Types Of Tube Filling Machine For Pharmacy

A tube filling machine is a powerful filling solution that works for different industries. Today, it is on the rise due to its great reasons. Types of tube filling machine for pharmacy shows how your machine is committed to an economical filling solution.

If you are looking for a machine that is intended to introduce viscous formulations with accuracy and precision, a tube filling machine is the best way! The type of machine is typically created with stainless steel to offer the safest solution.

1.What are the different types of tube filling machines for pharmacy?

When you check the available options for tube filling machines. You will simply find three main types:

Automatic Tube Filling Machine

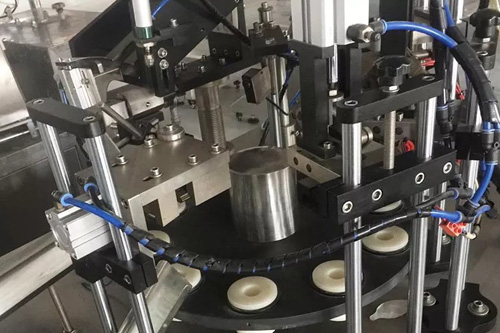

With the grace of modern technology, the tube filling process can be handled ergonomically.

An automatic tube filling machine is specially designed to introduce the formulation in rigid or flexible tubes.

This machine is suitable for bulk production lines as they remarkably support high filling requirements in less time. From loading material to sealing, the entire process steps are completely mechanical. This is a powerful machine that allows you to configure operating parameters as per protocol via a programmable interface unit.

Semi-Automatic Tube Filling Machine

The semi-automatic tube filling machine is a great option for filling various kinds of formulation (semi-viscous, viscous), which is suitable for utilizing multiple types of soft plastic or metal tubes.

Due to innovative concepts, high production, and low cost represents the machine is one of the best choices for beginners or people with small to moderate production lines.

The prime features are adopted from the automatic machine with slight modifications. Such as no power conveyor, manually uploading and discharging of tubes, lesser production capacity as compared to an automatic machine, etc. But, its overall efficiency profile is considerably great as compared to a manual tube filling machine.

Manual Tube Filling Machine

This is a simple, basic, and robust solution to fill ointment, pastes, and other materials. You do not require power supply to operate the machine. Traditionally, this machine was high in demand due to its reliability and efficiency. Today, it is still loved by pharmacy, cosmetics, R&D, and herbalists. This is because of its various qualities, e.g., compact, durable, safe, cheap, precise, etc., It is a great option for home and small companies with low growth and budget.

Although its functional range is minimum, though, it is used for clinical trials studies before marketing and producing any product in bulk. The entire working of a manual tube filling machine can be operated by a technician.

2.What types of tube filling machines for pharmacy be used for?

Types of tube filling machine for pharmacy are implemented in the domain of drug development, marketing, storing, and dispensing to the end-users. There are some important applications of tube filling machine:

| Pharmaceuticals

|

|

Pharmaceutical products like analgesic creams, healing formulations, steroids, gels, and topical preparations are commonly filled in tubes. |

| Cosmetic Care

|

|

Tube filling machines are used in the cosmetic care industry to inject, foundations, creams, primers, concealers, facials masks, and gels into the tubes. |

| Food Manufacturing Unit

|

|

Food products like pastes, purees, mayonnaise, ketchup, and sauces, are filled in tubes of various sizes. |

| Stationery Products

|

|

This machine helps to inject watercolors, oil paints, glitters, and adhesive materials into the tubes. That’s why a tube filling machine is a popular equipment used in the stationery industry as well. |

| Hygiene Products |  |

Industries belong to the manufacturing of products like toothpaste, shaving gels, shaving foams, hair removal creams, shower gels, face washes, face cleansers, etc make use of tube filling machines. |

3.What are the ideal characteristics of types of tube filling machine for pharmacy?

Types of tube filling machines produce premium quality performance and excellence. Due to its ideal characteristics, manufacturers do not need to spend much time when dealing with formulated products.

It Gives You the Best Possible Filling Solution

A tube filling machine provides you best solution for filling therapeutic medicines. An automatic tube filling machine with a conveyor belt ensures users with the best and most efficient filling options.

It Allows you Flexibility

Every manufacturer has a unique approach when filling medicines. That’s why many brands offer bespoke solutions and services to tailor fit to customers’ needs. The versatility of the tube filling machine gives you overwhelmed possibilities for efficiently presenting your medicines.

It Gives You a Reasonable Rate and Timeline.

Compared to other ways of filling, a tube filling machine saves your time and cost. In return, you can dispense a quality product that is accompanied by high shelf life, more potency, and efficacy.

It Ensures High-Quality Operation and Compact Housing

Pharmaceuticals or pharmacies always strive to deal with their formulation through high-quality and safe machines. The tube filling machine ensures superb operational conditions under a compact housing.

You Don’t Require Labor Cost

The machine immediately picks up the fault and troubleshoots itself without requiring the technician’s effort.

4.What are the major structural features of types of tube filling machine for pharmacy?

A tube filling machine is designed with a simple to complex form. If you consider a manual version, this would be the simplest in design. As modern sciences have emerged with new amendments, more and more complexities are absorbed. Mentioned below are the major structural elements of the tube filling machine that you can possibly find in each edition.

| Hopper: The purpose of the hopper is to store the prepared formulation. Where a funnel helps in the transferring of material from the receptacle toward the filling nozzle. |  |

| Tube Feeder: This unit is especially meant to feed aligned tubes for filling processing. |  |

| Filling Nozzle: This is a narrow passage that controls the flow of material into the container precisely. |  |

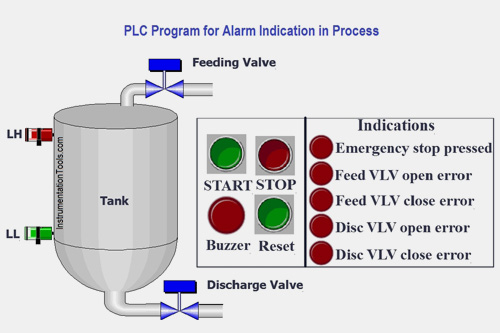

| Dosing Pump: This is an integral component of the tube filling machine. A pre-determined concentration of material is dispensed as ordered by the fed protocol in the PLC programming. |  |

| Tube Holder: This is also an essential element that supports tube holding for the filling job. |  |

| Heat Sealer: After tube filling, the heat sealer firmly seals the tube to protect your formulation.

|

|

| Cutting Jaws: It helps in the fine cutting of edges after being processed from the sealing unit. |  |

| Circulatory Unit: This unit allows availability of each tube for the filling job, as the tube is filled, a circulatory unit rotates to continue with the filling next tube. |  |

| Discharging Unit: As tubes are filled and sealed, they are discharged securely via discharging unit. |  |

| Control Panel: This is known as the brain of the system. You can regulate different parameters of the process via the control panel. |  |

| Safety System: Modern tube filling machines are accompanied by a safety system; this device ensures operating functions are being performed in a protective working environment. In case of unwanted mishaps, the system alarms you before causing any harm. |  |

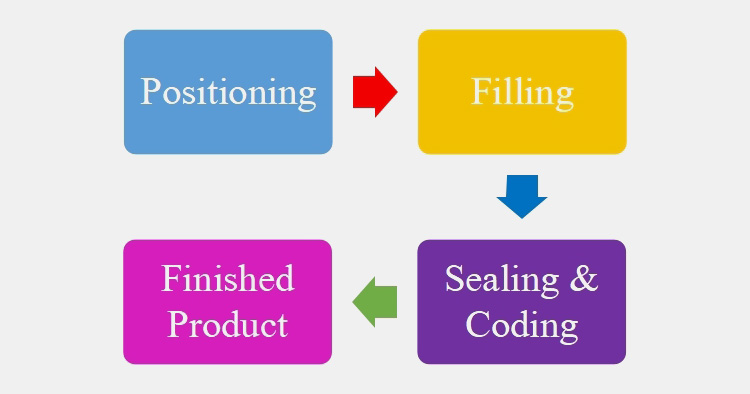

5.How do types of tube filling machines work?

The working process of the tube filling machine is based on the following steps:

Positioning

A tube is positioned on the tube holder according to the given mark on it, this amazing feature is only offered by automatic tube fillers as well as in some semi-automatic machines.

Filling

A tube is filled with formulation via a filling nozzle. There are two basic filling types.

| Vacuum Filling | Volumetric Filling |

| A vacuum filling utilizes a vacuum pump and vane cell feeding. Material is introduced into tubes via vacuum pressure. This system ensures a continuous flow of material. | An accurate volume of material is transferred into tubes via two methods: Gravity Filler: material is filled using gravity. Piston Filler: Is used for filling viscous formulation, piston is used to push the material into tubes. |

Sealing and Coding

The tube is sealed via heat sealers. Side by side, coding is done automatically with the production date, expiry, and bench number on the tube’s edge.

Finished Product

A finished tube is discharged to the collecting unit.

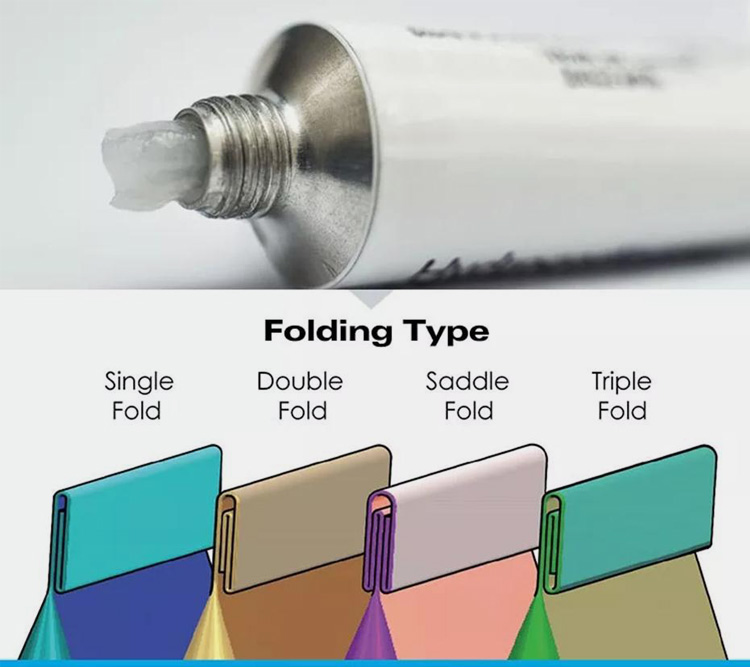

6.What are the different sealing systems used by types of tube filling machines?

Types of tube filling machines are accompanied by various sealing types. Heat sealers are also known as Heat Welding, which ensures airtight and water-tight sealing. It is capable to give versatile sealing properties such as:

- Single Fold,

- Double Fold,

- Saddle Fold,

- Triple Fold.

Mentioned below are the types of sealing units offered by the machine.

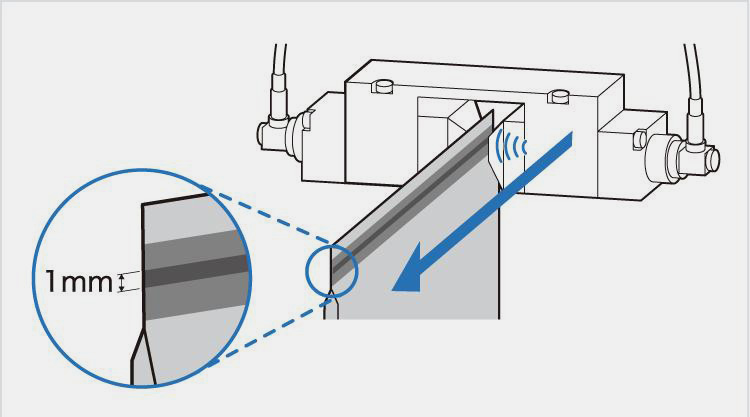

Ultrasonic Heat Sealing

An ultrasonic vibration with high frequency generates instant thermal energy that ensures the sealing of the surface of the tubes. This is of prime importance as it removes oil, grease, and extra impurities from the surface during the process.

Contact Heat Sealing

A small electric heater rapidly melts and seals the tube with heat. It produces a smooth sealing surface of the tube.

Hot-Air Heat Sealing

In this heating method, a high temperature is used to blow hot air inside the tube opening, then with a help of a piller, the tube ends are sealed.

Non-Contact Heat Sealing

Here, an electrical heater is used to warm the metal. As metal gets red-hot, it closes the tube’s ends. This is a traditionally used method for tube sealing.

7.Want to grow your business? What types of tube filling machine for pharmacy helps to boost your profit?

Every growing business requires flexible machinery to sustain its productivity. When it comes to pharmacy, keeping formulation potent, effective, and stable is the key to a profitable product.

A tube filling machine is an entrusted equipment evolving continually. Medicines are filled the way they ensure high product integrity. Here are some ideal secrets that entail how a tube filling machine can grow your pharmaceutical business.

Strong and Safe Filling

Medicines are formulated under a strict environment where you deals with excipients and active pharmaceutical ingredient. Indeed, you cannot ignore production and required physical and chemical parameters to avoid cross-contamination as well as oxidation. This is why a tube filling machine must be utilized as it maintains controlled conditions with safe filling and packing.

Precise Volume

You must deserve what you expect when formulating any medicine. Sustainability and precision must be maintained for every generated batch. Furthermore, a tube filling machine offers you filling as well as printing features to improve patient compliance.

Low Budget- Excellent Outcome

Compared to other pharmaceutical machinery, this machine saves labor cost, product wastage, and production time. The machine is also economical to purchase and easy to control. In return, you will get quality filling that is synonymous with the drug’s therapeutic property.

A question always knocks on your mind what type of tube filling machine for pharmacy is ideal? Assessing your production capacity, formulation requirement, tube material, production timings, and level of hygiene will help you to determine the right choice. For instance, as we discussed above, for small production to large production, you can opt various options varying from manual to automatic tube fillers.

8.What tube material can be used on types of tube filling machines for pharmacy?

A tube must be flexible for any age group. The material used in its manufacturing should be capable enough to dispense formulation easily. A tube filling machine can be used for certain types of materials:

Plastic Tubes or PE

Plastic tubes are commonly used for daily usage. For instance, cosmetic products (sun block, eye creams, foundation, primer, etc), oral hygiene (toothpaste), etc., and plastic tubes are mainly made up of polyethylene or PE. Its monolayer or multilayer coating ensures excellent protection against external harm.

Laminated Tube

The product material is prepared from PE along with an extra lamination coating that offers ultra-protection and more shiny effects to enhance aesthetic appearance.

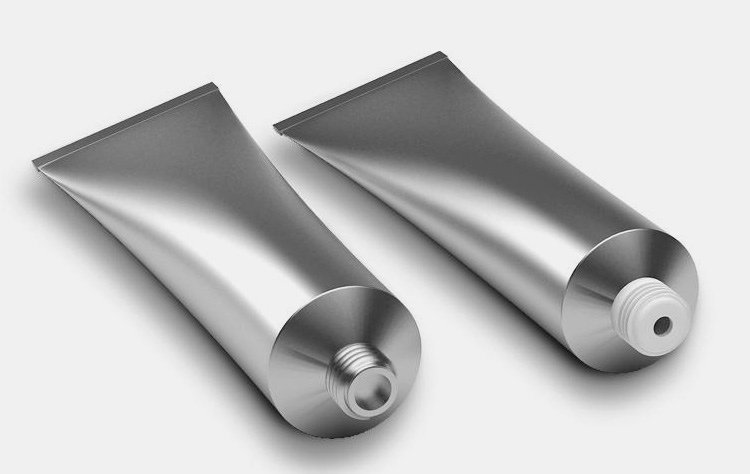

Aluminum Tube

They are also known as collapsible tubes because once they acquire a distressing shape, they cannot be recovered. It is commonly used to fill formulations such as topical antibiotics, medicated ointments, and cleansers.

9.What certifications you should look for types of tube filling machine for pharmacy?

Choosing the right medical equipment from the right manufacturer will always facilitate you with the best product suitable for medical purposes. Types of tube filling machines for pharmacy must comply with certain sets of certifications offered by your vendor.

- ISO Standards

- FDA

- CE Mark

Conclusion

Types of Tube Filling Machine for Pharmacy article basically highlights integral points that you must know as an entrepreneur or business person. Aipak’s extensive experience in the manufacturing of tube filling machines for pharmacy allows them to offer the best solution for clients. You can contact us to optimize your production needs or manufacturing setups. We are available to offer you Free Consultation 24/7.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine