Key Criteria for Choosing a Blister Packaging Machine

Do you know how and Why Choosing the Right Blister Packaging Machine Matters? For this, you should have fundamental knowledge related to the Key Criteria for Choosing a Blister Packaging Machine. In the manufacturing era, reliable and fast blister packaging machines are as important as your formulation.

For this reason, choosing the right machine directly impacts on true safety, quality, and efficiency of the packed items. Also, it helps in developing consumer trust and your market value. In this article, we aim to provide a comprehensive discussion related to blister packaging machines that will help you to get the right one.

1.What Are the Basic Points Related To Understanding Blister Packaging Machines?

Blister packaging is a modern yet flexible mode of filling and securing manufactured products. A blister is a cavity filled with substances. So, the delicate blister is formed with the help of specified raw materials. To achieve this packaging, you will need basic elements to understand. This could be related to types of materials, classifications of machinery, applications, and others. For example:

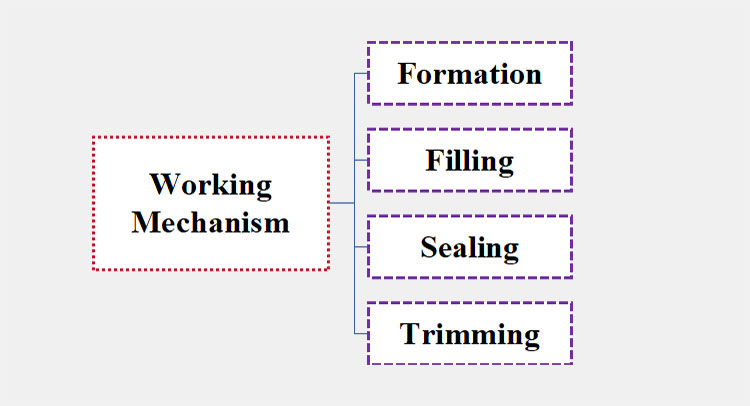

Operating Mechanism of Blister Packaging Machines

The first thing you should understand is the operating mechanism of the blister packaging machine. This is based on four major sections. For example,

Points Related to Basic Working

Formation

Formation- Picture Courtesy: Gmpua.com

The cavities or blisters are formed by the induction of heat. It melts the strength of molecular bonds of the material and ensures flexible molding. The plastic film creates a shape known as blister pockets.

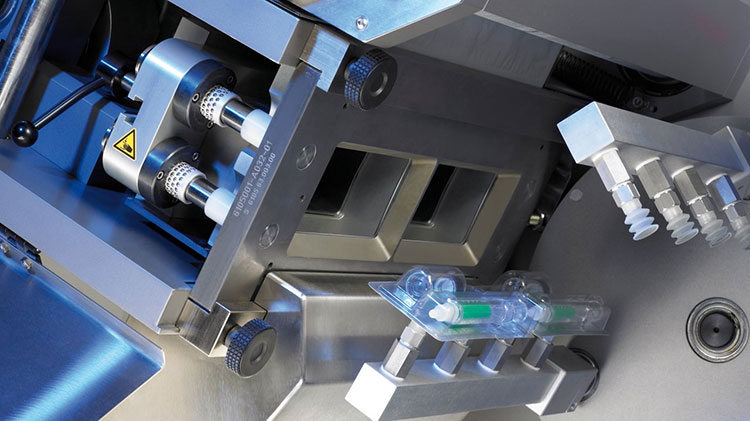

Filling

Filling-Picture courtesy: Vendorite

The filling materials like tablets, pills, capsules, or any other material, such as electronic gadgets and toys, are positioned inside the cavities automatically or manually (based on the type of machine).

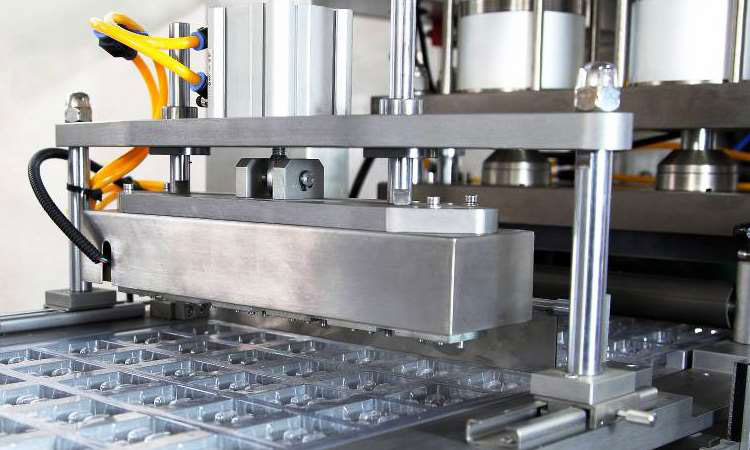

Sealing

Sealing

To secure and support the product, the aluminum, paper, cardboard, etc., is applied backside of the packaging. The procedure is facilitated with the help of a heat as well as a pressure system to form secure and tamper-resistant packaging.

Trimming

Trimming- Picture Courtesy: Korber Pharma

The blister packaging sheet is a continuous layer that is separated with the help of punching or trimming. This part of the machine is known as the cutting section. The machine is composed of sharp knives designed with flat or rotary cutting dies. The powerful stamp over the packed sheet helps in the precise splitting up of the product from the series.

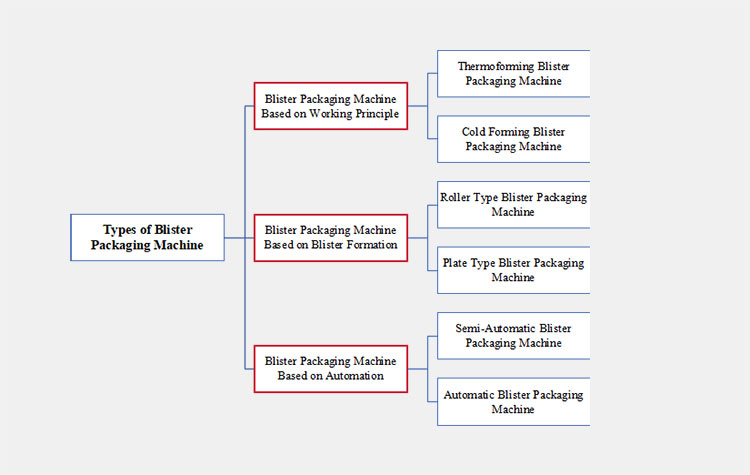

Major Types of Blister Packaging Machine

The blister packaging machine is the most innovative solution of today’s manufacturing and packaging era. If you consider their types, the state-of-the-art machine is available in a wide range. Each type of machine is associated with specified, customizable, and tremendous properties. This is all based on the types of production lines you’re running. However, the basic types of blister packaging machines are described below:

Major Types of Blister Packaging Machines

Blister Packaging Machine Based on Working Principle

The types of blister packaging based on the forming method are:

Thermoforming Blister Packaging Machine

AIPAK DPH Blister Packaging Machine

The thermoforming blister packaging machine is commonly used for machines that utilize heat for mold formation, sealing, and coding principles. The heat helps in the melting or softening of the plastic material. Along with heat, other parameters such as vacuum, pressure, and strong force are also implemented to make blister packaging possible in a good quality way. The formed cavities are then filled with products and sealed by securing a lidding to create an individual packaging with excellent protection.

Cold Forming Blister Packaging Machine

Blister Packaging Machine

The cold-forming blister packaging machine is also known as a cold form foil or CFF blister packaging machine It utilizes a strong pressing method to create blisters instead heat. In this way, aluminum-based film can be flexibly compressed to form a mold in a required size and design. This is a suitable option for the packaging of moisture-sensitive as well as heat sensitive products.

Blister Packaging Machine Based on Blister Formation

Based on the blister packaging formation, the blister packaging is classified into the following:

Roller Type Blister Packaging Machine

Roller Type Blister Packaging Machine- Picture Courtesy: Chinnofi

A roller-type blister packaging machine is designed with a type of roller or circular plates. The metallic dies are heated to create cavities from fed plastic films (ideally PVC or PVDC). The formation and sealing processes utilize heat, pressure, and vacuum to perform blister packaging effectively. A high-speed machine that is mainly used in pharmaceuticals for large-scale production and packaging.

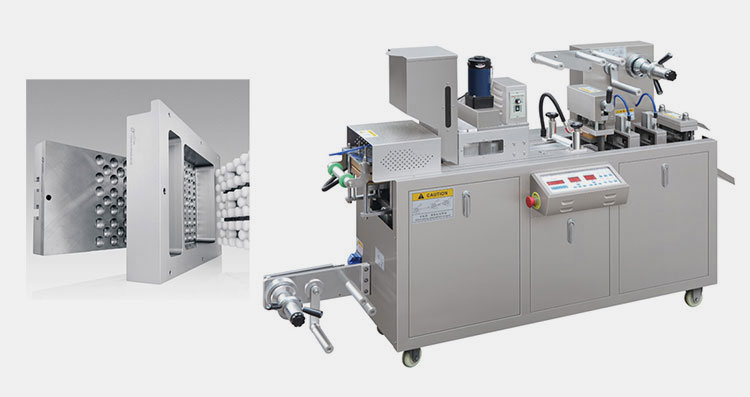

Plate Type Blister Packaging Machine

AIPAK Roll Plate Blister Packaging Machine

A plate-type blister packaging machine is commonly used to create blister packaging with the help of flat plates. The machine also uses positive pressure to improve the work with more efficiency and precision. This machine is used in pharma and electronics for packaging small items with uniformity.

Blister Packaging Machine Based on Automation

Based on automation, the blister packaging machine is classified into the following:

Semi-Automatic Blister Packaging Machine

Semi-Automatic Blister Packaging Machine- Picture Courtesy: Sepha

Semi-automatic blister packaging is another revolutionary development in the packaging industry. This solution is introduced for medium or moderate production capacities. The specialized machines where all procedures are carried out using efficient automatic features, except loading and final removal of the packed items. Consequently, the machine itself can yield greater production outcomes with intact and tamper-evident sealing. So, the machine required little human intervention for its functionality.

Automatic Blister Packaging Machine

AIPAK Automatic Blister Packaging Machine

The automatic blister packaging machine is ideal for expanded production capacities. The machine complements high operating speed, minimum or no human involvement, and provides a larger production output. It can perform the entire working parameters automatically. Moreover, product safety is ensured with the help of modern inspection systems designed in machines, where early detection can save your time and energy.

Understanding Types of Materials

Types of Materials- Picture Courtesy: FDKM

Blister packaging machines are compatible with certain types of materials to perform packaging. For instance:

Polyvinyl Chloride or PVC

The type of plastic that is commonly used in blister packaging. It helps in presenting subtle visual clarity and flexible options.

PVDC

This is known as a high-performance blister packaging material with extensive moisture resistance properties. Most often, it is used as a base over PVC to promote excellent barrier properties. This is a stable and more protective solution for the packaging of products.

Polyethylene Terephthalate or PET

This type of plastic is known for its greater moisture-resistant properties as compared to PVC, with additional high shelf life.

Polypropylene or PP

This is also one of the popular materials used in blister packaging, which is sustainable and recyclable. As compared to PVC and PET, this is somewhat difficult in thermoforming.

Lidding Material

To support blisters or cavities, support is provided. The backing is meant to make the product stable till the user reaches. The commonly used materials for lidding are described below:

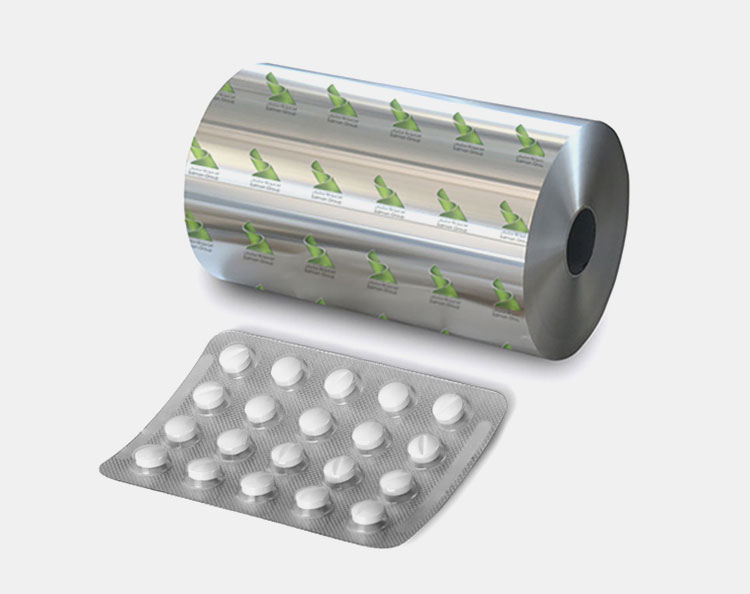

ALU or Aluminum Foil

This is a very commonly used material in blister packaging for medicinal and medical-grade packaging. It gives high protection and tamper-evident sealing, which is delicate but so durable.

Paper–Alu Laminate

This is commonly formed from paper and aluminum foil. The modern intervention in packaging offers protection with an easy mode for printing. Therefore, branding and visual appearance are enhanced.

Alu–Alu Composite or Cold-Formed Foil

The ALU-ALU composite is the combination of multiple materials, such as nylon/ALU/ and PVC. Therefore, this is strong material and is used for packaging delicate materials and sensitive medications.

Applications

Applications- Picture courtesy: Nutraceutical World

You must understand the basic applications and scope of blister packaging machines in the production world. For example:

Pharmaceuticals: The common applications of blister packaging machines involve in the packing of capsules, tablets, pills, injectables, pre-filled injections, ampoules, and related formulations.

Toys: small, medium, large, battery-operated, manual, and other toy items.

Electronics: batteries, plugs, switches, cards, computer-related gadgets, etc.

Hardware: nuts, bolts, various hardware tools, etc.

Foods: seasoning products, food colors, baking items, spices, etc.

Nutraceuticals: nutritional supplements in solid dosage formulation and parenteral forms.

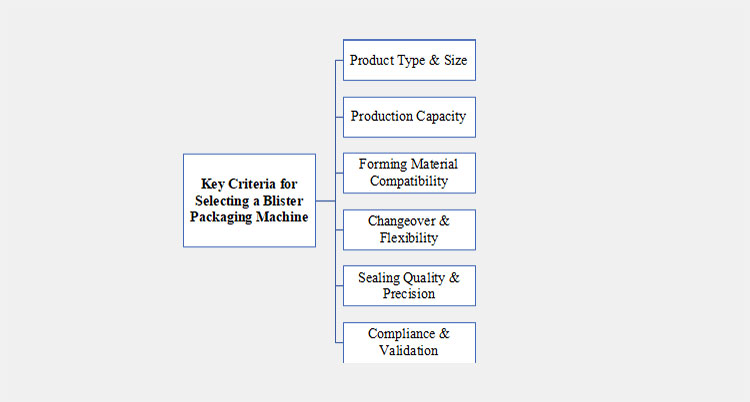

2.What are the Key Criteria for Selecting a Blister Packaging Machine?

The key criteria for selecting a blister packaging machine are described below:

Key Criteria for Selecting Blister Packaging Machine

Product Type & Size

Nature Of Packaging-Picture Courtesy: T.O Plastics

The key criteria for selecting a blister packaging machine are to evaluate whether the machine is adaptable to produce the shape of a particular item. Indeed, the product can be of a specific shape, size, and may require a unique cavity. Therefore, it is important to understand machine is ideal enough to process and pack individual products in a proper mold and presentation. For example, the packaging of medications, toys, electronics, etc.

Production Capacity

Production Outcomes- Picture Courtesy: SEA Vision

The packaging design, blister packaging material type, and automation; these three features can help in determining the achievement of the ideal goals. The modern and high-performance machine can give you precise and tremendous throughput per hour. Therefore, you can meet large production capacities when executing a workout related to estimating the production objectives. If the machine is modern, with automated functional keys, it can cut down the labor costs and constant labor involvement. Nevertheless, investing substantially can improve handsome productivity. However, automation provides major handling automatically, which can be profitable with remarkable quality and processing.

Forming Material Compatibility

Forming Material Compatibility- Picture Courtesy: ACG

When choosing a blister machine, it must be compatible with certain materials such as PVC, PVDC, and others. During the formation of packaging, such as cold forming or thermoforming, compatibility is a critical parameter that helps to produce consistent packaging with strong sealing.

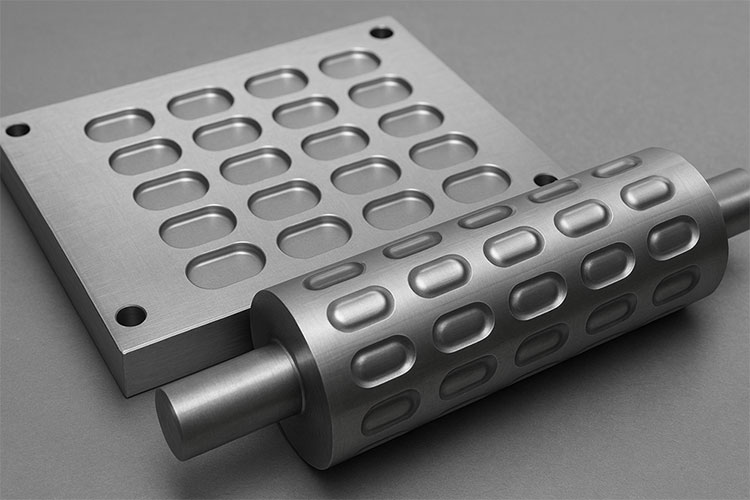

Changeover & Flexibility

Flat Plate and Roller Type Blister Packaging Machine Mold

You can consider that the blister packaging machine must be versatile. This term can encompass various factors, such as quick and flexible changeovers. It improves the packaging time and efficiency. Therefore, if you are running a broad spectrum of products with different shapes or sizes, then a smooth changeover can save time from complicated adjustment procedures.

Sealing Quality & Precision

Sealing Quality & Precision

A blister packaging machine must be provided with good sealing quality and precision. A minor leakage gateways the moisture, light, or oxygen entrance, which results in product degradation. Therefore, stable sealing quality and precision can protect the items and make them stay longer with improved physical appearance. For example, food products, medicines, electrical items, and related products tend to degrade fast in the external environment.

Compliance & Validation

Regulatory Compliance- Picture Courtesy: HCM

A trustworthy supplier should provide all relevant documents and mandatory principles related to machines. The offered products must be compliant with international standards such as GMP, ISO, etc. These formalities can help in maintaining equipment validation and audits.

3.How do you compare blister packaging with other kinds of medicine packaging?

Medicine packaging is mainly attempted with a strip or bottle packaging. Discuss below the major points for comparing blister packaging with other kinds of medicine packaging.

Blister Packaging VS Strip Packaging

Strip Packaging- Picture Courtesy: LSKB

Blister packaging provides an extreme degree of protection to each product packed in the cavity. It is all due to its tough structure that ensures tamper-evident, moisture-resistant, and light-resistant effects to medications. The packaging process is considered complex and forms a particular cavity for a specific dose.

Strip packaging is a commonly used medicine packaging that offers protection, which is not as durable as blister packaging. However, this is an effective mode of packaging and is used as the second popular packaging type after blister packaging. This is a continuous process and has a flexible mechanism with an affordable packaging cost.

Blister Packaging VS Sachet/Stick Packaging

Sachet or Stick Packaging

Blister Packaging is used for solid dosage formulation, such as pills, tablets, and capsules. In other cases, pouch, stick, or sachet packaging is used for powder or liquid medication and is used for a single serving. As compared to blister packaging, stick or sachet packaging is less protective and provides limited physical protection. Moreover, blister packaging can offer child-resistant barrier properties, which are not available in the case of stick or sachet packaging.

Blister VS Bottle Packaging

Bottle Packaging

As compared to blister packaging, bottle packaging contains bulk quantities of medicine. When it comes to considering cross-contamination, blister packaging is extremely safe with no chance of external exposure. While bottles need to open and close for each use of pills, this may expose medicines to the physical environment. Hence, it can minimize the shelf life and potency over time.

For fast packaging, the bottle packaging needs a comprehensive series of bottling lines (unscrambler, bottle counting machine, desiccator inserting machine, capping machine, induction sealing machine, labeling and cartoning machine. In the case of blister packaging, you will need a labeling and cartoning machine for the entire packaging solution.

4.How to Evaluate a Supplier of Blister Packaging Machines?

A good supplier is the bridge that connects you with a successful packaging journey. How to get the good one? For this, please find below the points:

Industry Experience

Top Blister Packaging Machine Suppliers

If the supplying company with a blister packaging background will always help you in offering the right solution. This would be included with documentation, your packaging objectives, and future outcomes. Therefore, opting for a supplier with particular experience will ensure smoother and quality blister packaging machine.

Technical Expertise

Technical Expertise- Picture Courtesy: Yundu

Purchasing a blister packaging machine from a supplier with excellent technical expertise is beneficial in many ways. The company can easily and swiftly find the solution whenever you need. This might be related to automation, design, managing basic or advanced issues related to blister packaging or blister packaging machines in a safe manner.

Machine Quality & Performance

Quality of Machine

The supplier must be confident to provide excellent and durable machines. Remember, machine quality and performance affect your overall processing and effective results. The materials used in it should be good-quality stainless steel with ideal operation. Machine specifications must be provided to customers so you can flexibly prioritize the estimation of packaging.

Customer Reviews & Reputation

Customer’s review- Picture courtesy: Flux Creative

Customers’ remarks and ratings matter a lot for the reputation of the company. Recently, knowing or catching good suppliers has been pretty easy. Reviewing customers’ comments related to suppliers, machines, working, training, and their overall progress can help with a touching base with top-notch and reputable companies. This way is helpful in purchasing the right machines without any doubt.

5.Case Example: Choosing the Right Blister Machine for a Pharma Start-Up

To choose the right machine for a pharma start-up, check the following points:

Sterile Blister Machine for Pharma Packaging

Sterile Blister Packaging- Picture Courtesy: Melimoyulodge

The start-up focused on a machine that supported GMP-grade operation design and carried sterile packaging. Equipment should support clean and sterile packaging of medication involving parenteral and solid dosage formulations. To achieve optimal product safety, a hygienic, compact, and enclosed structure should be highlighted to prevent any cross-contamination risk.

Product Characteristics Assessment

Product Characteristics Assessment

Your products can be heat and moisture sensitive. Heat-sensitive medicines need machines that can work at a controlled forming temperature. Similarly, light-sensitive medicines need opaque and aluminium-based foils to prevent degradation. This evaluation step streamlined the decision of a suitable machine for the start-up.

Unit Dosage Formulation

Unit Dose Packaging

The unit dose blister machine is the right solution for individual packaging of products such as solid dosage, parenteral, and semi-solid dosage formulations. By considering the right packaging planner can validate the quality standard machine for precise and unit packaging.

Tamper Evident & Child Resistant Blister Machine

AIPAK Blister Packaging Machine

The machine must possess features of packaging that offer push-through foil along with a perforated line. This would help you to boost customer satisfaction as they’re provided with tamper-evident medication. Additionally, opting for multi-layer foil would help child-resistant packaging that entirely makes your medication pretty safe without defects or imperfections.

Conclusion

The Key Criteria for Choosing a Blister Packaging Machine involved significant points such as fast, safe, cost-effective, meeting production goals, etc. that must be built attributes of the machine. In this article, we have briefly talked about each aspect with importance. If you are looking for a reliable solution from a top-notch supplier, contact AIPAK’s team now. We’re right here to provide, process, and package solutions, and customer guidance support related to blister packaging machines.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine