Ribbon Blender:The Ultimate Buying Guide in 2024

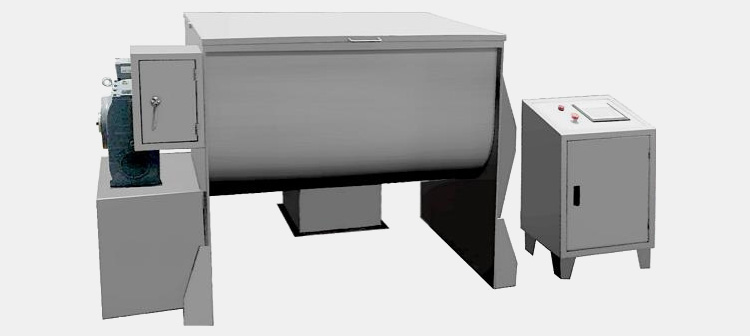

Ribbon blender is designed for dry materials mixing, meantime liquid streams can be added.It is increasingly utilized in the industry as it is an economically viable option for mixing substances and saves a lot of valuable blending time.

Ribbon blender can mix many kinds material especially for the powder and granular which with stick or cohesion character, or add a little liquid and paste material into powder and granular material. Moreover, we will discuss how to effectively handle ribbon blenders for efficient mixing.

Now,let's drive to the subject of this topic directly.

1.What do you mean by ribbon blender?

A ribbon blender has got its name from a thin ribbon-designed metal mixer that controls blending functions. Ribbon blenders are exclusively meant for easy mixing and disperse the ingredients that are pre-processed. For instance, dried granules, pre-sieved ingredients, etc.

Ribbon blenders have five high-performance trough designs for mixing powders, pastes, and chemicals into a homogenous product. They are commonly available from 100 liters capacity to 500 liters.

Ribbon blender design allows the powder processing near outside the container that moves in one way whereas in the center it moves to the opposite direction in order to achieve a fast and homogeneous mixture.

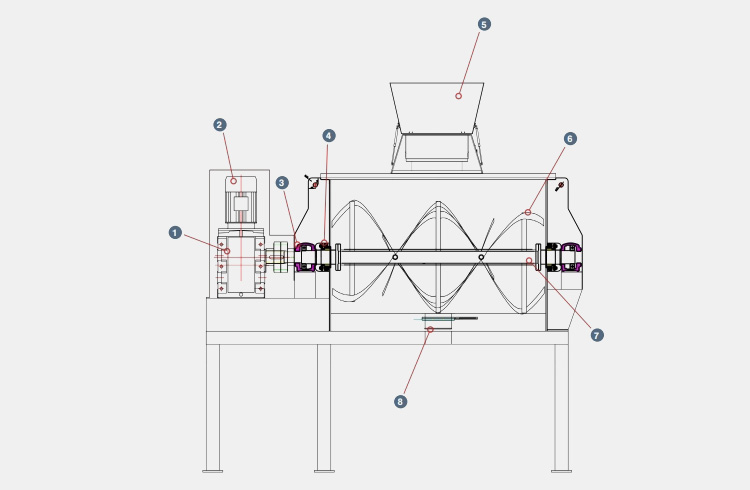

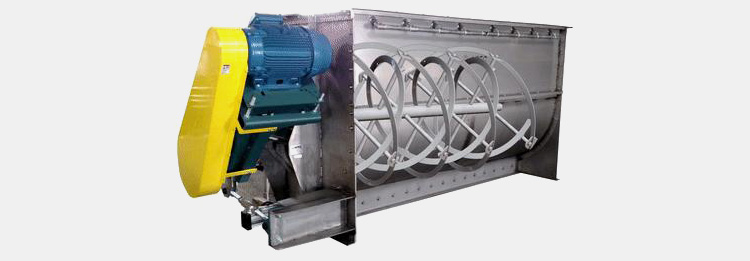

Ribbon Blender

There are several manufacturers available who offer different types of ribbon blenders used in different industrial sectors such as vertical ribbon mixers or horizontal ribbon blenders.

Ribbon blender capacity is ideal to deal with a large concentration of material needed in various industries.

2.Can you explain the ribbon blender parts?

The following instrumentation of ribbon blender is mentioned below:

Components of Ribbon Blender

1.Gearbox

A ribbon blender is comprised of a gearbox that drives the system.

2.Motor

A ribbon blender is powered by a motor which is generally 10 HP to 15HP (horsepower) for 1000kg of mass to be a blend.

3.Bearings

Bearing supports the flexible movement of the blending assembly.

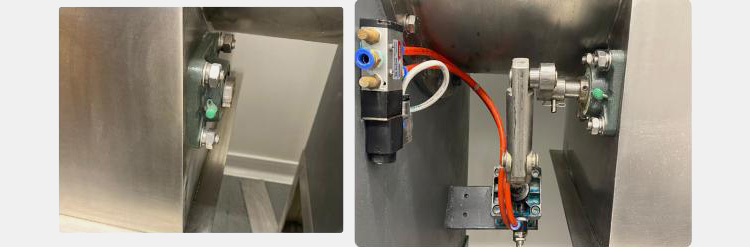

4.Seal

The seal is a part where the shaft exits the container. Sealing arrangements ensure that material does not move outside the container. They act like guards that are attached at either end of the ‘rotating shaft’.

They not only protect the movement of mixing material from escaping but also prevent foreign particles to enter inside the mixing tank.

5.Powder Inlet

Material is introduced into the ribbon blender via nozzle/powder inlet or feeding hopper. It is mounted on the top of the ribbon blender.

The inlet cover is also provided in order to maintain the protection of the material from the outside.

Ribbon Blender- Inlet/ Hopper/Feeder

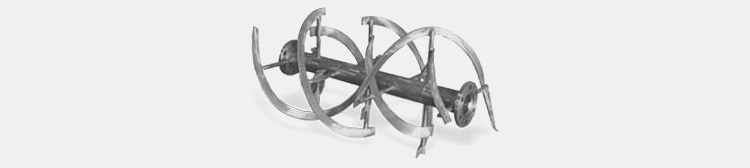

6.Ribbon Agitator

Loaded material is blended by a ribbon agitator.

A ribbon agitator is U-shaped horizontal trough designed to operate at peripheral acceleration also known as ‘tip-speed’.

The ribbon agitator pushes the blended material from both sides of the mixing tank that ultimately results in the continuous flowing of ingredients from various directions and blending.

The loaded material into the blender should typically be filled up to 40 to 70% of the total volume of the container/drum/cylinder.

Generally, it should be filled up to the point of the outer ribbon’s tip.

7.Rotating shaft

A ribbon blender is consisting of a rotating shaft that allows the blending of ingredients by conveying and intermixing material via moving ribbon agitators.

8.Spray Pipe

A spray pipe is utilized for incorporating liquids is mounted above the ribbons. For materials that tend to agglomerate, a high-speed chopper is facilitated to keep material disintegrated against agglomeration.

9.Discharge Chute

When blending is achieved material is discharged from the ribbon blender through discharging valve which is present at the bottom of a trough.

10.Control Panel

The Control panel of the ribbon blender allows users to make settings, adjustments, and feeding protocols to the system as well as running and terminating the operation.

3.What is the working principle of ribbon blender?

The working principle of a ribbon blender is based on two parts; feeding and blending. Material is introduced by feeding hopper which in turn transferred into blending cylinder which is accompanied by blending agitator.

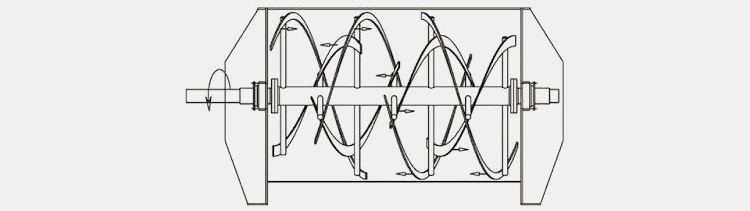

Ribbon Blender Working Principle

As mentioned earlier, a ribbon blender has a blending agitator which is consists of an inner and outer set of helical blades pitched in the opposite direction for fast and thorough blending.

The outer helical blade throw material toward the middle of the trough and the inner blade moves the material towards the outside of the trough. Thus, causing convection mixing, and shearing in the material cylinder.

Materials of various sizes and bulk densities are blended evenly, rapidly, and efficiently in a short time.

A variety of discharge valves are available including knife gate valves for simple and reliable operation.

A liquid spray bar assembly can be used for evenly coating powder as they are being blended in the trough.

4.Do you know how many ribbon blender designs are there?

There are three different ribbon blender design offered by manufacturing industry. You may select them according to your application needs.

1.Spiral ribbon blender design

2. Paddle ribbon blender design

3. Hybrid ribbon blender design

1.Spiral Ribbon Blender Design

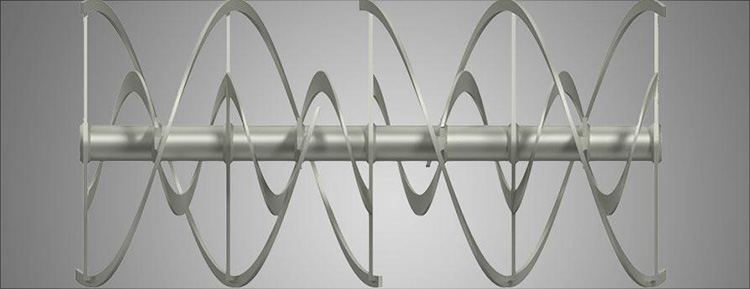

In U- shaped Mixing Tank a horizontal agitator shaft is mounted in the center of trough and the ribbon arms are mounted on main agitator shaft. While on ribbon arms a helical-shaped spiral blade is welded.

You can categorize spiral ribbon blender into two sub-types such as; single helical ribbon blender and double ribbon blender.

a)Single Helical Ribbon Blender

A single helical ribbon blender has only an outer helical ribbon agitator mounted on a horizontal shaft. This type of ribbon mixer is dependent upon types of application and nature of raw material.

This machine is specifically used for mixing raw ingredients with dry or wet substances by soft and gentle agitation to ensure uniform coating.

Single Helical Ribbon Blender Type- Picture Courtesy- QPS Engineering

b)Double Helical Ribbon Blender

A double ribbon blender has distinguished inner and outer spiral shape ribbon blades. Both inner and outer ribbons are mounted on a horizontal agitator shaft which is supported by ribbon arm.

This is a highly sturdy and durable machine that is used for mixing of several powders, solid-liquid pastes, and granules in various industrial platform.

Double Helical Ribbon Blender- Picture Courtesy- cheminear

2.Paddle Ribbon Blender Design

A paddle ribbon blender is used for mixing substances that are fragile in nature. It works the same as a double helical ribbon blender; the paddle of this machine is accurately fixed on an agitator that moves the material in reverse and forward motion.

This machine is a heavy-duty machine that offers a mixing process for free-flowing powders or where treatment for heavyweight powders and wet-type material is required.

Paddle Ribbon Blender- Picture Courtesy-Orbis machinery

3.Hybrid Ribbon Blender

As its names shows, in hybrid type design, raw material is encountered with ribbon and paddle type design. This design is efficient and cost-effective to achieve mixing of heavy large size production batches.

This type of design is also preferred in Research and Development (R&D) laboratories.

5.A ribbon blender or paddle agitator- What’s better?

Many of you do not even understand what ribbon and paddle blenders are?

Let’s compare!

Paddle Agitator

The structure of the paddle agitator is very simple…the blades of the paddle agitator are made up of flat steel, possessing 2,3, or 4 number leaves.

1.The blending time of mass production of paddle agitator is short whereas, the ribbon mixer machine displays a good overall blending process in a short time with high efficiency.

2. Paddle mixer is suitable for treating low viscosity ingredients, suspensions, and solutions.

3.Paddle agitator is suitable for blending ingredients of dissimilar sizes, shapes, and densities.

4.Paddle mixer is used in batch as well as continuous style mixers.

Ribbon Blender

1. Ribbon blender is good when you need to blend materials are of the same size, shapes, and densities such as granular particles.

2.A ribbon mixer is a highly efficient machine that is broadly used for highly viscous material, blending of powders and dried granules. Ribbon blender is widely used in food, cosmetics, animal feed, pharmaceutical, and so on.

3. Chopper is used when incorporating fluids, pastes, or to disperse minor materials.

6.What is the industrial usage of ribbon blender machines?

Discussed below are industrial applications of ribbon blender:

1. Pharmaceutical Industry

The pharmaceutical industry uses ribbon blenders for efficient blending of dry granules, powder, pellets, and other solids.

Moreover, ribbon blenders are used for pharmacological assays, biochemical assays, protein, vitamins, and the mixing of polymers.

2. Agricultural Industry

The agricultural industry widely uses ribbon blender machines in the production line of agriculture such as pesticides, insecticides, herbicides, etc, and for making fertilizers such as ureas, organic manure, roughage, as well as for protein supplements, animal feed, veterinary medicines, and plant protective base, conditioners, etc.

3.Food Industry

Ribbon blenders are used for bakery productions in all leading manufacturing industries. They are extensively used for mixing, blending, drying, reducing the size of particles, emulsification, and homogenization.

A ribbon blender is required for preparing bread, cookies, chocolates, brownies, cakes, and other baking goods with a high degree of accuracy. For instance, ingredients used in these products require precise proportions for manufacturing and final packaging such as flour, sugar, milk powder, etc.

4.Cosmetics Industry

Ribbon blenders are extensively used for various development and manufacturing of personal care products and cosmetics. For instance, you might have heard about carbopol gel, which is mainly used for making lotions, shampoos, hair gels, sanitizers, toothpaste, lipsticks, compact powders, etc.

For that, you require a generous blending of ingredients to form a stabilizing emulsion.

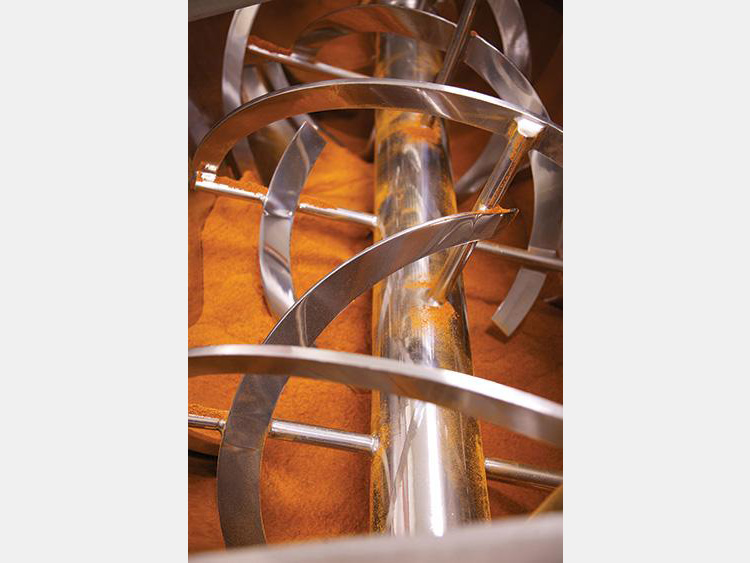

5. Spices Industry

construction of ribbon mixer is done with food-grade stainless steel broadly used in the spices industry. A multifunctional ribbon blender machine is characterized by a high mixing precision, suitable for spice mixing, dispersing, size reduction, and blending.

For instance, cumin, bay leaves, and red chili are commonly used together in many cuisines.

6.Chemical Industry

We find chemical products everywhere in our daily life. During the production of chemicals, you may require vigorous mixing, blending, heating, or cooling. It has diversified science with complex production processing.

A ribbon blender is a reliable mixing unit especially for manufacturing chemical products in a safe and hygienic environment.

7.Nutraceutical Industry- Vitamins, Protein Powders

Stainless steel, horizontal double ribbon mixer is used for the preparation of nutraceutical products, such as vitamins, proteins, protein powder, etc. Ribbon mixer blender works following hygienic design and products in contact with the material are smooth surface instead of joints.

Applications of ribbon mixer in the life sciences area include infant formulas, nutritional supplements, aroma, Lecithin powder.

7.What is the classification of the ribbon blender machine?

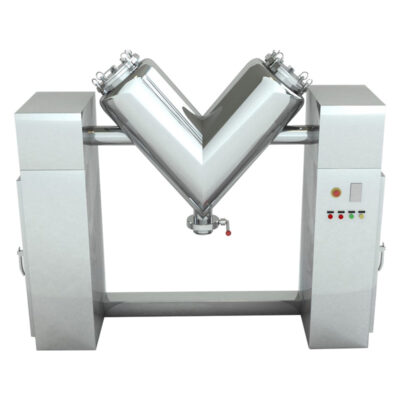

1.Vertical Ribbon Mixer

A vertical ribbon screw blender is also known as a conical screw blender that is mostly used for blending powders, granular products, slurry, and viscous materials. The vertical ribbon blender is equipped with a spray system according to user requirements.

Vertical Ribbon Blender

Vertical ribbon screw blender is constructed into vacuum state, pressure state, heating as well as cooling process condition.

Blades of Vertical Ribbon Blender

This machine allows a suitable condition for material blending, stirring, dispersing, etc.

Conical or Vertical Ribbon Blender

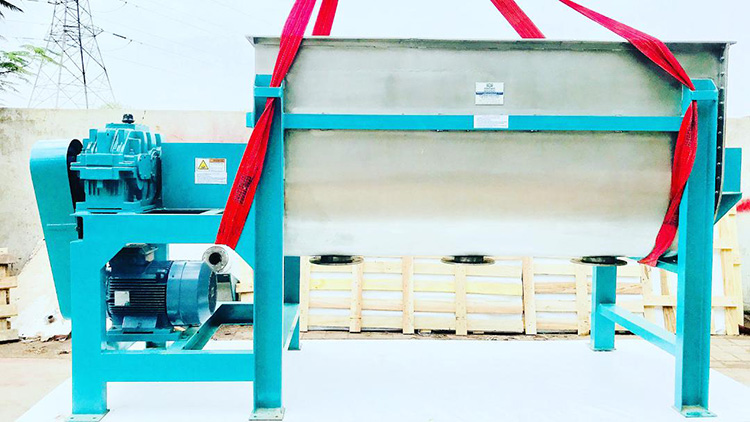

2.Horizontal Ribbon Spiral Blender

Horizontal Ribbon Spiral Blender

A horizontal ribbon spiral blender is a special kind of powder mixer that is widely used in pharmaceutical, food, agriculture industries, and much more. For instance, milk tea, food additives, spices, protein isolates, etc.

A horizontal ribbon spiral blender is easy-to-clean equipment that meets every production batch in a timely manner. Not only this! you can also find amazing options for internal cleaning without any dead ends.

The mixing speed of the horizontal ribbon spiral blender is very high. Typically, a large batch of the material requires one to ten minutes for fully mixing of material.

8.What are the most common ribbon blender processes?

A ribbon mixer machine is a highly applicable instrument in a broad spectrum of the industrial sector. The following most common processes performed by ribbon blender are discussed below.

1.Ribbon Blender for Powder Mixing

Ribbon blender for dry powder mixing is perhaps the most common process. For example, baking mix, tablet formulations, protein supplements, etc.

A typical cycle of ribbon blender mixer takes no more than 15 minutes.

Since according to powder characteristic some optional features of ribbon blender is also worth considering;

- To control dust; a dust-tight discharge valve and a clamp are available to secure gasketed cover.

- Positive air pressure is maintained in order to prevent coarse/abrasive particles from penetration into the stuff box and shaft from wear.

Ribbon Blender for Powder Mixing

2.Coating Particles with Minor Ingredients

Coating solid particles with minor fragments that may be other solids that may be smaller in sizes or liquid materials such as flavoring oil with coffee beans.

Ribbon blender facilitates accurate mixing of minor or trace ingredients.

Ribbon Blender- Ideal for coating particles

3.Mixing Solids of Different Shapes and Sizes

An excellent example of this category is blending of trail mix (mixing of foods)- a snack that is composed of nuts, dried fruits or granola, etc.

Here each component of a product is of a different shape and size.

Ribbon blender provides a balanced mixing with lower chances of damage to delicate food pieces.

Ribbon Blender for Trail Mix

4.Preparing Solid-Liquid Suspensions

A ribbon blender is suitable for treating discrete solid chunks within a low viscosity liquid vehicle. For instance, pasta sauces, ready-to-eat soups, foods for pets, etc. The jacketed ribbon blender mixer enables the trough to control the temperature of the product.

Ribbon Blender is ideal for blending solid-liquid suspensions

5.Slurry and Paste Mixing

A ribbon blender machine is widely applicable for viscous material such as cake batter, industrial formulation (adhesives, pastes, etc).

Ribbon Blender Machine

6.Vacuum Drying- Ribbon Dryer

The vacuum drying process is done on a horizontal blender ribbon machine, that is equipped with a ribbon agitator and paddle blades or both.

A horizontal ribbon mixer machine is efficient equipment to deal with the removal of volatile components from pharmaceutical ingredients, plastics, ceramics, and others.

The combination of lowered pressure, and constant agitation boosts up drying process even at a very low temperature. Vacuum drying is an ideal option for processing heat-sensitive products with minimum risk for thermal degradation.

9.What are the benefits of ribbon blender?

The advantages of ribbon blender machines are as follow:

1.Cost-Effective & Versatile Equipment

Ribbon blender is a most versatile and cost-effective machine used for dry solids, liquid-solid suspensions, powders in various industrial units.

2. Fast & Thorough Blending

Ribbon blender has a high shear speed that facilitates more efficient and smooth output. Significant sealing of ribbon blender protects the mixing ingredients from being leaked.

3. Safe & Hygenic

Ribbon blender ensures excellent hygiene and cleaning services and avoids your product from cross-contamination. A stainless-steel ribbon blender construction boosts the durability and hygiene of this machine.

4.High Degree Homogeneity

Ribbon blender provides a high degree of homogeneity to raw material required for pharmaceutical and chemical industries.

5.No Dead Spots

There is a finely gauged distance between the ribbon agitator and mixing tank allows no dead spots.

6.User-Friendly

Ribbon blender is easy to use, easy to evacuate, easy to tilt the machine.

7.Dry and Wet Application

The mixing blades of ribbon blenders are designed with sealed ends that make this equipment suitable for dry and wet uses.

8. Powerful, Reliable Transmission & Large Capacities

A ribbon blender is a trouble-free machine with a powerful rugged motor function. It is available in various capacity ranges.

10What are the installation instructions and materials needed for the ribbon blender?

For installation ribbon blender you will be required a fork lifter and two to four personals depending upon the type of machine.

- Forklifter can securely attach the machine and position it according to your assigned location carefully.

- Ensure the machine is placed on flat ground.

- Plug the ribbon blender into an appropriate electrical unit.

- Now it’s time to test the machine by performing TEST RUNsoon after installation.

- Switch ONthe machine, press the green button to START the system.

- Check the ribbon blender without adding the powder to it. Assess the abnormality during operation. Ensure ribbon agitators do not touch the mixing tank.

- If everything works fine, then pour 10% powder to its full volume, later you may increase the amount.

11.How to operate a ribbon blender machine?

To operate the ribbon blender you will need to follow mentioned steps;

Ribbon Blender Operation

Pre-Start-up

- Wear food-grade latex gloves, safety goggles, mask before operating the process.

- Ensure, discharge chute is properly closed.

- Plugin the ribbon blender and Press ON the green button and START button.

Start-Up

- Open the cover of the mixing tank by hand.

- Introduce the raw material into the mixing tank.

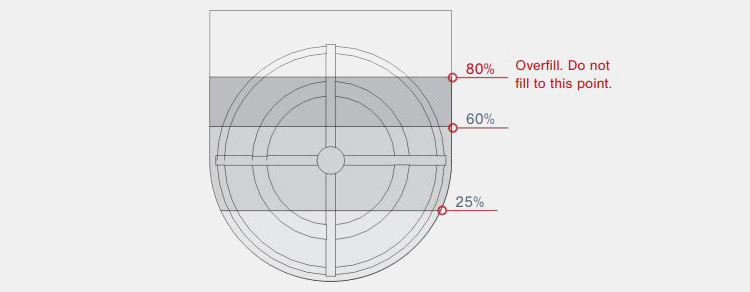

- Always keep in mind to not fill the mixing ingredients into the tank more than 70%. If you fill up to 80% it will be considered as ‘overfill.

- Now the close cover of the tank.

- Adjust the timings (minutes and seconds respectively).

- Turn ON the process.

- The machine itself will stop after attaining desirable mixing and process completion. Generally blending is achieved within 15-20 minutes up to 90-95%.

- Now you can press the discharge START button in order to open ‘discharge chute’.

- After discharging material, press the STOP button to close the discharge chute.

Ribbon Blender Mixer Machine

End-Up

- To empty the ribbon blender, STOP the motor and place a discharging box in front of the cabinet.

- Use the Discharge motor to evacuate the cylinder completely.

- After removing, Close the discharge box and ‘OFF’ the system.

12.Do you know the operational specification of the ribbon blender?

Ribbon blender possesses strong operational specifications.

A GMP compliant ss ribbon blender construction has been done with rugged motors and thorough engineering.

Ribbon blender is a reliable, cleaned, a corrosion-resistant machine that satisfies most of the manufacturing industries fulfills a large capacity requirement.

Mixing blades are mounted into a cylinder with the perfect sealing device at each corner that allows liquid or semi-liquid material, dry material treatment without worrying about leakage.

A simple to clean device negates the corrosion and discoloring of sensitive materials, hence this is ideal for food processing and pharmaceutical manufacturing units.

13.What are some Do’s and Don’ts associated with ribbon blenders?

1.Do Opt a Right Place for Ribbon Blender

A ribbon blender mixer machine is generally manufactured as a floor-mounted design that requires a smooth floor level and appropriate bolting. Bolting a ribbon blender on an uneven floor may deform the trough and cause problems between trough and ribbon.

2. Don’t overfill and underfill your ribbon blender

Always take care of the filling volume of the ribbon blender. If you underfill the blender tank at least 30-40% of volumetric capacity or overfill more than 70%, then you won’t get adequate mixing. Working with a smaller volume may fail to generate significant outcomes.

3.Do use a Variable Frequency Drive

A variable frequency drive or VFD allows gradual start under a full load and prevents the machine from a spike in start-up torque. The electronic soft start-up enables a single-speed procedure during blending.

4.Do Fine-Tune Shear Input

To disperse lumps and handling fragile components chopper blades are installed through the side of the vessel or mounted on the top of the cover.

14.What are the tips to extend the life of a ribbon blender?

To ensure the long shelflife of the ribbon mixer machine a regular checkup and maintenance is essential.

1.General Cleaning

A- For Small Ribbon Blender Machine

General cleaning points for mini ribbon blender are as follow:

1. With help of a bagless vacuum clear all the unwanted materials from the exterior of the ribbon blender.

2.Open the lid and examine the interior of the cylinder/mixing tank. Vacuum the mixing tank till all the residual pieces are removed.

3. Clean the mixing tank with a cleaning cloth, potable or purified water, and a cleaner solution. Ensure to clean all the areas of the mixing tank including ribbon agitator and rotating shaft.

4. Dry the Mixing Tank's interior with a clean cloth.

5.Open the Discharge Chute and clean it with a tidy cloth, potable water, and cleaner.

6.Using a clean cloth, dry a Discharge Chute.

B- Large Ribbon Mixer Machine

1.For an industrial scale ribbon blender use a shop vacuum to clean the exterior of the ribbon mixer machine.

Large Ribbon Mixer Machine- Picture Courtesy- Arvinda Blender

2.With help of a ladder you may access the top of the mixing tank.

3.You can clean the interior of the mixing tank with help of a shop vacuum and wipe out all the residual material present inside the tank

4. With help of a pressure washer clean and expel the residual ingredients.

Ross Ribbon Blender (Industrial ribbon blender)

2.General Maintenance

1. Monitor the ribbon blender thoroughly & regularly for the signs of wear or tear and replace the worn-out parts immediately before operating the unit.

2. Examine the triangular belt if it is loosely adjusted in order to protect the belt from skidding or abrading. It shouldn’t be much tightened as it may cause overheating.

3. Ensure all electrical wires are kept dry.

3. General Lubrication

Regular greasing of the machine may increase the prolongation of the operational life of the ribbon blender. If parts of the machine are not fully lubricated, they may seize up and cause big problems later on.

1.Open the machine and lubricate the Gearbox and bearings of the ribbon blender. Monitor them weekly or every hundred hours of usage.

2.Grease the rotating shaft with help of a grease gun.

3.Each side of the discharge chute is attached with bearings that required regular greasing as well every week.

4.Check the main shaft sealing rope at each end of the rotating shaft, as it may cause powder leakage from the main shaft. In this case, replace the old shaft rope with a new compression packing rope.

4.Monitoring the Driving Unit Tension

The driving unit of the ribbon mixer blender is the most valuable component. By keeping the reducer belt, chain, as well as sprocket, properly lubricated is one of the best ingredients to keep the ribbon blender maintained.

5.Monitor the Discharge Gate Processing

With time, dust, dirt, and foreign sticky material get stuck in the discharge gate that causes the gate to not completely closed. Therefore, you must ensure that the discharge gate opens or closes properly. If you notice the gate does not open completely then it may cause the material to enter the mixer or vice versa.

Ribbon Blender Discharge Gate

Ribbon Blender Machine

6.Protect the Mixing Tank

The body of the blender machine is an important component of a ribbon mixer. Whether you use any type of ribbon blades mixer if its agitator is extremely closed to the walls of the tank it may cause damage to the machine. For instance, bits of metals or tiny rocks can damage the mixer during operation.

This will not only damage the tank but also contaminate the ribbon mixture by incorporating trace metal into it. Thus, if you hear any vibration or unusual sound then you align the blades/agitator with an appropriate distance from the walls of the container/mixing tank.

Ribbon Blender Machine

15.What are the expected failures and limitations of ribbon blenders? How do troubleshoot them?

Generally, unavoidable problems occur whenever you operate the ribbon mixer. But do not worry!

We have enlisted several methods to remedy these problems. Lets’ have a look.

1.Blockage of ribbon agitator with ingredients

Ribbon Blender- Ribbon Agitator

Possible Cause

1. You may face this problem when you use powder’s bulk density in a high concentration.

2. Furthermore, the batch size of the raw material is too large.

Remedy

1. You can avoid this problem by using lower bulk density for blending material.

2. You may reduce the number of ingredients that should not be exceeded up to 70% of the mixing tank.

Material Takes Long Time to be Mixed

Ribbon Mixer Blender

Possible Cause

1. You may face this problem when the mixing tank is over-filled.

2. Sequence of ingredients introduced in the mixing tank is incorrect.

Remedy

1. Use an optimum concentration of mixing ingredients.

2.Ensure the amount of smaller ingredients are properly loaded in between larger materials.

Particles Leaking from Corners of Mixing Tanks

Ribbon Blade Mixer

Possible Cause

1. You may face this problem when seals are broken.

2.Moreover, compression ropes inside the seal may also be worn out.

Remedy

1. Substitute the seal at each side of the mixing tank.

2.Replace the compression ropes present inside the seals.

Mixing Tank/Cylinder Stops During Process

Possible Cause

1. Mixing the tank most often stops working when you overfill the tank with raw material.

Remedy

1. Reduce the level of powder in the mixing tank that should not cross the level up to 70%.

16.What are the future trends of ribbon blenders?

The market trend of ribbon blenders is rapidly growing in a huge range of manufacturing regions recorded by industrial data across the globe.

It is recorded that ribbon blender has driven the best annual revenue in 2020 which was valued at 108.43 million US dollars, and it is expected to grow with a CAGR of 5.64% by 2020 to 2027. The prime application covers from 2021 to 2027 are the food, chemicals, pharmaceutical, and cosmetic industries.

17.What are important aspects to consider before purchasing a ribbon blender machine?

Ribbon blender machine is a versatile machine available in various features, sizes and designs. Furthermore, manufacturers also offer multiple capacity ranges too. However, before buying a ribbon blender machine you must follow some important check points.

Ribbon Blender

1.Variable Acceleration

This is one of the important factors to consider when buying a ribbon blender machine. Because not all ribbon blenders run at the same speed, every machine has different speeding criteria. Therefore, assess for ribbon blenders that can run the blending process according to the type of product to be mixed.

2. Torque of Machine

This is another prime factor you must consider because there are many blenders that delivers high torque and horsepower and they are cost-effective too.

So, look for such a blender!

Apart from this, there are some blenders with slow-speed starters that also proved beneficial. Those machine induces low-stress factor and improves efficiency and performance on a large scale.

3. Area Capacity

Before buying a ribbon blender machine you must assess the area capacity for placing the machine. It should be placed in a spacious and ventilated room with smooth flooring in order to carry a perfect installation procedure.

4. Interior and Design of Ribbon Blender

For effective outcomes, it is of prime importance to find that ribbon and shaft compliments with each other. It helps to protect the ribbon blender from mechanical failures and boosts up the performance of device in various ways.

5. Belt and Direct Drive

Some ribbon mixer processing depends upon direct drive while some of them belt drive. The direct drive is most often considered as reliable and most efficient. Because it is compact in size. Furthermore, to evaluate the type of seals fixed in ribbon blender is also important in order to protect downtime in future processing.

6. Competitive Vendors

This is very important to reveal a true and competitive vendor for procurement your machine. For ribbon blender you must scrutinize for those manufacturing companies who are willing to provide best quality equipment with affordable ribbon blender prices. Most often you must look for low ribbon mixer price, we suggest looking for quality rather price, as you get what you pay!

A good vendor always streamline you with excellence services ranges from transportation, installation as well as post sale services.

Final Thought

Ribbon blender is the most versatile equipment used for processing powders, granules, dry and wet ingredients around. A spiral mixing agitator across the mixing shaft ribbon blender creates a helical flow within a blending chamber which is an ideal tool for blending free-flowing powders, flakes, slurries, dough, etc.

We hope, you’ve found this comprehensive blog informative and interesting. Now you’ll be able you find the right selection of ribbon blender machines for business.

Not only this but this blog is also comprised of operating, cleaning, and maintenance tips that ensure a high shelf life for your future equipment. Happy Shopping!

Bin Blender Related Products

Bin Blender Related Posts

Bin Blender Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours