Tyvek & PETG Blister Packaging for Medical Devices: A Guide to Syringe Packing & Robotic Integration

Medical device packaging is not easy. You have irregular shapes, strict sterilization rules, and a need for high speed. If you choose the wrong machine or material, you will face waste and safety risks.

To package medical syringes efficiently, you should use a flat-plate blister packing machine like the DPP-150 combined with Tyvek and PETG materials. These materials allow for gas sterilization while keeping bacteria out. Integrating a robotic arm for feeding can also significantly reduce labor costs and improve hygiene standards.

Tyvek and PETG blister packaging

If you are not interested in improving your production efficiency or ensuring product safety, you should stop reading now. This guide is only for manufacturers who want to lead the market.

1.How Did We Handle the Initial Inquiry for Irregular Syringe Packaging?

We received a difficult request from a US client. They had irregular syringes, not standard pills. They were worried about finding the right supplier. We had to prove we could do it.

We proved our capability by showing past project data immediately. Speed is trust. We used our FedEx VIP account to get their physical samples in just four days. This allowed us to create a precise design drawing within a week, solving their doubt about irregular shapes.

Syringe samples

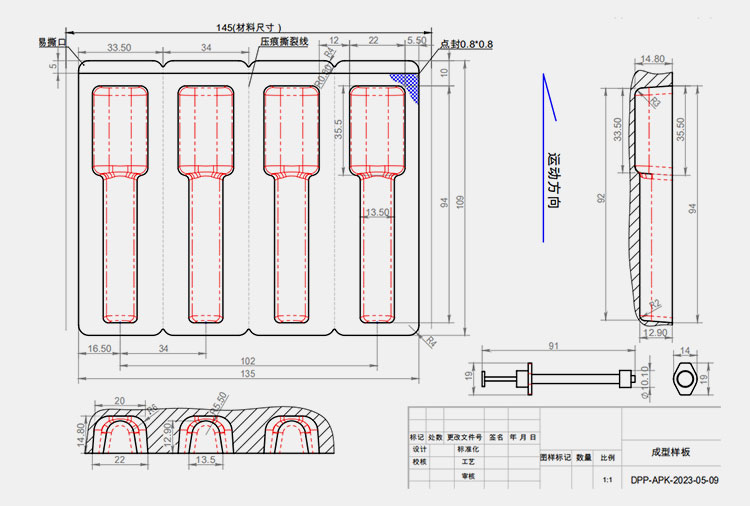

Blister design drawings

When we get an inquiry, we do not just give a price. We look at the problem. In late April 2023, a client from North Carolina, USA, contacted us. They needed a machine. But they did not want to pack simple tablets or capsules. They needed to pack medical syringes. These syringes are not flat. They are round and have long plungers. This is an "irregular product."

Many suppliers avoid this. It is hard to design the mold. But at AIPAK, we have done this for many years. I immediately showed the client photos and videos of similar projects we finished before. This made the client feel safe. They saw we knew what we were doing.

However, pictures are not enough. We needed to measure the real product. We asked the client for 100 sample syringes. The client was in a hurry. Because we are a VIP customer of FedEx, we arranged the pickup ourselves. We sent FedEx to their factory in North Carolina.

The package left the USA and arrived at our desk in China in only four days. This speed surprised the client. Once we had the samples, our engineers measured every millimeter. We made a design drawing that fit the syringe perfectly.

From the first email to the final design, we took less than one week. This efficiency is why the client chose to trust us with the next steps. It shows that in B2B manufacturing, time is money.

2.Which Blister Machine Model Best Fits High-Speed Syringe Production?

The client needed a specific output speed. They also had limited space. We had to calculate the best machine size. We did not want to sell a machine that was too big or too slow.

We recommended the DPP-150 blister packing machine. Based on the syringe size, we designed a mold that packs four syringes at once. With a cutting speed of 50 times per minute, this machine produces 200 blisters every minute.

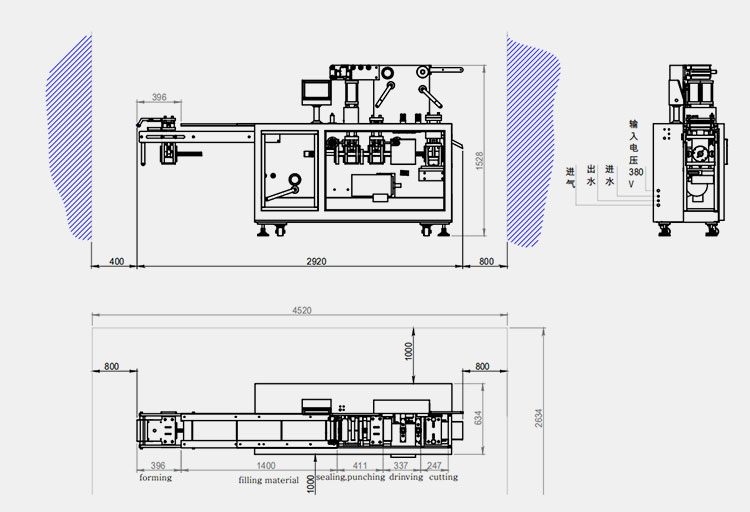

DPP-150 Blister packaging machine layout we provided to customer

Choosing the right machine is about math and physics. The client provided their production goals. They wanted a steady output. They also gave us the dimensions of the syringe.

We looked at our machine list. The DPP-150 is a flat-plate blister machine. It is very stable. For the client's syringe size, we calculated the mold area. We could fit four syringes in one "stroke" or cut. This is called a "one-out-four" design.

The machine runs fast. It cuts the plastic sheet about 50 times every minute. If you do the math:

* 50 cuts per minute

* x 4 syringes per cut

* = 200 syringes per minute

This speed matched the client's goal perfectly. We also looked at the feeding method. Syringes are hard to feed automatically with a standard feeder. The DPP-150 has a long working platform. This gives space for manual feeding or, as we will discuss later, a robotic arm.

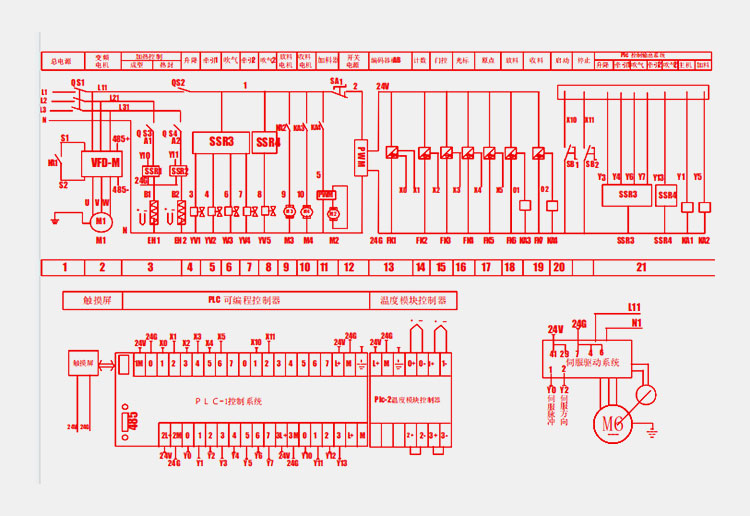

Circuit diagrams we provided to assist customers with subsequent debugging

This machine is also compact. It does not take up the whole factory floor. For a medical device company, cleanroom space is expensive. A smaller machine with high output saves rent and energy. This recommendation showed the client we cared about their operational costs, not just selling a big machine.

3.Why Choose Tyvek and PETG Over Traditional Alu-PVC Materials?

Standard pills use foil and PVC. But medical devices are different. They need to be sterilized after packaging. The packaging material must breathe but stop germs.

We recommended Tyvek and PETG. Tyvek is a special paper that lets sterilization gas in but keeps bacteria out. PETG is a strong plastic that can handle high heat. This combination ensures the medical device remains sterile until opened.

Tyvek and PETG material rolls

In the pharmaceutical world, most people know "Alu-Alu" or "Alu-PVC." These are great for pills. They stop moisture and oxygen. But for a syringe, they are often the wrong choice.

Syringes and medical devices often need "terminal sterilization." This means you kill the bacteria *after* the product is inside the package. You often use a gas called Ethylene Oxide (EtO). This gas needs to get inside the package to kill the germs, and then it needs to get out.

Aluminum foil seals too tightly. The gas cannot get in. That is why I recommended Tyvek paper from DuPont.

Here is a simple breakdown of why we chose these materials:

| Feature | Standard PVC/Aluminum | PETG/Tyvek |

| Breathability | None (Air tight) | High (Tyvek lets gas pass) |

| Bacteria Barrier | High | High (Tyvek blocks germs) |

| Strength | Medium | High (PETG is rigid) |

| Sterilization | Not suitable for Gas | Perfect for EtO Gas |

PETG is also very clear. The doctors can see the product inside. It is stronger than PVC. It does not crack easily. To make sure the client liked it, we sent them samples. We sent different thicknesses of PETG and Tyvek. We labeled them with red tags so the client could feel the difference. They tested them in their lab and agreed with our choice. This expert advice saved them from buying the wrong material.

4.How Do We Ensure Accurate Printing and Coding on Tyvek Surfaces?

The client needed to print codes on the package. Tyvek is not smooth like plastic. It is made of fibers. Printing on it can be tricky if the ink spreads.

We installed two specialized printers and adjusted them for Tyvek material. Tyvek contains non-woven fibers, which can make ink blurry. We tested and tuned the printers to ensure every QR code and batch number was sharp and scannable.

Printing on Tyvek with QR codes

Medical devices have strict laws. In the USA and Europe, you need a UDI (Unique Device Identification). This usually means a QR code or a Datamatrix code. The client sent us their artwork. It had a lot of variable data. This means the numbers change for every batch.

Printing on aluminum is easy. It is smooth. Printing on Tyvek is hard. Tyvek looks like paper, but it is spun plastic fibers. If the printer is not set right, the ink "bleeds." The lines of the QR code get fuzzy. If the lines are fuzzy, the scanner cannot read it. If the scanner cannot read it, the hospital cannot use the product.

We saw this risk early. We set up two printers on the machine line. We did not just bolt them on. We spent hours adjusting the print head distance and the ink type. We ran tests. We printed codes and tried to scan them with a phone and a professional scanner.

Video we sent to customer

We sent a video to the client. In the video, we printed a code and scanned it immediately. It worked perfectly. We also checked the position. The code had to be in a specific spot on the lid. We adjusted the machine timing so the print landed in the exact right square every time. This attention to detail prevents recalls later.

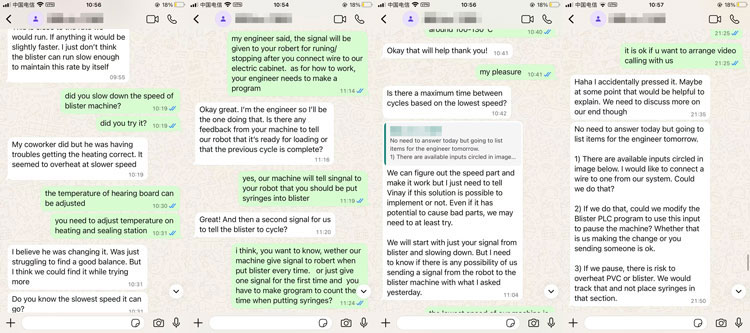

5.How Can Robotic Arms Integrate with Blister Machines for Automation?

Manual feeding is slow and dirty. The client wanted to save labor. We suggested a robot. We helped them integrate a US-bought robot with our Chinese machine.

Recommendation to the customer

We recommended a robotic arm to replace manual loading. Since the client wanted to buy the robot locally in the USA for better support, we installed a signal handshake system. We guided them remotely to connect the robot to our machine, ensuring perfect synchronization.

Robotic arm feeding syringes

During the project, we thought about the client's workers. Loading 200 syringes a minute by hand is impossible for one person. It is also risky. Humans carry bacteria. The more hands touch the product, the higher the risk of contamination.

I suggested: "Why not use a robotic arm?"

The robot can pick up the syringes from a tray and place them gently into the blister pockets. It never gets tired. It is clean. The client loved the idea. However, they were worried about fixing the robot if it broke. They wanted to buy the robot arm from a local US company.

We respected this. We did not try to force them to buy our robot. Instead, we made our machine "robot-ready."

We did several things to help:

1.Signal Reservation:We added a plug and a program in our PLC (computer brain). This allows our machine to say "I am ready" to the robot, and the robot to say "I am done" to the machine.

2.Remote Support: When the machine arrived in North Carolina, the local robot company came to install the arm. They had questions about the wiring. We got on a video call. We showed them exactly which wire goes where.

3.Extra Prep:We also provided detailed circuit diagrams and layout drawings months in advance.

Three extra sets of cutting knives

We also thought about the **PETG material**. It is harder than PVC. It dulls the cutting knives faster. We made three extra sets of cutting knives for the client. We packed them with the machine. We did not want their production to stop just because a knife got dull.

Maximum roll size

We also told them the maximum roll size their machine could handle. This helped them order the right size Tyvek rolls from their supplier. We tried to think of everything before it became a problem.

6.What Is the Value of On-Site Support and Long-Term Partnership?

A machine is a big investment. Clients worry about being abandoned after the sale. We prove we are different by visiting them. Our CEO flew to the USA to check on the machine personally.

Our CEO, Andrew, visited the client in North Carolina shortly after the machine arrived. We checked the equipment, offered maintenance advice, and discussed future market trends. The client was impressed that we were the first supplier to visit them in person

CEO Andrew visiting client in USA

Selling the machine is just the start. The real relationship begins when production starts. At AIPAK, our sales team and engineers travel every year. We do not just sit in the office.

After the client received the machine, our CEO Andrew planned a trip to the USA. Before he left, I emailed the client. I asked, "Is the machine running well? Do you need any spare parts? Andrew can bring them in his suitcase."

The client said the machine was running great. They did not need parts. But they were happy to meet.

When Andrew arrived at the factory in North Carolina, the client was very welcoming. They walked through the plant. They watched the DPP-150 machine running smoothly with the robot. Andrew gave them some tips on how to maintain the heating plates to make them last longer.

He also shared information about new packaging trends we see in Europe and Asia. The client told Andrew, "You are the first equipment supplier to actually come visit us here."

This visit built deep trust. They saw we are real people who care. The client told us they have confidence in us. They plan to expand their line soon, and they said AIPAK will be their first choice. This is why we go the extra mile. It turns a one-time buyer into a lifetime partner.

Conclusion

To succeed in medical packaging, you need the right machine, the right materials like Tyvek, and a partner who supports you from design to robotic integration and beyond.

Don't forget to share this post!

Tyvek & PETG Blister Packaging for Medical Devices

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine