Induction Sealing Machine: The Complete Buying Guide in 2025

Do you know induction sealing has created a hermetic seal that prevents your products from leaking at the closure?

Apart from that , an airtight seal will also protect your products from exposure to air, and ensure your product freshness.

Hearing so much benefits of this induction sealing ,do you want to have a try?

Today I am going to guide you through every aspect of this induction sealing machine from benefits,application,classification,working principle and FAQ about this machinery.

Let’s drive to the subject of the topic directly.

1.What is Induction Sealing?

Induction sealing-photo credit: sigmacapseal.com

Packing any preparation is a very crucial step for its safe transport and storage. In pharmaceutical preparation, it plays an important role in maintaining the efficacy of the drug throughout its shelf life.

Introduction

Generally speaking, induction sealing involves the bonding of thermoplastic materials by the application of induction heating.

Induction sealing is a process that involves the sealing of a capped bottle. It involves the creation of hermetic sealing on a bottle after it has been filled and capped. It involves the application of eddy currents.

It is important to know that the container or the contents of the container are not harmed by the heat produced due to the eddy currents.

2.What is the Best Induction Sealing Materials?

Various induction sealing products

While making any choice, the most important thing to be taken into consideration is compatibility.

The choice of the induction sealing material also depends upon its compatibility with the requirements. The choice of the induction sealing materials is different for;

- Welded foil seals

- Peelable foil seals

- Single piece liners

- 2-piece liners

Welded Foil Seals

It is used in that market where the requirements are tamper evidence or anti-counterfeiting. The distinguishing feature of this kind of seal is that it requires the puncturing or cutting of the foil to gain access to the container.

The bonding between the lip of the container and the foil is made so strong that it cannot be opened without damaging the neck of the container or leaving behind a bit of residue of the foil.

This strong bonding is done so that the customer gets satisfied while purchasing the product.

Pharmaceutical preparations, chemicals, pesticides, insecticides, and motor oils are some of the examples in which the welded foil seals are used.

Peelable Foil Seals

Unlike the Welded foil seals, the Peelable foil seals can be comfortably and neatly removed from the neck of the container without leaving any residue on the neck.

This type of seal generally requires a tab that can be used to grip for the removal of the seal from the neck of the container.

Peelable foil seals have a wide range of applications including food, beverage, personal care products, and cosmetics.

However, some challenges appear during this type of sealing which should be taken into consideration and overcome during the application of this type of sealing.

These challenges may include interference with the cap and heat-loss into the tab.

Single Piece Liners

There is no re-seal material present in a single piece liner and it is transferred to the container from the cap as it is.

The single-piece liners should have adequate structure and sufficient rigidity that is enough for retaining them inside the cap throughout the supply chain, beginning from the insertion into the cap to the point where they are applied to the container.

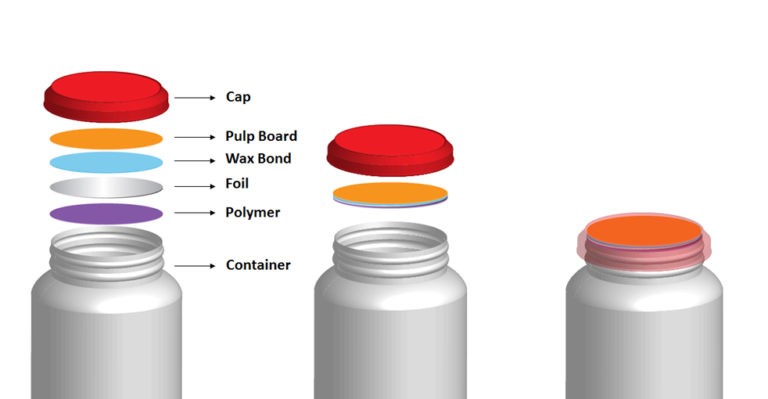

2-Piece Liners

They generally have a re-seal material (Typically, a pulp board or a high-temperature resistant foam).

The re-seal material is bonded to the foil seal through a low-temperature medium (usually wax is used for this purpose).

The foil is bound to the container by the heat seal layer.

The re-seal liner is released from the foil by the melting of the low-temperature medium. On removing the cap, the foil gets sealed on the container while the re-seal remains in the cap.

Basic Requirement

Irrespective of the type of seal you are using, the basic and most common requirement is the compatibility of the heat-seal layer with the material of the container.

A suitable material should be identified according to the container material. After you have identified the suitable material, it should be tested for its compatibility such as there is a test performed to confirm that the product-contact issues are not present.

Sometimes, a problem arises because of the reaction of the product with the aluminum layer present in the sealing material.

This can lead to the degradation of the seal or the breakdown of the bond between the container and the foil.

Now a question arises in your mind: how can you overcome this problem?

You can overcome this problem by introducing the barrier layers between the aluminum foil and the heat seal. However, it is strongly recommended that you should test the compatibility of the actual product, the container, and the foil you are going to use in the process to avoid any problem.

3.Why should you Invest in Induction Sealing?

Before investing in anything, you should make sure that the thing you are going to invest in is worth it.

The induction sealing process has so many advantages that can convince you to invest in that. Some of them are described below

Freshness Preservation

Freshness of the product matter-photo credit:Geo-fresh.com

The unwanted microbes or pollutants are kept away from the food inside the container by induction sealing, thus preserving the freshness and may enhance the shelf-life of certain products.

Prevention of Leakage

Induction sealing can be applied to the container to make it leak-proof. The absence of a proper seal would lead to a lot of spillages, causing financial loss and may cause a threat to marine life if hazardous chemicals get spilled in the sea during shipment.

Tamper Evidence

According to the regulations of the FDA, the packing of material must be Tamper-resistant. Most importantly, the packing of pharmaceutical products is of great concern.

However, the induction sealing process meets or maybe sometimes exceeds the regulations imposed by FDA.

Pilferage Preservation

Unnecessary interference of the products is made very difficult due to induction sealing. The pharmaceutical companies use the inner seal that will leave a foil residue on the bottles. However, the food companies prefer using a seal that will not leave any residue on the bottle.

Enhanced Durability

Properly sealed containers do not allow any contaminants to enter the container, thus increasing the shelf life of the product.

Customer Satisfaction

A properly cap-sealed container creates an impression of credibility on the mind of the customer, assuring him the overall product quality.

4.Which Industries should Induction Sealing are widely used?

Induction sealing is a process that finds application in almost any kind of packing. It protects the contents of the container and so it is widely used. Nowadays, it is used in almost all industries.

Some industries that use induction sealing are the pharmaceutical industry, nutraceutical industry, food and dairy industry, beverage industry, cosmetics, health & beauty industry, chemical industry, agricultural industry, animal care and medicines industry, goods supplier industry, pastes industry, paints industry, home remodeling products, musical instrument supplier industry, dental, personal pleasure products, manufacturing shop supplier industry and school supply products industry, etc.

5.What is the History of Induction Sealing?

Jack Palmer, the inventor of induction sealing -photo credit: wikipedia.org

Before talking about the present scope and applications of anything, we must know its history, from where it all started and how it came to its present form.

Looking into the history of induction sealing, we get to know that from 1957 to 1958, the real techniques and basics of induction sealing was drawn up and aroused by that time engineer Jack palmer (with FR corporation at Bronx, NY) for solving the problem of leakage of liquid from their packaging during their shipment.

In 1960, the United States Patent was granted to an engineer Jack Palmer, in which his ideas and techniques of induction sealing were broadcasted. In the mid-1960s, Induction sealing was internationally accepted and globally used. In 1973, the solid-state cap sealer was first launched.

For induction cap sealing, the air-cooled power supply was firstly transistorized in 1983.

The year 1985 marked the debut of the technology of Universal coil. Seven years later, in 1992, an IGBT -based sealer that was water-cooled, was inaugurated.

The year 1997 marked the launch of small and support free Waterless cap sealers comparatively.

The latest advancement in this regard was in the year 2004 when the system of 6kiloWatt was introduced to the world.

6.What is Induction Sealing Machine?

AIPAK Induction Sealing Machine

Induction sealing machine is a machine that is used for the sealing of non-metallic containers (maybe plastic or glass containers) by the application of the technique of induction heating.

The induction sealing machine has many different uses but its most common application is in cap sealing.

This machine brings eddy currents into the application An electrical field is created by the sealing head of the induction sealing machine heating up the foil liner on the inside of the cap.

The hot foil causes melting of the polymer coating present on the inner-seal. Coupling of the heat with the pressure generated by the cap leads to the formation of a hermetic seal.

7.How Many Types of Induction Sealing Machines are there?

AIPAK Automatic induction sealing machine

Induction sealing has a vast scope around the world and the process is used in many different industries and so different types of induction sealing machines are required by manufacturers. There are many different types of induction sealing machines.

- Automatic Induction Sealing Machine

By the application of the advanced technology it uses, an automatic induction sealing machine is a very fast and efficient machine. Automatic induction sealing machines provide brilliant results and definitive performance.

Some advantages of automatic induction sealing machines are that it is highly efficient (uses less energy and provides more output), can be used for both large and small scale outputs and can be adjusted easily according to the need of the user.

The disadvantage of an automatic induction sealing machine is that it is very expensive as compared to other induction sealing machines.

- Semi-automatic Induction Sealing Machine

Semi-automatic and automatic induction sealing machine

Semi-automatic and automatic induction sealing machines are almost similar and just differ in the type of electronic grade used for the machine.

Semi-automatic induction sealing machine uses a semi-automatic type of automated grade while an automatic induction sealing machine uses the automatic type.

Some advantages of semi-automatic induction sealing machines are that it can be applied for small to very large operations, is very easy to install and use, does not require much maintenance, is very fast and has a vast application in different industries.

The disadvantages include that it is not suitable for use with metallic caps and bottles and it does not run smoothly in harsh conditions like high pH or humidity.

- Manual Induction Sealing Machine

Manual induction sealing machine

It is a manually driven induction sealing machine that is mainly used for small scale input and output.

Some advantages of manual induction sealing machines are that it is cheaper than others, has a considerable speed of sealing around 360 containers an hour and it is very suitable for small scale induction sealing.

Some disadvantages of manual induction sealing machines are that it is not suitable for extensive induction sealing and it is not applicable for metallic bottleneck containers.

8.What are the Advantages of Induction Sealing Machine?

In the modern era, many developments and inventions have made our lives easier. There is a solution to every problem that arises.

Likewise, the invention of induction sealing machines has proved to be very beneficial in the sealing of bottles and other containers. Some advantages of induction sealing machines are:

- They have vast applications in many different kinds of industries like the pharmaceutical industry, food and dairy industry, beverage industry, etc.

- They provide fast and continuous sealing of the containers

- They are available in different forms and can be customized according to the needs.

- Most of them are user-friendly and easy to install.

- They can be applied for small to very large operations.

9.Are there Any Drawbacks of Induction Sealing Machine?

Semi-automatic induction sealing machine

It is a fact that anything that has advantages, has disadvantages as well. Some disadvantages of induction sealing machines are:

- They cannot be applied for metallic caps

- They do not run smoothly in harsh conditions like high pH or humidity

- Some of the induction sealing machines (like automatic induction sealing machines) are very expensive.

10.What are the Main Components of Induction Sealing Machine?

The induction sealing machines have many varieties depending upon the operation they are desired to perform. However, the basic components are the same for all kinds of induction sealing machines. Some basic components are

- Mains power supply

- Sealing head

- Inductive unit

- PLC

- Pneumatics etc.

However, the main components are only two

- Mains power supply

- Sealing head

Mains power supply

The electric power is transferred to an inverter from the wall socket. The incoming power is then regulated and transformed into the form that is appropriate for that particular induction sealing machine.

For different types of induction sealing machines, the energy demand varies. For example, manual induction sealing machines may require a power supply of around 1kW while the automatic one may require power up to 6kW.

Induction sealing machine`s power rating should be confirmed as it tells whether it is suitable for the required operation or not.

Sealing head

Sealing Head

Based on the number of containers to be sealed, the suitable type of sealing head may vary from vast to small. In the inductive head, the inductive coil emits the eddy current by getting the power supply from the mains power supply.

An electrical field is created by the sealing head of the induction sealer heating up the foil.

The coating of the polymer on the inner-seal is melted by the hot foil. Then due to pressure a proper sealing take place.

11.How does Induction Sealing Machine Work?

Nevertheless, the sealing process varies for cap induction sealing and direct induction sealing.

1- For cap sealing, caps are required with also aluminum liner.

2- The bottles are then closed and transmitted to the sealing head by the conveyor. An electrical field is created by the induction sealing machine`s sealing head of, heating up the foil liner on the same side of the cap.

3- Polymer coating on the inner-seal has to be melted by the hot foil. It results into better sealing.

4- Capless induction sealing applies an airtight seal directly to the container unlike other kinds of induction sealing.

5- This type of induction sealing does not require the usual requirement of a screw thread or a cap.

6- In contrast to conventional induction sealing, this form of induction sealing is somehow more complicated. First of all, the foil must be placed in a reel.

7- After the foil has been placed, it is pressed by the sealing head, initiating the process of induction sealing that terminates by adhering the seal to the container.

12.What Factors will Affect the Induction Sealing Efficiency?

To understand a steady item seal these defined items need to match well.

- Bottles

- Cap conclusion

- Lining material

- Machine Type

Bottles

Most of the enlistment fixed bottles are either plastic or glass.

Cap Closure

The cap closing needs to have a level inside the zone to hold an acceptance liner.

Screw-on covers consider a more extensive scope of hard and delicate cap lining materials.

Snap-on covers are by and large more fit to milder cap lining material.

In the event that utilizing a two-section enlistment fixing material where a foil isolates from a support material, the cap has to have highlights that hold the material that is backing when the two-section acceptance material isolates as the bottle is opened.

Coating Materials

The assurance of the suitable acceptance seal material is subject to the accompanying:

- What is bottle made of ?

- Item content

- Span of utilization

- Cap Tolerance any Type

The technique for which the coating material will be embedded into the cap

Induction Sealer

Choosing the right machine for your needs is an important task. You have to have the right machine, at the right time, and the right place for the smooth running of the process of induction sealing machine.

13.What are the Differences Between Induction Sealing and Other Types of Sealing?

Induction Sealing vs. other Types of Sealing

Shrink Wrapping

Other than induction sealing other methods are used too.

This what we gonna look here:

Heat Sealing

| Conduction Sealing | Shrink Wrapping | Heat Sealing |

| Conduction fixing is the utilization of a conduction sealer to seal the compartments airtight.

The method includes passing the container under a hot heated head. Which helps foil sealing. It is contacting process, not like induction sealing. The heated head required some time to heat up. Opposite to the induction sealing here sensor needs to activate. The main role in induction sealer is related to the electromagnetic. Whereas in the conduct sealing foil sticks with more heat. |

It is pretty simple compared with induction sealing.

This process is about covering the bottle or container with a wrap of shrink. Afterward, heat is applied and it gives shape to the product for sealing. A gun is used for blowing heat like an air dryer. Different types of thermoplastics can be used in this process. Only 2 things are required in that. |

Compared with induction sealing here pressure and heat are used to seal two thermoplastic materials.

Lid or Cap is not mandatory in this method. It is in this way not quite the same as the enlistment fixing where you may require a top/cap or liner. It is also a contact process nit like induction sealing. It is just like conducting sealing. It is also a bit time taking process because the machine needs to reach a specific temperature. Likewise, it has a few limitations since you need to lead change a couple of parts and plans. The heat sealing machine does not offer different sizes and shapes sealing. |

14.What is the Special Usage of Induction Sealing to Pharmaceutical Industry?

There are many possible reasons why the pharmaceutical industry is so linked with the induction sealing machine and it is considered as specially made for industrial usages.

Tamper evidence

Tamper evidence portrays a gadget or cycle that makes unapproved admittance to the secured object handily identified. Seals, markings, or different methods.

Leak prevention

It is the best solution for the liquid as well as the powder spillage or leakage of the medication.

Freshness Retention

With such sealing, it keeps the tablets and capsules fresh and does not let any humidity in.

Protection against package pilferage

Bundle pilferage is the robbery of part of the substance of a bundle. It might likewise incorporate stealing of the substance yet leaving the bundle, maybe resealed with bogus substance.

With the induction sealing type, it does not affect these things too.

Sustainability

One more reason for being better than many other types is sustainability. The production process is sustainable. Induction sealing machines showcase the same level of efficiency each time when it is work over that.

Production Speed

The production speed of the induction sealing machine is faster than all available types of sealing machines in the business of drugs. That is why pharmacists always prefer this machine over every other.

15.What Quality Standard should Induction Sealing Machine Conform to?

Quality standards provide requirements and guidelines that ensure the right working of a certain product or a process. The basic requirements an aerosol filling machine is required to fulfill include:

- Current Good Manufacturing Practices Quality Standards, cGMP

It ensures continuous production of high-quality products. The word current refers to the most recent standards.

- International Standards Organization Quality Standards, ISO

These are international standards for quality control.

- Food and Drugs Admin Quality Standards, FDA

These standards ensure public health protection

- Electronics Quality Standards CE

This guarantees that the product compliances with the EU standards for the protection of health and the environment.

The product should be made up of high-quality stainless steel, it must be safe and easy to operate. In short, the product must be user-friendly.

16.How to Troubleshoot Common Problems of Induction Sealing Machines?

Induction sealing machine

Like any other machine, an induction sealing machine can face different problems during its process of filling.

The most important requirement of the induction sealing machine is its smooth and efficient working.

Most of the problems arise during the process of sealing. Some of the common problems faced by induction sealing machines, along with their solutions are listed below;

Improper Sealing by the Induction Sealing Machine

This problem may occur if the duration of heating of the inductive head is shorter than the required duration or if the inductive head of the induction sealing machine is damaged. This can be solved by increasing the heating period or replacing the damaged inductive head with a new one.

Failure of the machine to operate even after the Hand Inductive Head Button is pressed

This problem may arise due to some fault in the switch of the button, poorly connected power plug, or damaged inductive head of the induction sealing machine. The possible solution to this problem can include replacing the faulty switch with a new one, properly reconnecting the plug, and in case of a damaged inductive head, replacing it with a better one.

Folding and Melting of the Sealing Film

Folding or melting of the sealing film can occur if the seal is exposed to inductive heat for a longer duration. However, by proper regulation of the heating period, this problem can be avoided.

Burning of the Cardboard Liner

The slow movement of the conveyor or surplus supply of power can lead to the burning of the cardboard liner. This problem can be avoided by adjusting the speed of the conveyor and adjusting the power supply properly.

Very tight closing of the caps

This may occur if the coil is placed too high and adjusting the height of the coil can overcome this problem.

Inconsistent Results

Sometimes the induction sealing machine starts giving inconsistent results of the induction sealing operation and this may occur if the cap torque is disturbed. Adjusting the torque of the caps makes the results of the induction sealing machine consistent again.

Insufficient Power of Sealing

The sealing power becomes insufficient if the guide rails (under the sealing head of the induction sealing machine) are metallic. To avoid this problem, you should make sure that the guide rails are not metallic.

17.How to Choose the Most Suitable Induction Sealing Machine?

Before choosing a machine, you should make sure that the machine fulfills all your requirements and is efficient enough to give you the desired yield. While looking for an induction sealing machine, you should consider the following aspects.

- Decide if you want an inner seal or not

The addition of an inner seal provides added qualities to your packaging and increases the shelf life of the products even more.

- Beware of Fraud

You should look for the companies` reputation before buying an induction sealing machine. If the seller is dubious, you should not buy a machine from that seller. Buying an induction sealing machine from such a seller is surely going to cause you financial loss.

- Make Sure the Company has Official Website

An official website is often a guarantee that the company, from which you are considering buying an induction sealing machine, is authentic and you can later claim any fault that arises in the machine.

- Evaluate the Quality and Performance of the Machine

You should make sure that the induction sealing machine is efficient enough to fulfill the demands of your production unit. You must prefer buying that machine which is flexible enough to seal containers of different types and different sizes.

- Check for the Availability of Spare Parts

You should make sure that the spare parts of the induction sealing machine you are going to buy are easily available so you do not have to face any problem in finding them when you need them.

- Look for the Best Price

You should survey the market and try finding the best machine at a reasonable price. This will save money for you without compromising on the quality of the induction sealing machine.

- Shipping Charges

For shipment of your machine, you should be looking for a service that is safe and reasonable at the same time. This will also save money for you.

- In-Time Shipping

It is very important that you get your machine shipped in the given time so you do not have to wait for too long and you would not get late in completing your required task.

18.What is the Future Prospect of Induction Sealing Machine?

This is where we will be explained what holds the future prospect of the induction sealing machine.

It is expected that by 2026, the international market for induction sealing machines will grow near to 140 million USD and also increase between this time too.

It has also noticed and study, in the coming time pharmaceutical industry, will be in the dire need of machine.

Other than that, the Induction sealing machine will grow in terms of the Application as well as the Types of machine.

Tablet Counting Line Related Products

Tablet Counting Line Related Posts

Tablet Counting Line Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours