20 Basic Tablet Counting Machine Parts You Should Know

Before selecting a tablet counting machine for your business, it is better to know about the tablet counting machine and its main parts. After knowing about the main parts and how they work, you would have a deep and better understanding of how to choose and tell the right tablet counting machine for your business.

Basic Tablet Counting Machine Parts You Should Know-AIPAK

Following this post "20 Basic Tablet Counting Machine Parts You Should Know," you will choose the right tablet counting machine for your business and learn how to use it. This can provide good help for your future business development. Take a look now!

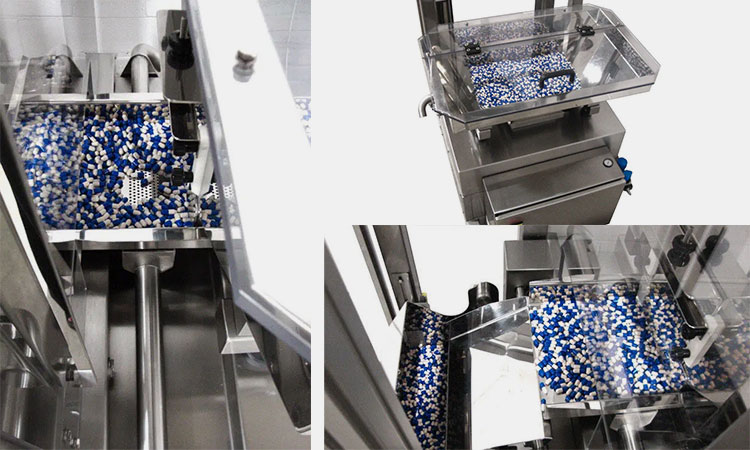

1. Hopper

Hopper-sourced: bellatrx

The hopper is a large container used to store large quantities of tablets and capsules before feeding them into the machine. This part is usually made of stainless steel or FDA-compliant materials.

You can apply this part to increase productivity by expanding the number of counts in a given time. The hopper gate adopts a closed design to reduce dust pollution on the cylinder and extend the service life of the cylinder.

2. Vibratory Feeder

Vibratory Feeder-sourced:directindustry

The vibrating feeder evenly distributes tablets and capsules from the hopper to the counting channel. It operates using controlled vibration to minimize the risk of product damage and ensure smooth flow.

When you are learning this part you will find that it can automatically dispense medicine in two stages, drip medicine evenly and count tablets accurately. The vibrating feeder is suitable for various single-bottle medicines and tablet types and can be used by changing the type mold without changing any type.

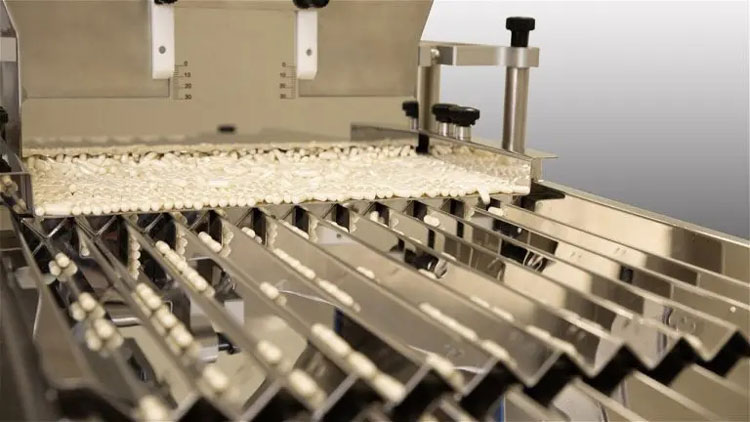

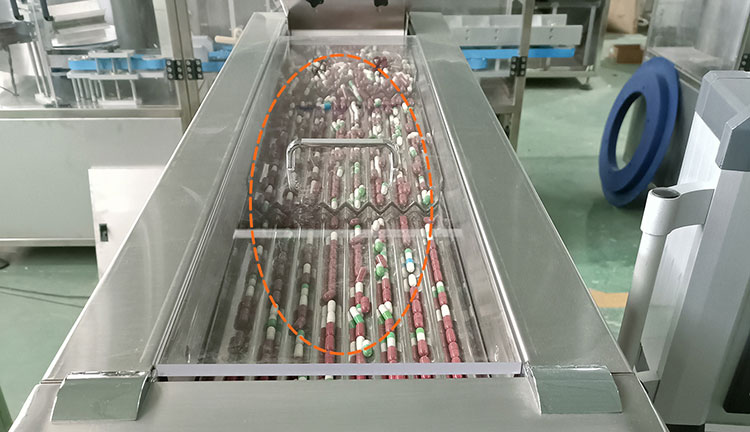

3. Three-stage Vibrating Counting Channels

Three-stage Vibrating Counting Channels-AIPAK

The three-stage vibrating counting channels are one of the best parts that you can imagine on the tablet counting machine.

The counting lane is a series of parallel tracks that transport tablets and capsules to the optical sensor. Each lane is designed to accommodate tablets or capsules of a specific size or shape, allowing multiple product types to be processed simultaneously.

With a three-stage electromagnetic vibrator with variable and adjustable frequencies, tablets and capsules can be counted individually, and have high object speed. These machines use multiple lanes to process various tablet and capsule sizes simultaneously, thereby increasing the efficiency and productivity of the packaging process.

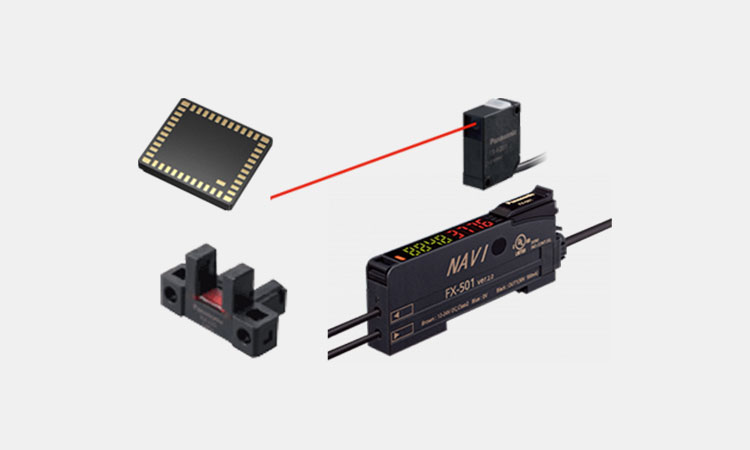

4. Photoelectric Eye and Optical Sensors

Photoelectric Eye and Optical Sensors-sourced: industrial.panasonic

Optical sensors are responsible for the accurate counting of tablets and capsules passing through the channel. Once you have recognized this part you may know these sensors use advanced technologies such as infrared beams, lasers, and high-resolution vision cameras to accurately and quickly detect and count each product.

Using the company's original high-tech dust-proof photoelectric detection technology, tablets (including special-shaped tablets), capsules, soft capsules (transparent, opaque), and pills can be counted and bottled.

5. Dispensing Mechanism

Dispensing Mechanism-sourced:altrimex

For the dispensing mechanism part, you can realize that once the tablets and capsules are counted, the dispensing mechanism will release the correct quantity into the container. The mechanism typically uses pneumatic actuators or servo motors to ensure accuracy and repeatability.

These machines use cutting-edge technology such as optical sensors, vibrating feeders, and programmable logic controllers (PLCs) to ensure precise counting and dispensing. After knowing that part, you can understand the tablet counting machine and its working principles.

6. Infrared Scanning System

Infrared Scanning System-AIPAK

You can connect the infrared scanning system with the electric eye part. Using an infrared scanning system, the counting accuracy is >99.98%, and the powerful photoelectric detection accuracy is >99.7%. Pass the detected and recorded data to the intelligent processor.

7. Bottling Hopper

Bottling Hopper-AIPAK

There is a vibration device in the hopper for you to avoid clogging the bottleneck and ensure accurate counting. The bottle conveyor is a conveyor belt type, which is reserved for your later connection interfaces and can quickly connect auxiliary equipment (bottle unscrambler, capping machine, etc.).

The light control technology automatically detects that there is no bottle or there is a bottle and will automatically alarm, minimizing the waste of capsules. The special structure of the hopper mouth prevents materials from clogging, and small-mouth bottles can be quickly filled.

8. Detection Modular

Detection Modular-sourced: richpacking020

You can adopt the detection modular with variable frequency speed regulation. The soft start speed regulation is sensitive, reliable, and stable, and can withstand large starting torque.

Adopting dust-proof photoelectric sensor technology, this part can work stably under high dust conditions. All molds adopt a cylindrical pin positioning design. It only takes 5 minutes to replace the mold and install it in place, which is convenient and fast.

9. Cylinder Modular

Cylinder Modular-sourced: kenweigh

You can add a cylinder sensor and check its response cycle for your tablet counting machine to ensure its smooth operation and controlled timing.

If an abnormality occurs during the expansion and contraction of the cylinder, you will be alarmed to stop the tablet counting machine to ensure accurate counting.

The gas storage and pressure stabilizing system ensures the stability and reliability of the pneumatic components. It will alarm and shut down when the pressure is too high or too low. This part ensures smooth and consistent product flow, prevents clogging, and double stacking, and promotes accurate counting.

10. Robust Structure and SUS304 Body

Robust Structure and SUS304 Body-AIPAK

With a compact, stable, and durable structure, there is no need for you to require regular replacement of parts. It occupies a small area and has low cost of use. The high-quality materials can assure you with continuous operation and long-term reliability.

Comply with national standards for counting machines, electric tablets, and capsule counting machines. By GMP standards, parts in contact with drugs are made of 304 stainless steel.

11. Working/Warning Light

Working/Warning Light-sourced: Walfront

With the working/warning light system, there is no need for you to be afraid of any problems occurring during the operation.

Used to indicate whether the machine is operating normally or has a malfunction. The working/warning light has a high degree of intelligence and has many control functions such as counting every bottle, fault self-detection alarm, etc.

There is an alarm system attached based on lack of materials, lack of bottles, etc. 3-color alarm lights are optional. Does not affect vibration during feeding.

12. PLC Touch

PLC Touch-sourced: richpacking020

The PLC is the central control unit of the machine and is responsible for managing the entire counting and filling process. It can help you receive data from optical sensors, process it, and control the distribution mechanism accordingly.

Using touch screen control human-machine interface PLC programmable controller technology, operators can easily set counting parameters, adjust settings, and access real-time production data.

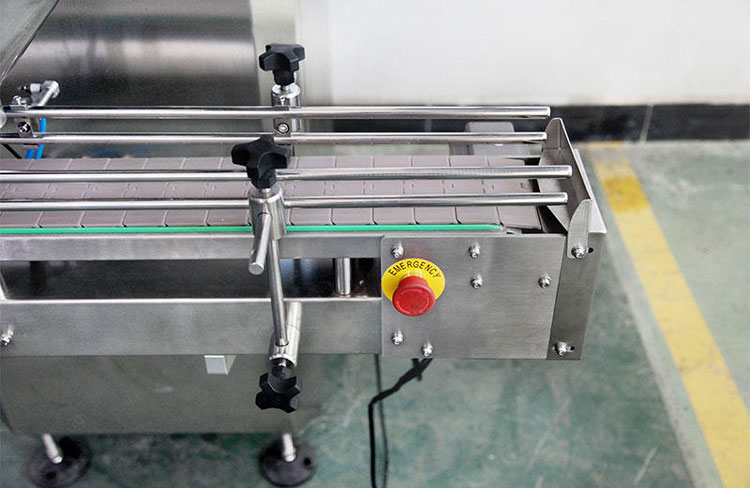

13. Emergency Stop

Emergency Stop-sourced: kenweigh

The emergency stop is specially designed for you to detect self-diagnosis errors, stop working, and alarm when an error occurs.

When the equipment is running, if there is any machine failure, counting function failure, automatic rejection system failure, the equipment stops running, etc., the automatic alarm system will respond to provide you with a safety guarantee.

14. Rejection System

Rejection System-sourced: richpackaging

The equipment is designed with an automatic rejection system to ensure 100% counting accuracy. Moreover, the machine is equipped with a self-diagnostic device to monitor fragments and overlapping parts and reject unqualified medicines.

The hopper is closely connected to the bottles to ensure that all medicines enter the bottles without clogging or splashing.

15. Dustproof Design

Dustproof Design-AIPAK

The dustproof design is good for you to improve your working hygiene. The special powerful dust-proof system can automatically adjust the fill light to ensure the counting accuracy of larger uncoated tablets, which is greatly improved compared with traditional photo-electricity.

There are different control modules for different specifications such as strong dust, particulate matter, and transparent capsules. Unique dust-proof photoelectric sensing technology can work stably even in high dust environments.

16. Transparent Operating Window

Transparent Operating Window-AIPAK

Key parts of the equipment, including counting and counting parts, are all made of transparent materials. This part can help you check and supervise the operation of the equipment during use, including counting, transporting, and bottling capsules and tablets.

This design also facilitates later equipment maintenance and fault repair. The operating window also allows you to take care of everything while the equipment is running.

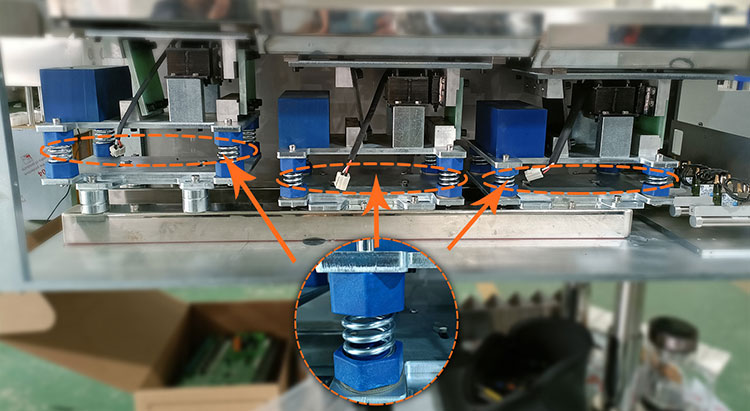

17. Low Noise Design

Low Noise Design-AIPAK

By installing a new spring shock absorb-er device on the equipment, the vibration and noise generated by the equipment during operation can be alleviated. Such a design can bring a good experience to users and avoid other safety issues caused by noise.

At the same time, you can also reduce the loss of equipment parts and reduce costs. This part can avoid noise and adverse effects on the surrounding environment when working at night.

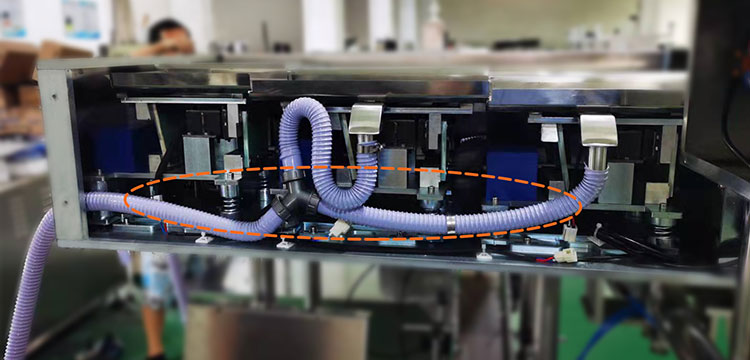

18. Dust Collection Design

Dust Collection Design-AIPAK

The dust collection design is convenient for you to collect the dust with easy work.

Uncoated tablets often generate dust during processing and counting, so a high-quality dust collection design device is very necessary. The dust removal design of this equipment adopts a vacuum suction design to eliminate pollution during the entire production process.

The system extracts dust at the batching slide in the hopper through the sieve holes on the vibrating plate and the slots at the end of the middle vibrating plate.

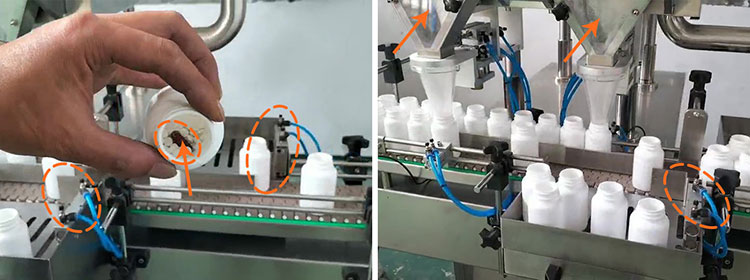

19. New Platform Structure

New Platform Structure-AIPAK

Using a new lifting platform structure, you can make your equipment adaptable for different bottle styles and sizes.

The counting mechanism is separated from the electrical control mechanism to ensure stable operation. This design can accommodate bottles of any shape and size.

By adjusting the height distance of the platform structure to adapt to bottles of different heights, the hopper and bottles can be closely connected to ensure that all medicines enter the bottles without clogging or splashing.

20. Automatic Detection System

Automatic Detection System-AIPAK

The automatic detection system is one of the best parts for you to inspect your products in the end with good effects.

Equipped with an automatic detection system that can automatically detect defective counting materials. A different number of sensors are installed on the conveyor belt of the medicine bottles.

These sensors use advanced technologies such as infrared beams, lasers, and high-resolution vision cameras to detect and count each product accurately and quickly.

Conclusion:

The tablet counting machine is a high-quality equipment for accurately counting and filling capsules or tablets. Through this "20 Basic Tablet Counting Machine Parts You Should Know," you can understand its most important parts. If there is a more in-depth explanation, would you like to know? If you want to know more, please feel free to consult us.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine