How To Open Blister Packaging?

According to research, every year, the Poison Control Center receives more than 500,000 cases related to children under 5 years of age with access to medication. This means one call every minute for every day. Isn’t it alarming? Blister packaging is a modern packaging solution that’s profoundly implemented across different industries.

What makes it most popular is its evident packaging properties. Nevertheless, it offers an intact seal, which is definitely tricky to open. The reason is to keep it safe from unwanted hazards. In this blog’ ‘How to Open Blister Packaging, we talked about all relevant issues that you’re looking for related to blister packaging, primary uses, tips and tricks to opening, and certain challenges, etc.

1.What is blister packaging?

Blister Packaging

A blister packaging is a transparent bubble that is created in a customized manner to hold the item. It is a pre-formed cavity from plastic wrap, such as PVC, PET, PETG, RPET, or eco-friendly plastics like HPDE, or pulp fiber. On the back side, there’s a supporting lid which is commonly made of paperboard or aluminum foil.

The ultimate result is to provide airtight and strong protection against unwanted physical factors, i.e., UV, excessive temperature, humidity, etc. Due to its significant benefits, it is mainly used in medicine, food, and health sectors and presented in many types such as face-seal blister, full-face seal blister, slider blister, trapped blister, and clamshell blister.

Along with securing the seal, you may find it challenging to open the packaging. Many consumers experience wrapping rage, which is a common problem of putting extra effort into popping out medication or items from blister packs. For this, you commonly necessitating with a supporting tool. Indeed, carelessness may often result in injuries or damage to the items. This is primarily important to extract or take out items safely to prevent harming yourself. Therefore, with proper knowledge and handling, you can pick items with preserved integrity.

2.Why Blister Packaging Is Used?

Benefits of Blister Packaging- Picture Courtesy: John Healthcare

The popularity of blister packaging is due to the following reasons:

Protection against Moisture, Light, and Contamination

The blister packaging seal is hard in texture and made up of rigid plastics. In this way, it gives a high level of protection against moisture, light, and contamination during distribution and market-related formalities. Whether there are perishable items or valuables, the blister packaging safeguards them completely. It negates the entrance external components, thereby improving the stability and shelf life of the products till the expected expiry dates.

Tamper-Resistance and Child-Safety Features

The promising property of blister packaging is to provide a built-in security element. Whatever design is created, it remains intact with blister packaging; in case of minor tampering or alteration, one can easily identify the opening of the packaging. PLUS, your children are safe with child-safety features which is designing of an extra layer to minimize the risk of easy access to medication. This safety feature reduces the chances of accidental ingestion and is considered a successful strategy for medication packing.

Compliance with Pharmaceutical and Retail Standards

The pharmaceutical and retail standards are fully compliant with packaging if they’re safe, with no trace elements, displaying proper information, dosing, and supporting the product. In this way, blister packaging plays an integral role in patient safety by supplying true items after being passed through various supply channels and processing.

3.What are the Safety Considerations Before Opening the blister packaging?

Even though blister packaging is quite protective and tamper-proof, opening it is a very frustrating, tiresome, and even dangerous task. Below are some significant precautions that must be taken before attempting to remove product from blister packaging:

Warnings: Avoid using sharp tools carelessly.

Using sharp tools- Picture Courtesy: Cubby

The most concerning and common safety risk before opening blister packaging is physical injury.

Cutting or Injuries: The tough plastic or aluminum foil can be sharp and pointed; thus, it can cut, nick, or scratch the hand or finger of the individual opening it. Hence, avoid sharp edges while handling. Secondly, don’t forcefully push the object out of the packaging as the backside foil may tear, which may injure sensitive skin.

Use Proper Tools: To access the inside product immediately, people may use unsuitable, sharp tools, such as knives, blades, or scissors, which could cut their fingers. It is important to use a safety blade that is specifically designed for opening to prevent these injuries. Cutting the packaging away from your body is integral to keeping yourself safe.

Keep away from children.

Blister packaging child-resistant – Picture Courtesy: Oliver Design

Blister packaging is child-resistant and requires a specific action combination, like peel and push or press and turn to open. However, these packs should still be kept away from the access of children. Ideally, they should be stored in locked cabinets or drawers, since young kids or toddlers could injure themselves trying to open blister packs.

In addition, opened blister packs should never be left within easy reach of kids. The remaining contents may be accidentally ingested, creating a severe choking hazard. In some cases, this can result in medical emergencies and hospitalization. Open packaging also exposes children to harmful or toxic substances, increasing the likelihood of accidental poisoning.

Avoid damaging pills, capsules, or medical devices inside.

Avoid Damaging The Content

One major safety consideration when opening blister packaging is to keep the contents from getting damaged. Excessive force is one of the biggest culprits in damaging, crushing, puncturing, or breaking the pills and capsules. These damaged pills lose their effectiveness and are unable to offer the intended therapeutic effect.

Fragile components, like medical devices, syringes, testing strips, electronics, and others, are damaged when using an inappropriate instrument for opening packaging.

Also, they may be bent, scratched, or crushed if extreme pressure is applied to open packaging. They could be subjected to harmful contaminants if the sealing is improperly opened. Either way, these delicate components may lose their functionality or sterility without the proper measures for opening blister packs.

4.What are the Methods to Open Blister Packaging?

The methods to open blister packaging are classified below:

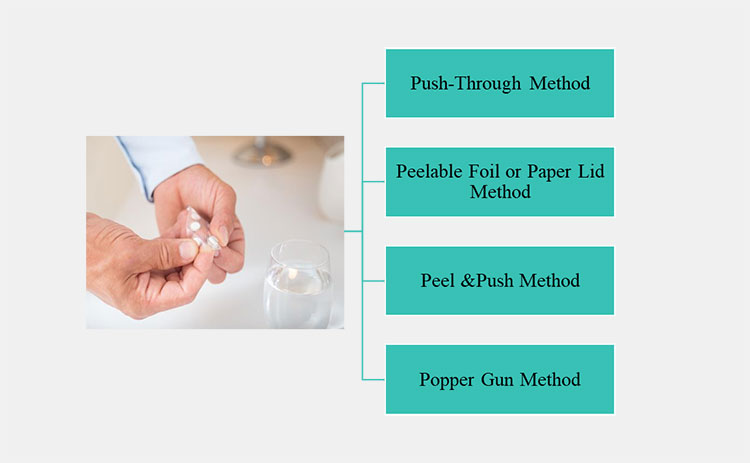

For Pharmaceutical Blister Packs

Pharmaceutical blister packs (medication, tablets, capsules) are a fundamental packaging option for safety and unit dose assembly. In many cases, the opening of blister packs is required to withdraw the medication packed in blister cavities safely.

For Pharmaceutical Blister Packs

Push-Through Method

Push through method- Picture courtesy: ROMACO

The classic design of blister packaging with a delicate plastic backing, which is mainly opened using push push-through method. This method is used to push out medication with press or push out product from the backside. The backing of the foil is mainly created with thin aluminium that allows easy rupturing with force application. As every item is placed individually, you need to push through every seal to recover the item. To some extent, this could offer a child resistance protection from medication.

Peelable Foil or Paper Lid Method

Peelable Foil or Paper Lid- Picture Courtesy: KAA Timex

Various blister packaging medications are sealed with multiple layers of lidding. The large medications, such as capsules or tablets with a large size, are mostly packed with peelable foils. This kind of backing is mostly used for those medications used for patients suffering from weak muscles. Therefore, the peelable foil is a significant method to peel the backing of the packaging to retrieve the item. This kind of method is ideal for child resistance medication packaging as it has multiple layers that a child can't access. The peeling action requires skills that adults can perform.

Peel &Push Method

Peel & Push Method- Picture Courtesy: Labels & Labeling

This is a method that is mainly used to deblister the child resistant packaging. This type of packaging is mainly designed with multi-layer sealing. Therefore, the user has to peel off the multi-layer backing and then withdraw the tablets, pills, capsules, or medication by pushing through the cavities. This is actually the two-step method, which is mostly can not be performed by children.

Popper Gun Method

Popper Gun Method

This is a manual unit that is capable of popping tablets or medication out of blister packaging. This is an easy solution for elderly patients and small pharmacies. You just need to press the pill, and it comes out into the collection chamber safely.

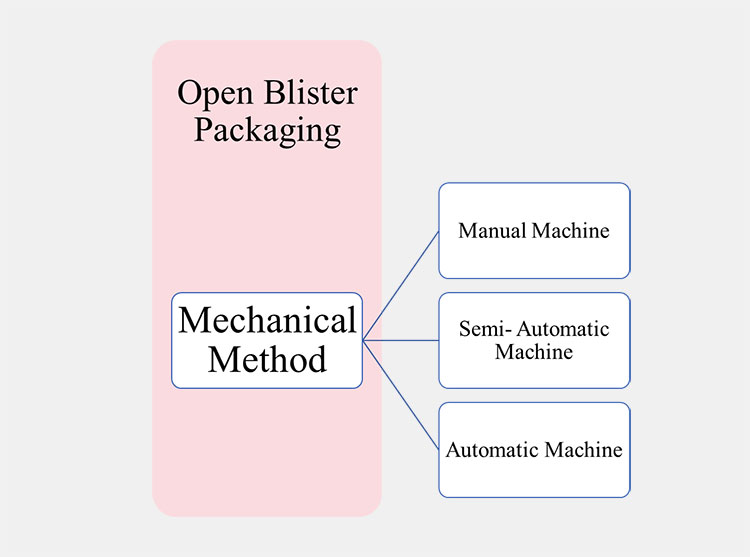

Mechanical Method to Open Blister Packaging

For large batches, such as in research labs, quality controls and related departments, you need a mechanical tool to dispart the packed lot. The commonly used methods to open blister packs in pharmaceuticals are described below:

Mechanical Method To Open Blister Packaging

Manual Deblistering Machine

Manual Deblistering Machine

The manual machine requires with handling of an operator. The blister packaging card has to be placed in the machine. The unit is capable of pushing out tablets or capsules once the roller or handle is pressed. It is a simple machine with safer and hygienic operating principles than manual separation.

Semi automatic deblistering machine

Semi-Automatic Deblistering Machine

The semi-automatic machine is the ideal solution for moderate batches of pharmaceutical preparations. It mainly works with automatic sensors and manual handling. The operator needs to push the blister card into the magazine. The automatic sensors disparts the tablets or items from the strip and safely draw them into the collector. The empty waste strip is collected into the waste bin. The operator has to collect the recovered medication once the process is completed.

Automatic Deblistering Machine

Automatic Deblistering Machine

To recover the large batches of medication, the automatic deblistering machine is used to open blister packaging. The equipment is introduced with blister cards in bulk. Upon feeding the settings, the machine itself starts the deblistering process according to protocol. The recovered tablets, capsules, or medications can be collected while the waste foils are sent to discarder.

For Retail/Consumer Goods

For Retail/Consumer Goods

For retail/consumer goods (electronics, batteries, toys), the blister pack opening method are described below:

Use Scissors or Utility Knife

This is a very common way to open a blister pack: take the help of scissors in a careful manner. The minor cut-out/tearing is done either with a knife or scissors to facilitate further opening of the blister pack easily to access the retail product.

Look for Easy-Open Features

Modern blister packaging provides a perforated opening for access to the consumer with an indication. You just need to tear the labelled hint and can easily open the product.

Specialized Tools

The small manual cutters are also available to open the blister pack of retail products. These cutters are sharp enough to open the toughest material easily, hence used in retail sections.

5.What are the Common Problems and Solutions of opening blister packaging?

There are various common challenges related to unsealing the blister packaging. The provided problems and solutions related to opening blister packaging can be helpful to read:

Wrap Rage (Difficulty Opening)

Wrap Rage (Difficulty Opening)- Picture Courtesy: HubPage

Many people find the unsealing of blister packaging frustrating. The difficulty in opening could be due to the hardness and toughness of the materials to maintain effective packaging. Side by side, this also puts you in trouble, as it does not allow easy accessibility.

Solution: There are some easy-to-access packaging designs of blister packaging, such as punching of perforation, creating a peelable covering or backing, and using tear tape. The utilization of these features may help in the comfortable opening of blister packaging by applying less force without risking children or any accidental ingestion.

Risk of Injury

Risk of Injury- Picture Courtesy: This Bug’s Life

Opening blister packaging with scissors, or a sharp tool is undoubtedly puts you in danger and at risk. A little mishandling could result in severe injuries.

Solution: With time, the occurrence of certain accidents, the manufacturers have redesigned the blister packaging with hybrid properties. For example, this is a combination of soft, clear plastic with a cardboard backing. This minimizes the options for using sharp tools and allows easy access. Moreover, the tin snips are suitable for opening blister packs as they offer mechanical strength to cut the pack and get the item.

Accessibility Challenges

Accessibility challenges- Picture Courtesy: Pineville Pharmacy

The blister packaging design is created in a way that specifies a strong barrier so children can't approach it. Therefore, elderly patients or people with chronic diseases are also unable to access them, such as an individual suffering from Parkinson's.

Solution: Today pharmaceutical industry has introduced a modern blister packaging option with push-through properties. In this way, the finger hole cutout ensures easy access for your items. Moreover, research is still going on to manage the issues with safety standards.

6.Do you know the Eco-Friendly and Accessible Alternatives to blister packaging?

Eco-Friendly And Accessible Alternatives Of Blister Packaging- Picture Courtesy: Plastic Free

Blister packaging remains a benchmark across various sectors such as the pharmaceutical industry, electronics industry, toy packaging, and other consumer goods. However, in recent years, there has been a shift to sustainable packaging considering environmental concerns. Some of the eco-friendly and accessible alternatives to blister packaging are mentioned below.

Recyclable & r-PET Blister Packaging

Traditional blister packaging contains a combination of non-recyclable multilayer materials such as PVC and aluminium, which often leads to an increase in waste streams. Therefore, companies and even consumers are shifting towards sustainable alternatives in blister packaging. Instead of using PVC, companies are incorporating mono-material plastics into blister packaging, such as PET or PP, which are more compatible with standard recycling regulations.

Cellulose-based Films

Cellulose-based biofilms are rising as a potential sustainable blister packaging alternative, since they are derived from plants and biodegradable, which means they break down naturally, reducing the environmental impact. Bio-based plastics like PLA, PHA, and cellulose can be manufactured into transparent films, which allows optimal visibility, offering easy access among the elderly and individuals with motor skills limitations.

Thin Aluminum Foil

Aluminium foil is an essential element in blister packaging as it offers excellent barrier protection and flexibility; it is also capable of effective lamination with other materials. However, ever since the growing emphasis on sustainable packaging, thinner aluminium foil for blisters is being incorporated, mitigating excess raw material usage, which eventually leads to reduced carbon footprint.

Paper-based Blister Packaging

Another eco-friendly substitute of plastic blister packaging is recyclable paper-based packaging. This innovation is effective for environmental impact due to its fiber-based framework, preventing plastic waste. The primary material used in this packaging is paper, which is mixed with a tiny amount of plastic or foil, enhancing sustainability while still providing the same qualities as traditional blister packaging.

Accessible Alternatives

Squeeze-open Packaging

Squeeze –open blister packaging consists of a flexible wall cavity that pushes the pill out of the packaging just by a gentle press. The squeeze-open blister packaging feature is most suitable for arthritis patients and individuals who struggle with fine motor challenges.

Smart Blister Packaging

Blister packaging incorporated with smart features such as QR codes and NFC tags offers easy access to product details and instructions, all while enhancing production protection. Just by scanning the code, consumers are able to gain product specifications and safety instructions. This innovative feature attracts consumers and enhances product integrity.

FAQs

Why is blister packaging hard to open?

The primary objective of blister packaging is to create an air-tight and safe packaging of items. For this purpose, strong and durable materials for cavities and backing are utilized. The firm bond of the cavity with the back makes a sealing that is hard to open.

Can I use a knife to open blister packs?

In the case of pharmaceutical products, many people use a knife or sharp tools to open the blister packs, which is not common. This is not even a preferred mode to open the blister packs due to the greater chances of injury. Instead, you can use methods such as push through, peel off, sliding, or peel and push to deblister the pack and take out the medications or other products. For commercial and retail, scissors can be used to open a blister pack.

What if a tablet breaks while opening?

If the tablet breaks while opening the blister pack, then it is not suggested to consume rather, discuss with a pharmacist. This is because some tablets may oxidize or destabilize. Also, broken pills may have altered dosing or have compromised safety. Therefore, it is ideally not preferable to administer them.

Are there tools to help elderly people open blister packs?

Yes, for elderly patients, there’s a pill opener tool, which is a handheld device manually used to press the items by pressing the foil. It is a flexible method that deblister tablets without damaging.

Is blister packaging recyclable?

Yes. Traditional blister packaging is made from a combination of PVC and aluminum with multiple layers, tightly bonded together, making it almost impossible to recycle. However, sustainable blister packaging is relatively easier to recycle since it consists of eco-friendly materials such as PET, PP, and paperboard. These are mono-materials, which makes them quite compatible with standard recycling systems while considering environmental concerns.

Conclusion

In a nutshell, blister packing provides a potent mode of packaging for manufacturers and consumers, too. This is an excellent way to achieve an airtight, tamper-evident, safe, and much more other packaging properties. Whether it is pharmaceuticals or retail goods, you can see the product with transparent and well-protected designs. In this blog, how to open blister packaging; we highlighted potent techniques used for opening blister packaging. Their implementation is effective and safe for withdrawing the packed product. To know about the right packaging, the right machine, and relevant information. Click us! AIPAK specializes to provide with high quality equipment, supplies, and packaging solutions to ensure promising outcomes.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine