Unit Dose Packaging: What Do You Know?

Have you ever gone to pharmacies and been overwhelmed by the endless array of packaging styles? There are so many options that it’s difficult to tell what’s what. Bet one particular style might have caught your eye! And it is unit dose packaging.

It is a hidden gem among a never-ending sea of packaging. With its separately packed meds and accuracy in dosing. No guesswork is needed. As compared to old bulk packaging, it holds medication ready for one-time use.

Besides looking neat and elegant, it boosts numerous sets of benefits, providing convenience to both its manufacturer and end-user. Want to know more? So, read through this blog post “Unit Dose Packaging: What Do You Know?” as we’re about to unseal all the ins and outs of this formidable packaging format.

1.How would you describe unit dose packaging simply?

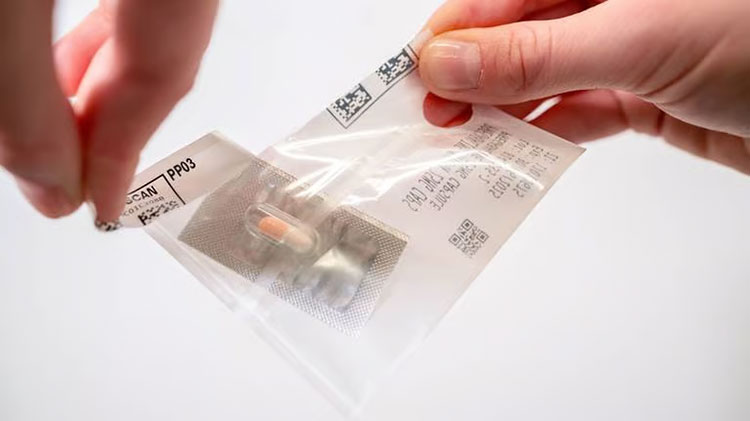

Unit dose packaging

In simple words, you can say that a unit dose packaging is an individual wrapping of medications. Whereas, a unit dose is defined by experts as a quantity of drug that is given to patients or other users in a single dose.

Thus, unit dose packaging is just the packing of the unit or single dose in protective and non-reusable containers. Simply, it is a distribution system, where medicines after preparation are measured loaded, and sealed into separate compartments or packets. So, you can immediately use them without first manually measuring or sorting them.

You just have to open the packaging to have your pill, powder, liquid, or injectable medication. With absolutely no hassle in hospitals, clinics, hospices, and, even homes.

2.What do you know about the history of unit dose packaging?

History- Picture courtesy:Swisslog Healthcare

Today, you’d likely find blister packs or vials everywhere in your home from the medicine cabinet, fridge, or, even kitchen drawers. Many of you certainly would have seen this sort of packaging in your entire life but may find it hard to believe that unit dose packaging is quite a modern invention.

In fact, it was first developed in the 1960s, which makes it just 6 decades old. Just like with other inventions, unit dose packaging is invented due to necessity. Prior to this packaging, you would routinely find meds in the bulk storing containers.

Since bulk packaging is often associated with medical errors, community hospitals first came up with the idea of unit dose packaging.

3.Why is unit dose packaging gaining popularity in today’s world?

Benefits- Picture courtesy: UW Health

Since its emergence, you’ll see more and more pharma companies opting for unit dose packaging in their productions. This is because of its higher acceptance by patients. The reason for its increased popularity is its numerous advantages to both the health sector and users alike.

No Confusion

No confusion

Normally, numerous patients, especially the elderly ones receive a huge set of medications. Unit dose packaging helps a lot in hospitals and hospices because, with it, you get each dose clearly labeled and stored in a separate compartment. This lowers the incidents of taking or giving the wrong med when confused.

Prevention of Dosing Mistakes

Prevention of Dosing Mistakes

Unit dose packaging surely comes to your rescue when you’re trying to prevent dosing errors in dosing. Indeed, it helps in ensuring the exact dose to patients with its individual packaging. You don’t have to measure the dose when giving medicines to your loved ones or other care recipients. Consequently, you can reduce the possibilities of dose miscalculations, overdose, or, underdose.

Following the Proper Dose Schedule

Proper Dose Schedule

Besides making medication safer, unit dose packaging helps you and other patients monitor when and which dose they’ve taken. So, you can not only reduce the likelihood of missing a dose but also follow your proper dosing schedule as instructed by your doctor.

Less Time-Consuming- Picture courtesy: National Geographic

In hospitals or other similar settings, the healthcare staff has to distribute the right med to numerous patients. And even seconds matter in case of emergencies. So, unit dose packaging allows you to lower time expenditure and swiftly give out doses to patients without first pouring the correct quantities of syrups or sorting out pill bottles.

Lower Wastage

Lower Wastage- Picture courtesy:Care Health Insurance

You’ll find it incredibly useful that there is every piece of information on unit dose packaging like the name of your drug, its strength, as well as the date on which it expires. This assists you in managing your meds inventory and minimizes medication wastage by aiding in their usage before their expiry date.

Cost Benefits for Patients

Cost Benefits for Patients- Picture courtesy: The Conversation

Using a unit dose packaging system is quite cost-benefitting for patients, as they just have to pay a small price for the medications they require. Rather than purchasing full bottles, pouches, or vials for higher prices.

Additional Safety Layer

Additional Safety Layer- Picture courtesy: GoodRx

Do you know that there are additional safety features on your unit dose packaging? Yes, you can observe various tamper-proof, such as tear strips, film seals, and other child-resistant elements on it. Which makes it easy to see if the product has been opened or changed in any shape or form. Beyond this, it also prevents accidental drug intake by children.

4.How many kinds of unit dose packaging can you get from the market?

Unit Dose Packaging

Whenever you go to buy medicines, you notice shelves full of blister packs, vials, and, more. Pharma companies have introduced a variety of unit dose packaging because of their convenience. People favor them because of their hassle-free dispensing. Here are some kinds of unit dose packaging that you can get from the market:

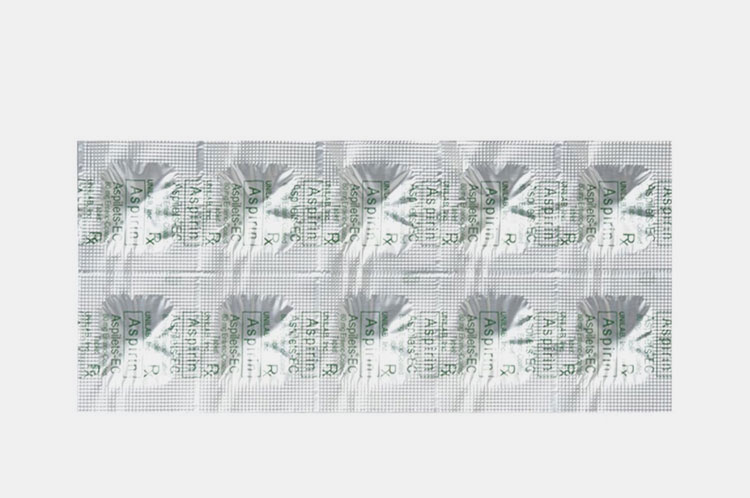

Blister Packs

Blister Packs

Yes, you will see blister packs quite frequently in markets. It is because they contain tiny compartments or cavities to hold single tablets, capsules, or lozenges. In addition, they are created with tough plastic materials and aluminum foil or plastic films on the back. Consequently, with this design, your every dose is more protected, resulting in a long shelf-life.

Environmental agents, for instance, moisture, light, air, and, dust are of no issue when you use blister unit dose packaging.

Not only this, it has a design simplicity. Which allows you to easily take your meds out by only pushing them through its back material. Also, you can see the inside pill clearly due to its transparent nature. It helps you in identifying medicines as well as noticing the signs if packaging is tampered with.

Many of your widely used pain relievers and allergy medicines are available in blister packs. You can get more mechanical protection with blisters because of their puncture-proof assembly.

Strip Packs

Strip Pack

People often mistake strip packs for blister packs. Due to their similar designs. Strip packs also have separate pockets for holding meds. But that’s where their similarities end.

Rather than molding cavities, strip packs are made by enclosing single doses between two webs of films, which could be either plastic or aluminum foil.

It leads to the making of a continuous long sheet of strips, where you see every dose parted from each other with tiny perforations or scored lines. Due to this strip packaging, you’ll provide more protection to your sensitive pills from humidity, ultraviolet rays, heat, and, oxygen.

You won’t be surprised to know that strip packs are more economical when their preparation expense is compared with blister packaging. In case you’re wondering about the reason for this plus point, it is very simple. Not only does it use one type of film but also it is very easy to make.

Vials

Vials

Small containers with cylindrical bodies, pack a single-use dose of injectable drugs. You often would’ve spotted them in hospitals, clinics, or even in your homes if you’re using insulin or other injectable.

You may think of them as a tiny bottle with rubber stoppers. Certainly, in many cases, vials are closed with rubber stoppers and aluminum crimps or in some cases, twist-off caps. Well, a rubber stopper isn’t just for the look but is on vials for sealing.

Rubber stoppers are typically the site where needles are inserted to withdraw the liquid. Also, these closures wade off various kinds of contaminants from getting into vials.

Although, vials are synonymous with glass but sometimes you’ll find them in plastic as well. Plastics are used owing to their higher shatter resistance. These containers aren’t exclusive to liquid, they can also carry freeze-dried form (usually white powder) of med.

Thanks to their single-use format, you can get exact med dosing and minimal product wastage with vials. Which is a major win for protecting patients and saving money.

Ampoules- Picture courtesy Reagent Chemicals

Think of them as little cylinders with slender necks. You might be surprised to learn that ampoule takes its name from the French word ampule, which means bulb. So, you’re spot on. They’re called as such because of their bulbous look.

More often than not, ampoules boost all-glass bodies, both inside and out, due to the chemical inertness and impenetrability of glass. But nowadays, you can also get them in plastic.

They’re part of unit dose packaging, meaning that they are designed to contain a one-time amount of med. Once opened, you can’t reseal them, and subsequently, you can’t use them again.

Usually, you’ll notice a round or pointy tip on ampoules. Its neck is very delicate and easily snapped off to extract injectables. But how do they get this fully enclosed look from the start?

To answer that by melting the neck with a hot flame. If you see pre-scored rings or other colored lines on ampoules, they assist in their breaking. A fully sealed assembly is for the protection of liquids inside the ampoules. This ensures that packed contents remain pure until used.

Unquestionably, they come with a higher price tag than vials but due to their superior hermetically-sealed nature, this cost is justified.

Sachets

Sachets- Picture Courtesy: V-Shape

For convenience, sachets are introduced in the market. Yes, they’re like mini pouches with the advantage of being lightweight and portable. You can easily store them in your backpacks or luggage and take your medications when you’re on the go. Moreover, they’re compact, so need space wherever you keep them.

Often, they feature a flat-sealed packet appearance. What’s more, they contain granulated and liquid medications in addition to powders. Your life-saving meds, for example, antibiotics, rehydration salts, supplements, energy boosters, and more are packed in ease-to-use sachets.

This makes sachet a pretty versatile choice. Besides enhancing the look, packaging materials also keep the inner contents fresh.

You can easily tear them open to take your meds. You’ll find them in diverse materials, like paper, aluminum, and plastic. Sometimes, you may get sachets that are made with a combo of numerous materials.

Stick Pack

Stick-Pack- Picture Courtesy: Aranow

Owing to their resemblance with sachets, many people consider them cousins of sachet unit dose packaging. Like sachets, they also have four distinct corners but stick packs are narrower instead of wide. You can picture it as a tube-like packaging.

Basically, they’re developed for holding one portion of your medication, whether, powders, granules, or liquids. With just tearing off their sides, you can consume their contents directly by pouring them in your mouth or you can blend them with a drink of your choice first.

The slim design of stick packs helps in their portability on traveling and their easy storage in pockets, wallets, or even palm-sized first aid boxes. So, you may carry them with you to your jobs or schools.

However, their sleek design is not just about creating a stylish look, it also uses less packaging material than other forms of unit dose packaging. So, wins brownie points for being greener.

Prefilled Syringes

Prefilled Syringes- Picture courtesy: Pharma Tech

Oh yes, prefilled syringes are the latest invention and are VIPs of unit dose packaging. Can you imagine avoiding every time-consuming and hectic step, such as measuring and pulling out doses? Indeed, it is possible with the use of prefilled syringes. One of the biggest pros of this unit dose packaging is that it is ready to use. All you’ve to do is to inject the needle into your desired body location.

Less time-consuming and easy to use because medications are already filled in ultrapure syringes. So, you don’t have to worry about guess-estimating the dose of medication and about contamination.

Furthermore, with prefilled syringes, there is less chance of germs spreading. Since you don’t have to use separate containers for injection, which is usually the case with ampoules and vials.

Besides saving your time, it comes in handy when saving lives, which is needed when injecting life-saving drugs. Like vials and ampoules, it is made for holding single-use quantities of parenteral drugs. If you need self-administration of drugs at home, prefilled syringes are your best option because of their user-friendliness.

For those of you who’re concerned about waste, here is good news for them. Prefilled syringes help minimize wastage because of no overfilling and fewer materials are used in them than vials and ampoules.

5.In what ways unit dose packaging different from multi-dose packaging?

Pharma Packaging- Picture Courtesy: Tifton Drug Company

Both these packaging systems are built for distributing medications to various patient groups and satisfy healthcare needs. However, you should know that unit dose packaging and multi-dose packaging are very distinct in their delivery styles and pros and cons. To add to your knowledge of both these packaging types, we’re penning their differences below in tabular form:

| Features | Unit Dose Packaging | Multi-Dose Packaging |

| Inner Contents | Contains one dose per container or compartment. | As the name suggests, has many doses in a single packet. |

| Exact Dose | Comes with high accuracy. Due to its premeasurement of dosing. | This depends upon the user. One may cause dosing errors while drawing or measuring doses. |

| Exposure to Contaminants | Very low since medications are sealed separately. | Very high because you’ve to access the container multiple times to take out your dose, which may introduce contaminants inside the packaging. |

| Patient Health Risk | No health risk. Because of no dosing errors or contamination. | Needs proper handling to prevent health risks. |

| User-friendliness | Ready-to-use | Hard to use, and normally involves counting, measuring, and sometimes even mixing in case of powders. Requires additional support tools, for example, syringes, measuring cups, spoons, etc. |

| Cost Per Single Dose | More than multi-dose packaging. Uses more material. | Lower |

| Tracking | Easy to track and remember. Improves patient compliance. | Difficult to track your medications. |

| Landfill Waste | More since packed individually. | Less due to bulk packaging. |

| Shelf-life | Smaller | Lengthy, as normally include preservatives while preparation. |

| Types | Prefilled syringes, sachets, ampoules, and, blister packs. | Multi-dose vials, syrup bottles, tubes, insulin pens, pouches, pill bottles, blister cards, and more. |

Conclusion

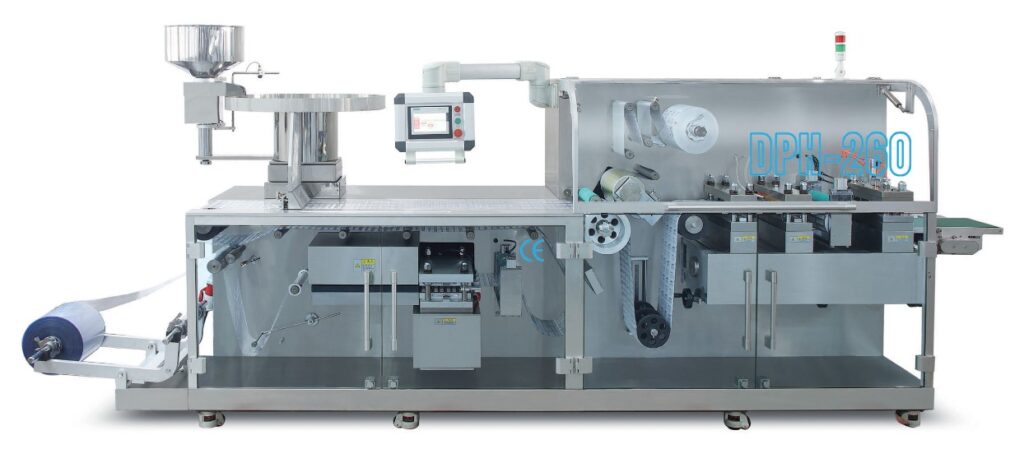

At first glance, unit dose packaging seems like a tiny packet but its benefits, for instance, dose accuracy, ease of use, and, patient acceptance are anything but little. Whether you want ready-to-use prefilled syringes, tear-open sachets, or push-through blisters, this packaging is always ready to serve you. So, you can get the exact dose at the right time with absolutely no bother. Particularly, unit dose packaging is very useful in fast-paced hospital settings or when you’re self-administering treatment. Still want to learn more about unit dose packaging or its related machines. No problem! Send us your queries using the form below. We’ve got you covered at AIPAK.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours