Blister Thermoforming Machine: The Complete Buying Guide In 2025

All those blister packs you see with crisp cavity and perfectly sealed foils, just don’t happened randomly. Their lies a machine doing all the very serious and complicated work of melting, forming, sealing and repeating with zero error. This machine is blister thermoforming machine.

These machines are made for heavy duty to keep up with the fast evolving world of consumer packaging where speed and precision are undeniable. Blister thermoforming machines are essential in the production lines to meet up the high speed demands of manufacturing.

Similarly, understanding the technicalities of the blister thermoforming machines is also equally important for optimization of the product integrity and efficiency. The following FAQ guide will help you explore the most common and somewhat over looked questions about the blister thermoforming machine. So let’s begin!

1.What is a blister thermoforming machine?

Blisters packs in various shapes and sizes

A blister thermoforming machine is specialized equipment used for the manufacturing of blistering packs, which are customized transparent containers with cavities or pockets for holding the product. It is named thermoforming because it specifically utilizes heat to mold the plastic sheets into required shape cavity.

The blister thermoforming machines make the use of heat along with pressure to transform the flat plastic sheets into specialized cavities or pockets, followed by the sealing process using materials like foil or card board. These blister packs can be used to hold medicines, toys and many other things.

2.What are the benefits of blister thermoforming machines?

Pharmaceutical blister packs-picture courtesy: blister packaging

Blister thermoforming machines are very useful in different manufacturing industries, including pharmaceutical, electronics consumer goods and many others. Some of the common things that make this machine very popular are given below:

Automation friendly:

Automation is human friendly-picture courtesy: Lars schatilow

- These blister thermoforming machines are easily integrated with the high speed production lines.

- They minimize the work load by easy and efficient integration with other sealing, packaging, filling and cutting mechanism going on.

- They are advanced and provide human friendly automation.

Versatile:

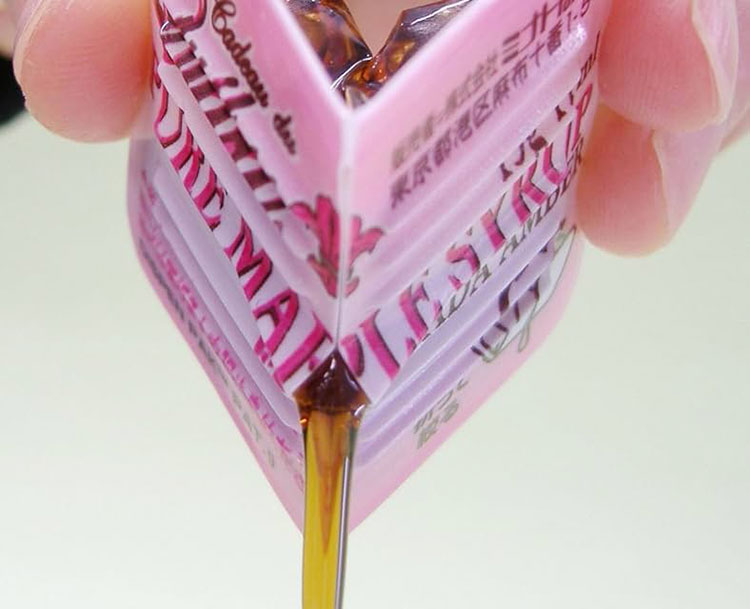

A thermoformed blister for olive oil-picture courtesy: mini oliva

- The blister thermoforming machines are so versatile in nature that they can offer blister packs in my unique forms which make the product tempting for the consumer.

- This packaging is suitable for pills, tablets, gels, injection solutions, food, electronics, stationary items and the list goes on, making them versatile and essential in industrial packaging.

- These machines are compatible with various materials, including PVC, PET, and PP etc.

Product protection:

Blister packaging of macrons to protect them from moisture

- The blister thermoforming machines make air sealed packaging of the product which protects the product from humidity, dust or any other kind of contamination.

- This helps in the shelf life maintenance of the product as well.

- This blister thermoformed packaging is firm, rigid and form fitting, which prevents the fragile or soft products from any kind of physical damage.

Cost effective:

A single tablet blister pack-picture courtesy: yellow images

- The thermoforming blistering machines make use of the thin, light weight plastic materials which make it cost effective due to less shipping weight and cost.

- These machines are therefore best suited for large scale manufacturing and ensuring the increase in economic value for the company.

Temper evident packaging:

Temper evident sealing of solutions-picture courtesy: manufacturer.vn

- The thermoforming blistering machines pack the blisters ensuring their seal is temper evident.

- The tempering is very easily visible on this packaging which maintains the integrity of the product.

Customized packaging:

A customized thermoformed blister

- The blister thermoforming machines uses heat to mold the plastic into any prescribes shape.

- This molding is very précised to fit according to the shape of the product, which uplift its appearance and make the product secure.

- This makes it ideal for unique shaped product as well as liquids or gels.

Transparency and brand visibility:

Ready to eat food in transparent blister packs-picture courtesy: webstaurant

- The blister thermoforming machines allow the addition of logos, labels or any kind of graphics on the blister packs which help with the branding of product.

- The blister packs made are usually transparent which ensure the direct display of the product to the consumer, which promote the trust with the consumer.

Child resistant packaging:

Picture courtesy: Tian Tuan pharmaceutical

The blisters formed by blister thermoforming machines are tempered resistant as well as they are child proof.

They are sealed using heat and vacuum making the seal resistant enough for toddlers, preventing any potential harm from the product.

3.What are the applications of blister thermoforming machine?

The versatile nature of blister thermoforming machine makes them suitable for various industrial manufacturing and packaging. Some very common applications include:

| Application | Example |

| Pharmaceutical and Healthcare

The medical blister trays either for medicines or medical devices provide sterile barrier packaging. They are cost effective, still providing protection, strength and defined packaging make them best option for the health care packaging. This packaging is compatible with all tablets, capsules, vials, syringes, ampoules and medical devices. |

Thermoformed blister tray for syringes-picture courtesy: T.O plastics |

| Clinical trials

The unit dose packaging of clinical trial doses has been made easy by the use blister thermoforming machines. It provides individual packaging to each tablet or capsules. Blister packs are made with printed dates and days schedule making it easier for the patient. For limited batched, blister thermoforming machines can be tuned for low to medium runs. |

Tablets for clinical trials in compartmentalized blister-picture courtesy: desang.net |

| Consumer goods

The personal care items like razors, toothbrush, grooming tools etc. are often sold in blister packaging. The clear view of the product through this packaging make it user friendly. This packaging is theft proof and widely used in retail setups. |

Regular consumer goods with blister packaging |

| Food packaging

The small snacks and other confectionary are best suited in blister packaging. These blister thermoforming machines can customize the blister packs in single serving or multiple cavity packs for food or other confectionary. The dietary supplements and nutraceuticals also use blister packaging for their products. |

Frozen smoothie flavors in blister packs-picture courtesy: evive nutrition |

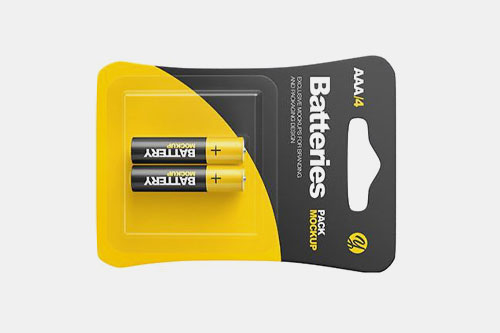

| Electronics and accessories

The electronic devices and other hardware accessories require thermoformed blister packaging. This packaging provides neat presentation of the product and protection of wires from tangling or damage. It is best for even small gadgets like memory cards, remote control and batteries. |

A blister pack of batteries-picture courtesy: yellow images |

| Cosmetics and personal care

The makeup products and skin care items packed in thermoformed blisters ensure the hygiene and visibility of the brand. The skin care and cosmetics line requires the packaging to be attractive and tempting for the consumer to buy. These products are usually delicate and blister packs provide them security and help keep them organized. |

Skin care products adjusted in blister tray-picture courtesy: some by mi |

4.What are the types of blisters formed in blister thermoforming machine?

The blisters produced through blister thermoforming machines are differentiated into following categories, depending upon their use, structure and method of sealing:

| Structure | Type of blister | Use |

| The blister cavity formed is placed on a coated cardboard and sealed on only face side over the cardboard base.

They are less in cost and offer good visibility. |

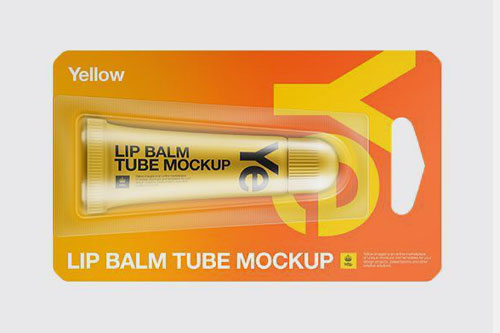

Face seal blister

Lip balm in face seal blister-picture courtesy: yellow images |

They are used in retails supplies mostly, like batteries, glue sticks or tooth brushes. |

| The blister covers whole of the cardboard base.

It is sealed by heat around the edges of the cardboard. Their seal is comparatively stronger. |

Full face seal blister

Calculator packed in full face seal blister |

They are mostly used for the heavier or premium products, like electronics or other high end products. |

| The blister cavity is not sealed directly; in fact it is trapped between two cardboards, at front and backside of the blister cavity.

This blister packing is sustainable and highly temper evident. |

Trapped blister

Samples for trapped blister-picture courtesy: agreen packaging |

Due to sustainable nature, they are preferred in ecofriendly packaging.

The high end branding requires such packaging. |

| They usually don’t have any base cardboard.

They are hinged plastic shell that folds over itself to give a close packaging. They can be further sealed. It is reclosable and product is visible from both sides. |

Clamshell blister

Macrons in a clamshell blister-picture courtesy: transparent plastic clear |

They are used for toys, electronics and hardware tools. |

| As the name suggest, the blister cavity slides into an already folded card and fits into it.

It can undergo further sealing if required. They are easily recyclable. |

Slide blister

A sliding blister-picture courtesy: green packaging |

They are used in confectioneries or other edibles packaging and also used for tools and light weight packaging. |

| This is most commonly known form of blister.

They are blisters with multiple cavities, sealed with an aluminum or plastic foil at the back. They are sterile and excellent protection to the product. |

Pharmaceutical blister

A tablet blister with aluminum foil at back side |

They are used for tablets or capsules.

Nutraceuticals, pharmaceuticals and clinical trials need this type of blister packaging the most. |

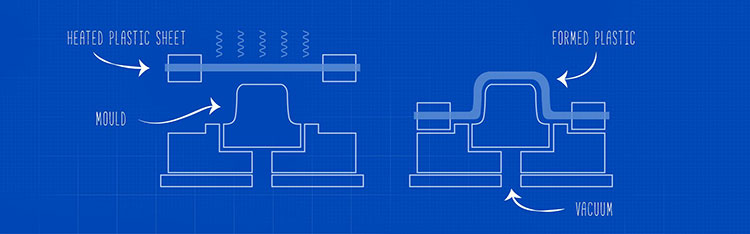

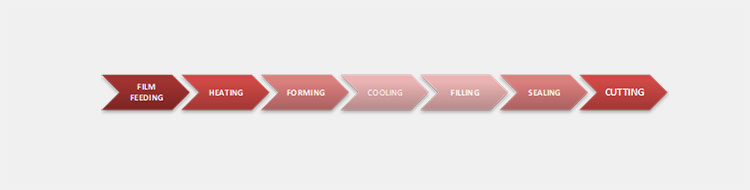

5.What is the principal and working of blister thermoforming machine?

Behind the blisters: how machine actually works:

Visual representation of molding a plastic sheet into blister-picture courtesy: munot plastics

The main equipment in blister thermoforming machine is the use of ‘heat’. This machine use high temperature to heat a firm plastic film into pliable form. Then this pliable sheet is molded into required size and shaped cavity or multiple cavities, which are called blisters. This is done by the use of air pressure or vacuum along with the heating.

This is further followed by filling and sealing procedures. Let’s go through the detailed procedure to understand it completely:

Magic of making a blister-step by step

Film feeding:

PVC film roll added in the machine-picture courtesy: jornen machinery

- A roll of plastic film, which is thermoformable, is fed into the machine.

- The film is fed into the machine through rollers attached to machine.

- The film is usually PVC, PET OR PVDC coated.

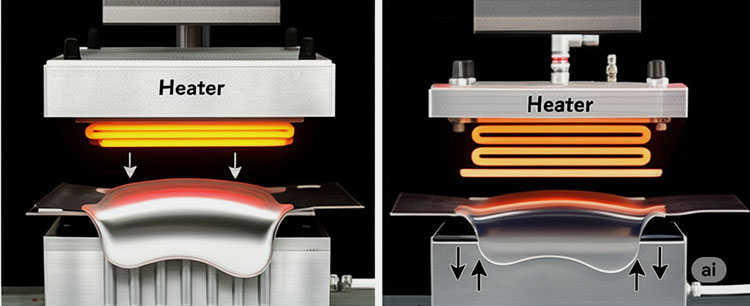

Heating:

Heating of sheet with the vacuum air pressure from below

- The film is passed through a heating station where there are upper and lower heating plates.

- The temperature is so high for the film that it becomes squishy and pliable.

- The pliable sheet can be molded using pressure into any shape.

Forming:

The molded blisters coming out of the heating and pressure unit-picture courtesy: amac technology

- At the forming unit, the heated film is pressed through pressure units into pre designed blister molds.

- This molding can be done through vacuum suction or air pressure or by using both.

- This procedure creates the required shape of blister for the product to be packed.

- These newly formed blisters are given time to cool off, become firm and retain their shape.

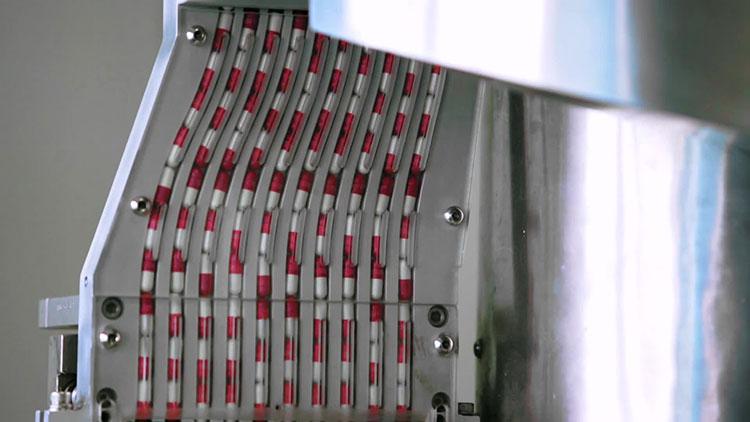

Filling:

Capsule filling in the blisters-picture courtesy: jornen machinery

- The machine is provided with special feeders that automatically fill the blisters with the product.

- The product can be capsules, tablets, electronics or any other accessories.

- This filling of the product is controlled by precise feeding mechanism.

Sealing:

Foil sealing of a filled blister-picture courtesy: custom packaging

- The sealing material differs according to the type of blister pack.

- In case of pharmaceutics blisters, usually aluminum foil is used for sealing.

- The sealing is done by applying heat and pressure at the sealing sites.

- The sealing is done maintaining the temper evidence and protection of the product.

Cutting:

Blisters formed and cut coming out of machine-picture courtesy: amac technologies

- There are special die cuts that are made to cut the large blister webs into desired shape and size.

- They could be cut into blister packs or strips.

- The finished blister packs, protecting the product within jumps out of the machine.

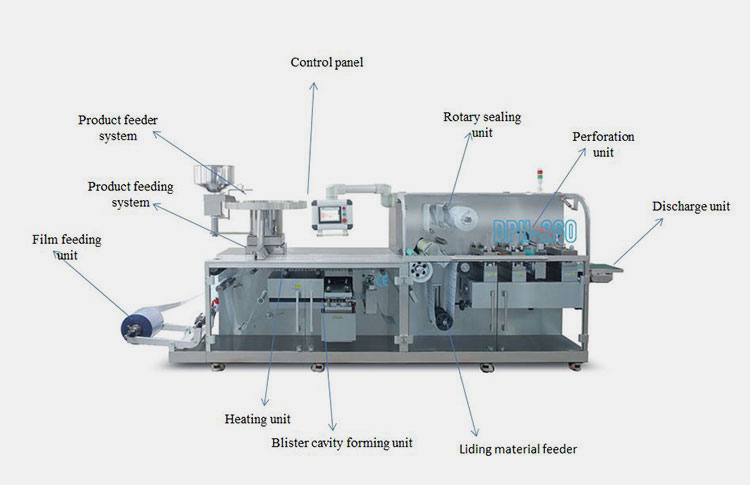

6.What are the main parts of blister thermoforming machine?

Labeled parts of AIPAK blister thermoforming machine

The following table describes the main parts of blister thermoforming machine:

| Part of the machine | Function performed |

| Human machine interface | It allows the operators to monitor and control the machine, provide all the protocols and act as a mediator between machine and human command.

It provides user friendly display. |

| Guiding Rails | The smooth and precise movement of film and components throughout the machine is ensured by these guiding rails |

| Motor / Drive Unit | The power utilized by the machine to carry out its function and movement of mechanical parts is supplied through a motor drive unit, which can be a servo or AC motor. |

| Film feeding unit | It unwinds and feed the thermoformable film to the machine.

It can provide with sensors or tension control system. |

| Heating Station | The heat is provided to the film from this unit by infrared heaters or direct heating.

The film is heated until it softens and pliable. |

| Forming Station | It forms cavities also called blisters in the heated film.

The shape forming can be done by vacuum or pressure forming |

| Cooling Station | The blisters are made firm and solid by the cooling process.

This helps the blisters to attain their form. |

| Product Feeding System | When the blisters are formed, this system accurately fills the blisters with the specified product.

It is provided with brush feeders or vibratory feeders. It also has inspection system for controlling any faulty blister. |

| Lidding Material Feeder | Just like the film feeding unit, the aluminum foil or other laminate sheet is fed from here. |

| Sealing Station | The filled blisters are sealed by the use of pressure and heat. |

| Perforation & Embossing | The perforation and embossing unit add perforations for the easy tearing of blister.

Embossing of logos is done to make the identification easy. |

| Cutting/Punching Station | The blisters when reach the punching station are cut into required size and shape.

The cutting units have dies according to the required shape of the blister. |

| Discharge Unit | The final filled, sealed and cut blister unit is discharged through here.

The discharge unit can send the final blister to further packaging phase. |

| Lubricating System | Last but not the lease, lubrication system makes sure the smooth working of the whole blister thermoforming machine.

It automatically provides lubrication to the moving parts of the machine. |

7.What is the role of temperature in blister thermoforming machine?

Temperature controlling device-picture courtesy: multispan

Temperature is essential component of the blister thermoforming machine. As the name suggests, “thermoforming is the process of heating plastic sheet until it’s pliable”. When the sheet is at pliable state, only then it can be molded into 3D shapes, by using combination of vacuum and pressure.

Therefore, temperature plays an important role in the formability, strength and seal integrity of the blister formed. Here are a few examples, how temperature effects:

Softening of the plastic film:

The optimum temperature is required for softening of the plastic film, where it is soft and pliable. The sheet shouldn’t be too brittle or too melted. A precise temperature is essential for balance in the softening of plastic film.

Accurate blister formation:

When the temperature applied is controlled and consistent across the film, each blister cavity is formed with similar consistency.

Too cold temperature = poor forming and cracking of the blister.

Too hot temperature = bubbles or sagging of the blister.

Enhance seal efficiency:

The sealing procedure requires heating to activate the adhesive layers of both the formed film and the lidding material, which is usually aluminum foil. The right sealing temperature lies from 180–220°C.

8.What are the different types of blister thermoforming machines?

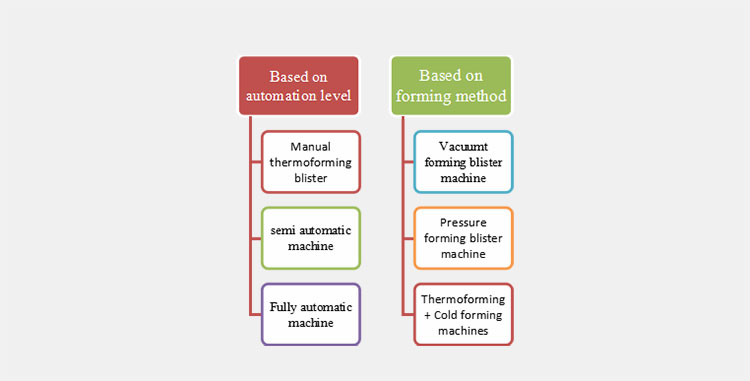

The blister thermoforming machines can be classified on the following bases:

The following table explains the main classes of blister thermoforming machines:

| Machine type | Example | Key features |

| Based on level of automation | ||

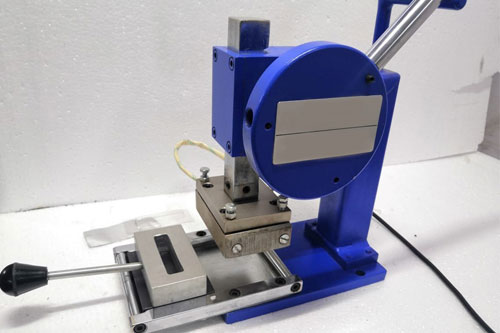

| Manual blister thermoforming machine

Use: They have a very low output, so they are used for trial batches or laboratory samples. They are compact so can be used in very little space environment. |

A manual table top blister forming machine |

It is a compact and simplest form of blister forming machine.

It operated by manually placing a plastic film on the forming area. The heating of the film is done through basic electric plate or a manual heater. The mold plate is manually pressed over the film to form the cavity, no use of pressure or vacuum. The sealing is done by manually pressing the heated sealing plate to bind the foil and plastic. |

| Semi-automatic machine

Use: It is used in research labs and clinical trials purposes. Its low volume commercial packaging makes it suitable for medium scale productions. |

Semi-automatic blister thermoforming machine-picture courtesy: chanshis |

It combines both manual handling and automatic processing for a cost effective production.

The loading of the plastic film and product into the machine is a manual process. The forming and sealing are done automatically. It is cost effective and easy to adjust and learn |

| Fully automatic machine

Use: They are best suited for large scale manufacturing unit. The precise and effective sealing of blisters make them best option for high speed production lines |

AIPAK fully automatic blister thermoforming machine |

It is a high performance industrial grade system.

All the processes of feeding, filling, sealing and cutting are performed automatically with very little or no human intervention. It has PLC based automation. It can produce hundreds of blister per minute. It is provided with sensors and alarms increase the efficiency. The automatic rejection of faulted item ensures precision and speed. |

| Based on forming method | ||

| Vacuum forming blister

Use: They are better suited for simpler blisters. The blister with less depth and simple designs, like in consumer packaging. |

Vacuum blister forming machine-picture courtesy: ritmin industry |

In vacuum forming machines the plastic film after heating up is pulled on to the mold cavity using vacuum suction.

Vacuum pump is used to remove the air under the film. The vacuum suction is applied beneath the plastic film to pull the film down. This machine has a low cost and easy to operate. |

| Pressure forming blister

Use: The complex designs with deep and sharp cavities blisters are formed in it. It allows pvc-alu blistering. They are used in complex tablets packs. |

AIPAK automatic pressure blister forming machine |

The plastic film after heating up is pushed down on to the mold through air pressure from above.

The air pressure from above exerts greater force on the film than the vacuum alone can offer. The air pressure applied is quite high, 0.5-1.5 bar. This blast of air pressure from above push the film deeply and precisely into mold. This machine is comparatively costly but better suited in high speed production lines. |

| Thermoforming + Cold forming machines

Use: They are best choice for industries with diverse range of products. They are ideal for high scale pharmaceutical as they require a higher barrier protection. |

AIPAK automatic alu-PVC blister forming machine |

These machines are also called the hybrid machines.

They are intelligent and designed to run both thermoformable and cold forming systems. It means they can produce plastic based and aluminum based blister packs at the same time. The plastic film is heated while the aluminum foil packing is done through cold forming. The cold forming of aluminum is done through mechanical pressure using die and punch. |

9.What are the materials used in the blister thermoforming machine?

The materials that are mainly used in making of blisters in the blister thermoforming machines are:

PVC (polyvinyl chloride):

PVC roll

- It is the most commonly known and used type of film in the blister forming.

- It has a lesser price, flexible, transparent and very easy to mold into any shape.

PVDC (polyvinyledene chloride) coated PVC:

PVC-PVDC made blister-picture courtesy: cloud film

- It offers better strength to the blister formed. It is thicker than the PVC alone.

- It is used when better or improved barrier is required.

- It is used for moisture and oxygen sensitive products.

PP (polypropylene):

Propylene blister pack

- It is not transparent usually.

- It can provide a better heat and resistance and good barrier from the surroundings.

- It is used for special applications which require more secure packaging.

Aluminum foil:

Aluminum foil blister packs-picture courtesy: CHAL aluminum

- It is used as the lidding material in blisters packaging.

- It provides better barrier from heat, light and moisture.

- It is most commonly used in pharmaceutical blisters lidding and sealing.

Paper foil laminate:

Paper aluminum foil roll

- It is usually preferred in non-pharmaceutical products.

- It is flexible and printable but it offers low barrier.

10.What are the common trouble shooting issues in a blister thermoforming machine?

Blister tray for different sized products-picture courtesy: some by mi

A few very common trouble shooting issues are describes below along with their causes:

Incomplete blister formation:

| Causes | Solutions |

| The incomplete blister could result from the improper heating of the plastic film. | Always calibrate the temperature of heating plate before starting the procedure. |

| Low pressure during the pressing can also cause it. | It is advised to inspect the vacuum and pressure pump. |

| When the mold cavities are damages or clogged due to any reason. | Efficient cleaning of the molds is required every time the procedure is done. Replace when required. |

| If you have chosen a wrong grade film which is too thick to be molded. | Make sure you are using the right kind of plastic film, with required thickness. |

Sealing defects:

| Causes | Solutions |

| Sealing temperature is not correct | Temperature has key importance in thermoforming blisters, so always adjust the heat settings before every operation. |

| Sealing plate is under uneven pressure | Make sure the alignment of the parts is correct and look for the worn out parts. |

| There are foreign particles on the sealing plate | The blister cavity formed and the lidding foils both need optimum cleaning to avoid any contamination to ensure proper sealing. |

Misaligned blister and foil:

| Causes | Solutions |

| The film and foil are on off tracks path | The re-adjustment of guided rails is required. |

| The feeding of the film roll is improper or the feeding speed is improper. | The feeding of film and foil need to be synchronized through the HMI or control panel. |

| The driver rollers have worn out. | The rollers are needed to be calibrated regularly and replace the worn out rollers timely. |

Product not filled into cavities:

| Causes | Solutions |

| Broken or malfunctioning feeder | The cleaning of feeders is required. |

| Irregular shape and size of the product. | Make sure the dimensions of the product and blister cavity formed are in accordance. |

Touch screen issues:

| Causes | Solutions |

| Software glitch | A very basic thing is to restart the system or it may need a HMI reset. |

| Unresponsive screen | It is recommended to check for the optimum power supply, touch screen calibration or may need to replace the touch screen |

Alarms triggers causing the machine to stop:

| Causes | Solutions |

| False alarm | The inspection of photoelectric and limit sensors is required. |

| Emergency stop pressed | Look out for the safety doors and E-stop status of the machine. |

| Over heating or overloading | The motor temperature always needs to be inspected to avoid overheating. |

11.What are the safety features in a GMP compliant blister thermoforming machine?

Here are a few main safety features that are required in a GMP compliant blister thermoforming machine:

- There should be emergency stop buttons that can halt the operation instantly in case of any emergency.

- The machine should have safety interlock doors, which can prevent the machines from operating if any door or cover is opened.

- These advanced machines have user access control system, which prevent any unauthorized person from changing the settings of the machine.

- These machines are provided with temperature and pressure alarms which immediately signal the operator of any unsafe temperature rising or sealing conditions.

- The GMP requires the machines construction to be hygienic stainless steel material which ensure easy cleaning, non-reactant and resistant to contamination.

- These machines are made with CIP (clean in place) friendly design, which allow the internal deep cleaning of the machine parts without the need of disassembling it. GMP requires round surfaces for easy cleaning.

Conclusion:

Blister thermoforming machines are not just providing us with regular packaging but they make sure to provide highly précised blister packaging. The use of heat, pressure and accurate timing transform simple film of plastic into professional grade blister packs of various size and shapes with so much versatility. These machines bring together the magic of engineering safety and speed in one cycle. Whether you are working in a lab or large scale high speed production lines, the speed, accuracy and compliance to the required standards make these machines irreplaceable. Blister thermoforming machines are leading the way through safe, sleek and precise drug delivery. For more information about the blister thermoforming machine visit our AIPAK website and team for further assistance.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine