Don’t Buy New Molds: How We Retrofitted Existing Molds to Save $10k on a New Gummy Machine

In early 2023, we received a desperate email from a client in Denver who was facing a manufacturing nightmare due to a broken machine and late orders.

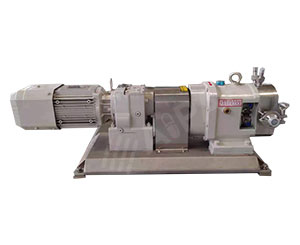

We solved this production crisis by verifying their existing molds fitted our equipment and immediately shipping an in-stock 40kg/h automatic gummy machine. Our CEO and engineers flew to the USA for setup, achieving full production in under 50 days.

AIPAK gummy machine installation in Denver factory

It was a race against time, but our team at AIPAK was ready to take the challenge to save their business reputation.

1.Why Was the Client Facing a Production Crisis?

We often hear from clients who are stressed because their equipment is not working, and this situation was very serious.

When a manufacturing machine fails completely, it halts the entire supply chain. This client faced a massive backlog of orders and needed a reliable gummy making solution instantly to keep their customers.

In the manufacturing world, time is money. This specific case started when we got an inquiry from a manufacturer in Denver, USA. At first, it looked like a normal request for a machine. However, after we started chatting, I learned the real story. They had purchased a gummy machine from one of our competitors not long ago. Unfortunately, that machine was completely broken and could not run anymore.

This was a disaster for them. They act as a co-packer, which means they produce goods for other brands. They had many orders waiting in the queue. Because the machine was down, they could not deliver products to their customers. They were very sensitive about the delivery time for a new machine because their reputation was at risk. If they delayed any longer, they might lose their contracts.

This gave us a clear goal. We did not just need to sell a machine; we needed to provide a rescue solution. We had to act faster than usual to help them regain the trust of their end customers. This required us to look at our internal process to see how we could speed everything up without lowering quality.

2.How Did We Save $10,000 on Molds?

We always look for ways to save money and time for our clients, not just sell them a new machine.

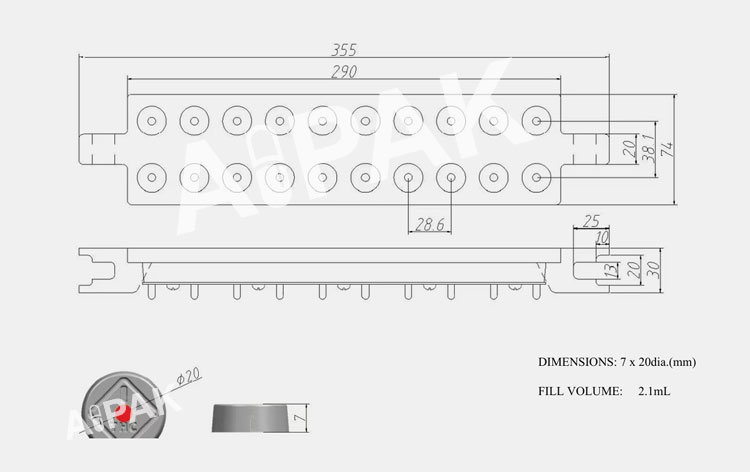

Mold compatibility is a critical factor in switching machinery suppliers. We analyzed the client's existing mold drawings to ensure they worked with our systems, saving weeks of production time.

Gummy molds technical drawing verification

When I found out the client already had a gummy machine, my first thought was about the molds. Molds are the heavy metal plates that give the gummies their shape. They are expensive, and they take a long time to make. Usually, making new customized molds can take 20 to 30 days. This client did not have that kind of time.

I told the client, "Even though your old machine is broken, the molds might still work on our AIPAK machine." This would mean they did not have to buy new ones. The client sent me the technical drawings of their existing molds. Our engineering team checked the dimensions, the pin placement, and the size carefully.

After a serious check, we gave the client good news: their molds were compatible. This was a huge win. It saved the client at least $10,000 in costs. More importantly, it saved weeks of waiting time.

| Item | Buying New Molds | Buying New Molds | Reusing Existing Molds |

| Cost | High ($10,000+ | Zero ($0) |

| Time | 3-4 Weeks | Immediate |

| Testing | Needs new samples | Proven design |

By using critical thinking and understanding the technical specs, we removed a huge barrier for the client.

3.Why Was the Video Inspection Critical?

Trust is hard to build quickly, especially after a client has had a bad experience with another supplier.

A live video inspection allows clients to see the machine running, ask technical questions, and verify the internal components before purchase, which speeds up the decision process.

Video call with client showing machine details

Since the client was in a rush, we could not wait for them to fly to China to see the machine. We checked our factory inventory immediately. Luckily, we had a small capacity gummy machine in stock. It was a 40kg per hour automatic model. This size was perfect for their immediate needs to clear the backlog of orders.

I told the client we could ship it anytime. To prove the quality, we booked a video call. This was not just a sales call. The client brought their core technical team to the meeting. They were very careful because they had been burned by the previous supplier.

During the video, they asked many technical questions:

* How does the heating system work?

* Can we see the electrical cabinet?

* How do we clean the nozzles?

We answered every question and showed them the machine running live. After the call, we sent them the detailed price list, the electrical circuit diagrams, and the layout drawings. They were very happy with the transparency and the price. Because we had the stock and provided clear answers, they ordered the machine very quickly.

4.How Did On-Site Support Fix the Timeline?

Shipping the machine is only half the job; it has to run perfectly in the factory to count as a success.

Professional on-site installation and training ensure that pharmaceutical and confectionery equipment reaches peak efficiency immediately after delivery, minimizing downtime for the manufacturer.

AIPAK engineers training client staff in Denver

The machine arrived in Denver a little over a month later. However, simply having the machine on the floor does not mean production starts instantly. The client encountered some trouble during the initial operation. This is normal with complex machinery, but remember, their orders were already very late. They were panicked.

Our CEO received an email about the issues. He decided to take immediate action. He did not just send a manual or a video link. He replied to the client and said, "I am coming to Denver with my lead engineer."

Our CEO photo with the Denver customer

We flew to the US to visit the factory. Our engineer stayed there for a full week. We did three main things:

Installation:We made sure every wire and pipe was connected correctly.

Debugging:We adjusted the settings so the gummies came out with the perfect weight and texture.

Training:We taught their engineers how to use and fix the machine.

We did not leave until everything was running smooth. This level of service is what separates a partner from a vendor. The client was extremely satisfied with this aftermarket service.

5.What Comes After the Production Rescue?

A successful rescue leads to a long-term partnership because the client knows we are reliable.

Once the primary production line is stable, manufacturers often look to automate downstream processes like bottle filling and packaging to match their new production speed.

Machine video running on Denver factory

Now, the machine is running normally in the Denver factory. They are catching up on their orders and their end customers are happy again. Because we helped them solve a massive problem in less than 50 days—from shipping to production—we built a strong bond.

Recently, the client started talking to us about the next step. Since they can make gummies faster, they need to pack them faster. We discussed their packaging needs. We recommended a standard bottle filling line. This includes counting the gummies, putting them in bottles, capping, and labeling.

They are very happy with our products and our service. They told us they plan to place the order for this packaging line in 2026. This case proves that when we focus on solving the customer's urgent pain points, we gain a customer for life. We helped them avoid a crisis, and now we are helping them grow.

Conclusion

By combining stock inventory, technical flexibility, and on-site support, we restored the client's production in 50 days, securing their market position and future partnership.

Don't forget to share this post!

Retrofitting Molds to Save Costs on New Gummy Machines

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine