What Do You Know About Powder Granulation Process?

What do you know about powder granulation process? For many people, powder granulation process refers to the primary process for many food, drink, medicines and so on. You may know the important position of powder granulation process as it takes the irreplaceable place for our daily life.

Here are all the things you should know about powder granulation process for your manufacturing. What industry may apply powder granulation process? What is the manufacturing process of powder granulation? How to choose your suitable powder granulation process? Here lets come to the reading!

1.What Is Powder Granulation And Powder Granulation Process?

Powder Granulation-Sourced:eirich

Powder granulation is the process which apply pressing technique and binding agents for the manufacturing of granules. Depends on the later application, there is the difference in granule size. Powder granulation is the common operation for many pharmaceutical industries.

Powder granulation process is the process which refers to the granulation of powder to granules. This process varied according to the different granulating technique. Powder granulation process can always make you the even and uniform granule. There are different technique and here welcome for the deep reading.

2.What Industry May Apply Powder Granulation Process?

What industry may apply powder granulation process? Here comes the industries which applied the powder granulation process frequently.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:sciencepharma

Powder granulation process makes the great work in pharmaceutical industry. This technique can reduce the risk of segregation and make the nice preparing for the raw materials. For active pharmaceutical ingredients, powder granulation process can make the even and predicable work here.

Food industry

Food Industry-Sourced:dacsa

In food industry, powder granulation process is frequently applied for the manufacturing of flavor extracts, instant blends and other powder products. This technique can make the sugar, soup, beverage and so on. Your powder granulation process makes your food products high qualified.

Chemical industry

Chemical Industry-Sourced:amazemet

There is also need in chemical industry for the alleviating of powder feature and quality for the better effect. Powder granulation process can benefit production in a comprehensive way. You may find the applying of powder granulation technique in fertilizer, agricultural products and so on.

Cosmetic industry

Cosmetic Industry-Sourced:hosokawa

In cosmetic industry, you may find the use of powder granulation process in powder granulating. For face powder, eye shadow, loose powder and various chemical products, powder granulation process makes nice work in the manufacturing of fine, even and uniform powder.

3.What Are The Types Of Powder GranulationProcess?

Here are different types of powder granulation process. And here are the typical type of powder granulation process.

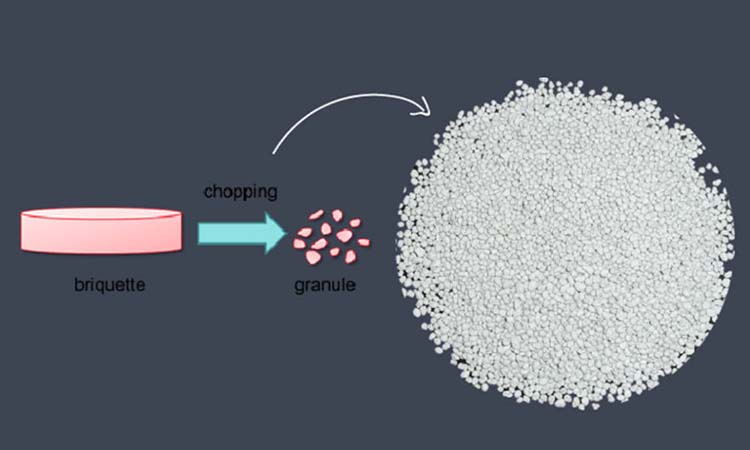

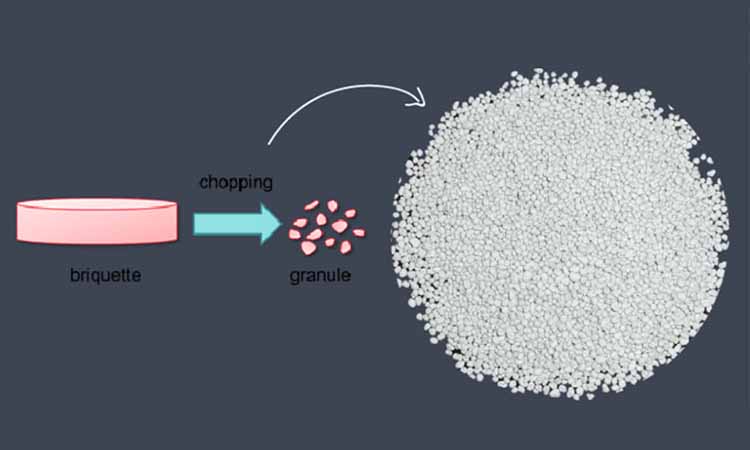

Dry granulation

Dry Granulation-Sourced:senieer

Dry granulation makes no applying of binding agent for the powder granulation process. It compacts the raw material with roller compactors and then break them into granules. Dry granulation is common technique in powder granulation process for its easy operation and low cost.

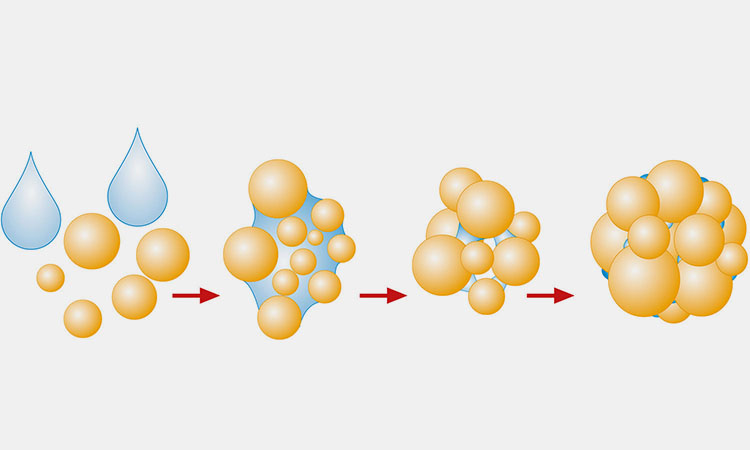

Wet granulation

Wet Granulation-Sourced:glatt

Wet granulation applies water or solution in the material mixture to agglomerate particle to the granule with ideal size and feature. It is a complex process and contains mixing, moistening, screening, drying, sizing and so on. There are high-shear granulation, low-shear granulation and fluid bed granulation for wet granulation.

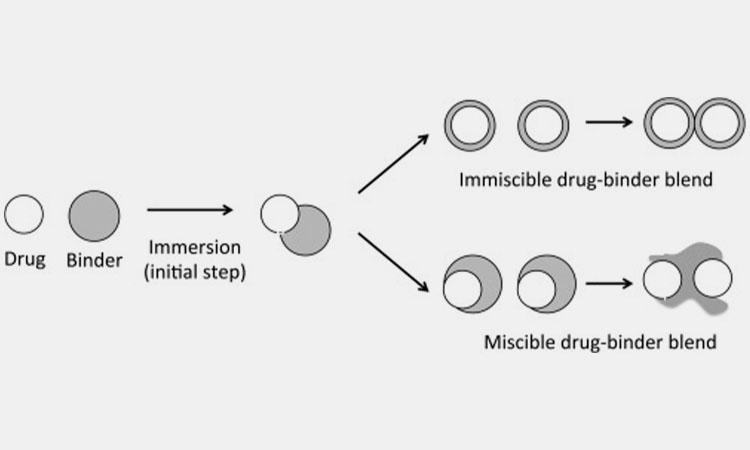

Melt granulation

Melt Granulation-Sourced:sciencedirect

Melt granulation can expand the size of your granules. It applies the binder for the binding of solid particle in formulation. You may find its applying in water-sensitive material. It takes less time and energy. For sustained-release dosage form using lipophilic polymers, it is also rather suitable.

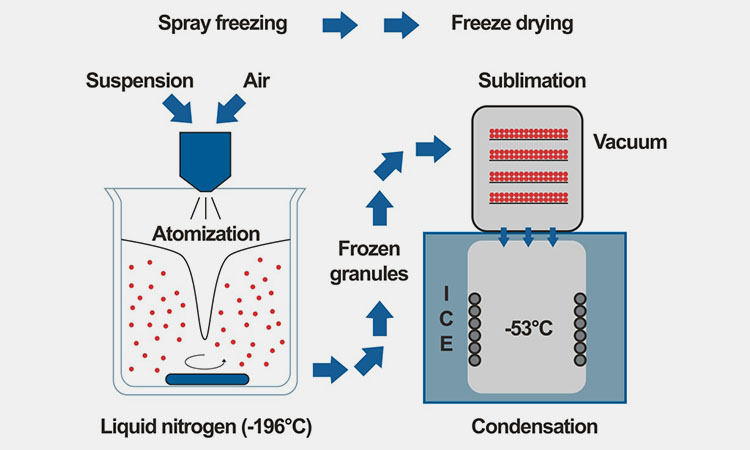

Freeze granulation

Freeze Granulation-Sourced:powderpro

Freeze granulation takes spraying droplets in liquid slurry or suspension into nitrogen. After the sudden freezing, you may then have the frozen droplets freeze-dried, the leaving ice sublimates are the dry granules. The freeze granulation is the highly efficient granulating methods.

4.What Is The Manufacturing Process Of Powder Granulation?

What is the manufacturing process of powder granulation? Here are the common manufacturing process of powder granulation.

Wet Granulation Process

Weighing and blending of raw materials

Powder Preparation-Sourced:refractorymetal

Powder preparation refers to the weighing and blending or raw material. The even mixing and blending of various powder material is the prove of your next granulation work and the prove of your even and uniform granule.

Preparation of binder solution

You should make the great preparation of binder solution. There are different binder type and for different granule type, you should apply different binder solution. For some binder solution, you should take time for the formulation of different binder type for your later granule work.

Wet massing

Wet massing is the important step of wet granulation. There you may get the raw powder material connected with the liquid solution for the mass type. You may find the fluid bed dryer, high shear granulator mixer and so on for the wet massing work.

Wet screening

Wet Screening-Sourced:quadro-mpt

The well massed granules should be milled and screened for the better appearance and better forming work for the later tablet manufacturing work. Screening and milling can be put together for the better granule feature forming.

Drying

Drying is usually applied in wet granulation for the removing of liquid binder. The reducing of moisture in your granule makes you the dry granule. And this is the essential step for your wet granulation. And for dry granulation and other granulation, this step is saved.

Dry milling

Dry Milling-Sourced:quadro-mpt

For the more even and uniform size and feature, you should make the suitable milling and sizing for your dried granules. This is the prove of your granule with great appearance and even feature. You should make the careful milling and screening for your dried granules.

Final blending

Your work of wet granulation can then be finally blended for the later applying of food, medicine or other products manufacturing. Final blending is the last step of your wet granulation process.

Dry Granulation Process

Weighing and blending of powders

Weighing And Blending Of Powders-Sourced:medicalexpo

For dry granulation process, you should make the weighing and blending of powders too. Here you should get the precise weighing of powder and comprehensive blending of your various powder material. This is the important step of your dry granulation process.

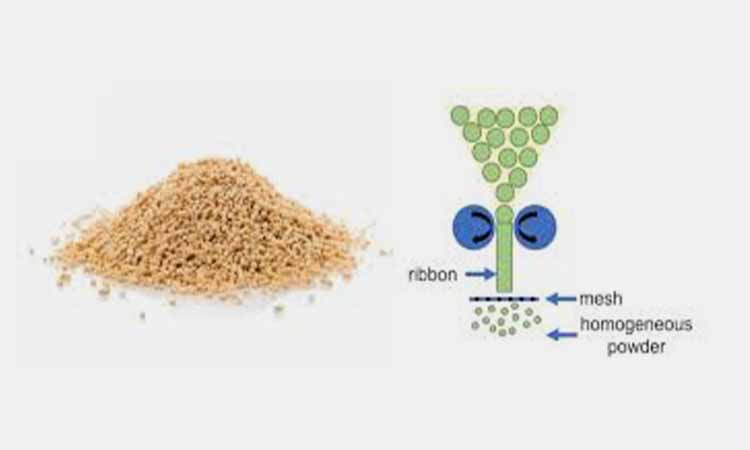

Compaction

Compaction-Sourced:senieer

Compaction is the step which decides the compressibility of your granule in your dry granulation process. You may apply the roller compactor for the compaction of your various particle products. And you may adjust the roller compactor for different parameter for your compressing.

Milling

Milling-Sourced:lkmixer

Milling is also the important step for your powder granulation process. It can make the nice appearance of your dry granulation products. The milling process can corporate with screening process for the production of the even and uniform powder type.

Final blending

Final blending makes the comprehensive blending of granule and other material. It is the essential step for the prove of uniformity, great flow and other features. The final blending is so important for the final quality prove.

Compression or filling

Compression Or Filling-Sourced:trustar-pharma

Compression and filling is the later manufacturing of your dry granulation products. It is the applying of your dry granulation products to other manufacturing fields. You may have your compressing and filling for various steps here.

5.What Are The Machines Used For Powder Granulation Process?

What are the machines used for powder granulation process? Here are the machines used for powder granulation process.

High shear granulator

AIPAK High Shear Granulator

High shear granulator makes the high speed granulation process which makes the rapid mixing and intense shearing work. For high-throughput production, robust materials, hard-to-process materials, high shear granulator may make the efficient granulating for your products.

Fluid bed dryer

AIPAK Fluid Bed Dryer

Fluid bed dryer is the equipment which contacts the fine solids with gas and makes the particle in specific gas velocity. It is versatile and can make granulation, drying powder and coating. The removing of the excess moisture can make your granule qualified.

Roller compactor

AIPAK Roller Compactor

Roller compactor makes the irreplaceable work for your powder granulation process. The consistent conveying of powder to two roller make the even slugging of it. The compacting work will then make the particle into ribbon or small pellets. Roller compactor can deal with your various active pharmaceutical ingredients and excipients.

Cone mill

AIPAK Come Miller

Cone miller is applied for the milling of granule and powder. You may adjust parameter of granule size or feature and then begin the milling work. The products from this machine is even and uniform. You may always get your efficient work from AIPAK miller.

Blender

AIPAK Blender

Blender is the essential equipment for powder granulation process. It can make the even and uniform mixing of the raw powder material which is the preparation of your next granulating. There are various blender machine like V blender, ribbon blender, bin blender and so on for the comprehensive mixing for your powder granulation process.

Tablet press machine

AIPAK Tablet Press Machine

Tablet press machine is the machine which make the next step for compressing or filling work for your medicine, food or other products type. You may get the efficient, excellent and high qualified tablet press machine here from AIPAK.

6.What Is The DisadvantageOf Powder Granulation Process?

Powder granulation process isn’t perfect. Here are also some disadvantages. Let us come to check it.

Great cost

Great Cost-Sourced:freshbooks

For your powder granulation process, there are various cost for the smooth and easy operation. And the cost for the purchase of machine and maintaining of machine is big. The great cost is one outstanding disadvantage of powder granulation process.

Labor training

Labor Training-Sourced:shutterstock

Machines applied for powder granulation process is complicated. And here are the need for you to make labor training. For compact roller, fluid bed dryer, high shear granulation mixer and so on, the operator should get comprehensively training for the nice work.

Segregation potential

There is potential of particle segregation in the process of powder granulation. It requires strict control for powder components and operating manner for the even and uniform granule manufacturing. The segregation makes the bad influence for your later work in powder granulation process.

Moisture and heat sensitivity

There are the special granulation technique for your moisture and heat sensitive products. But the adding of liquid of wet granulation can of course make the heat in granulation process and make the trouble for your sensitive products.

7.What Decide The Characteristic Of Particle From Powder Granulation Process?

What decide the characteristic of particle from powder granulation process. Here are the characteristic of particle in powder granulation process.

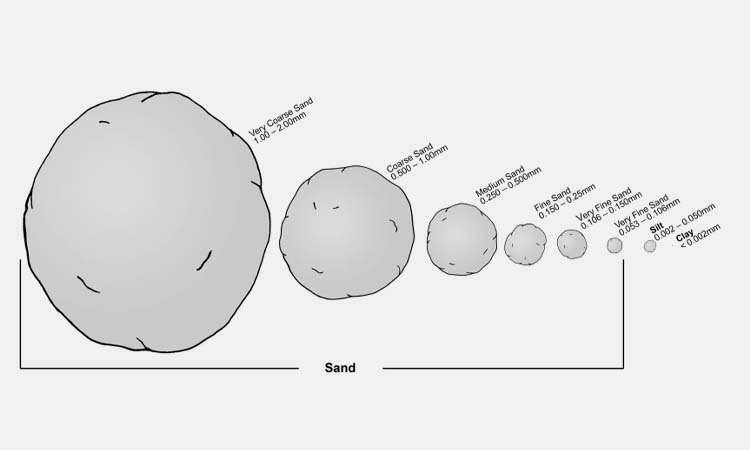

Particle size

Particle Size-Sourced:dcsturf

The size of drug and excipients make great influence for characteristic of particle from powder granulation process. Of course, the larger particle size makes the larger granule size. And you may adjust the size according to your request on granule.

Binder type

The binder added for your powder granulation process makes also affect for your characteristic of your powder granulation process. The type, concentration and volume of your binder or solvents make your granules varied. Binder type selection is also the important thing in your powder granulating process.

Granulating time

Granulating Time-Sourced:horobox

Granulating time affect your granule particles also. For some material, there needs the long granulating time and for other, there is no such need. Your granulating time affects the quality and feature of your powder granulating process. You should pay attention to granulating time.

Granulator type

There are different granulation process and different granulating technique applied. Granulator type refers to the granulator manner in some way. The different granulator manner makes different affect for your granule products from powder granulating process,

Drying time

Do you know that drying time makes different affect for your powder granulating process. Temperature and time applied in drying time affect your granule of powder granulating process.

8.Why Powder Granulating Process Important For Tablet Manufacturing?

Powder granulating process is important for tablet manufacturing. Do you know the reason? Here you may find the reasons.

Better flow

Better Flow-Sourced:granutools

Your granule will have better flow after the powder granulation process as granule has better flow and more predicable compared with powder. The better flow makes great affect for your tablet manufacturing process and your tablet quality. With powder granulation process, you will get the great flow for your tablet manufacturing.

Even API

Even API-Sourced:sinay

Granulation process will help make the even distribution of active pharmaceutical ingredients in your granule. This is rather important for the ensuring of the precise dosage of your tablets. And for the improvement of your medicine safety and effectiveness, even API is also rather important.

Improve tablet quality

Improve Tablet Quality-Sourced:matconibc

You may have your tablet quality improved with the applying of granule. It can improve the hardness of your tablets and improve the appearance of your tablets. And the granule can also prove the nice shape of your tablets. You may improve the tablet quality from powder granulation system here.

Avoid pollution

Granulation process can reduce the production of powder or dust. This can benefit the safety of operator and can also reduce the risk of cross-contamination in the process of pharmaceutical manufacturing.

9.Why You Should Apply Granule Rather Than Powder For Your Tablet Manufacturing?

Why you should apply granule rather than powder for your tablet manufacturing? Here are the reasons you cannot ignore.

Flow

Flow-Sourced:azom

Granule has better flow compared with particle. The better flow make the greater and easier manufacturing work in tablet manufacturing process. Your tablet can have the weight and strength proved with great flow work.

Compressibility

Compressibility is also the pursuit of high qualified tablets. The great compressibility refers to the suitable hardness of your tablets products. And the suitable hardness can make your tablet products high qualified.

Uniformity

Uniformity-Sourced:jenike

Granule can improve the uniformity of your products and make the tablet products of high quality with the risk of segregation reduced. The tablet products with higher quality comes from the even and uniform granule distribution.

10.How To Choose Your Suitable Powder Granulation Process?

How to choose your suitable powder granulation process? You should conform the below tips for the selection of your suitable powder granulation process.

According to material

According To Material-Sourced:processingmagazine

Different material applied different powder granulation process. For the material with poor compressible and low flow, you should apply wet granulation. For material which is sensitive to heat and moisture, you may apply dry granulation which has the liquid saved in the compressing work. You should also take excipients, particle feature and so on into consideration.

According to technique

There are different granulation technique. And different technique has different feature. You may get the one suits your material and business most. The advanced granulation technique can help you make your fabulous granulation once you get the suitable one.

According to production need

According To Production Need-Sourced:marketing91

How about your production need? You should take the consideration of your production scale, production size, production throughput, scalability and such factors for the choose of your suitable powder granulation process.

According to cost

According To Cost-Sourced:aspireapp

You should consider the cost for your powder granulation process seriously. The cost may cover purchase cost, maintaining cost and various cost for your smooth granulating process. There are always equipment with more excellent work, and you should consider the powder granulation process in your budget.

Conclusion

What do you know about powder granulation process? The deeper knowing of powder granulation process can help you a lot in your various medicine manufacturing. You should make clear the powder granulation process for your better later work. If you have any problem or question, contact AIPAK now.

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machin