Optimizing Blister Machine Output: How Custom Film Width Reduces Material Waste?

Material waste is a silent profit killer in pharmaceutical packaging. Many manufacturers accept standard machine limitations, not realizing that a small adjustment to the equipment design can save tons of PVC and aluminum foil annually.

Customizing the film width capacity of a blister packaging machine significantly reduces waste by optimizing the layout of the blisters. By extending the machine chassis to accommodate a slightly wider film (e.g., increasing from 250mm to 265mm), manufacturers can fit more blister cards per stroke (such as 1-up-3). This maximizes the use of the raw material area and drastically lowers the cost per unit over the long term.

Optimizing blister machine film width

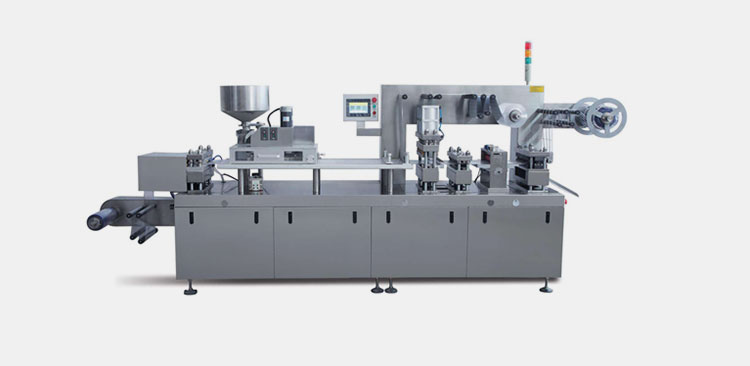

I recently worked on a project that perfectly illustrates this concept. A client approached us with a specific request for packaging softgel capsules.

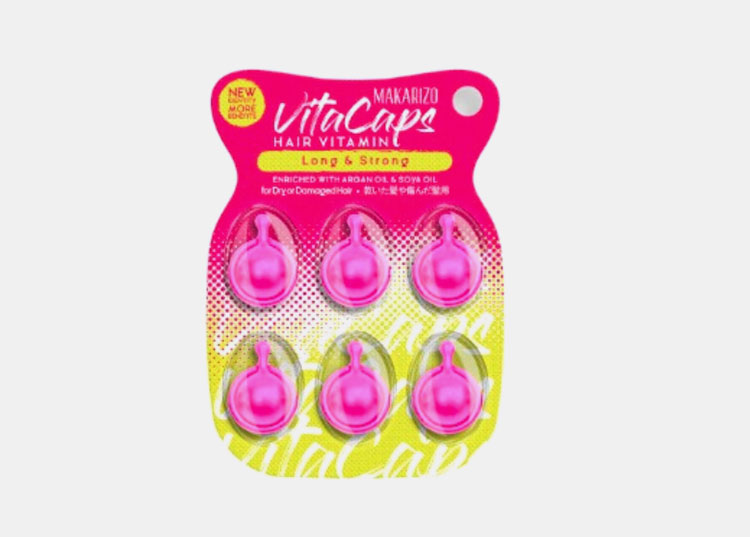

Sample image from customer

They had a sample image and a rough idea of the layout they wanted.

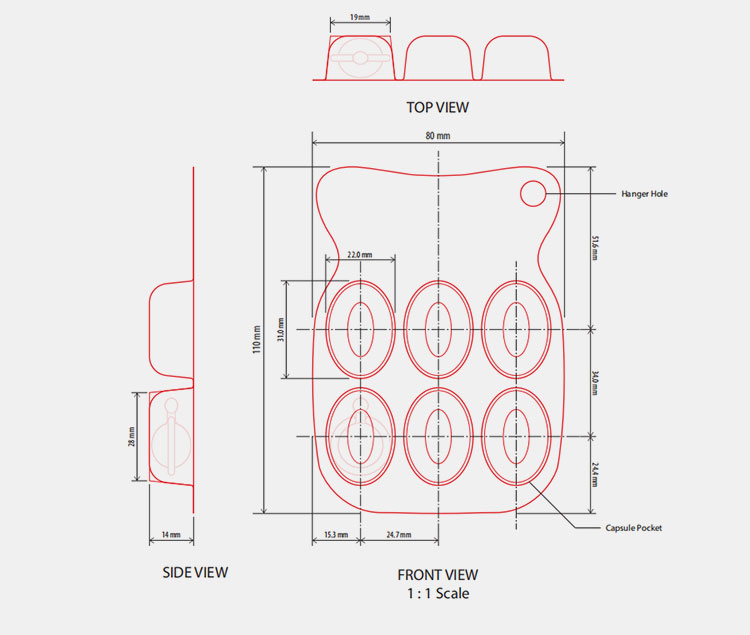

Layout from customer

However, as we dug deeper into their production goals and the specific dimensions of their product, I realized that a standard machine would be inefficient.

We had to balance speed, orientation, and material costs. In the following sections, I will share the step-by-step process of how we optimized their production line, from the feeding system to the machine chassis design.

1.Does manual feeding affect blister packaging speed?

Softgel capsules are difficult to handle because of their shape and smooth surface. Many clients want them perfectly aligned in the blister pockets, but they do not realize that achieving this perfect orientation often requires sacrificing significant production speed.

Manual feeding allows for perfect alignment of softgels, but it drastically reduces output speed and increases labor costs. For high-speed production (over 1000 blisters per hour), an automatic disc brush feeder is necessary. While this may result in random softgel orientation, it ensures consistent, high-volume output that meets industrial demands.

Disc brush feeder for softgels

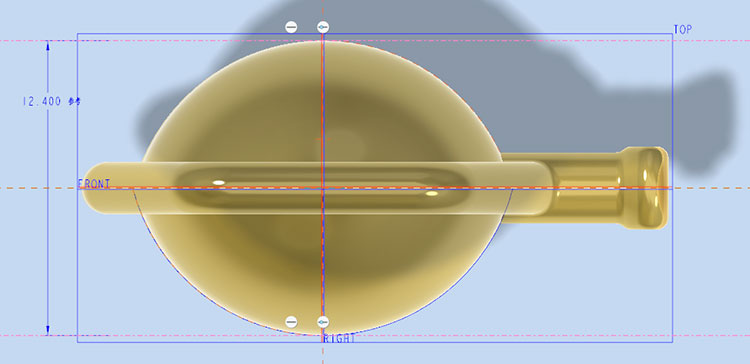

In this specific case, the client initially sent me a sample image of an Alu-PVC blister pack. They wanted to replicate the shape and layout. Their target speed was between 600 and 2100 blisters per hour. Based on this volume, I quoted them our DPP-250 Alu-PVC blister packing machine. This model is a workhorse for this type of production.

I calculated that with a disc brush feeder, we could achieve a speed of 1400 to 1600 blisters per hour, which fit perfectly within their required range.

However, a challenge arose regarding the look of the final product. The client noticed that in my proposal, the softgels might sit in different directions within the pockets. They asked if we could make them all face the same way.

I had to be honest with them. If we want every single capsule to face the exact same direction, we usually have to use manual feeding. A worker has to place them by hand or use a very slow, specific alignment track. If we did that, the speed would drop well below their 600-per-hour minimum. The actual speed would depend entirely on how fast the worker could move their hands.

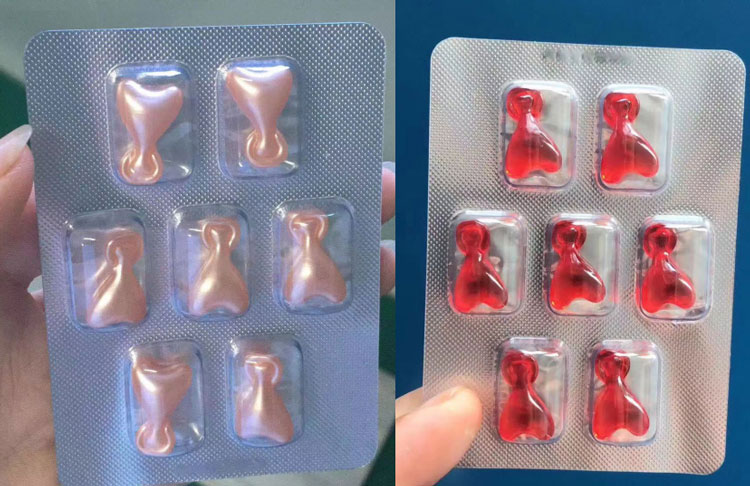

Samples with different orientation or same orientation

I sent them samples of previous softgel blisters we had made using the automatic feeder. I explained that while the orientation is random, the efficiency is much higher. After seeing the samples, the client agreed that speed was more important than having every capsule point north. They accepted the random orientation. This decision allowed us to move forward with the high-speed automatic solution.

When you are planning a blister line, you must decide what matters more: aesthetic perfection or production volume. For most B2B manufacturers, volume wins. The disc brush feeder uses a rotating motion to sweep the capsules into the pockets. It is fast and reliable. It eliminates the bottleneck of human labor. This was the first step in defining the machine, but the biggest optimization was yet to come.

2.Can extending machine length reduce material waste?

Standard machines come with fixed maximum film widths, which can limit how many blisters you can produce in a single punch. If your blister layout does not fit perfectly within that width, you end up with a lot of unused plastic and foil on the edges.

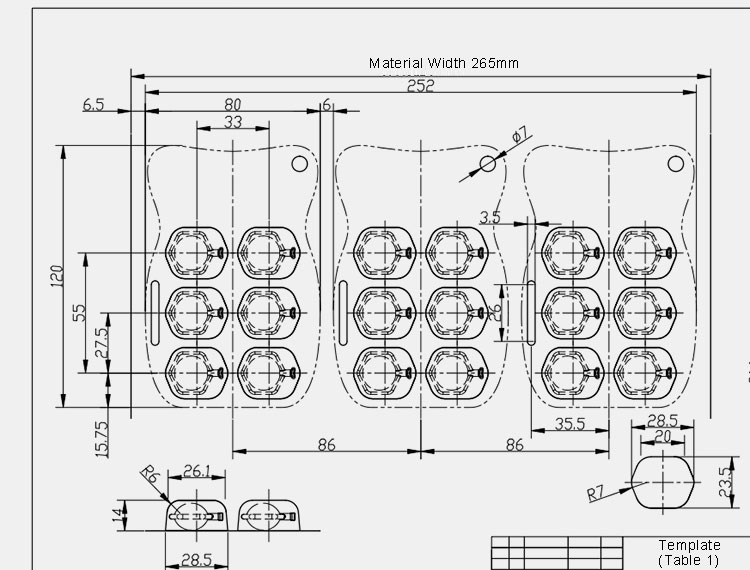

Extending the machine length allows for a wider maximum film width, which enables a more efficient "up" layout (number of blisters per stroke). By increasing the width from 250mm to 265mm, we can arrange the layout to produce three blisters at once (1-up-3) instead of two. This slight machine modification significantly increases daily output and reduces the percentage of scrap material.

1-up-3 blister layout diagram

After we settled the feeding issue, the client made a change. They decided to change the shape of the softgel.

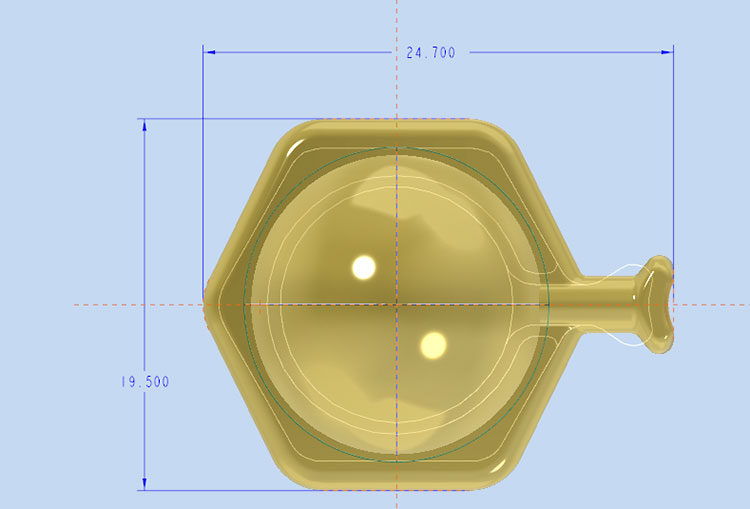

New dimensions of the dried softgel sent by customer

They provided me with the new dimensions of the dried softgel. This changed everything regarding the mold design.

DPP-250 blister packaging machine

I looked at their new dimensions and the layout they wanted. I realized that on our standard DPP-250 machine, the maximum film width is 250mm. With the client's new capsule size, a standard layout would be awkward. We would likely only get two blister cards per stroke, and there would be a wide margin of wasted PVC and Aluminum foil on the sides.

I did some calculations. If we could just get a little more width, we could optimize the layout significantly. I proposed a solution to the client: let's lengthen the machine chassis.

By making the machine body longer, we could accommodate a wider forming and sealing station. This modification increased the maximum film width to 265mm. It sounds like a small difference—only 15mm—but in engineering, it is huge. This extra space allowed us to design a "1-up-3" mold. This means for every single punch the machine makes, it produces three complete blister cards.

I explained the math to the client. Yes, the machine would cost a bit more upfront because of the customization. However, the savings in raw materials would be massive over time. We are using more of the film's surface area for the product and less for the trash bin.

Here is a breakdown of why this critical thinking helps the client:

| Feature | Standard DPP-250 | Customized Extended DPP-250 |

| Max Film Width | 250mm | 265mm |

| Layout Capacity | 1-up-2 (2 cards/stroke) | 1-up-3 (3 cards/stroke) |

| Output Efficiency | Standard | +50% Increase |

| Material Waste | High (wide edge scrap) | Low (optimized edge scrap) |

| Long-term Cost | Higher (more film used) | Lower (less film wasted) |

The client saw the value immediately. They understood that the initial investment in a longer machine would pay for itself by saving on PVC and Aluminum foil costs every single day of production. Plus, their output capacity jumped up without needing a second machine. This is how we provide value—not just by selling a machine, but by engineering a business solution.

3.Why choose silicone brushes for softgel feeding?

Equipment reliability depends on the quality of the components and how gently they handle the product. Standard nylon brushes can sometimes be too stiff for delicate softgels, potentially causing scratches or minor defects during the high-speed feeding process.

Silicone brushes are superior for softgel feeding because they are softer and more flexible than standard bristles. They gently guide the softgels into the pockets without scratching or damaging the shell. When combined with high-quality electrical components like Siemens or Schneider, the machine ensures both product safety and long-term operational stability.

Silicone brush feeder

Once the mechanical design was set, we moved to the electrical and component specifications. The client was very specific about quality. They requested that all electrical parts be major international brands like Schneider or Siemens.

We always try to accommodate these requests, but sometimes complete brand uniformity causes issues. I found that some specific Siemens components did not communicate perfectly with certain Schneider parts in our machine program. Compatibility is key for a stable machine. I explained this to the client.

We compromised by using a mix of Siemens and Schneider for the majority of the system, selecting the specific models that we knew worked perfectly together based on our testing.

To show our commitment to quality, I also upgraded their photo eye (sensor) to SICK, a premium German brand, at no extra cost. This sensor is crucial for registering the print on the foil and ensuring the blisters are cut in the right spot.

| Item | Specification | Manufacturer |

| PLC | DVP32ES | Siemens |

| Touch screen | TK6071IP | Siemens |

| Frequency Converter | VFD015E21A | Siemens |

| Encoder | E6B2-CwZ6C | Omron |

| Servo Motor | MPF47-Y1.5-4P-43.05-M1 | Delta |

| Pneumatic Cylinder | MTBL32脳10U-WZ934C | AIRTAC |

| Pneumatic Cylinder | SSA32脳5 | AIRTAC |

| Oil/water separator | BL-2000 | AIRTAC |

| Solenoid Valve | 4V210DC24V | AIRTAC |

| Temperature Controller | XMTG-3410V | Siemens |

| A.C Contactor | CJX2-2510 | Schneider |

| Solid-Relay | 380 D25 | Longlive |

Optimized components

Then, we addressed the feeding mechanism again. In standard machines, we use a disc brush feeder with normal bristles. However, softgels can be sensitive. If the brush is too hard, it might mark the surface of the gel.

I recommended a silicone brush system. Silicone is much softer than nylon. It has a natural grip that helps move the capsules efficiently, but it yields when it hits resistance. This prevents the "fighting" between the brush and the capsule that can lead to damage.

The client was impressed by this detail. They realized we were not just looking at the machine, but looking at *their product*. We were thinking about how to protect their softgels.

This combination of electrical reliability and product handling expertise is what builds trust. We didn't just say "yes" to everything; we guided them on the electrical compatibility. We didn't just use the standard feeder; we upgraded it for their specific product type.

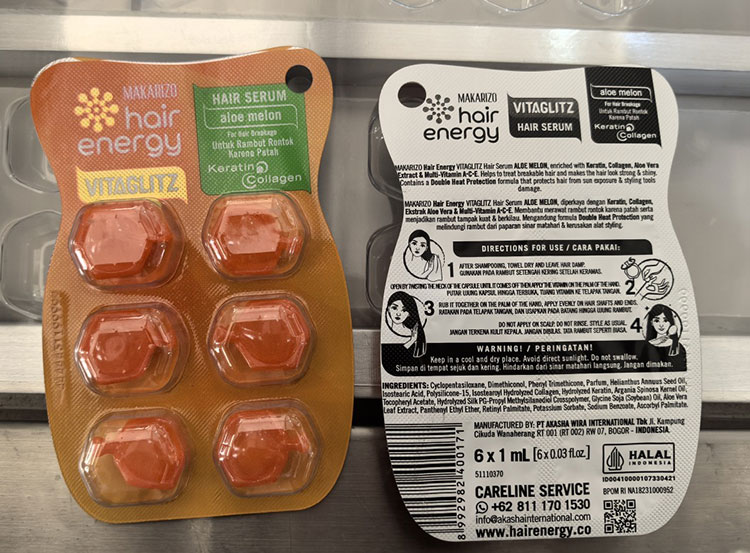

Final blister packaging from customer

By the time we finalized the proposal—extended chassis, 1-up-3 layout, silicone brushes, and premium electronics—the client felt secure. They sent the Purchase Order (PO) because they knew they were buying a solution tailored to their success, not just a catalog item.

Conclusion

Optimizing a blister line requires looking beyond the catalog specifications. By customizing the film width, we increased output and reduced waste. By choosing silicone brushes, we protected the product. True efficiency comes from engineering the machine to fit the product, not the other way around.

Don't forget to share this post!

Optimizing Blister Packaging Efficiency & Material Savings

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine