Bottle Sealing Machine: The Complete FAQ Guide in 2024

What if you make everything perfect and still unable to seal the bottle perfectly?

The ultimate result will be the lots of moisture and microbes in the bottle affecting the medicine.

Also, in result of that you will have lots of customer complains too.

Make sure you use this latest machine which works amazingly and save yourself from such disasters.

A bottle sealing machine is auto equipment that spots and seals bottle covers on various kinds of bottles.

In the present guide, you will find out the main insights related to a bottle sealing machine.

1. What is Bottle Sealing Wax?

Bottle Sealing Wax-Photo Credit: Globalsolutiononline

The Bottle Sealing Wax is utilized to give a seal on the better closing of the pharmaceutical as well as other bottles too.

Without a safe seal, microscopic organisms and air can get into the item, which in the end would cause ruining the item.

2. What are the Different Application for Bottle Sealing Wax?

This how it looks-Photo credit: premierbottle

Sealing wax gave numerous advantages.

For example,

- Making a dampness hindrance

- Keeping toxins out

- Giving a strong seal

- Taking into consideration simple expulsion

- Customizing the jug's outside

3. What are the Chances of Microbial Insertion if you don’t Seal the Bottle Properly?

There are very high chances of your bottle being contaminated.

Other than that there are possible chances of:

1.Impurities

2.Dust

3.Dampness

4. How to Handle Two Bottles Sizes on One Line?

Manufacturing expert has been recently working on that to make it possible.

They looking towards the better approaches for the pharmaceutical sector.

Normally for 2 sizes two lines are required. However, with the latest research at a place.

On every one of Innovation's three separate CMOP lines, two super seal Touch Cap Sealers were coordinated.

The result permitted Innovation to keep on shipping two bottles with different size on a solitary line.

5. What is Blow Fill Seal(BFS) in the Health care Market?

BFS is known as blow,fill, market is a service for the packing pharmaceutical products and who predict the future of this business.

They are known for the forecasting and according to them until 2026 these packing business gonna go up more 7% because of pharmaceutical manufacturing firms.

6. What is Bottle Sealing Machine?

AIPAK Bottle Sealing Machine

The bottle sealing machine also known as the bottle sealer is a device which is automatic. It is used for closing the face of the pharmaceutical bottle/container etc known as sealing.

7. What are the Possible benefits of Bottle Sealing in Pharmaceutical Industry?

Sealed Bottle-Photo Credit: Canadianmedhealthsupplies

The major advantages of utilizing bottle sealing in the drug business include:

Sealing of the bottles goes as the basic storing form for the drug items.

- Bottle sealed packs go about as a directing the measure of drug items accessible for use.

- Bottle sealing helps the legitimate the dividing process of the drug items as it makes it simple to move.

- Shields the substance from outer obstruction by other natural factors, for example, light and water.

For example, a 100 ml bottle directs that the container contains 300 ml of medicine.

- It assists in distinctive one drug item from another to evade any kind of confusion.

For instance, there is packing that differentiates syrups and pills.

- Container sealing is non-destructive and synthetically inactive in this way ensuring the trustworthiness of the drug items.

Sealed Bottles-Photo Credit: Vector

- By sealing the medicine in the form of bottles increase the authenticity of the bottles.

- Aside from that, diverse types of sealing of bottles additionally direct the method of medicine application.

- The kind of packing of bottle additionally makes it simple for you to recognize the sort of item.

8.What are the Advantages of Different Type of Bottle Sealing Machine?

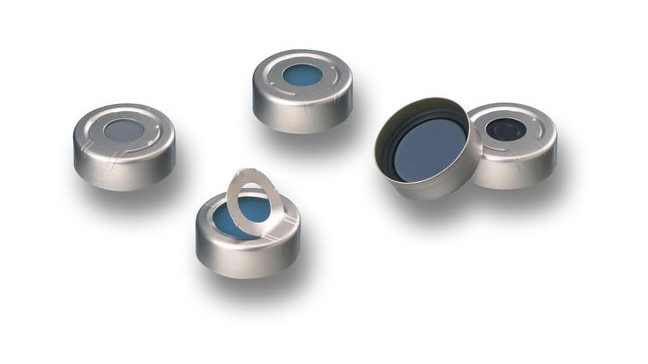

Benefits of Crimp Seal Machine

Crimp Sealed Products

Here are some following benefits that you can get using this machine.

Crimp Seal Vial Machine Include:

- Auto crimp sealer takes out the issue like weak sealing which is problematic wit normal manual sealing machine.

- It can save money and the expense of creation and time as it can crease bottles quickly and increment of the pace of producing items.

- Crimp sealing method of sealing the bottle is precise and accurate.

- You do not have to employ labor to assist for the sealing of the automatic crimp sealing machine.

- It is not difficult to clean and keep up with components that you can without much of a difficulty you can add and remove as well.

Alcohol Packed Bottles-Photo Credit: Vector

- The machine is not difficult to work with a machine interface aiding with proper checking and also maintaining the things from the screen.

- Crimp bottle sealing machine is most economical as it lessens wastage of material sealing.

- It gives the most effective stage to performing various tasks as it can seal various bottle sizes and shapes.

- It gives the best workplaces.

- The machine gives a ton of space to updating with new types of mechanical advances.

Advantages of Induction Bottle Sealing Machine

- Machine also does not need lots of electric power subsequently saving money on the measure of electricity being used.

- Seal head is adaptable and can adjust to different types of holder determinations in the fixing cycle.

- The machine stamps a safe seal that is profoundly secure and offers insurance from harm.

- The machine is adaptable and permits you to change the bottle diameter, heights, and power of the machine.

- Machine puts a carefully designed seal upon the pharmaceutical bottles shielding the substance from outer obstructions.

- The machine likewise saves time and builds profitability as it is possible with this machine to seal lots of bottles in a shorter span of period.

- Most of the working of the induction sealer task are auto accordingly improving the degree of exactness and proficiency.

Bottle Screw Cap Sealing Machine Advantages

The basic points of interest of utilizing screw cap sealing machine offer these advantages:

- In the same manner, the user-friendliness is another advantage of this machine.

- You may undoubtedly coordinate the machine into the creation line to make a total line of production.

- Aseptic consequently making it simple to clean and keep up the screw cap sealing machine.

- The machine helps to increase the yield as it can make the seals quicker.

- It likewise helps in increasing proficiency of production and exactness through exact sealing.

- You do not have to recruit a ton of humans, particularly when you are working with an auto sealing machine.

- The sealing made screw cap machine does not let exist any type of microbes creatures henceforth protecting the items.

Benefits of Bottle Heat Sealing Machine

Heat Sealed Bottles

- It saves your time and also quicks the production because of the automatic system.

- There is very little possibility of the margin of error in the bottle sealing machine because of its effectiveness.

- In fact, the heat sealing machine has a sensor and also an alarming system that increases the security.

- This machine can be customized so it is possible for this machine to handle various shapes and sizes of bottles.

- With the heat sealing machine, you don’t need the lots of labours as it runs most functions automatically.

- With heat sealing machine no worries about breaking down you can work for a long hour and it will increase your yield.

- It will increase the overall productivity of your production line.

- The heat sealing machine is not really hard to work with firstly, it is user-friendly and secondly, it comes with the control system.

- Because this machine has replaceable parts you can take that off clean and put that again.

Advantages of Ampule Sealing Machine

Ampoule Sealed Bottles-Photo Credit: Skindeepsaloon

The primary points of interest of utilizing the this machine are below:

- Fixing blazes can be handled by this machine because it has a meter that assists during the process.

- When you think of maintaining the Ampoule sealer you don’t have to worry because it is easy to manage.

- Ampoules will shield the medication substance from natural pollution, for example, dust and different types of pathogenic miniature living beings.

- You does have the ability to changeover with this machine for the better and quicker results.

- With this machine you can reach the limit of production of the ampoules near to 15000+ ampoule within the time frame of an hout.

- Ampoule sealing machine is very simple to operate machine with some additional functions like and cooling in case of heat and handling of there is more heat.

- With the UI just like many automatic machine you the monitor the whole process which is the only requirement of the automatic machine.

- You can without much of a stretch incorporate the machine with present-day fabricating advancements to make a proper line of production.

- The offer of sealing the best product is another key feature.

- With this machine the chances are near to zero that you will waste any material.

9. What are the Disadvantages of different Type Bottle Sealing Machine?

Upper Part of Bottle-Photo Credit: Theexmen

Now you will be explained the drawbacks of different types of bottle Sealing Machines. They are very less indeed and was hard to locate too.

Induction Sealing Machine Disadvantages:

The fundamental drawbacks that you will insight by utilizing bottle fixing machine are listed as:

- A higher introductory expense of buying and introducing the machine.

- You need to prepare some of your staff to have each and every detail of the user and processing of the machine that is considered bit expensive.

- In spite of the fact, the way that it is auto, you need to have a couple of individuals to aid the whole processing system.

- The acceptance aluminum foil fixing machine is unequipped for fixing metallic bottles and putting metallic covers.

- The innovation can be obsolete whenever thinking about the high pace of advancement in the business.

Disadvantages of Heat Bottle Sealing Machine

Some limitations of Heat Bottle Sealing Machine by Heating

Some minor disadvantages or you can say drawbacks you can get using this machine.

- The expense of buying and introducing an auto bottle sealing machine by heating is a bit higher.

- Normally, in this case of the crimp sealing machine you might need a bit more space than normal.

- Heat bottle sealing machine is very explicit in this manner lessening its adaptability to different types of process sealing.

Ampoule Sealing Machine Disadvantage

Ampoule Sealing

Regardless of the positive jobs that the ampoule filling machine plays.

You will encounter the accompanying issues:

- There is always a chance of the product inside the ampoule be contaminated because glass can fall in.

- As you are well aware that this is a type of glass sealing process. Indeed it is the hardest one of them all-cap sealing processes.

- Pharmaceutical Industry

- Chemical industry

- Agricultural industry

- Fertilizer bottles

There are different disadvantages of the Bottle Screw Caps Sealing Machine

Bottle Screw Cap-Photo Credit: Ideon

The listed below are the disadvantages:

- The installation of the machine cost is higher so does the beginning cost of the bottle screw caps sealing machine

- Screw covers/caps are regularly close in this way decreasing oxidation of certain types of bottles, for example, wine.

- First you have to put the caps and then you start the sealing process of the bottle sealing.

- Taking the machine starting with one spot then onto the next is a troublesome assignment since it has more weight.

- The size of the machine additionally requires a greater establishment space hence expanding the expense of speculation.

Crimp Sealing Machine Disadvantages

Crimp Seal Pack

The significant disadvantages are enlisted below:

- You have to have a steady ability to empower the productive and smooth tasks of the sealing machine.

- Foil of aluminum is utilized in the crimp sealing process and there is no other available choice in such cases.

- Just like many other machines, the beginning cost for this machine is quite higher has better long term advantages.

10. What are the different Industrial Usages of the Bottle Sealing Machine?

Sealed bottle-Photo Credit: Pinterst

Following industries use bottle sealing machines one way or another and help these detail written products sealing.

Pharmaceutical Industry

Veternity Supplies

Veterinary supplies for example for animal used products.

Powders and Pills when they are closed in a bottle they are sealed in such a way so they can be used for a long period of time.

Pharmaceutical raw materials is also kept sealed, they can be used in medicine making properly.

Beverage Industry

Beverage Sealed-Photo Credit: pressconnects

Wine and Canned beer are sealed even in the tins or bottles with the help of sealing machine.

Soda and Water are sealed in the same manner as mentioned above as wine.

Food Industry

Canned Food-Photo Credit: St.joseph

Meat and Seafood are canned and packed with the assistance of the sealing machine so they can be stored and used in the future.

Honey and Nutrition Powder are sealed with the caps and sometime with and a lid and then sealed.

Chemical Industry

Chemical Sealed

Cooking oil tins are sealed with the properly covered material by using this machine.

Glue, Paint and Farm chemicals are also sealed in the respective manner.

11. What are the component of the each type of Bottle Sealing Machine?

In this part you will be explained all different parts of all sealing machines:

1- Different Parts of Induction Sealing Machine

Induction Sealing Machine has various kinds. Well, here we will be discussing all parts of the all available type of bottle sealing machines.

Components of the Induction Sealing Machine are Below:

1. Power System of Induction Sealing

This is the principal reason for the electricity that starts all parts of the induction sealing machine once this is in running.

For example, it gives enough force that can warm the loop for the purposes of sealing.

2. Controlling Meter for Setting Parameters

This part of the machine is specifically designed for setting the parameters of the machine. Your program and give commands to the machine even before starting the process.

3. Head and Sealing System

This is the fundamental piece of the machine that does the genuine arrangement and bottle sealing.

4. Inverters

Force inverters control and change capacity to the appropriate force range for using the machine for sealing.

5. Inductor Sealing Coil

This is the fundamental warming component of the machine that gives the head enough warmth.

6. Touch Screen System

You can see all the running functions of the machines and notice them from this digital touch screen panel of the Induction sealing machine.

7. Cooling System

The cooling framework comprises cooling fans that remove abundant heat within the machine.

2- Bottle Screw Cap Sealing Machine Components

The second machine components which you will be explained are below:

1. Sealing Head

Here is what we called real process starts.

Sealing Machine Parts

2. Transmission System for Product

It comprises of the transport lines that help with moving items starting with one station then onto the next.

3. Fundamental Structure

The screw cap sealing machine’s this part actually hold everything in it.

4. Star Plates

The star plate keeps on the bottle's hold as long as they are not sealed properly.

5. Bowl for Handling Caps

Also known as the cap storing place this is where caps are stocked and then moved on for the sealing purpose.

6. Electricity Panel

This part of the screw cap sealing machines controls all the machine activities related to the power.

7. Product Height Adjustment Screw

It makes sure the bottle is adjusted so, they can be sealed in the best possible way.

8. Main Engine

The engines help with starting and controlling development, particularly on the transporting of medicine frameworks.

9. Cap Delivery System

Okay. you will move the caps in this process and then transfer them to the sealing station.

10. PLC Control System

The screw cap Sealing machines have a PLC unit have a complete touch screen system and are easy to understand.

11. Sensors and AC Drives

If there is any type of the glitch in the running machine, you are using the sensor to find the immediately.

As long as the AC’s are used in the machine too, they are for cooling down the machine once they are heated up.

3- Crimp Sealing Machine Main Components

The primary components of Bottle Sealing Machine are these:

1. Stainless Steel Frame

The crimp sealing machine has a stainless steel frame which makes sure it does not get rusty.

By using steel also makes the frame of the machine very strong.

2. Crimping Phase

The main functioning of crimping while using the foil happens here.

For sealing the bottle by the crimp process, there are some rollers that apply pressure to seal the bottles.

3. Auto Vibratory Bowl Table

Auto Vibratory Bowl Table

For the accurate filling of the bottles, this is what makes everything possible. It is vital for helping bowl system.

4. Auto Servo Automatic Changeover gadgets

The servo auto changeover gadgets have flexible engines that impact alteration of the sealing limits.

5. Optic Fiber Sensors

The connection between the computer and sensors makes it is more use able and it transmits all the signal to the computer if there is mishap happen you can understand immediately.

6. On/Off Switch

There is an auto on and of the system of the machine when there any type of glitch in the crimp sealing machine.

In case there is no raw material for running the process machine will go into the rest mode.

7. Conveyor Belt

It comprises of engines, a belt that keeps on moving that aids the rolling of the machine from one place to another.

8. Digital Control System

How would you feel sitting and monitoring all the running activities.

It has a Control Unit with an adaptable and inviting menu for setting the gadget to specific fixing conditions.

9. Lubrication framework

For the smooth running of the machine, this is what you need in a machine.

The grease framework consequently greases up the moving components in this way decreasing contact.

10. Pneumatic Cylinder

The core purpose of this part of the machine is to apply enough pressure so the process of the sealing may help in a perfect way.

4- Parts of Ampoule Bottle Sealing Machine

The ampoule bottle sealer comes with the filling line ass well.

The main parts of the ampoule filling machine are like these:

1. Filling Source

Here is the place where you fill the ampoules getting the material from a tank.

2. Transport line

A conveyor belt is used for the purpose of moving the ampoule from the filling part of the machine to the sealing part.

3. Turning Pumps

It guarantees that the ampoule bottles have the correct pressing factor.

4. Hardened Steel Belt

Stainless Steel Belt

It gets the ampoules in the wake of going through a sealing cycle.

5. Adjustable Volume Wheel

It changes the volume of the fluid that gets into the ampoules

6. Unclogger Unit

This part of the machine pushes the fluid from the filling stations into the ampoule.

7. Pedal Switch

Looking at the choices you are able to adjust the operational mode of the machine by using this part.

8. Sensors for Volume Management

Reacts to the adjustments in volume as per the changes on the customizable wheel of volume.

9. Bevel Needle

To permit entry of the filling fluid from the source of filling in the bottle.

10. Sealing Station

This is where you seal the product.

5- Parts of Bottle Heat Sealing Machine

The auto bottle heat sealing machine relies upon the accompanying parts to play out its capacities.

1. Blades

It does a function of cutting the material so well it can fit upon the bottles and properly seal the bottles.

2. Alarm System and Sensors

Alarms are used in the machine so in case if any type of emergency occur that can be detected.

Sensor are sensing different functions. Like checking for heat there are heat sensors.

3. Guide Rails

Sealing machine this part is also known as the conveyor belt and moves the bottles from one place to another.

4. Electric Power Unit

Electric Power Unit

This the reason for the electricity into the whole machine.

5. Coil

Coil is responsible for the creating the heat into the system.

6. PLC control framework

It is part of almost every pharmaceutical machine. SO does it is also used in the sealing machine too for handling all the process in the machine.

7. Pneumatic

Without applying the proper pressure on the seals it would impossible to do sealing this part also play a major role in sealing by applying enough pressure for proper sealing.

8. Oiling System of Sealing

The oil framework oils all the moving pieces of the machine along these lines expanding the adaptability of the machine.

9. Fixing Plug

This part is has the responsibility of placing the seals onto the bottle.

10. Cooling framework

Machine must require the cooling system. Since the machine relies upon a warming guideline for sealing bottles.

11. Hopper

Hopper is used for the foil to be placed in that.

12. What is the Working Principal of Bottle Sealing Machine?

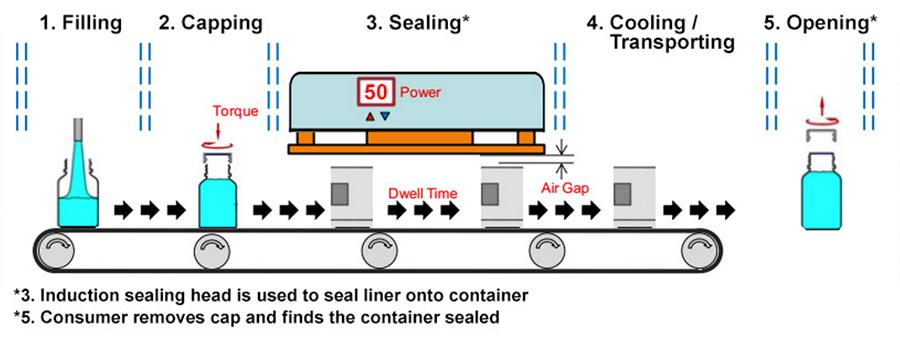

1- Working Principle of Induction Sealing Machine

Induction sealing Process-Photo Credit: tienlicks

The fundamental working rule of the machine relies upon the heating as well as the sealing process of the bottles.

The basic working principle of the sealing machine follows these steps:

1. Sealing Material Preparation

For this situation, the cap is used as a material sealing thing. The process however starts with the two-piece liner.

The liner comprises:

- Paper

- Wax

- Foil

- Polymer covering

These are actually for different types of sealing bottles.

Simultaneously, you also need make sure one more thing that the machine is in best working state.

Set the electric consumption so does according to the different bottle type specifications will be set.

If less force is applied the chances are very less that it might seal the bottle perfectly. So, enough force is required for the proper sealing.

You need to certain you do the proper inspection of the bottle so it does not have any dents and not curved.

The cap of the bottles should be fitting well too.

2. Putting the Seal

Just place the cap carefully and the seal will be placed in the induction bottle sealing machine process.

Try not to apply an excessive amount of tension on the cap in the process of sealing as it would cause a damaged seal.

The vast majority of these applications are auto in the scenario you are using one of the auto-induction sealing machines.

Afterwards, the induction sealing machine puts the bottle on a transport line which transports them to the heading for the sealing.

3. Applying of Induction head

This is the primary process of the sealing.

Here the sealing function on the bottle head starts.

Don't bother you trying to apply seal when you don't have a cap on.

This is where it goes under the coil of induction.

The curl will emanate high recurrence and vigorous electromagnetic field which liquefies the conductive aluminium.

During the process, now the wax will be melted.

Now, the melted wax will go on the surface of the foil and covers up the sealing of the cap.

The cycle should take not exactly a couple of moments to start the sealing.

4. Cooling Process

The cooling process is for throwing the cool air on the bottle as the passes through the zone of cooling.

This powers the liquid polymer to cling to the side of the bottle making water/air proof seals.

In some type of machine cool water is used for sealing and sticking purposes.

5. Check stage

At this phase of the machine, you can take a check for the damaged pieces and take them out.

You may likewise keep an eye on sealing which needs to make sure that it does not cause any problem like not opening up.

In the event that everything is great, the container is currently prepared for packing.

2- Working Principle of Screw Cap Sealing Machine

- Loading the Screw Caps

- Placing the fixing material on the covers

- Sealing Process

- Additional Processes

While working a screw cap fixing the machine, you need to experience the accompanying system:

Loading Screw Caps

To start with, you need to stack the screw covers on the bowl for covers before the fixing cycle starts.

Since the screw cap fixing machine is important for a line of production, it has an association with the filling machine.

Inferring that the container will be coming from the filling machine through to the fixing machine on star plates.

The transport lines additionally empower the quick development of the star plates.

Make sure to stack the material for sealing onto the fixing material container.

Placing the material on covers

The machine will gather the material sealing from the fixing/sealing material container.

By and large, the material for sealing is elastic.

Simultaneously, the cap conveyance chute conveys the covers.

The machine puts the elastic seals inside the covers in a uniform way.

This is where a portion of the machine brand elastic sealing.

Sealing Process

As the container moves to the fixing station, the covers total with the elastic seals additionally moves to a similar station.

Once at the station sealing, the machine consequently puts the covers on the containers, and the cap is sealed.

The container as a rule has coordinating strings with the cap subsequently encouraging a smooth screw cap sealing method.

Simultaneously, it figures out how to seal the containers happens through the screw cap.

Additional Processes

It is imperative to examine the containers in the wake of setting the screw cap seal.

You can recognize a couple of irregular examples to check the respectability of the seal.

Ensure that the seal is tight yet doesn't represent an incredible test with regards to opening.

- How Vial Crimper Machine Works

Coming up next is a bit by bit method of how the vial crimper machine functions.

- Preparation stage

- The Orientation of the Vials

- Crimping the Sealing Material

- Further Processing

Preparation stage

Storage on the first place and then you can start the process.

Raw material should be there.

The machine must be in good working condition.

If you sense everything is okay begin the process.

Crimping of Sealing Material

In this phase of working.

Crimper rolls are used here for sealing of the vials or whatever material is used.

A tension will be applied by the creasing during the process.

Sometimes, during the process sealing can also be placed after putting the caps on the vials.

Vials Arrangement

Here once the process will be started, a belt will be bringing all the vials into a circular moving thing.

They will come into the sealing station.

Then, at that stage of sealing vibrating bowl will you with the process.

At that stage, now sealing will start as the machine will pick the sealing material.

Further Processing

This addition part is used for the checking your vial and doing the proper investigation of the process. In case every is done accurately. If it is not it will be taken back and sealed properly.

Later, on process of the labeling, naming and so forth things start.

4- Working Principles of Plastic Bottle Heat Sealer

- Preparation Stage

- Preparing the Sealing material

- Actual Sealing Process

- Cooling Stage

- Inspection Stage

Coming up next is a bit by bit controlling cycle on how the plastic container heat sealer functions.

A- Preparation Stage

Hopper is used in the preparation stage for putting the foils.

Here you also need to make sure that sealing machine is good conditions of working.

For fixing the material you also need to stack the greasing material, for better coordination between sealing bottle and material.

Once you are settled you just need to begin the function.

B- Preparing the Sealing material

In this stage of the working by using a belt the foil is brought into the function.

Here the foil is taken into the sealing place.

As, foil is the basic material for sealing.

C- Actual Sealing Process

Now, the containers and the Sealing materials meet at the Sealing stage.

With the assistance of the round wire change packs, the machine spot and shapes the Sealing materials on the containers.

Simultaneously, the electric unit gives enough ability to warm the warming curls or warming bar.

Try not to put the warming bar straightforwardly on the Sealing material as it would cause consumes.

All things being equal, permit the transport line to move the containers under the Sealing area.

The measure of warmth is adequate to dissolve part of the Sealing material and permit it to stream onto the cover.

You should control the warmth to keep it from softening the entire Sealing materials and the containers.

D- Cooling Stage

From that point forward, the transport line will move the plastic containers quickly to the cooling framework.

The cooling framework has a progression of fans that shoot cold air on the seals constraining them to cool.

The liquid foil clings to the container and makes an airtight seal.

E- Inspection Stage

It is imperative to investigate the seal and affirm that it is great.

You will likewise understand that the recuperating cycle didn't meddle with the containers.

5-How Ampule Sealing Machine Work

- Pre Processes of Ampoule Sealing

- Gassing the Ampules Before Using

- Filling of Ampules

- Post gassing Stage

- Sealing of Ampules

- Discharging of Ampules

Ampule Sealing Machine Working Principle:

The ampoule sealing process goes like this.

Pre Processes of Ampoule Sealing

In the first step here, the Ampoule using a belt comes in then you do sterilization in that process.

From that point forward, Ampoule are placed at the right place for filling firstly and then sealing.

By using the moving system ampoule are first placed on the wheel and later on the cradle of the conveyor.

Gassing the Ampules Before Using

In a very normal case, there are is a system of gassing ampoule each phase.

If there is any air available in the ampoule will be removed at this phase of processing.

It is additionally known as the sterilization of the ampoule.

Filling of Ampules

Here filling Ampoule happen.

Post gassing Stage

From that point forward, Ampoules come again for the post gassing working process.

This step is for making the ampoules ready for the sealing and any type of the gas are being removed at this stage again.

The ampules at that point proceed onward a transport line to seal.

The ampules turn on the transport line as they approach the sealing stage of the machine.

Sealing of Ampules

To start with, first of all, you need to heat up the machine to a certain level for the reason you want to do the final process of sealing here.

From that point onward, the machine will go the ampules through the fundamental warming stage at high temperatures.

The glass ampules will at that point soften and structure a total seal over the ampules.

Discharging of Ampules

At the last stage, the trimmer will eliminate the extra glass upon the ampules.

They are released here and then check properly and lastly, packed.

13. Why of Bottle Sealing in Considered Important in Pharmaceutical Industry?

You will have the option to realize that the drug substance the container is protected when the seal is unblemished.

By sealing the bottles with material like foil or tin helps in getting in bad stuff.

No Leakage and No Spillage.

A seal assists in offering the security of the pharmaceutical bottle as it makes them resistant to many things.

You can’t afford unsatisfactorily products.

14. What Should be the Quality of a Safe Bottle Sealing Process?

Nature of a Safe Bottle Sealing Mechanism

The fundamental prerequisites that you must have to set up for the quality control of the bottle sealing processing have listed down.

Quality has a direct relationship with some features like well-trained employees, better facilities, and know-how of the whole process of the bottle sealing.

You need to have a self-decision making department for checking the quality of the products being made. They should be independent so the product quality won't be compromised.

You also need to handle the things with the proper database system like who made that for a legitimate review of the cycle.

The fundamentals of value control are the duty of the maker during the process of production.

Be certain that the quality team checks each and every bottle.

To guarantee that the buyers of the drug items get drug results of top-notch, you just need to to think about these factors too:

Pharmaceutical products must be sealed in such a way that it has all the details of the regulatory party.

Other than that the bottle sealing process also needs to run the thing as per cGmp standards which force on the defect less products.

One more thing is, choosing the random sample and test run for the sealed atoms and doing some statistics for the products.

15. What are the Different Bottle Sealing Machine Types?

Since there are diverse bundling systems, you ought to likewise hope to have various sorts of container fixing and covering components.

The fundamental sorts of jug fixing and covering systems include:

1- Heat Sealing Machine

Heat Sealing

Heat sealing machines are flexible gadgets that rely upon a warming standard to make sure about a seal on a jug.

The machine makes a hermetical seal on various sorts of containers in various businesses.

You can utilize the machine in various enterprises, for example, drug, food, synthetic, and makeup among others.

It has the ability to expand the time span of usability of the container content by putting a defensive seal.

2- Screw Cap Sealing Machine

Screw Cap Sealing Machine

By using this technique machine makes sure it gets a better deal.

Sealed with this machine makes sure no spilling at all.

It assists in improving the manageability of microbes.

3- Crimp Sealing Machine

Crimp Sealing Machine

This is a non-shearing and patent forthcoming machine that utilizes persistent movement to consequent crimp and flip-off covers.

The innovation gives a productive method of sealing/fixing various sorts of containers utilizing aluminum foils.

4- Induction Bottle Sealing Machine

AIPAK Induction Sealing Machine

It is a no contact process in general with fastness.

Induction sealing strategy for bottles includes control warming of an electrically directing article by electromagnetic acceptance through warmth that comes from vortex flows.

5- Ampoule Sealing Machine

Ampoule Sealing Machine

It is required when their glass bottle required glass sealing too.

The machines must have unique plans that can without much of a stretch seal the medications in the little glass bottles.

At the point when you required to make a total seal that will shield the substance from ecological impurities.

It can't be used for every kind of process. It has only specific field usages.

16. Compare these Induction and Heat Bottle Sealing Machine?

| Induction Bottle Sealing | Heat Bottle Sealing |

| l Induction machines have a smaller machine foot print.

l It has less price. l As machine is auto does not need handling by human. l Safer to use as there is no heat. l Handles different shape and size known for the versatility. |

l Heat bottle sealing does have a large foot print.

l It has more price than induction sealing machine. l May need human beings for handling the process. l It is heated machine so one has to be careful. l Less versatile compared to the induction sealing machine. |

| Screw Bottle Sealing | Crimp Bottle Sealing |

| Screw seals are bit of expensive.

Screw sealed better is not better than crimp. Screw sealed products are easy to use. However, it does not have the variation in the depth. |

Crimp Sealing is low cost process

Crimp sealing is considered better. Crimp seals products are hard to use. Crimp seals has a problem of variation of depth. |

Ampoule Bottle Sealing

This is the hardest sealing method.

Process is bit longer.

Lots of care is required.

17. What Points you Should Consider while Buying Bottle Sealing Machine?

Maintenance & Use

You must need to have information on how to use a bottle sealing machine.

By and large, the machine is auto and it comes with the human control controller and the method of activity is simpler and easier.

Other than this, the machine is not hard to clean and keep up to expand the solidness of the machine.

Safety Of Machine

The well being of the machine ought to likewise be probably the best need.

You must view the well being as far as your own security and the security of the bottle sealing machine.

Make sure you choose such a bottle sealing machine that has an automatic alarming function which informs you in case of danger.

Manufacturing of Bottle Sealing Machine

You should go for a machine that will guarantee a productive and happy workspace.

This incorporates take a look at variables, for example, low commotion levels and negligible natural contamination through the insignificant arrival of smoke.

Optimum Sterilization

Your decision for a machine ought to be liberated from impurities that would somehow defile the trustworthiness of the substance.

Precise Driven Unit

The driving system ought to have the choice to decide the sealing boundaries precisely and limit any type of fixing blunder.

It ought to adjust and precisely follow the fixing settings as per the auto controlling framework.

Production Capacity

The limit of production of the sealing machines regularly shifts relying upon the degree of the automatic system.

You ought to consider an auto bottle sealer that has an exceptionally high limit of production in a machine.

Simultaneously, auto bottle sealing machines have a fluctuating limit of production relying upon the machine’s size.

Simplicity to Adapt to Varies Bottle Sealing Solutions

In any type of pharmaceutical machine, you need to see if it is the solution to many problems. The more flexible the bottle sealing machine is better it is.

It ought to be adequately adaptable to change parts naturally because of the Automation plan.

Automation Level

Filled bottles

While buying a bottle sealing machine you are provided with a manual and you have to choose between:

- Manual

- Semi-automatic

- Fully Automatic

You should go for the fully automatic bottle sealing machine, it is expensive but it has fully automated systems.

Complete Safety Options

While buying a bottle sealing machine your top priority should be safety. You should look after your safety. Machine should be consist of sensors that automatically give the signal to the machine in event of an emergency.

Environmental Friendly

Your machine should be environmentally friendly and should be comfortable for the working environment. The machine should be of low noise and less environmental pollution and less release of smoke.

Precise Drive Machinery

The sealing parameters of your machine should able to identify and remove the errors precisely. Your machine should follow the settings settled in the program on the PLC system and should be accurate.

Sealed bottles-Photo Credit: Sksbottles

High Production Capacity

You should select a fully automatic bottle sealing machine because it has a higher rate of production.

The production rate of these, machines depends upon the level of automation. Dimensions of the machine are also the main factor in production.

Affordable & Easy Handling

Induction sealing process

While buying a bottle sealing machine you should keep in mind that the machine is flexible and can be adapted for many sealing purposes.

It should be flexible enough that it can change parts spontaneously in response to the software design schedule.

18. How do you troubleshoot Bottle Sealing Machine?

Bottle Sealing Machine Issues-Photo Credit: R&Dworld

Much the same as some other kind of gear, the Bottler sealer/ sealing machine encounters a few difficulties.

Here is a portion of the issues, and the probable reasons for the issues, and the answer for the issues.

1- Machine not Working

The primary driver of these issues and their answers include:

There is a possibility of the not working switch must be altered.

The power plug is poorly connected which needs to be unplug and safely reconnecting the attachment.

2- Working Mark Problem

The primary driver of the issue and their answers include:

Inadequate breaker which you ought to settle by changing the wire

Harm on the inductive head which you can essentially change with a productive one.

In the consistency of the material of sealing or object

By proper change of sealing objects and material for inductive, you may solve it.

3- The Foil Used and the Contact Part is not Properly Attached

It may be because of the too long or the shorter duration of the heating.

You need to find out first thing first, what is the ideal time span for the proper joining and then give that proper time of the heating to the process.

4- In Some Cases there is a Burned Linear Card

There are two possible cases in such situation either it is belt moving slower or the more pressure is being applied.

Need to make sure the speed. So, does the amount of pressure being applied.

5- Caps are Very Tight and not Easy to Remove

There is power issue in the bottle sealing machine which you can manage by using the power adjustment tool of the machine.

Another problem can be too high settings of the coil system, it can be managed well by managing the coil’s height.

6- Sealing Results are not Same

Issue with Bottle-Photo Credit: optomechenginnering

It is possible if there are chances of conflicts between the sealing burrs and lips.

Here you need to make sure something related to the torque of the caps so they are not cocked.

7- Not a Proper Power of Sealing

This can be because of the metal watchman rails being excessively near the fixing heads.

You can supplant the metal gatekeeper rails that are excessively near the fixing head with non-metallic watchman rails.

19. What are the Technical Specification of Bottle Sealing Machine?

| Sealing Machine Features | Details |

| Packing Material | Plastic |

| Packing Type of the Machine | Foil |

| Type of the Machine | Sealing Machine |

| Application of the Machine | Pharmaceuticals, Beverage, Textile, Chemical and Cosmetics |

| Automatic | Semi Auto |

| Driven System | Electric |

| Volts | 220V |

| Power Consumption | 1.2 KW |

| Dimension weight | Length 35

Width 27 Height 13 cm |

| Capacity | 50 bottles per min |

| Weight | 6 kg |

20. What are the different Auxiliary Equipment Used With Bottle Sealing Machine?

Auxiliary equipment is also known as the equipment for making the complete production line of the process.

Capping Machine

AIPAK Capping Machine

The next process is like more sealing in a better way that is covering the bottle up with the different types of the caps.

Printing Machine

Now, it's time to mention the different details related to the product you have filled already.

You can print batch details, date of manufacturing, and expiry date as well.

Packing Machine

The second last step is packing each item into the box or whatever packing they go it and that is possible with the packing machine.

Box Making Machine

The last step is making the cartons of all the products with cartooning machines.

That is what makes the whole production line for the bottle sealing machine.

21. What are the Different Quality Standards for Bottle Sealing Machine?

Standards-Photo Credit: standardsworld

The different quality standard bottle sealing machine makes sure it is a quality product plus, it meet the different worldwide requirements too.

Those standards of the machine are these:

- cGMP

- ISO

- CE

- FDA

- Japanese Standards

22. How do you Maintain a Bottle Sealing Machine?

The procedure to maintain a bottle sealing machine is as follows:

Maintain Voltage & other Electric levels

First of all check for voltage fluctuation and make sure that earthing wire is properly inserted.

Leakage Proof

You must check the leakage of the compressor regularly and also check for abnormal voice and damage to the machine.

Maintain Functioning Parts

Check for proper functions of the conveyor belt, bottle placer, vibrator, and vibrator coil. Check functions of safety switches, movement of jaws, and gear speed reducer.

Oiling & Lubrication

Check the bearing and tension spring and grease all the bearings. Don’t forget to change gear oil and clean all moving parts regularly.

Sealed ready to use bottles

Cleaning & Stain Free

The cleanliness of the environment is also to be maintained because it prevents exterior Eco-friendly factors from entering the bottle.

Don't forget to share this post!

Induction Sealing Machine Related Products

Induction Sealing Machine Related Posts

Induction Sealing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine