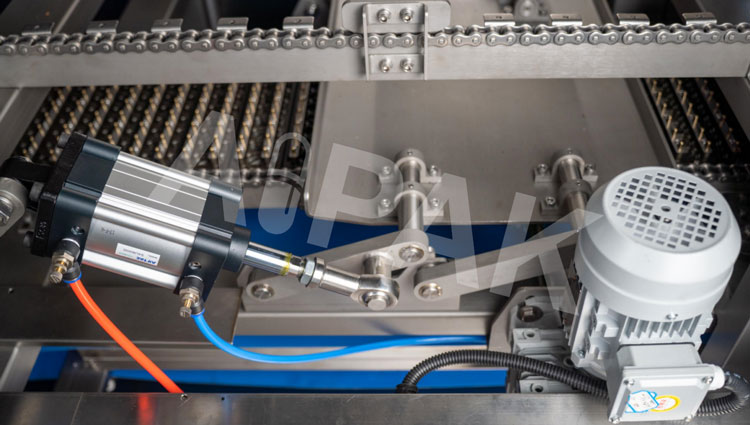

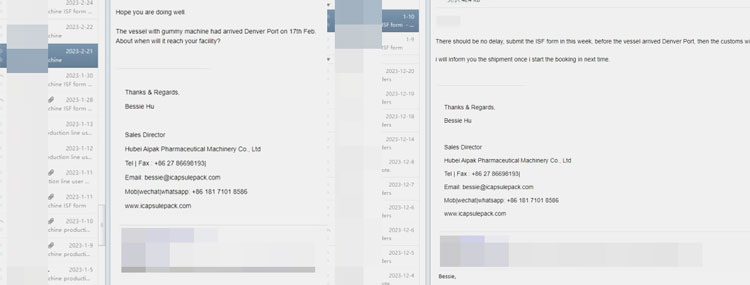

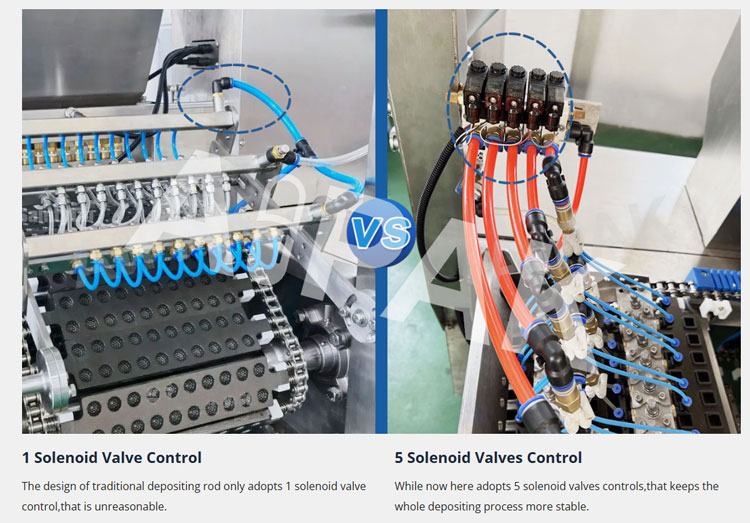

We use a servo control depositing system. This is different from old air-cylinder systems. A servo motor is precise. Our machine runs at 35 to 45 strokes per minute. Each mold has 20 cavities. If you do the math, the output is guaranteed. We also prove this with a Factory Acceptance Test (FAT) using real ingredients, not just water.

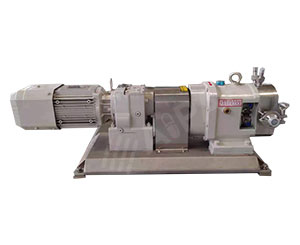

Servo motor depositing system detail

Let’s break down the capacity question using critical thinking and math. The client needs to see the numbers to feel safe. Here is the formula we used to prove the capacity of our APK-GM150 line:

| Depositing Speed | 35 strokes per minute (minimum conservative estimate) |

| Mold Capacity | 20 candies per stroke (20 holes per mold) |

| Time | 60 minutes per hour |

Calculation:

35pcs/time* 20*60min = 42,000 pcs

If each gummy weighs 4 grams:

42,000pcs*4grams= 168,000grams = 168kg/hour

This 168kg/h is actually *higher* than his 150kg/h requirement. This gave him confidence.

But numbers on paper are not enough. The client told me his previous supplier tested the machine with water. Water is thin. It does not behave like pectin or gelatin. I told him we do things differently. We have two 600kg gummy lines in our factory right now doing FAT (Factory Acceptance Test). I sent him videos of us testing with *real* gummy slurry. He saw the machine handling thick, sticky material smoothly.

We also addressed the spare parts issue. He was worried about downtime. I showed him our warehouse. We keep parts in stock. If he needs a part, we ship it in 3-5 days. This combination of transparent math, real-material testing, and after-sales support convinced him that our capacity claims were real.

3.Electric vs. Steam Heating: Which Saves More Money?

The client needed to cook the syrup. He asked if he should use electric heating or steam heating. I looked at his long-term costs. Electric is easier to install, but steam is much cheaper to run.

I strongly suggested steam heating for a 150kg line. Steam heats the cooker much faster than electric elements. This means you can start production sooner every morning. It also uses less electricity. I created a detailed comparison table for him to show the massive difference in power consumption.

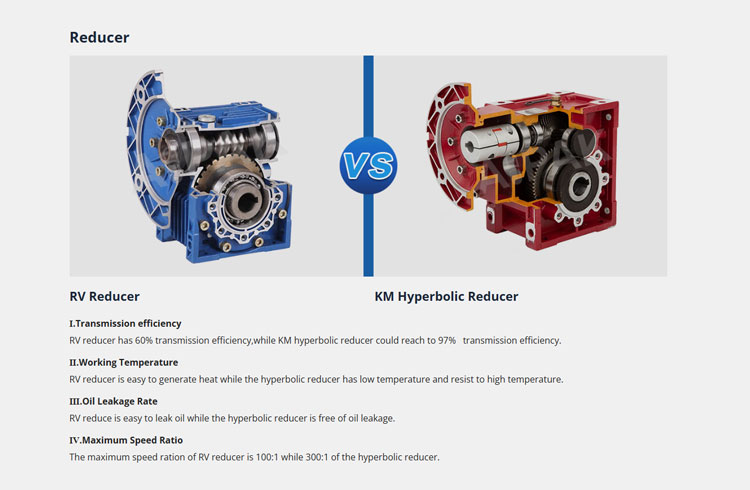

Steam heating vs electric heating diagram

To help the client understand the value of steam heating, I performed a detailed energy analysis. Many clients choose electric heating because they do not want to buy a steam generator. However, for a commercial line, electricity costs are very high.

I provided the client with this specific breakdown of the two options for the APK-GM150 line:

| Equipment Component | Electric Heating Version (kW) | Steam Heating Version (kW) | Notes on Steam Advantage |

| 200L Cooker (x2) | 27.0 kW | 3.0 kW | Steam does the heating work |

| Mixing/Storage Tanks | 21.0 kW | 3.0 kW | Maintaining temp is cheaper with steam |

| Depositor & Cooling | 28.0 kW | 28.0 kW | These parts always use electricity |

| Pumps & Mixers | 13.0 kW | 13.0 kW | Motors need electricity |

| TOTAL POWER | 89.0 kW | 47.0 kW | Steam saves ~42 kW of electrical load |

Why this matters:

1.Energy Savings:The steam version uses almost half the electricity (47kW vs 89kW). Over a year of production, this saves thousands of dollars in electricity bills.

2.Heating Speed:Steam carries "latent heat." It transfers energy into the syrup much faster than electric coils. The syrup reaches boiling point quicker, reducing the waiting time between batches.

3.Temperature Stability:Steam provides a very consistent heat. Electric coils can create "hot spots" that might burn the sugar or gelatin near the coil.

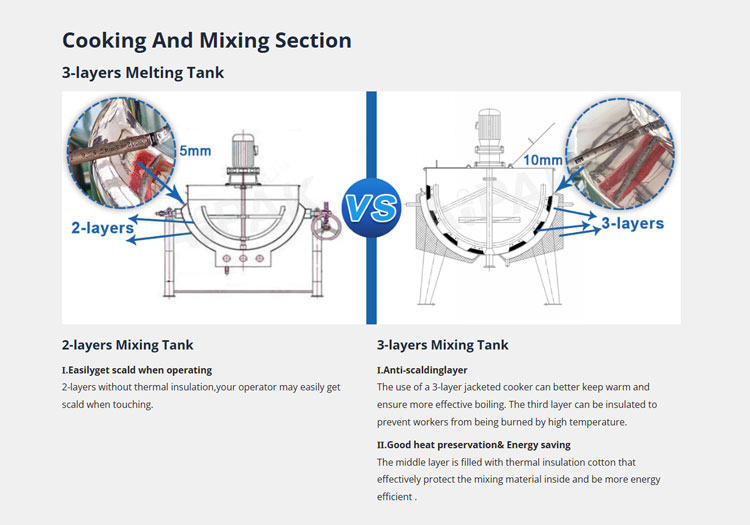

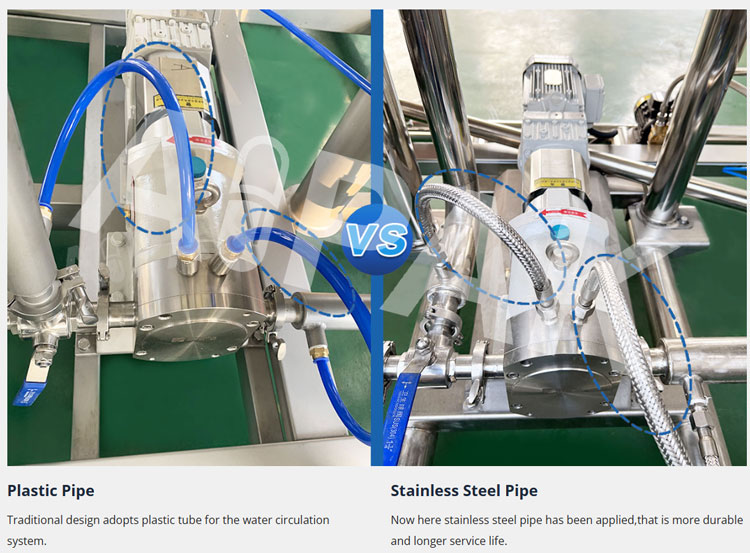

Other advantages we showed to cutsomer

After seeing this data, the client realized that while setting up steam takes a little more work initially, the operational efficiency is far superior. He chose the steam heating option.

4.How Do We Handle Complex Shapes and Logos?

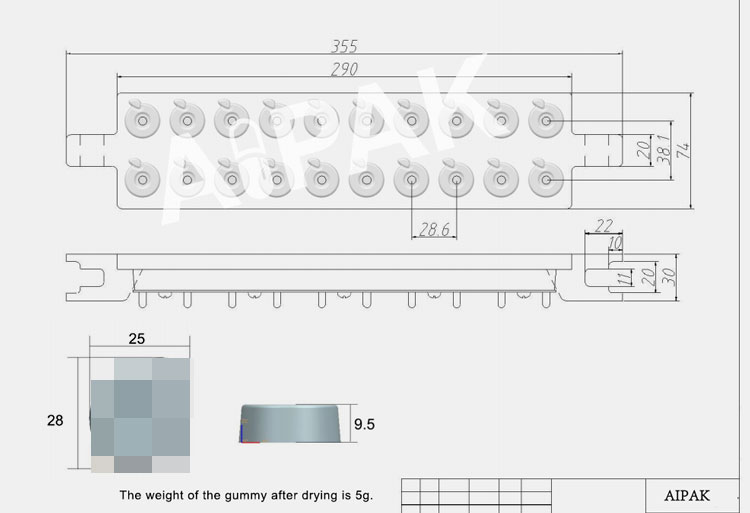

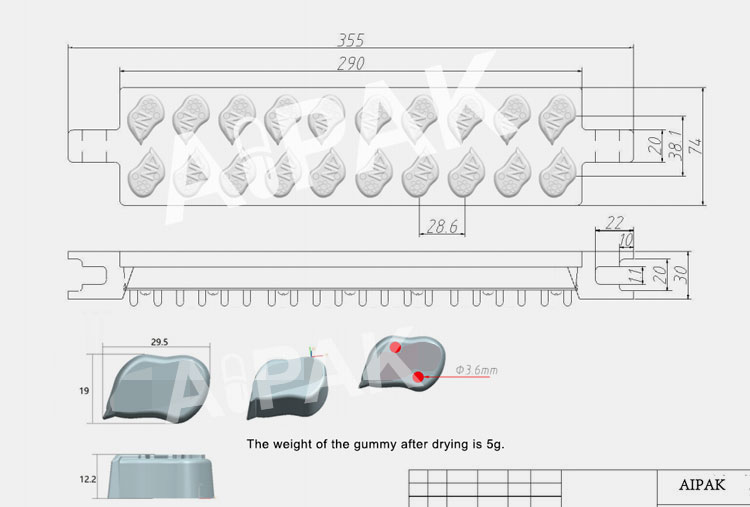

The client had a special request for his product design. He wanted two specific gummy shapes that included his logo. He was worried the machine would crush them.

Customer gummy shape

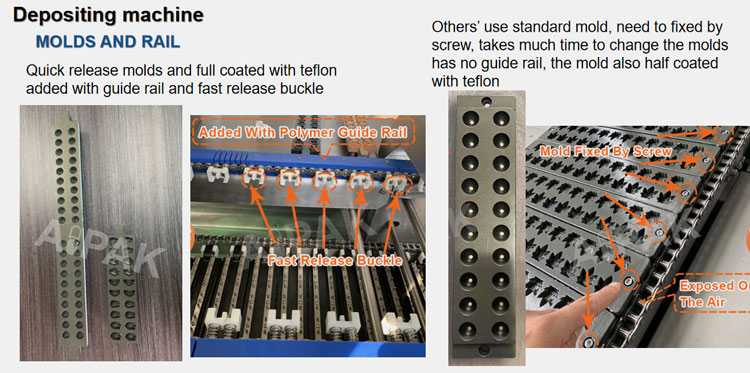

Standard machines use a simple pin in the center to push the gummy out of the mold. If you have a logo or a complex shape, the pin can leave a mark or deform the gummy. We designed a custom mold with pins on the sides. This pushes the gummy out gently without touching the center design.

Custom gummy mold with side ejector pins

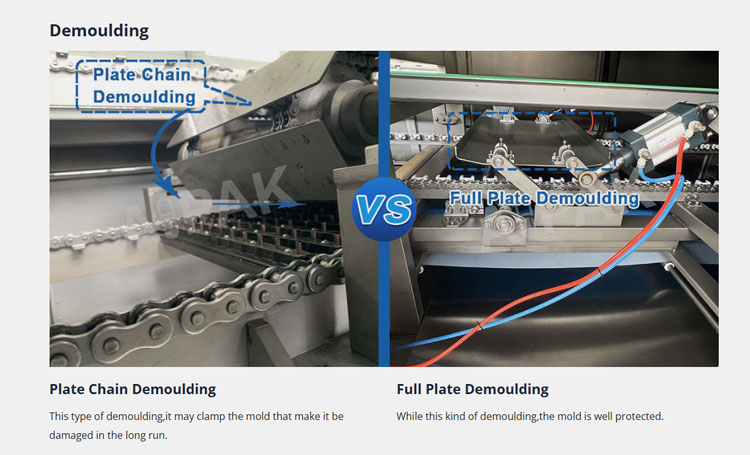

Customization is where we really separate ourselves from "off-the-shelf" cheap machines. The client’s request was specific: he wanted his brand logo on the gummy. In the gummy manufacturing process, "demolding" (getting the candy out of the metal tray) is a critical step.

In a standard cheap mold, there is a single "ejector pin" right in the middle of the cavity. When the mold turns over, this pin pops the gummy out.

The Problem:If you have a logo in the center, the pin hits the logo. It can blur the design or make a dent in the face of the gummy.

Our Solution: We engineered a mold with **side-mounted ejector pins**. Instead of poking the center, these pins push on the rim or the non-detailed parts of the gummy.

This design requires more precision in the machining of the mold (CNC machining), but it ensures the product looks premium.

We also looked at his factory floor. He sent me his room dimensions. A standard line might not fit perfectly. I drew a custom layout for him. We adjusted the position of the cooling tunnel and the tanks to fit his specific room shape. This is part of our service. We do not just ship a crate; we ensure it fits your workflow.

Layout we designed for customer

By solving the shape problem and the space problem, we removed his final doubts. He saw that we were partners in his production, not just sellers.

Conclusion

The client moved from a failed 40kg/h line to a verified 168kg/h solution by choosing servo technology, steam heating, and custom engineering.

Don't forget to share this post!

Gummy Making Machine Related Posts

Scaling Gummy Production with Servo & Steam Technology

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine