Automatic Tablet Counting Machine: the Complete Importing Guide In 2025

Have you ever encounter problem of filling your tablets in a bottle?

With the advancement and growing technology in medical field the method of dispensing medicines in the form of pills and tablets also needs to be updated. The invention of Tablet Counting Machine was the need of hour. This machine is more of a technological solution to this problem.

This machine uniformly counts the pharmaceutical and food products through an organized assembly of systems. Pills, coated tablets, capsules in the form of soft and hard gelatin are easily counted through this machine. It will also give you the facility to fill the bottles by the use of dual nozzle and will eventually saves you from the hustle of counting and filling your tablet bottles.

This machine works on the principle of Advanced Real- Time Image Processing to give 100% efficiency and counts bulk of tablets. The other major advantage of Image Processing Technology is that it allows you to count multiple items like capsules, pills and tablets all at once through the use of single wide track. That’s why it allows “Bulk Counting”. Thus in each cycle you will have 3-5 times of the overall output as compared to the use of separate bottles for counting as it also reduces the effort of spacing and then feeding the separate bottles at specific intervals.

How to choose the best tablet counter to meet your requirements today I am going to give you more knowledge about that.

Spend a few minutes reading through, you will find the best answer to suit your needs.

Let’s drive the subject directly.

1: What is Automatic tablet counting machine?

An automatic tablet counting machine is an automatic machine used to precisely count the pills, capsules and tablets according to prescribed needs of patient. The invention of this machine has revolutionized the pharmaceutical industry. It reduces the error and costs of pharmacy and nursing home. In addition it ensures safety, accuracy of prescribed dosage and increases efficiency.

Automatic Tablet Counting Machine

2: What type of products can be counted using Automatic Tablet Counting Machine?

This machine is useful in counting of all types of pills, tablets whether coated or non-coated, and capsules either in the form of hard or soft gelatin. Besides its pharmaceutical use this machine can also count chocolate balls, bubble gums, beans as well as candies for you so it also plays a major role in food industry.

Tablets and Capsules

Chocolate Balls

Gums and Jellies

Beans

3: What are the components of Automatic Tablet Counting Machines?

Following are the main parts of Automatic Tablet Counting Machine. These are all contact parts so that it will be easy for you to remove the parts and clean the machine.

- Touch Screen Control System

- Feeding Machine

- Integrated Dust and Chip Extension

- Feeding Trays

- Conveyer Belt

- Hopper Feeder

- Hopper Sensor

- Flexifill System

- Trap Boxes

- Camera

- DC Motor

- Switch

Touch Screen Control System:

PLC Control System

It works in coordination with Siemens device that makes it easy for you to operate it. The number of tablets to be counted will be entered here.

Integrated dust and chip extraction:

They are used to remove the accumulated dust.

Feeding Machine:

The tablets for counting are placed on the feeding tray.

Feeding Machine

It further includes the following parts.

Hopper Tray

Conveyer Belt, it will transport your tablets from one place to another.

Hopper Feeder, it feeds the tablets to the feeder trays.

Flexfill System, this system will controls the whole process of counting and filling of tablets in the bottles.

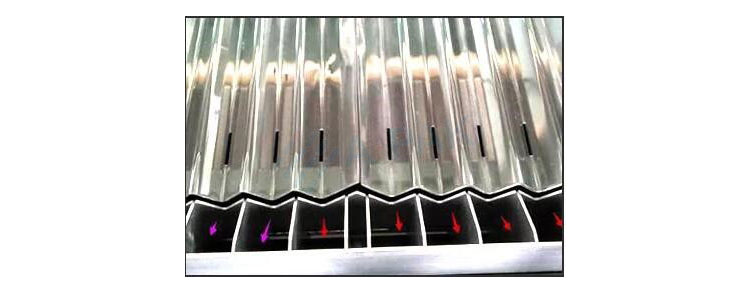

Trap Boxes:

They are used for counting the tablets of small proportions before filling them in the bottles.

Camera:

It captures the images while counting of tablets.

Motor:

It controls the movement of conveyer belt.

Switch:

It is used to turn ON and OFF the machine.

4: What are advantages of Automatic Tablet Counting Machine?

This modern technology is a solution to many industrial challenges. It eliminates the need of labor, shortens the hectic work hours, it also saves you from the intricate insurance processes. It will give you confidence of safe and precise dispensing.

1) Accurate Counting

With the manual counting methods there are high risk of error in counting, and any doubt during the counting will let you to start the counting process all over again. So with this machine you will have confidence in the accuracy and efficiency.

2) Cost-effectiveness

It eliminates the need of hiring staff for counting the pills hence saves the money. You only need to have a skilled operator of machine. It will prove a lifelong investment for you.

3) Time-Saving

It saves you the time of sorting, counting and then dispensing pills of hundreds of types, colors and sizes. A single tablet counter will saves your hours of labor, increases the productivity and eliminates all kinds of doubts that you will encounter while manual counting.

4) Customer care

It enhances the customer and build customer’s belief on you as it put a full stop to customer’s complain of getting wrong pills and wrong bottle.

5) Prevention of Contamination

During manual handling of pills there is need to wear gloves or any other protective layer to avoid direct contact with the pills, however it increases the chances of contamination that may lead to different types of infections to patients and eventually risk their lives, whereas in automatic tablet counting there are no such risks. Thus, a tablet counter is need of hour and is most cost effective and efficient tool in modern world of pharmacy.

5: What are other applications of Automatic Tablet Counting Machines?

Automatic tablet counting machine finds its uses in healthcare, food industry and chemical engineering along with pharmaceutical industry.

1) Healthcare Sector:

A huge number of health care products especially ointments require proper filling in bottles with great precision and accuracy. Thus, tablet counting machine plays major role in this sector.

2) Food Industry:

With the acceptance of capsules and vitamins food industry finds its way for the use of Tablet Counting Machine to enhance the process of food gelatins and capsules.

3) Chemical Engineering:

Overall composition of chemicals depends upon precise amounts of elements thus in chemical engineering you are fully dependent on this machine for high level of accuracy and up to the mark filling.

6: What is the working principle of Automatic Tablet Counting Machine?

You will need to turn ON the push button and check for the system of machine if it is according to your requirements.

You can adjust the time and speed of machine as per your requirements by using touch screen control system. The tablets will be feed in the feeding units, then the tablets will move from tablet manufacturing unit to tablet counting machine.

You can also use the automatic tablet filling machine which automatically fills the tablets after loading, making your task easy. Tablets enter the counting machine through feeding trays. The tablets are automatically guided by the machine throughout the process. This makes the high efficiency and accuracy of results.

The tablets level in the trays is continuously being checked by the hopper system. As tablets will move through conveyer belt, infrared rays will count the tablets and camera on the machine will captures the images of working process. Some of the machines too have function of vibrating and aligning of tablets properly for counting process.

Then the broken tablets are separated, the machine is designed in a way that broken tablets move to another side of fine tablets. After successful counting of tablets you can shut down the machine and clean it.

7: What are the major types of Automatic Tablet Counting Machines?

There are two main types of Tablet Counting Machines.

- Automatic Tablet Counting Machine

- Semi-Automatic Tablet Counting Machine

- Manual Tablet Counting Machine

Both of these types have their own features, advantages and disadvantages. We will discuss both of them in detail to give you complete knowledge before buying.

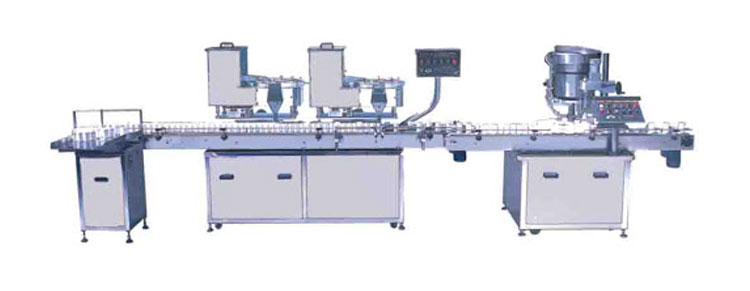

Automatic Tablet Counting Machine

This is modern type of tablet counting machine and is relatively faster than the manual one. It yields accurate results in shorter span of time thus saves you money and time. It will count your product in bulk and ideally it counts 500 to 800 tablets per minute which is much more than any manual counting machine.

Its biggest advantage is that it counts tablets as well as capsules of all sorts, size, color and shape. With its digital touch screen you will be able to control the speed, tablet thickness and pressure, it gives you high efficiency with little effort as it adjusts all the parameters automatically. In case of any issue or emergency there is an emergency stop button too.

This machine is capable of both counting and filling of tablets. The high speed PLC system monitors the whole system and controls the process of counting and filling. During filling bottles are placed at conveyer belt, so that they will be automatically filled at high speed without any distortion.

With the increase of patient demands this technological development is an ideal solution to ensure safe, accurate and efficient dispensing of medicine. This machine has become an integral part of pharmaceutical packaging industry as it is very handy for both qualitative and quantitative packaging and with the shift of centralized hospital pharmacy to decentralized pharmacies it plays a major role in worldwide pharmaceutical industry. Besides this its uses has also been observed in scientific research centers and in average level laboratories.

Automatic Tablet Counting Machine

Advantages of Automatic Tablet Counting Machine:

Following advantages of tablet counting Machine makes it a best choice for you.

Time Saving

It saves you the time of counting pills manually, furthermore it allows you to perform other tasks while machine is operating. You will also no need to stop your work for dispensing pills or tablets in the bottle. All the tasks will be performed by machine at very high speed of 500-800 pills every minute.

Safety

It saves the contamination of pills that occurs while manual counting, thus it gives the confidence to your customer about the safety of process. Also you feel more accomplished and confident, and that ultimately increases your market share.

Cost-effectiveness

This machine will save you from the cost of labor, it counts tablets in bulk thus reduces the need of labor, also it performs counting, filling and packaging of product on its own so you just need to have only one skilled professional to operate the machine.

Accuracy

The results are 100% accurate, there is no doubt in the accuracy and efficiency of machine as chances of miss counting of tablets or any other error are zero.

Customer Care

It improves your customer care as it saves you from hustle of handling the prescription, thus gives you a chance to talk to your customers and ask for their demands from you. You can also tell your customers how dedicated you are to improve their quality of life.

Disadvantages of an automatic pharmacy tablet counting machine

Following are some disadvantages of automatic tablet counting machines that you need to kept in mind, so that you will be fully aware of your choice.

- With the advancement of technology several designs of automatic machine have been developed so each type has its own operating procedure that makes it little confusing.

- If you are not a trained and skilled person the latest model will be complicated for you.

- If there is dust accumulation in the tray sensor then the chances of error occur and this issue will persist until the technician finds it and corrects it.

- It will also lead to miscounting of pills thus patients end up receiving wrong medication.

- It uses the most advanced technology thus if you don’t have trained personal there will be delay in the services that ultimately lead to machine breakdown.

- This machine will going to cost you high as compared to manual tablet counting machine.

Semi-automatic Tablet Counting and Filling the Machine

As the name indicates this machine works on semi-automatic transmission mode and makes use of both manual and automatic transmission. First it makes use of those functions that require human efforts and it occurs while operating and then it intermittently shifts to tasks that would occur with machine. It will too yield results of your requirement.

Semi-Automatic Tablet Counting Machine

Some silent features of semi-automatic machine are:

- It has both Human module interface and PLC system.

- A glass rotary table for automatically supply of bottles.

- High accuracy of filling.

- There is an automatic infeed and discharge of bottles.

- It is certified with cGMP.

- There is limited change of product over the interval.

There are some differences of semi-automatic machine from fully Automatic Machines. These will let you decide which will suit best to your needs.

- The production rate of fully automatic tablet counting is quite high than that of semi-automatic one.

- The fully automatic tablet counting machine yields bulk counting in shorter span of time than the semi-automatic one.

- There is no need of labor as such in fully automatic machine while semi-automatic machine depends on monitoring from human resources.

- There is 100% accuracy of results in fully automatic machine as compared to semi-automatic one.

- The final cost of semi-automatic machine is less as compared to fully automatic machine.

- The technology used in fully automatic machine is modern and fulfill the requirements of present era.

Although the above points lies more in favor of fully automatic tablet counting machine but at the end the choice is completely yours depending upon your needs and level of your industry, demands of your industry and its production needs.

Manual pharmacy pill counter machine

This is the simplest version of tablet counting machine. It is in the form of simple tray that has two parts. The lower part has no holes in the tray and is simply plain, while the upper part of tray has holes. These holes are of different sizes and shape which make it suitable for counting of tablets and capsules. This machines has different number of wholes that count tablets in range of 5 to 250. You will put your pills on the top and shake then tablets will find their way in the respective holes. For accurate results you will need to check that if all holes are filled with tablets. All excess tablets will fall in a tray placed beneath the counter of machine. After counting you will have to manually pack the tablets in the bottles.

Manual Tablet Counter

Advantages of Manual tablet Counting Machine

- Such machines are useful for small scale pharmacies and hospitals.

- They are cheap.

- They are simple and easy to operate.

- They don’t require skilled technician for the operation of machine.

- In case of any problem or error it is easy to tackle the issue as it is very simple.

Disadvantages of Manual Tablet Counting Machine

- Although it is cheap and costs less but its accuracy is very low as compared to automatic tablet counting machine.

- You will have to hand filled the bottles as machine doesn’t perform filling function.

- There are high chances of pill contamination.

- This machine requires your full attention to operate, handle and then pack the tablets. Thus it takes a lot of your time, ultimately delay of your other tasks.

- It needs large number of pharmacists to handle the manual counting at machines.

8: How can you clean your Automatic Tablet Counting Machine?

The machine needs to be clean after every 8 days or when there is any error in the system. If there are most dust generating medicines then you will need to clean it on regular basis. This machine has automatic cleaning reminder but you can customized it by turning the cleaning checklist off and adjusting the cleaning frequency.

Some medicines like sulfa will automatically generate the cleaning reminder for you. You will need 70% of isopropyl alcohol and distilled water along with glass cleaner liquid, mild soap and paper tower for cleaning the machine.

Firstly you will unplug and turned off the machine completely and then you will start cleaning the parts of machine one by one.

Funnel Cleaning:

Firstly you will clean the funnel by removing it from the unit and then with mild soap, water and alcohol you will clean it thoroughly inside and outside.

Glass Detector Window:

Glass Detector Cleaning

You will remove the square guards by unscrewing the two round thumbscrews present on the top of the unit. By carefully lifting the entire system you will wipe the extra dust using a dry cloth present inside of four clear detector windows. Then you will use the mild soapy water or alcohol on a clean cloth to further clean the glass window. Carefully wipe back and forth and not up and down. Then you will dry the window by using computer screen cleaning cloth and remove all the streaks.

Then you will check the outer parts of the inner assembly to check the dust, you will clean any dust using the distilled water and wipe to dry it.

When you get satisfied with the cleaning you will carefully assemble the system at its place and behold it by tightens the thumb screws. At the end you will push down the sliding rings so that two black clips will spreads to gently hold the glass window so that it doesn’t break.

Counting Tray Cleaning:

You will simply use mild soapy water to clean the tray, generally alcohol is not recommended for this purpose.

Tray Sensor Cleaning:

This try is present behind the counting tray and it indicates that the counting tray is present correctly. You will remove the tray and clean it with distilled water and dry it with the wipes to remove any streaks.

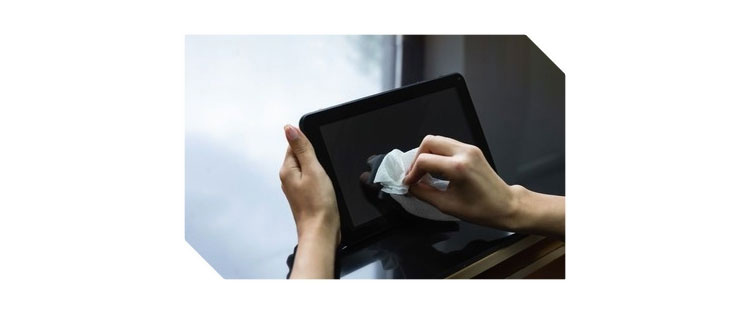

Touch Screen Cleaning:

You will use the computer glass cleaner on the soft cloth to clean this screen.

This whole step by step protocol will clean your machine like the new one and solves the any occurring error.

9: What points you need to kept in mind before buying Automatic Tablet Counting Machine?

Some silent features you need to check before buying an automatic counting machine are following:

Automatic Product Setup:

Always select the machine with latest automation of hardware and software, it will give you an ease while operating the machine. In latest technology the product is calibrated by placing it on a special calibration tool, where it is scanned by the camera, and it will automatically arrange and set the tablets based on size, color and other features. This feature is very helpful as it completely eliminates the chance of any human error.

Production Capacity:

Always select the machine with high production capacity, in this regard you must always choose the machine that will count the complete pharmaceutical product you will produce.

PC Based Operation System:

This is the most user friendly and modern system that works through a color touch panel and its internal and external functions are controlled through one HMI in a matched standard.

GMP Design:

You must always choose the good GMP product design with no blind spots as it is designed in a way to help operator to observe each unit of product from hopper to the bottle.

This feature help in prevention of cross contamination of tablets.

Budget:

Always look for your budget before buying. The more you invest the more accurate the output and bulk production at the end. Thus spend wisely.

Accuracy in counting of Pills:

Always choose the machine with 100% accuracy, as this machine is a technological solution of manual tablet counting. Also check for the automatic weight adjustment of tablet when the machine transits from one lot to another.

Fragmented Pills Detection:

You must check for the automatic pill detection in the machine, although the ICU-40 is a vision based system that accurately detects the pill. The machine detects the smaller broken particles of even 0.5mm. It also checks whether the broken tablets have been poured in the system or the complete weighing load. In this way it sends the notification through an email to the operator to remove the fragment it saves both time and money by the rejection of broken or any size varied tablet.

Facilitate Cleaning and Changeover:

You must check for the machine that is designed for tool-free release to assists in cleaning process.

There must be spare part tool kit to assists in five minute change over from one part to another. In this way we can clean the machine after every 8 hours during the process or when needed.

Dust insensitivity:

In modern machines you will get to see that the counting machine is separated from the truck and it will always alert you when the dust will accumulate. Moreover the vision based system also has a magnetic flap connection that reduces the dust effects on the machine.

On Screen Instructions:

These instructions on the machine will help the user to operate the machine and how he/she will count the tablets. By following these instructions there will be no chances for the error also it saves the time of the person who is using the machine for the first time.

RX Verification

The biggest advantage of this machine is that it cross check the prescription and the drug being administrated for the counting. It scans and compares the supply bottle with the RX label thus preventing human error. When these two codes matches machine gives the signal for continuity of counting.

10: What important features you must take in account before importing Automatic Tablet Counting Machine?

You must be aware of all the quality standards of the machine before importing it.

Certification:

Always look for the quality assurance certificate before importing. Check with the seller for CE, UL and SGS quality certificates. If the seller doesn’t provide you with these certifications don’t buy from them.

Don’t fell prey to scams:

Online shopping is very risky, so beware of scams and check the reviews and authenticity of seller before making final deal. Don’t waste your money on frauds.

Check for Authentic Website:

Don’t only go the profile of company on Alibaba or Amazon, always check for the website of company and also try to make the deal on website. Do your proper research before buying.

Qualified Detectors:

The performance of machine completely depends upon its detectors, a machine with high quality sensors will surely benefit you in long run.

Operational Speed:

A fast operational machine will perform its tasks in lesser time and will yield high outputs.

Delivery Time:

Ask the company for the required time of delivery before ordering to avoid any hustle later on. Also ensure with the seller to deliver it as soon as possible.

Price Negotiation:

Always look for the best possible price, don’t compromise on the quality but do your research beforehand and then negotiate with the seller for best possible price.

Performance satisfaction:

Make sure the machine is stable in its performance as slow but stable machine will more benefit you than the faster but unstable one. An unstable machine will waste your time and money to maintain it.

Company Reputation:

Reputation of company matters a lot, a good reputed company will definitely provide you with the excellent quality to maintain their market image. That’s why always go for reputed company.

Shipment Cost:

Being a good businessman you should know how and where you can save your money. So always try to look for minimum shipment cost without risking your machine quality.

11: How to tackle common problems of Automatic Tablet Counting Machines?

Along with its huge number of advantages in pharmaceutical industry some problems may arise in the machine because of improper handling of machine or due to some technical fault.

Here you will be guided with some of problems along with their solutions, so that you will not feel helpless or worry at the time of need.

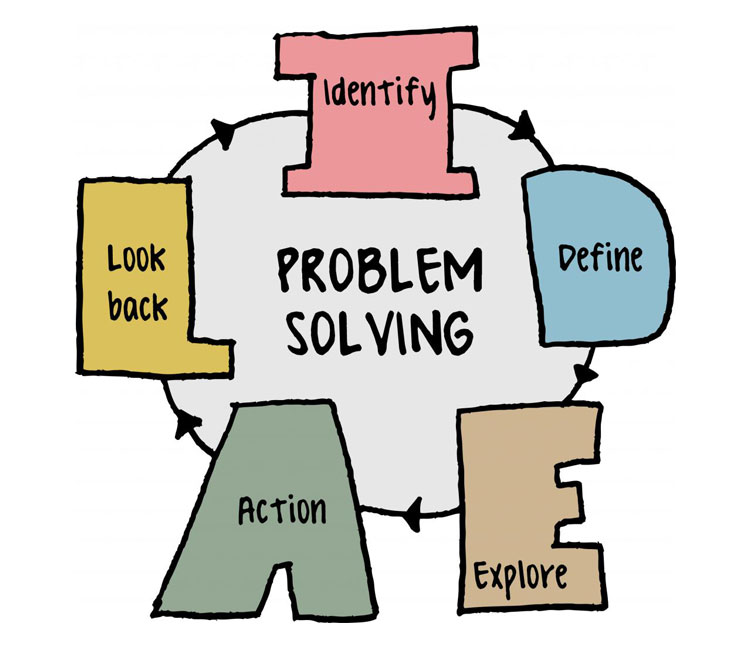

Problem Solving Technique

Counting error:

It occurs in the form of over or under counting of pills.

In over counting of tablets the number of counted tablets is more than the requirement, it mainly occurs due to fragmentation of pills or if there is any dust on the glass window of detector. This causes disturbance to both patient and pharmacists. You can avoid this problem simply by checking the fragmentation of tablets at the medical counter, secondly you need to take care of glass window that it must be clean free of any dust and contamination.

In case of under counting of pills the number of counted tablets is less than the required quantity. And it occurs because of improper handling of machine by pharmacist. In this case, the number of pills counted is lesser than the actual number of pills. If the pharmacist pours tablets at high speed or if he/she pours tablets directly into the hole of funnel. The machine too will show you the warning of “pour slowly”. This can be avoided by simply reducing the speed of pouring tablets.

Display error:

This problem occurs in two forms.

Display of “__” instead of “0000” after insertion of tray.

Display of “0000” even when the tray is not properly inserted

In the first one there is problem in the insertion of tray or contamination of tray with dust. So this can easily be solved by correct insertion of tray and removal of dust.

In the second one there is damage or contamination of sensor window, that’s why it continuously shows “0000” even before the proper insertion of tray. You just need to find the root cause of the problem and then solve the problem accordingly i.e. replace the broken glass window or clean any kind of contamination if present.

Unit Count Error:

Any kind of dust on glass window detector or on the tablet may lead to this problem. To solve this issue you just simply need to replace the glass window and ensure cleaning.

To avoid all these issues you just need to have trained personal to run the machine smoothly. Along with this you need to be very careful about the maintenance of machine especially cleaning of machine after specific time.

Conclusion

This machine has been an integral part of medical field, it help pharmacists to attend so many patients at a time without any trouble, thus resulting in good pharmacist-customer relationship, high profit revenue. It gives confident to both pharmacist and patient of their safety. Thus, it will prove a great investment for your business.

Tablet Counting Line Related Products

Tablet Counting Line Related Posts

Tablet Counting Line Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine