What Do You Know About Wet Granulation Process?

Do you know how powder particles transform into uniform granules – much like a damp soil? There is a process used in most of pharmaceutical company to transform powder particles into free-flowing granules, for the formation of tablets, pills and capsules. This transformation is made possible due to wet granulation process; an important method responsible for uniform compressibility, dust reduction and consistency dosage.

Any idea how wet granules formed in this fascinating process? A liquid is added to powder to make it a loose solid, a fine granule suitable for use in product manufacturing process. These sticky powder particles play a big role in life-saving medications.

Different questions may arise in your mind while reading concise introduction above. Isn’t that so? Don’t worry- You will find answers to questions like, what is this process, an advantage, steps in wet granulation process, equipment use in the process and many more. Let’s get started.

1.What do you know about wet granulation process?

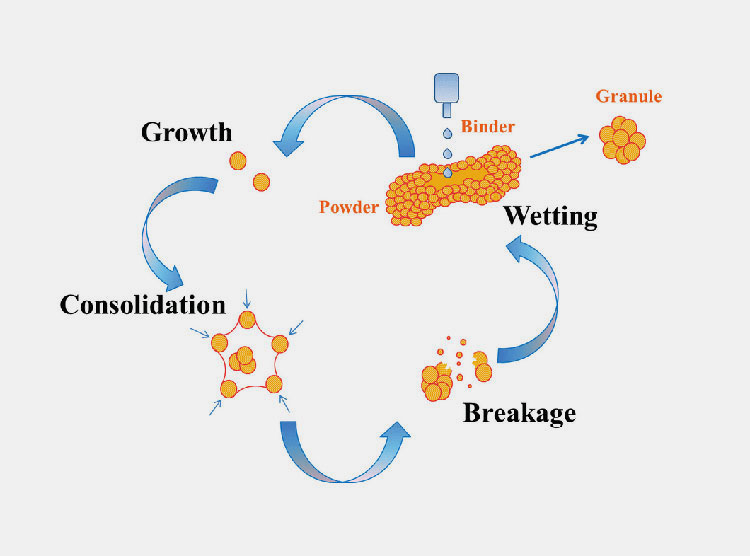

Wet granulation process

Wet granulation process is the process of transforming powder particles in granules through granulation. Liquid binder is added to the powder to get a large lump. This is wet, broken into desired granules sizes, and then dried to achieve desired moisture level. The process is aligned with different machines being use in the process. Pharmaceutical industry widely uses the process for capsule filling and tablet compression, due to its features of flowability, and compressibility.

2.What benefits can you get from wet granulation process?

This process level up the effectiveness and efficiency of tablets. Do you know how? Wet granulation process turns the powder in manageable granules that does not break the tablet, or improving the consistency; doesn’t make poor quality medication during the process. Let’s know the benefits.

Good compressibility

Good compressibility

Do you know the importance of compressibility in pharmaceutical industry? So, this granulation process is used to achieve better compressibility. To inform you, a soft or too hard tablets will form due to poor compressibility. Like effervescent tablets dissolve easily due to its adequate hardness.

Lower the dust generation

Low dust generation

In handling powder, it gets aired in dust form. This poses many problems for operators and compromise the quality of granule formation. However, the process reduces dust formation. How? By binding powder particles together in cohesive large granule mass. This can lower the product loss.

Improve flowability

Improve flowability

Generally, powder has poor flow and often clump to form lumps. This results in erratic flow. Wet granulation process change powder into granules with improved flow features. These characteristics are necessary where accurate and precise dosage or filling is required. It fastens up the product efficiency with pharmaceutical grade equipment.

Improved solubility

In case of pharmaceutical products like tablets or pills, they need too be dissolve either in stomach tract or in glass of water. But how will this be possible? This process enhances the dissolution power of products by increasing their dispersion or surface area of poorly soluble drugs.

Adaptability or customization

If talk about wet granulation process in pharmaceutical industry, some of the medications are sensitive to heat and moisture but this process is carried out in equipment that maintain moisture level and other environmental factors. There can be fast drying methods, and could be adjusted to widen up the adaptability.

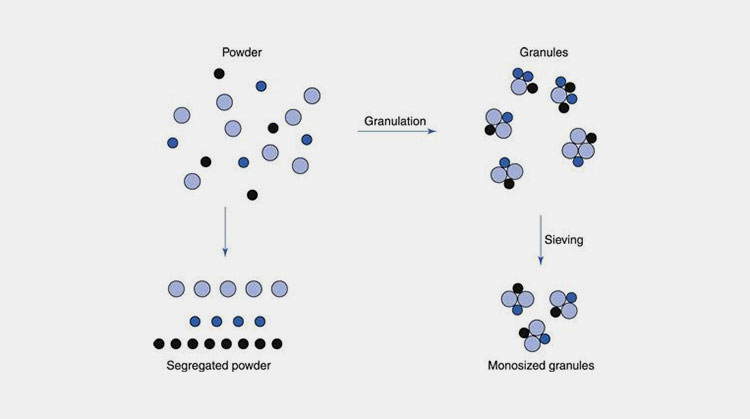

Minimize segregation

Minimize segregation-Picture courtesy: basicmedicalkey.com

In dry granulation process, powder is compressed directly in granules where there are more chances of segregation; differences in size and density parts in segregation. Whereas in wet granulation process, powder is compressed, wet and then turned into fine granules, less chances of segregation.

3.What are the key applications of wet granulation process in industries?

Wet granulation process not only use in pharmaceutical industry but its application is extended beyond it. The food, chemicals and other things also exist in powder form where precision and particles uniformity are necessary. Following below are the industries where this process is undertaken.

Pharmaceutical industry

Pharmaceutical industry

It is mostly commonly used in pharmaceutical industry. In tablets, capsules or pills formation, accurate and consistent filling of ingredients are highly required. This can be achieved by this granulation process. Poor compressibility reduces the shelf life by its segregation; but due to this process, compressible granules are produced.

Food industry

Food industry

Foods like soup powder, spices, and others are in powdered or granules form. Their physical properties are of high standard. Do you know how this is achieved? Food industry also uses wet granulation process increases solubility, attractiveness, flowability of the food product. Flavors, vitamins, sweeteners etc. are also handled.

Cosmetic industry

Cosmetic industry

In cosmetic products, an accurate moisture level and dispersion or mixing of ingredients are required for effectiveness of product. As many cosmetic products are applied on skin. So, their positive effectiveness depends on uniform distribution of active ingredients are necessary as wet granulation ensures stable texture and powder cohesion.

Agricultural industry

Agricultural industry

Agricultural products such as fertilizer, pesticides and others are manufactured using wet granulation process. These are made free flowing so can be easily spread in fields. Manufacturing is done under controlled environment. Hence, it is environmentally friendly.

Nutraceutical industry

Nutraceutical industry

In nutraceutical industry, vitamins and natural extract tablets are formed. Here the granulation process is used. In these calcium or other minerals tablets, powder consistency, uniformity, flowability and accurate moisture level are vital. These features involve in easy compression of granules in tablets, or pills.

4.What are the components used in wet granulation process?

In this granulation process, powder particles are compressed and change in granules. This involves various materials to due to which compressed granule structure come into existence. Each component plays its role. These are

Active pharmaceutical ingredients

Binders

Disintegrants

Granulating fluid

Glidants

Here is the detail view of above-mentioned components used in wet granulation process.

| Components | Explanation |

| Active pharmaceutical ingredients

Active pharmaceutical ingredeint-Picture courtesy: chisellabs.com |

The main components in its formulation are API. These ingredients are uniformly mixed with excipients to increase the compressibility. It also enhances effectiveness of product. |

| Binders

Binder-Picture courtesy: camachem.com |

Have you guessed its function from its name? well, it binds particles together during granule formation. The binders strongly bind the particles so they don’t break while drying. Binders can be Hydroxypropyl methylcellulose, gelatin etc. |

| Disintegrants

Disintegrants-Picture courtesy: rakshbioscience.com |

It helps in disintegration of granules, present in tablets to improve digestion, ensures quick drug release. Crospovidone, Sodium starch glycolate etc. are disintegrants used in wet granulation process. |

| Granulating fluid | The granulating fluid can be water or isopropyl alcohol that wet the powder but not make it a fully liquid as it doesn’t dissolve the ingredients. Actually, it activates binders and by wetting it, the particles bind together. |

| Glidants

Glidants-Picture courtesy: serinatrading.com |

This component reduces friction and increases flowability of granules. Glidants such as colloidal silicon dioxide or talc are used to prevent sticking of granules. |

5.Can you explain the steps involved in wet granulation process?

Different steps are involved in wet granulation process. Each is carried out under controlled environment. Let’s uncover the steps.

Weighing and blending of ingredients

Weighing and blending of ingredients

Accurate and precise presence of ingredients are necessary in granules formation. So, Ingredients are weighted and then, blended in order to uniformly mix ingredients and powder together. Do you know why these are mixed together? To ensure each granule (Product) carry equal components.

Preparation of binder solution

Binder is used in binding powder particles together which is necessary in granules. So, binder is used in the process. First thing you have to do is to prepare binder solution such as starch, hydroxypropyl methylcellulose etc. The solution should be consistent so granule strength and size would have no variability.

Wet massing and screening

Wet massing and screening

After preparation of binder solution, it is added to powder. Powder agglomerate and become wet. Size of the particles increase to a suitable granule size. A cohesive mass of the jumble powder is formed. Then, the wet mass is passed through sieve to achieve the desired granule size.

Drying of wet granules

Drying of wet granules

Wet granules are wet and have liquid solution in them. So, its drying is necessary to remove the binder solution. You should dry them under control condition because over-drying can result in brittle of granules and under-drying results in pre-mature wet.

Dry milling

Dry milling

The dry granules are further reduced to size to achieve even more uniform and give regular shape to make it compressible. This improves flowability and density of granules.

Final blending

Finally, dry granules are blended with glidants, disintegrants and other components to make it available for use in other final products. you can use the final blend for compressing. In pharmaceutical industry, it ensures smooth and uniform forming and filling of capsules and tablets.

6.What is the equipment used in wet granulation process?

As you have read various steps in wet granulation process. These use different machines to handle the process. Followings are the equipment use in the process.

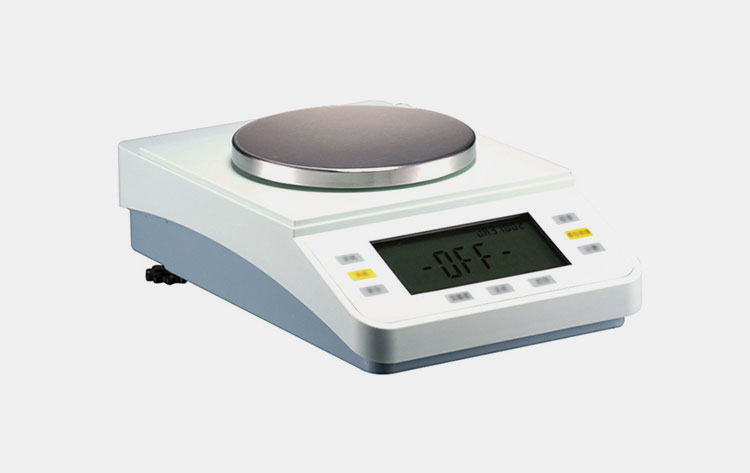

Weighing balance

Weighing balance-Picture courtesy: melseytrading.com

Weighing balance is used to measure weight of active ingredients and other components. Accurate and precise weight is necessary in getting accurate, consistent and high standard product. The reason is any deviation from desire weight is to prevent inconsistent granule formation.

High shear granulator

AIPAK high shear granulator

In this equipment there is mixing chamber, blades, spray nozzle for binder solution, and others. Ever thought how mixing is done? Here, a powder is loaded in mixing chamber. Blades rotate at high speed that ensures uniform blending of powder that ensures no clumping. Then, ingredients such as binder and granulating fluid are added to make it wet. A cohesive large mass of granule is made.

Fluid bed dryer

AIPAK FG Series Fluid bed Dryer-bed dryer

It contains heater, blower, air distribution plate, filter etc. By working on fluidization, the above product is moved to this equipment in order to dry it out. An ideal heat is applied to remove moisture. Hot air is given to the wet granule from the perforated plate as this will allow uniform drying. It is widely used because it can handle large volume without compromising drying time.

Bin blender

AIPAK HDT Series Bin Blender

As from its name, it is cleared that process of blending is carried out. Before compress in capsule, tablets and in other product, they are blended so ingredients mix uniformly. Blending bin rotates at speed that consistently tumble and mix the granules. Bin blender is used in final stage of wet granulation process.

7.What are the factors that can affect the wet granulation process?

Several factors are responsible for the success of wet granulation process. During the process, if granules are over-wet, or not uniform granules formation, factors like granule size, uniformity, drying and others play a key role in these issues when controlled improperly. You should keep in mind the following below factors when handling the wet granulation process.

Mixing parameters

Mixing parameters include mixing speed and time. Mixing is done to remove clumps or distribute ingredients evenly. When you place a mixing time very short, components don’t mix together, uneven granules are formed. Sometimes, over mixing results in over dense of the granules.

Type of binder

Type of binder-Picture courtesy: ubuynepal.com

Different kinds of binders are available in market, as synthetic, or natural. Particles bind together due to binders. Do you know binders affect granules properties? Yes, granule size, stability or disintegration can be affected due to type of binder. A weak or less concentrated binder results in weak, poor dispersion and too much binder solution can cause hard granules production. It also reduces the flowability of granules.

Particles size and binding

Particle size and shape

Have you ever wondered powder particles size and shape affect binding? Small particles can easily bind together. This is because they have large surface area. Large particles don’t bind as effectively as small particles when get wet.

Granulation equipment

Different equipment used in wet granulation process. This equipment affects the granules formation; the size, density, shape and components distribution and mixing. Fluid bed machine responsible for drying granulators and high shear mixer is designed for uniform mixing.

Environmental conditions

Environmental conditions

Environmental conditions such as temperature, air, moisture or humidity can influence the process. These should be controlled effectively for better results. Issues like static electricity results in case of low humidity. When moisture level or humidity increase from certain point, over wetting or sticking of powder problems could be face. Temperature also affects the wet granulation process.

Drying process

Drying process

Another factor that affects wet granulation process is drying process. In this process, powder particles are wet and then dry. Do you know how these are dried? Pharmaceutical grade machines are used for drying; to remove moisture content. Under-drying results in poor compressibility while over drying results in granules brittle or hardness.

8.What is the difference between wet granulation process and dry granulation process?

Wet granulation process and dry granulation process

Granulation is mostly commonly used in industries where powder and granules are handled. There are two methods of granulation such as wet granulation process and dry granulation process. Some of the industries use dry powder process while some a wet granulation process. The choice depends on target flowability, use of binder, properties of drug etc.

| Difference | Wet granulation process | Dry granulation process |

| Definition | This is the process in which powder is wet using different ingredients such as binders, granulating fluid etc. Then passed through different stages to form granules. | In this process, powder is directly compressed into large slug, then passed through different steps to form granules. |

| Liquid usage | To bind the particles together, a liquid is used. This liquid is binder such as water or isopropyl alcohol to bind particles to form granules. | As you can guess the use of liquid from the above definition. No liquid is used in the process. This is dry process where powder is transformed into granules using force. |

| Use of equipment | Different equipment uses in the process. These are fluid bed dryer, granulator, high shear mixer etc. | In this process, equipment uses are different from wet granulation process. These are tablet press, roller compactor and other supporting instruments. |

| Ideal for | This process of granulation is ideal for powder that can tolerate moisture and heat and could not degrade easily when get wet or dried. | Moisture and temperature sensitive powder is handled by this granulation process when transformed into granules. |

| Granule properties | Granules formed as a result of this process are strong, uniform, accurate sizes and has better flow. | The result product(granules) of this process is less uniform and dense. |

| Example | Wet granules are used in making tablets, pill, capsules etc. | For temperature-moisture sensitive products such as aspirin, vitamins supplements etc., dry granulation process is used. |

9.What factors to be maintained to ensure batch consistency in wet granulation process?

As you have read above that there are factors that can compromise wet granulation process. but don’t worry- this guide of AIPAK will not discourage you. There are factors that should be maintained to ensure batch consistency, a high standard, stability and efficiency. Here you go.

Quality of raw material

Quality of raw material

A good quality of raw material such as active ingredients and powder matters a lot. It can contribute to uniform particle size, flowability, shape etc.

Quantity of granulating liquid

You should know that amount of granulating liquid you are using can have impact on granule formation. How? Using too much or less liquid is not ideal; results in over-wetting or under-wetting and entire batch will be affect. Before adding this liquid, measures its volume or use volume control instrument.

Binder concentration

Binder concentration

Another factor that you should ensure is binder quality. Use a binder that has same viscosity, concentration and type across the batch. Any change in binder can compromise the size, shape, strength of granule. Make sure binder is evenly mix and distribute in the batch.

Drying condition

For granules making, powder is first wet and then dry. But control dry time is necessary. To prevent the problems of over-drying and under-drying, ensure a uniform and consistent drying conditions and time. Set a drying time and install instrument to monitor moisture content. Temperature should be maintained throughout batch.

Real time check

Check granule size, shape, binding strength, and moisture level from time-to-time. If you feel any change in these key things, act wisely as soon as possible because it can reduce batch compromise.

Conclusion

To conclude guide, it must be noted that in this wet granulation process, powder is mixed with liquid to make it wet. But you may have seen that granules are in dry form. The wet granules are dried. Granules are used in various industrial products; thus, this process is used in many fields, ensures a standard compressibility and flowability. The process consists of various steps. Different equipment is used in the process. Each has its own role, adds a precision in wet granule formation. If you have any query, contact with us. Thanks!

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machin