Top 11 Things You Must Know About Tablet Counting Machine for Foodstuff

Do you know how food products are equally counted and dispensed to end users? We think the food industry is a fundamental production area that is closely related to people's lives! Whether you buy chocolates, coffee, candies, or sugar tablets, the final step of their production line is the implementation of a tablet counting machine for precise and accurate packaging without extra labor or manual operation. This ever-growing technology brings endless significance and benefits to the industrial sector. If you’re in the food production market, then Top 12 Things You Must Know About Tablet Counting Machine for Foodstuff will help you to learn important aspects about the machine.

1.Tablet Counting Machine for Foodstuff & Beverage

The foodstuff and beverage industries are involved with the endless production of eatables associated with food processing, counting, packaging, and distribution. Therefore, to perform this job you always require robust, fast, and efficient machinery.

Tablet counting machine is traditionally and long-accepted technique that may add more profitable business. Because when processes are performed efficiently, apportioned final product, and perfectly packed it ultimately saves your time, minimizes unwanted errors, and boosts up your brand.

Irrespective of the foodstuff industry, the manufacturer always prioritizes end-user satisfaction, quality assurance, and precision. You should know that weight fluctuation negatively impacts brand reputation; therefore, tablet counting machines for foodstuff can genuinely give you 100% accurate counting and packaging of final goods that’s why manufacturers may mostly prefer this equipment.

This equipment not only offers exact control, and high user compliance but also improves production due to reduced wastage or extra product.

2.Benefits of Tablet Counting Machine for Foodstuff

Some incredible benefits tablet counting machine for foodstuff offers:

Cost-Saving

If you compare the price of the machine and labor cost then labor cost will be lesser, On the other hand, it takes a lot of time when counting manually.

Moreover, tablet counting machines for foodstuff cost you higher, but the entire task will be done by the machine. Thus, your food production team can concentrate on other chores instead of spending their precious time counting.

Timesaving

Every food production department deals with thousands of processes each hour. Tablet counters are fast and deal with a large amount of counting products in a shorter timeframe. Importantly, it can perform this job with 100% precision and correctness. So, what you’re waiting for?

Accuracy& Error Proof

Error with manual counting often happens! Whether it is from distraction or other it gives worse effects.

Processing foodstuff usually necessitates accuracy, flexibility, and consistency. Having a high-speed automatic tablet counting machine is helpful for bulk production sectors while eliminating breakage or inaccuracy.

Always Remember! Accuracy depicts food safety and exact nutrition in each packaging you distribute. So, the tablet counting machine for foodstuff is not liable for errors.

Happy End-Users

Of course, opening your foodstuff with an accurate bunch of happiness will make the end-user fully satisfied. Thus, a counting machine boosts up your business and makes it more successful by offering incredible counting properties.

No Contamination

When counting manually, wearing gloves is mandatory to protect the food product. Although it won’t cut down the risk of developing cross-contamination.

A tablet counting machine for foodstuff is excellent equipment that protects the product quality and maintains potency via a cleaning procedure.

Compact Housing

This machine is a compact and single unit that comprises all the necessary elements required for counting and filling foodstuff. Means you don’t need add-on parts for its working.

3.From Stand-Alone to Fully Automatic Tablet Counting Machine for Foodstuff

Packaging of food products usually requires counting instead of weighing or volume. In the food industry for packaging of large batches demands a standalone, automatic tablet counting machine which is now approaching high speed and offers a flexible job.

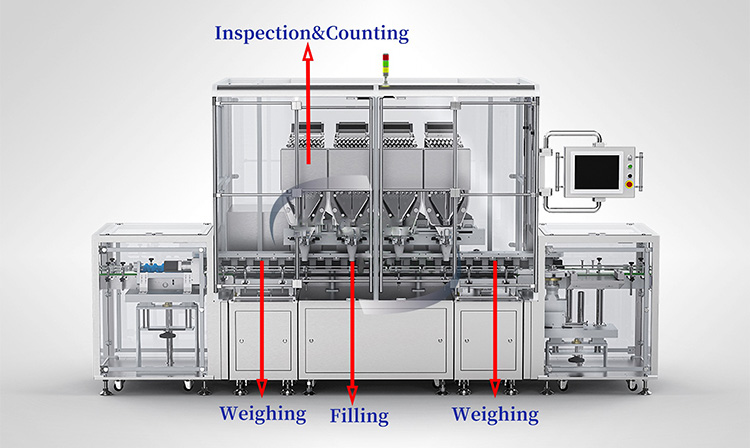

Advanced Counting Configuration

Today’s tablet counting machine for foodstuff is categorized into single, twin, or quad configurations that allow high-speed counting machine packaging flow.

Tool-Less Change Over

Automatic tablet counting machines share various modern attributes where toolless change over is simplified feature ensuring easy to manage and easy to maintain equipment.

Multi-Counting Channels

An automatic tablet counting machine is designed with multi-counting channels up to 12 counting trays with one or two filling stations (brand to brand) that counts thousands of foodstuffs per minute.

Incredible Automatic Programming

The machine is equipped with PLC touch screen operating options, LED optical sensors, as well as dust sensors. It means you must be stress-free when processing food products as a machine can identify a minor object that passes through it.

Storing and Retrieving Data

The machine stores informative data relevant to the wholeness of the products and retrieves it when required.

Accept and Reject the Product

An automatic tablet counting machine for foodstuff features high sensor adjustability helps you to detect broken products and therefore rejects the batch.

4.Incredible Industrial Applications of Tablet Counting Machine for Foodstuff

A tablet counting machine for foodstuff is multi-tasking machine employed for various industrial applications such as:

Pharmacy

Tablet counting machines for foodstuff is utilized in pharmacies for decades. This machine helps in saving your time and money by reducing dispensing errors. Busy pharmacies generally rely on this equipment for efficient, error-free medication ensuring customers receive a proper prescription every time.

Education

Top universities and research centers around the world takes advantage of using tablet counting machine for foodstuff to get simplified and accurate medication. All you need to plug in the machine and be ready to begin the counting.

Pharmaceutical Industry

Indeed, the machine is a leader in tablets, capsules, and pill counting. In fact, every established pharmaceutical firm uses a machine that counts pills of different shapes and sizes quickly and accurately. Also, the machine is ideal for verifying, identifying, and packaging the product.

Veterinary

A tablet counting machine for foodstuff is ideal for veterinary. Now you can spend more time with animals rather than counting tablets, capsules, etc., This is a versatile and affordable machine used by the veterinary sector worldwide. The simple, easy-to-use equipment reduces staff time wastage allowing them to care for the pets.

Food & Beverage

The food and beverage industry is a challenging business where a time-sensitive supply chain goes very fast. The food companies are strictly scheduled, with specialized storage and transportation with sensitive inventory control. Therefore, the manufacturing sector demands safe and hygienic food handling; the tablet counting machine for foodstuff includes everything from cleaning to quality control ensuring high-quality margin.

5.The Working Principle of The Tablet Counting Machine for Foodstuff

The basic working principle of the tablet counting machine for foodstuff is:

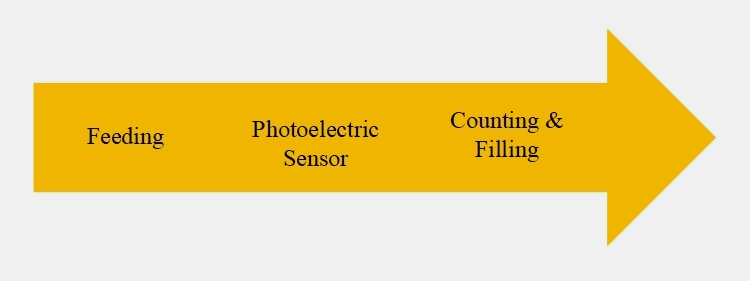

STEP 1. Program Setup

The working of automatic machines begins when feeding important parameters on it using active user input. The working principle of the tablet counting machine is based on a vibration motor that gives shaking effects.

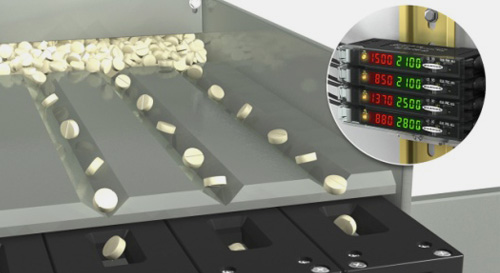

STEP 2. Feeding

At this stage, the assigned food product is entered into the hopper that flows product into the feeder tray where a hopper sensor regulates the process smoothly.

STEP 3. Photoelectric Sensor

Here a photoelectric sensor identifies the product to be counted and records it automatically. It has the capability to detect defective products even with improper shapes, sizes, and colors.

STEP 4. Counting & Filling

After passing through the photo-electric detector food product is recognized and considered as counted and ultimately added to the downstream for filling and packaging job. The correct product is considered as accepted while with fault is identified as rejected one. The operation continues till you achieved the desirable count.

6.What Are the Various Components of Tablet Counting Machine?

Some basic components of tablet counting machines are penned below for your understanding:

| Height Adjustable Base

The assembly of tablet counting machine can be easily moved up and down with height adjustable base to accommodate bottle varying sizes and widths. |

|

| Touch Screen

These equipment are furbished with programmable touch screen display that is used to instruct parameters for efficient machine running and tablet counting. These intelligent panels are also used for real-time data reporting and self-diagnosis. |

|

| Vibrating Channel

The function of this unit is to shake and distribute tablets uniformly and with precision to counting area. |

|

| Bottle Conveyor

This component is formed by servo drives, conveyors belts, feed sensors and stopping systems. These are used for transferring bottles from one station to another. |

|

| Hopper

The bulk quantities of tablets are filled inside the hopper part for counting. Adjustable parts are employed at the bottom of hopper for accommodating tablets of various geometries. |

|

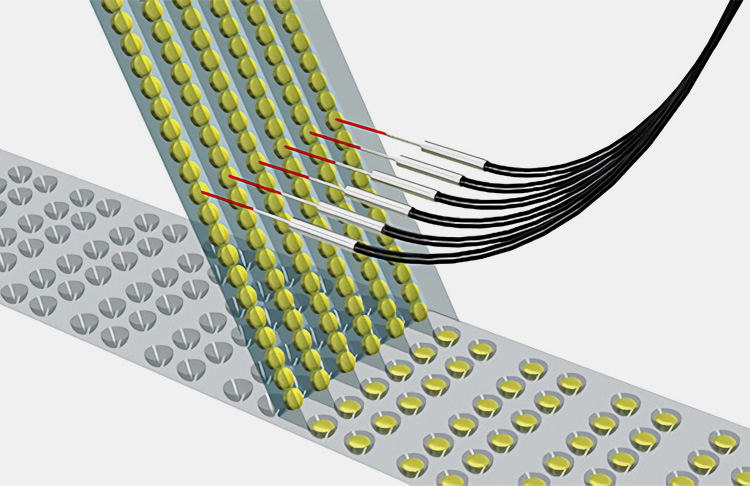

| Photoelectric Counting Sensor

This component is present in counting unit and its function is to detect tablets while they are being dropped down from vibratory channel. |

|

7.How does Tablet Counting Machine for Foodstuff Give you Safe Food Packaging?

The tablet counting machine for foodstuff are specially designed to deal sensitive products ranges from small to large batch sizes. Investing in this machine means you can obtain counting and filling job without interruption. Also, you can save your time and money in the term of speed and safety. This machine can easily be fitted into your facility, moreover an opened design gives you the seamless access for:

- Cleaned procedures,

- Intense monitoring,

- Fast and accurate detection of faulty products

- Stainless steel construction

- Good working order

- Reliable results

- No chances of cross-contamination

- and easy maintenance that reduces the chances of mishap.

8.What Are the Significant Features of Tablet Counting Machine?

Tablet counting equipment have major handy attributes that speed up the performance and efficiency of your food manufacturing line: Some of these features are detailed below:

- Tablets counters are manufactured with stainless steel material according to GMP standards. These machines have clean design and are equipped with dust extraction devices that put a stop to food contamination.

- These equipment have modular assembly and can be scaled up according to counting requirements of manufacturer. Maximum of 12 counting heads can be installed in these machines for increasing efficiency.

- Tablet counters are versatile automations and are utilized from counting variety of products whether these are gummies, candies, chocolates, coated or dusty.

- These high-end instruments are equipped with State-of-The-Artvision systems, fiber optics, infrared camera technology and futuristic microprocessors for highly precise and accurate counting of food good.

- It has unmatched performance and counting efficiency with their fast change of parts and low maintenance needs. This tool-less change of parts aid in quick and effortless cleaning.

- The rapid rejection systems installed in these counters recognize and discard foreign items without shutting down equipment. This camera technology identifies faulty products and prevents their packaging.

9.What Are Possible Problems and Troubleshoot When Operating Tablet Counting Machine?

| PROBLEMS | CAUSES | TROUBLESHOOTING |

|

Noisy Vibration

|

Loosened screw of vibration tray

Blockage of the hexagonal screw and engaged block Vibrating tray outlet is in contact with inlet discharging channel |

Screw tightening

Removal of the block and the inside hexagonal screw Adjustment of both |

| Simultaneous discharge of more than one bottle | Loosened screw of discharging flipper | Screw tightening |

|

Counting error |

Mixed fragments | Removal of fragments |

| Overlapping of tablets due to higher feeding hopper | Height adjustment of the hopper | |

| Powder contamination on sensor | Cleaning of the sensor | |

| Overlapping of tablets due to fast speed | Speed is lowered | |

| Heated machine | Move the machine away from sunlight | |

| Unadjusted sensitivity | readjusted | |

| Degradation of the sensor | Replace with the new one | |

| Internal copper deterioration or loosened plug wire. | Re-welding | |

|

Machine hanged up No change on panel number |

Exposure to light | Locate machine at cool and shady place |

| Loosened socket | Properly fix the connection | |

|

Machine errors and incorrect efficiency

|

Excess distance between sides of baffle and track | Adjustment of locations |

| Low sensitivity | Change of the sensor | |

| Disturbed location of the photoelectric head | Adjustment of the photoelectric head to the right | |

| High sensitivity of the stainless-steel electronic counting machine | Reduce the sensitivity |

10.Global Tablet Counting Machine for Foodstuff Market

Tablet counting machines occupies a central place in packaging of food stuff. These instruments are utilized for speedy and accurate counting of various confectionaries such as gummies, candies, and foot items for instance biscuits, coffee beans, cereals, etc.

The increased in demand for packaged food items has boosted the market size of tablet counting machines. Today, more and more manufacturers are investing in tablet counters for their food packaging line. It has been estimated that market of tablet counters will grow with the CAGR of 7.4% from 2019 to 2027.

America, Europe, and China are the world leaders in manufacturing of tablet counters for food industry. The growth of tablet counter in these regions is because of government friendly initiatives and high capital investment.

These sophisticated engineering solutions give unprecedented counting output and meet accurate packaging needs. Modern tablet counters for food industry are extremely sensitive and are customized with intelligent computerized interfaces that make programming and storing of data recipes convenient and fast.

CONCLUSION

When it comes to dealing foodstuff for your business, there are a lot of options available you must take into account specially for counting and packaging job. The tablet counting machine for foodstuff is the smartest solution and check weighers. For purchasing and further information make sure you get technical assistance and best machines- Because it always better to be specific than sorry! Aipak Pharmaceutical is one stop solution offering you the best and reliable tablet counting machine for foodstuff. Send us message for technical help or equipment quotation.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine