Integrating Capsule Filling with Blister Packing: How to Design an Efficient Packaging Line

Do you know how an integrating capsule filling with blister packing can streamline the work process? A large manufacturing company always strives for high-speed operating machines to ensure flexible outcomes with equipment compatibility. How to design an efficient packaging line? This would be tricky for anyone new to the packaging field.

The article on ‘Integrating Capsule Filling with Blister Packing: How to Design an Efficient Packaging Line’ is particularly created to discuss the comprehensive points in understanding basic to advanced parameters. In the end, you will be able to decide the right option to design an efficient packaging line.

1.What is Integrating Capsule Filling with Blister Packing?

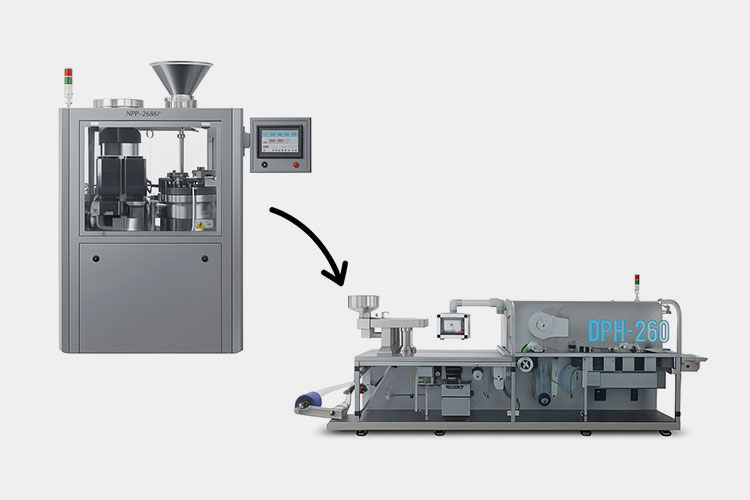

Integrating Capsule Filling with Blister Packing

An integrating capsule filling with blister packing is a solution for seamless workflow related to the filling of capsule material along with its final packaging. This system is composed of a capsule filling machine, capsule polishing, capsule sorting, blister packaging machine. All integrating equipment ensures smooth alignment and dispensing of product without chances of formulation loss with excellent monitoring features.

The solution is always in demand in pharmaceutical and other manufacturing production fields for standard dosing and optimal packaging in a series. The objective for integrating capsule filling with blister packaging is to reduce human intervention in production steps, consequently minimizing contamination. The series of equipment is ideal for high efficiency, which complies with GMP standards.

2.What are the Capsule Filling Process Steps?

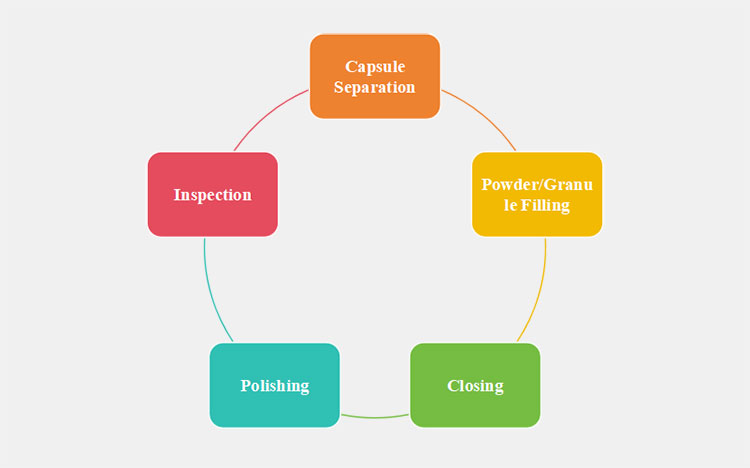

The working steps of the capsule filling process are described below:

Capsule Filling Process

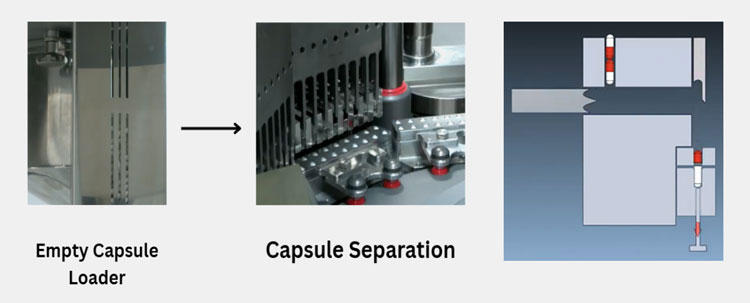

Capsule Separation

Capsule Separation

The capsule filling process begins with the separation of empty gelatin capsule bodies. A set of empty capsules is loaded into the machine’s hopper. The automatic transferring of capsules to the capsule loader occurs to avoid trouble during the filling process.

The capsule is mainly based on two prominent parts, the head and body. The machine is responsible for separating the empty capsule parts automatically. The prime reason behind this step is to prepare the capsules for uniform filling without interruption. Also, they are placing well-oriented and organized way which ensures a smooth filling in a well-organized manner.

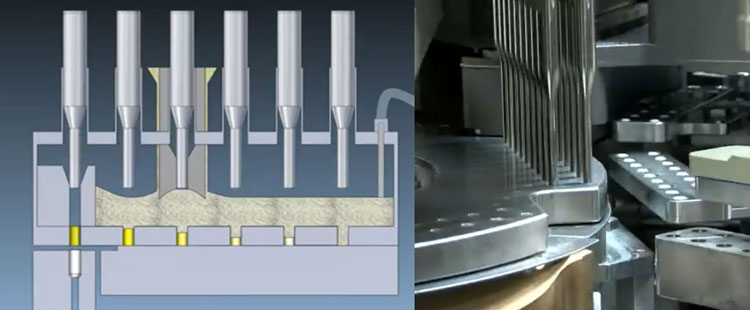

Powder or Granule Filling

Powder or Granule Filling

The automatic capsule filling machine with high-performance properties helps in the precise filling of the formulation. This could be either free-flowing substances, powders, granules, pellets, or mini/micro tablets, etc.

The customized formulation, either in single or combination, can be correctly filled in each capsule with the help of modern technology, including the tamping pin principle for dosing.

The machine works based on ‘no capsule- no filling’ principles. Additionally, vacuum dosing with the help of dosator technology fills material into each capsule, ensuring uniformity with no dose variation. Therefore, ideal for pharma or health-related product standards.

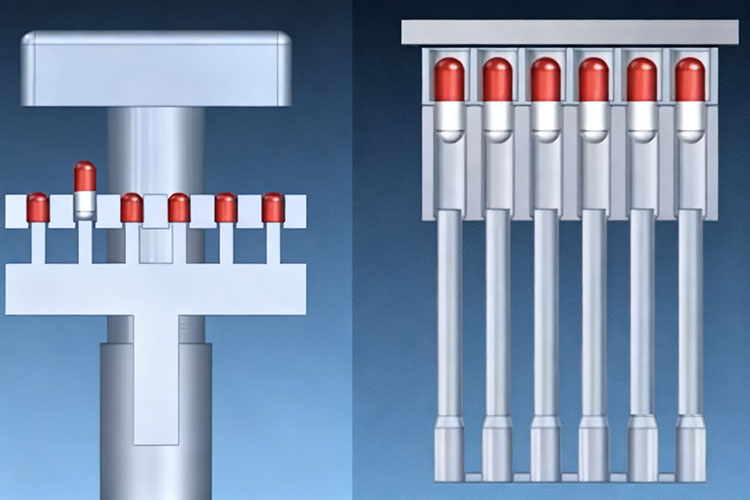

Capsule Closing

Capsule Closing

The capsule filling machine is designed in a way that various activities take place simultaneously. This includes separation, filling, and capsule closing. The closing principle of the capsule ensures an airtight sealing that protects spillage of the materials and their contamination. In this step, the caps of the capsules are firmly adjusted over the filled capsule's body. Therefore, closing is equally important as the above steps to maintain the product’s integrity.

Capsule Polishing

Capsule Polishing

To eliminate the presence of dust particles over the capsule’s surface, the capsule polishing is carried out. The step gives you three results: dust removal, enhanced cleanliness, and a boost in appearance. The process takes place with the help of an air jet and a vacuum. Therefore, after polishing, capsules are ready to pack and are fully presentable for marketing.

Capsule Inspection

Capsule Inspection- Picture Courtesy: CapPlus Technology

The capsule inspection includes analysis of inaccuracies, cracks, weight variations, and incomplete closing or sealing of the capsules. This process takes place soon after the closing of the capsule without interrupting the remaining process. If there are issues in any batch, it will be directly sent to the rejection section. The batches passed are sent for further processing of packaging to ensure uniformity and quality of the filled batch.

Key machines

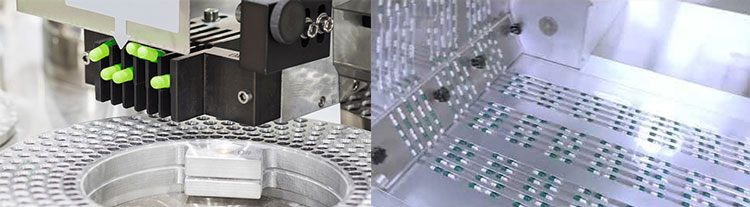

Automatic Capsule Filling Machine

AIPAK Capsule Filling Machine

An automatic capsule filling machine is an advanced machine that delivers filling materials in empty capsules with safety and precision. It supports the filling of material by accompanying steps such as loading, filling, and locking of the capsules. The machine with stable operation is suitable for handling capsule sizes 000 to 5. With modular containments, the machine is available in smart automation, such as semi-automatic and automatic, meeting high production capacities.

Capsule Polisher

Capsule Polisher

The capsule polisher is an effortless machine that ensures easy cleaning and polishing of the capsule surface. Nevertheless, the capsule filling is associated with dust that directly impacts overall appearance. The capsule polishing machine uses a high air jet, and a vacuum sucks the presence of dust particles effectively. The process does not damage the capsule, and soft brushes made up of nylon gently wipe the particles and send the capsules to the next packaging phase.

Capsule Sorter

Capsule Sorter

The capsule sorter is a fundamental machine in the pharma sector. It automatically sorts the capsules, where the right capsules are collected, and defective ones are separated from the batch. Therefore, the capsule sorter only allows first-class capsules to be selected with remarkable precision. The consistent flow of well-oriented and qualified capsules is now sent to the final steps of blister packaging.

3.What are the Blister Packaging Process Steps?

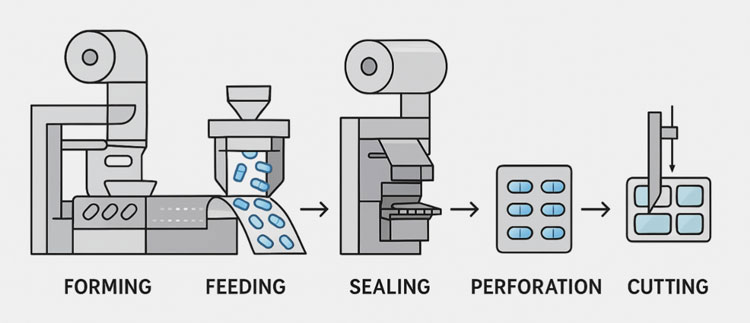

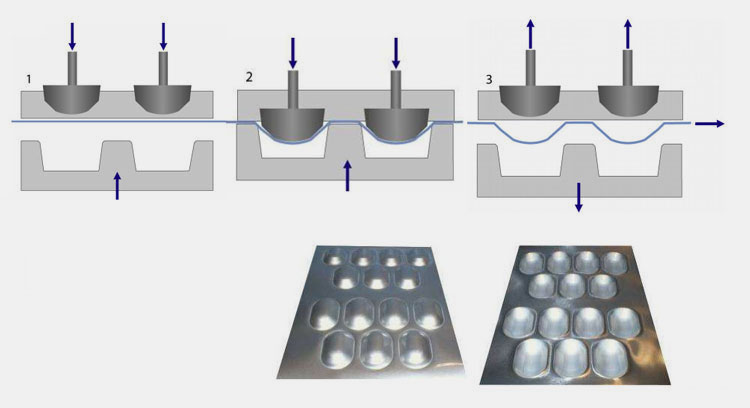

Forming

Forming

The blister packaging process begins with the forming step, where a plastic film is heated until it becomes moldable. Once softened, uniform cavities are created by applying vacuum or air pressure. However, it can also formed using pressure and force which is known as cold forming. These cavities are designed to securely hold products like capsules within the blister pack.

Feeding

Feeding

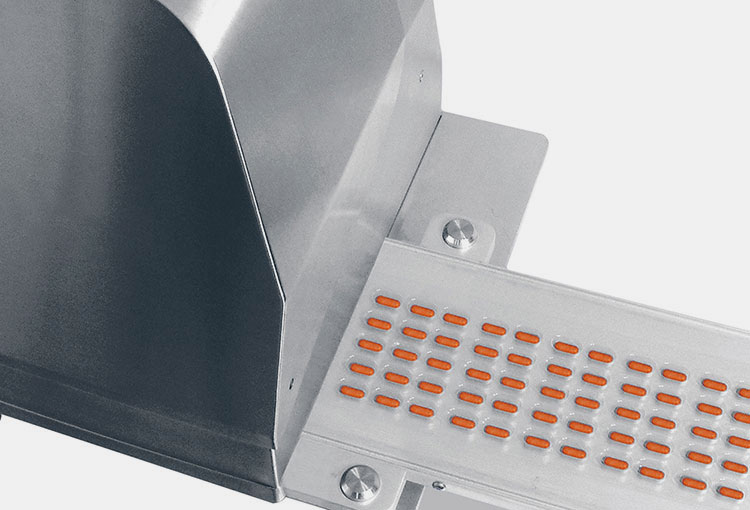

This step deals with the accurate feeding of capsules into the cavities. Generally, this step is performed by using automated machines. Each cavity receives a single capsule with right alignment before moving towards the sealing.

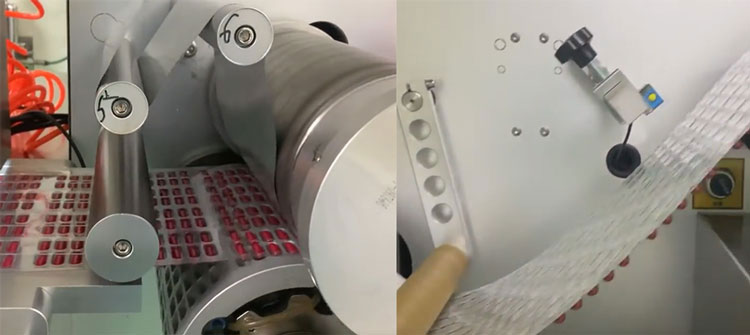

Sealing

Sealing

During sealing, the aluminum foil is applied over the plastic film. This step is carried out by using heat or air pressure, ensuring an airtight pack. Sealing prevents the contact of capsules with moisture and contamination and increases their stability.

Perforation

Perforation

Perforation takes place by creating the lines or holes between the cavities of the blister pack. This step makes it easier to separate blisters without causing any damage to the pack. It also supports the easy handling of individual doses.

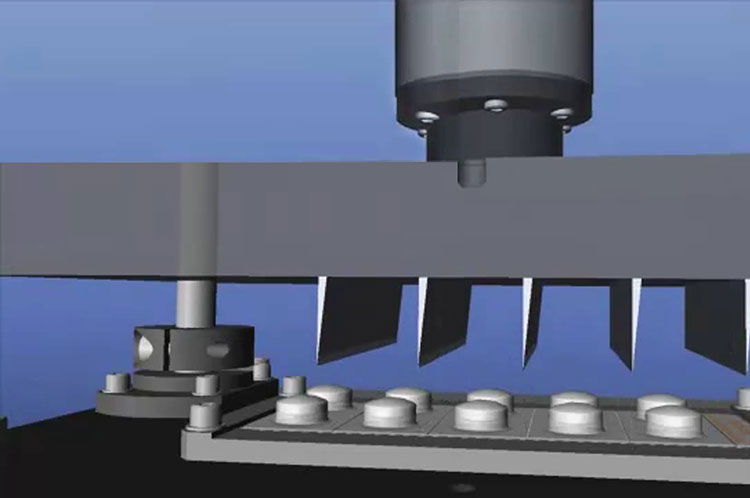

Cutting

Cutting

Cutting involves the separation of finished blister packs from the main sheet. The blister is cut into individual or multi-dosing packs relative to packaging requirements. This is the final step of blister packaging; now blister packs are ready for inspection and cartoning.

Key Machines

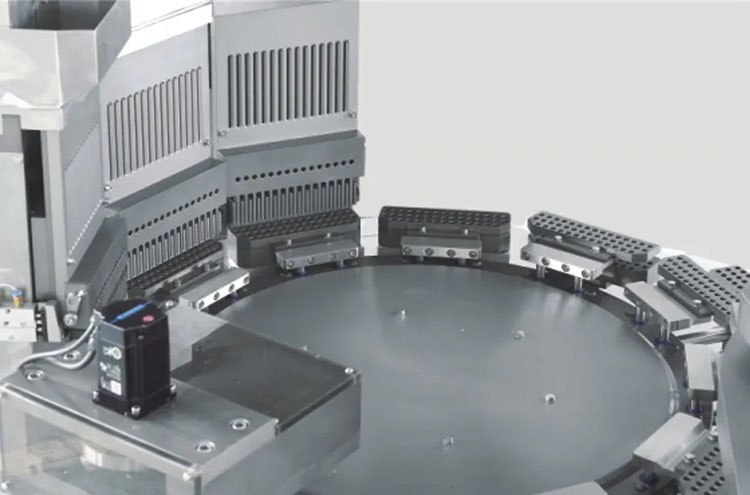

Blister Packaging Machine

AIPAK Blister Packaging Machine

A blister packaging machine is an automatic machine used in the pharmaceutical industry. It is employed to carry out the entire blister packing process with accuracy and uniformity. This equipment creates cavities in a plastic sheet, feeds it with a capsule, seals it with foil, and cuts the packaging as per demand. This machine not only encloses the capsule with accuracy but also ensures the safety and stability of them.

Cartoning Machine

AIPAK Cartoning Machine

A cartoning machine is used to carry out the secondary packaging of blister packs. This machine starts its process by forming rectangular cartons. Afterward, blister packs and leaflets are inserted in the carton either vertically or horizontally. Finally, blister packs are sealed by using tuck-in or adhesive methods. It is also equipped with an automatic feeding system, barcode reading system, and rejection system to ensure precision and consistency in the entire packaging process.

4.Why is Integrate Capsule Filling and Blister Packing required?

An integrated capsule filling and blister packing technology is not a simple machine, but if you have sound knowledge of oral solid dosage formulation, you’re very likely to know the solution. That’s all because this is a famous technology that allows independent processing. The need to integrate capsule filling and blister packing is described below:

Improved Dosing with Safeguarding Product

Blister Packing mproved dosing and safeguarding- Picture Courtesy: APTAR

For a proper therapeutic response, the dose of medication should be precise and accurate. The capsule filling with blister packing line is the solution that provides improved dosing with a high degree of protection. Integration helps in filling with proper monitoring and measurement. Whereas the blister packing allows individual sealing of capsules in each cavity with physical barrier properties, maintaining the quality of medication.

Increased Production Efficiency & Extended shelf life

Capsule with Blister Packing line, High Production and Greater Shelf Life

With the help of automation of capsule filling with blister packaging, it fundamentally presents a faster workflow. The improved efficiency is not possible with conventional methods. Therefore, this system is ideal to preserve production goals with high protection. The packaging stability is promising as it gives tamper tamper-evident seal, which is likely to indicate alteration if it occurs. Moreover, blister packaging ensures the extended shelf life of medication, preserving the overall integrity of the products.

Space and Cost Optimization

Space and Cost Optimization

The compact solution of capsule filling with blister packing offers less floor space for installation of the setup. The integrated system is also cost-friendly and requires less investment. Moreover, when it comes to considering energy consumption and looking after the unit, the overall result is optimized in terms of budget. That’s why it is known as the essential factor for manufacturing companies belonging to large-scale production.

5.What are Key Design Considerations for an Integrated Line?

Key Design Considerations for An Integrated Line

To design an integrated line, here you get an insight into the major factors that ensure consistency during the whole operation.

Continuous Product Flow

A manufacturer always strives for efficient operation. Therefore, an integrated line must be designed in a way that supports the smooth movement of the product between machines. There must be no delay or hindrance that could result in bottlenecks. Continuous product flow enhances the efficiency of the process and also maintains the uniform production speed.

Equipment Compatibility

For ideal operation, the machine’s compatibility cannot be ignored. The integrated line maintains the compatibility between machines in terms of speed, capacity, and operation. It boosts the performance of the machine and results in uniform output.

Maintenance and Accessibility

The layout of the integrated line must allow the proper cleaning and repairing of machines. It should provide enough area to the operator to get access to crucial parts of the equipment. The convenience in maintenance and accessibility helps to reduce the downtime and ensures a uniform quality product.

Regulatory Compliance

Adherence to regulatory compliance helps the production process meet the industry standards like GMP, ISO, and FDA requirements. All the machines, materials, and procedures used in the integrated line must follow the approved methods and be properly documented. It enhances the reliability of the product and allows it to enter the market with legal guidelines.

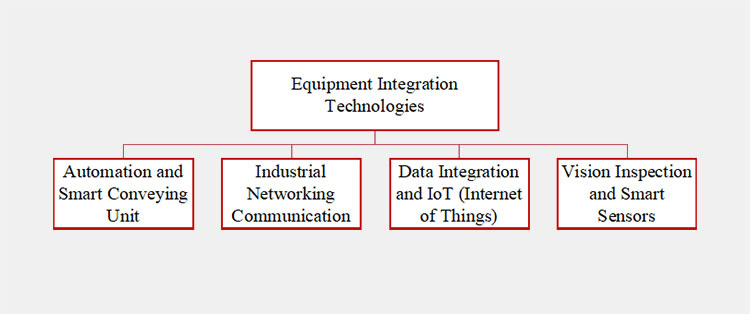

6.What are Equipment Integration Technologies?

Equipment integration technologies are a crucial part of any integrated line. With the help of these technologies, machines are able to work together easily and efficiently. They also allow efficient interaction and real-time data transfer among connected equipment. Let’s have a look at these technologies!

Equipment Integration Technologies

Automation and Smart Conveying Unit

Automation And Smart Conveying Unit – Picture Courtesy: OPTEL

Today’s technologies are all about automation. In an integrated line, PLC, HMI, and Supervisory Control and Data Acquisition or SCADA serve as the main control unit. It coordinates the timing, sequence, and communication between capsule filling with blister packing. The smart conveying system ensures automatic transferring of the capsule from the filling, polishing to the blister packing machine freely. This advancement will save downtime and product damage with efficient automation.

Industrial Networking Communication

Industrial Networking Through Ethernet

Industrial networking is a crucial part of automation and control systems. It enables the connection between all equipment, sensors, and controllers. The following keys are in a production line with the help of standardized communication protocols like Ethernet/IP, Modbus, PROFINET, etc. This interconnection allows synchronized control and efficient data flow between the capsule filling and blister packaging machine.

Data Integration and IoT (Internet of Things)

Data Integration and IoT-picture courtesy: IMA Group

By using sensors and a cloud system, data integration and IoT gather machine data instantly. This helps to predict the errors and enhance the overall performance of the equipment. In this way, the system simultaneously removes the capsules or blister packs with faults or defects.

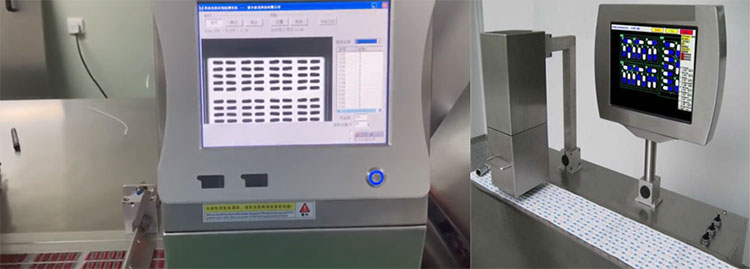

Vision Inspection and Smart Sensors

Vision Inspection and Smart Sensors

Nowadays, the capsule filling with blister packing integrating line is designed with high and efficient vision cameras with auto-detectors. These features help in scrutinizing the overall process. It is included with orientation, accuracy of batch, speed, and other parameters. The high-intelligence system allows high productivity with retained consistency.

7.Case Example: Efficient Capsule-to-Blister Line Design

The basic efficient capsule-to-blister line design is mostly intended in manufacturing companies to get a single synchronized system. The purpose of the case example is to examine how carefully a system is prepared to provide high productivity.

Steady Process

Capsule Filling with Blister Packing Steady Process

The capsule filling is intended to give dispensing, polishing, and inspection, which is connected to the blister line. The connection is done in an enclosed conveyor system to limit the involvement of physical factors. While the blister line packs them once the capsules are introduced. The purpose of this design is to fill, transfer, and pack in a steady process that saves manual intervention and minimizes risks of contamination.

Modern and Hygienic Layout

AIPAK Capsule Filling Machine Modern Layout

The innovative layout of both machines aims to have hygienic processing. The single unit is capable of adjusting in the same room/lab to limit the footprint or external hazards. As the modern machinery with a sturdy body of stainless-steel framing maintains easy cleaning and less contact with medication. Consequently, the setup layout and material combined will offer clean and hygienic working, which supports safe medication.

Operational Efficiency and Changeover

Operational Efficiency and Changeover- Picture Courtesy: SEPHA

The fully automated integrated line with visual detection and tooling enables rapid operation. The fast changeover lets the operator switch molds and materials in less time with low downtime. Therefore, it can improve production with a broad production portfolio.

Conclusion

We hope the article on ‘Integrating Capsule Filling with Blister Packing: How to Design an Efficient Packaging Line ‘would be a fruitful effort. In the pharmaceutical manufacturing world, the integration of capsule filling with blister packing has revolutionized modern packaging. This approach provides smooth and seamless production with high productivity. Thus, this strategy may require a slightly higher investment than usual packaging lines, but it will represent a high approach for profitability and efficiency by eliminating manual handling and errors. Interested in exploring machines and services? Discover more about integrating capsule filling with blister packing simply by contacting AIPAK’s experts.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine