Alu-Alu Blister Packaging Strategy: How to Share Tooling for Tablets & Capsules to Reduce Cost?

Pharmaceutical manufacturers often face a difficult choice between high costs and production flexibility. You want to produce different products, but buying separate machines for every single format is expensive and takes up too much space.

Yes, you can share tooling on an Alu-Alu blister machine if the tablet and capsule sizes are similar. The best strategy is to use the same forming mold to reduce costs, but you must use separate feeders for each product to ensure smooth loading and packaging stability.

Alu-Alu blister packaging machine setup

I recently worked on a project that illustrates this exact situation perfectly. A client from Malaysia came to me with a specific request. They wanted to buy a DPP-260 Alu-Alu blister packaging machine. However, they had a tight budget. They wanted one machine to handle both their tablets and their capsules. I knew that simply saying "yes" was not enough; we needed a smart technical plan to make it work.

1.Can One Machine Handle Both Tablets and Capsules?

Many factory owners feel frustrated when they have to buy multiple machines for small batch runs. You want flexibility in your production line, but equipment costs can quickly destroy your yearly budget.

One blister packaging machine can absolutely handle both tablets and capsules. The key is analyzing the dimensions of your products. If the size difference is small, we can design a versatile solution that handles both formats on a single DPP-260 unit.

DPP-260 blister machine with tablets and capsules

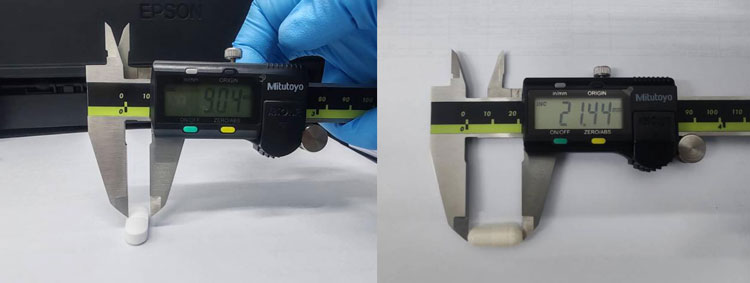

When I started talking with the Malaysian client, their main goal was to save money. They asked if the DPP-260 could pack a hard capsule and a round tablet. I asked them to send me the exact drawings and samples of their products. This is the most important step in the process. I looked at the length, width, and thickness of the capsule. Then, I looked at the diameter and thickness of the tablet.

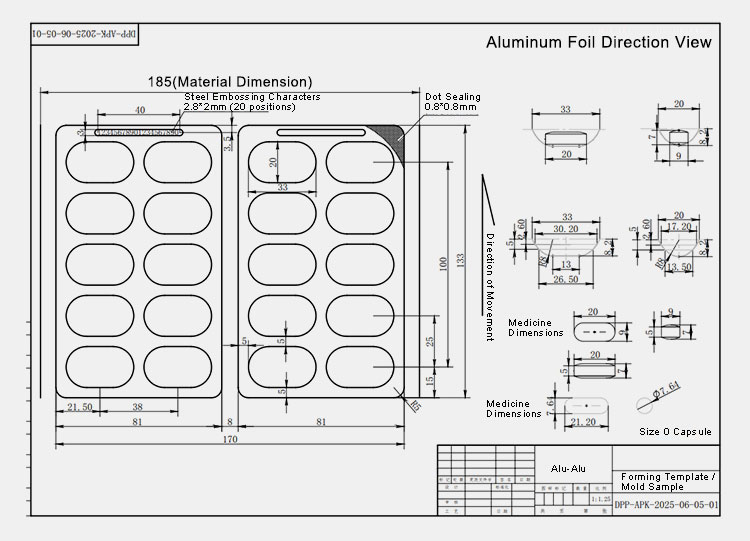

I discovered that the physical size difference between their specific tablet and capsule was very small. This was good news. It meant that the "pocket" or the "blister" formed in the aluminum foil could be the same size for both. If we made the pocket big enough for the capsule, the tablet would also fit inside it comfortably.

However, simply fitting inside is not the only thing that matters. We have to think about how the product moves. Tablets are flat and round. Capsules are long and cylindrical. They behave differently when they fall from the hopper. But regarding the expensive part—the forming mold—I realized we could save the client a lot of money. I proposed a plan where they would only pay for one set of forming molds. This decision immediately lowered their initial investment cost. It showed the client that I was on their side and wanted to help them save money, not just sell them more metal.

| Feature | Tablet | Capsule | Shared Tooling Solution |

| Shape | Round/Flat | Cylindrical | Design pocket for the largest dimension |

| Material | Compressed Powder | Gelatin/HPMC | Alu-Alu Foil works for both |

| Cost Impact | High (if separate) | High (if separate) | Low (Single Forming Mold) |

2.How Does Shared Tooling Work in Alu-Alu Packaging?

You might think that sharing molds means you have to compromise on the quality of the final package. It is scary to think about machine jams or empty blisters because the tooling isn't perfect for the specific product.

To share tooling effectively, we use one common forming mold for the blister pockets but require specific feeders for each product type. This method saves significant money on molds while maintaining high speed and accuracy during the feeding process.

Universal feeder vs dedicated feeder for blister packing

I explained to the client that while we could share the "forming" part, we could not share the "feeding" part. The forming mold punches the shape into the aluminum foil. Since the pocket size was designed to hold the larger item (the capsule), the smaller item (the tablet) would sit inside it easily. This covers the most expensive part of the tooling changeover.

But, getting the product *into* that pocket is a different story. This is where many manufacturers make a mistake. They try to save money by using one universal feeder for everything. In my experience, this leads to problems.

"For this project, I specifically advised against using traditional brush feeders due to hygiene concerns and the risk of micro-scratches on the Alu-Alu foil surface. Instead, I proposed a more advanced Vibratory Channel Feeding strategy based on product dimensions:

Scenario A (Similar Dimensions): If the capsule and tablet sizes are compatible, a Universal Vibratory Track Feeder is the optimal choice. It provides precise guidance without physical abrasion, ensuring a cleaner process compared to brushes.

Scenario B (Different Dimensions): If the sizes differ significantly, we insist on configuring two separate sets of dedicated vibratory feeders. Even in this case, we avoid brush feeders to maintain strict GMP hygiene standards and protect the aesthetic quality of the aluminum foil."

If we tried to use the capsule feeder for tablets, the tablets might flip over or stack on top of each other. If we used the tablet feeder for capsules, the capsules would likely break or not enter the pocket at all.

Molding sample

By splitting the solution—**Shared Forming Mold + Separate Feeders**—we achieved the perfect balance. The client saved money on the heavy steel molds. But they spent a little extra on a second feeder to ensure the machine would run smoothly. This setup guarantees that the DPP-260 runs at high speed without stopping for jams. It is a practical application of "spending a little to save a lot" in the long run.

3.Why Is Vision Inspection Essential for Alu-Alu Blisters?

Manual inspection is slow, expensive, and prone to human error, especially when lines run fast. You cannot afford to send empty or broken blisters to the market, as it ruins your brand reputation and endangers patients.

A vision inspection system uses high-speed cameras to check every blister pocket before sealing. It detects missing pills, broken pieces, or double-fills and automatically triggers a rejection device to remove bad packs without stopping the machine.

Vision inspection camera system on blister machine

During our discussions, I noticed the client was very concerned about quality. Since this was an Alu-Alu machine, the packaging is opaque. You cannot see through the aluminum foil once it is sealed. If a pocket is empty, you will not know until the customer opens it. That is a disaster for a pharmaceutical company.

I recommended adding a visual inspection system. I explained the working principle in simple terms. We install a high-speed camera right after the feeding station and before the sealing station. This camera takes a picture of every single blister sheet.

The system checks for:

*Missing Product: Is the pocket empty?

*Broken Product: Is the tablet chipped or the capsule crushed?

*Double Filling: Are there two tablets in one pocket?

If the camera sees any of these errors, it sends a signal to the machine's computer (PLC). The machine remembers which blister sheet is bad. Then, at the end of the line, a mechanical arm or air jet kicks that specific sheet into a reject bin.

The client hesitated at first because of the extra cost. But I explained that this system replaces two human workers who would have to stand there watching the machine all day. Humans get tired; cameras do not. The camera ensures 100% inspection. Once they understood that this system protects their quality and reduces labor costs, they agreed. They decided to equip the full camera detection and rejection system on the DPP-260.

4.What Value Does On-Site Installation Add to Your Production?

Buying a complex machine from overseas can feel risky and stressful for a business owner. You worry that if the machine arrives and does not work, you will be left alone with a pile of expensive metal and no support.

Professional on-site installation ensures your equipment runs at peak performance from day one. Our technicians handle mold changes, parameter tuning, and staff training, which prevents startup delays and ensures your team knows how to operate the machine safely.

Technician installing blister machine in factory

The deal was signed, but my job was not finished. The machine arrived in Malaysia, and we sent our technical team to their factory. This step is where we truly prove our value. It is one thing to sell a machine; it is another thing to make it work in a real factory environment.

Our engineers helped with the installation of the DPP-260. We set up the shared forming mold and taught their operators how to switch between the tablet feeder and the capsule feeder. We also spent a lot of time calibrating the vision camera. We had to teach the camera what a "good" tablet looks like and what a "bad" one looks like. We tested the rejection system repeatedly until it was perfect.

But we went further than just our contract. While we were there, the client mentioned they had other machines in the factory that were not working well. These were old machines bought from other suppliers. Our engineer took the time to look at them. We helped them troubleshoot electrical issues and mechanical wear on equipment we didn't even sell.

We helped them fix their production bottlenecks. This act of service built a huge amount of trust. The client realized we were experts in the entire process, not just salespeople. Because of this successful visit, the client shared their future plans with me. They explicitly stated that they will buy their next production line from us. This experience reinforced my belief that in the B2B machinery business, technical expertise and genuine service are the keys to success.

Conclusion

Sharing tooling on an Alu-Alu blister machine is a smart way to cut costs without losing quality. By using a single forming mold and separate feeders, combined with a vision inspection system, you get a flexible and safe production line.

Don't forget to share this post!

Reducing Costs Through Tooling Sharing

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine