Automatic Labeling Machine: the Complete FAQ Guide in 2025

Labeling is one of the most critical components in a pharmaceutical tablet/capsule counting line.

A customer’s perception to the quality of the medicine is directly related to the quality of the label on that medicine bottle.

As it’s on the labels that you will indicate some important information about the medicine such as name,ingredients,specification,manufacturing date ,expiration date,etc.

Therefore,labelers must be precise to show quality and also be flexible to meet the changing regulatory demands.

Well,today I will use this guide to make you know more from classification,benefits,working principle,FAQ about this automatic labeling machine.

Spend a few minutes reading through ,you will appreciate how effective this automatic labeling machine works in labeling various products.

Now Let’s drive to the subject directly.

1.What is an Automatic Labeling Machine?

Automatic labeling machine is a machines that distribute, apply or print as well as apply names to different things, items, boxes and even on the containers.

Makers of the labels make labels for various purposes, for example, transporting addresses, item data, price tags which can be scanned and stock control.

2.What are the Benefits of Automatic Labeling Machine?

For you to finish the assembling cycle successfully, you need to have an automatic labeling machine. You must be craving for that.

What I can let you know here is that if your objective as a business is to interest your objective market, there is no uncertainty that you have to put resources into this automatic labeling machine.

You need your items to highlight top notch logos, text, or even designs if at all you need to make a good market which is better than your competitors and you want your product a high end one.

Furthermore, that is the place where labelling machine gets helpful.

So in this segment, I urge you to take have a general view of the indispensable and useful reasons that would make you put resources into this sort of machine.

These are some of the following major benefit of then labelling machine which you can get when you buy;

Adaptability and productivity in Labeling prerequisites

Not only in the labeling business, but also in every kind of the business efficiency is the top priority.

Presently, this is the thing; at whatever point you need to attempt a labeling cycle on your items, one basic thing you demand is effectiveness.

The other essential angle that this machine brings is adaptability.

If you are a generally enormous scope labeling doer, it implies that every now and then you'll be marking or labeling various items.

Utilizing this sort of an automatic machine, thus, offers you the adaptability to modify or change the applicable setting to influence the specific labeling item.

To speed up Production

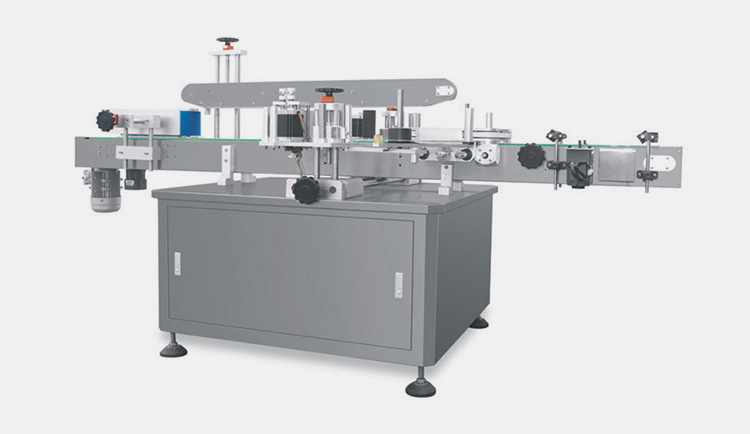

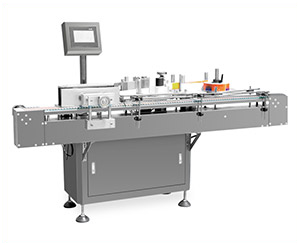

AIPAK Automatic Labeling Machine

Most importantly, you need to comprehend that these days speed of the production is a vital component which even influences the market.

Imagine you have enough orders but, some what you are lacking in the technology and not achieving the target on time.

That will be big trouble for you indeed.

So, what the solution of this , An Automatic Labeling Machine?

What I am attempting to state here is that the quicker your items get into the market, the higher the odds of expanding deals and creating more income.

So utilizing this machine without question, will make it feasible for you to expand the speed of the production line.

Less worker needs and expands throughput

There is no doubt in that labor is expensive and everyday the cost of labor is increasing.

When you see it from the cost prospective, When you have numerous individuals working for you, the odds are high that you turnover rate will be less when you compare it with the automatic system with the less labor.

Laborers will require pay rates, rewards, breaks, excursion days just as other pay.

This isn't the situation with regards to an automatic labelling machine to labeller.

So you'll see that you spare a serious meaningful amount of cash and simultaneously take the production cycle to the next level.

Improved labeling in terms of safety

Appropriate handling of the machine is a must things and its needs to be taken care of.

Machines can be a risky thing and unsafe in the event that you neglect to deal with or work properly.

So with a programmed labeler, your betterment measures are sure given that the majority of its boundaries are very easy and simple to cooperate with.

This unit includes all the conceivable which not only make sure the safety of the machine but also the product you are labeling.

Lessen the number of Errors

The more the number of the errors the lesser the efficiency. The lesser the efficiency the lesser the productivity.

So, in one way or another number of errors effects lots of things in the process.

Evidently, putting resources into an automatic labeling machine makes it feasible for you to lessen the quantity of mistakes essentially.

If you think, this is a technological device which comes or rather includes a few boundaries including confirmation choices.

This machine additionally includes scanners and imagers which help check the readability of the standardized tags and messages.

So in a general sense, these are certain and important factors why init can be your perfect reason to put resources into this machine and use it in your production facilities as soon as possible.

As should be obvious, these reasons are very reasonable, and they go far in making sure that you get an incentive for your cash.

3.What are the Application of Automatic Labeling Machine?

This part will be bit briefer than the earlier.

Through out the article, it is very evident that the uses of this auto labelling machine are very a few.

That regardless, let me drive you you through quite a major of the uses.

Production of the Pharmaceuticals

It is one of the most well known businesses that utilization this sort of machine widely.

The greater part of the drug items are named and by the way it a lawful necessity.

That is the reason various sorts of auto-labelers are generally utilized here to guarantee that they give data with respect to the item.

As should be obvious from this article, drug industry uses different things, holders, container, vials and ampoules among others.

Also, since every one of them must be labeled, it gets sensible to utilize this machine.

You can discover them in different business pharmacological organizations just as other small business.

Beauty and Cosmetic Industry

This industry likewise uses this machine broadly particularly in cosmetic industry for labeling them.

It is additionally a necessity that these items are labelled as a method of managing and defending customers in an unexpected way.

They help in giving data with respect to a specific item.

Writing Material

The makers of writing supplies likewise utilize this machine in marking a wide scope of their items.

The explanation here is that they need to recognize their items and things by making them one of a kind consequently expanding their appeal to the intended interest group.

Light Ventures

Light ventures that fabricate various kinds of items, for example, cleansers and treatments among others will in general utilize this machine broadly.

It empowered such makers to innovatively put or apply their particular marks on the things to prepare them for purchasers.

Synthetic Enterprises

As a lawful necessity, all synthetic items require to be marked to make it feasible for clients to recognize what they need and how they use it.

So the majority of these manufacturing plants will in general guarantee that they put resources into great programmed marking machines for such purposes.

Food and Refreshments

In the event that you go to food joints or markets, you'll notice that all nourishments and drinks have names and labels.

Thusly, it makes it simple for customers to understand what they're exactly buying.

Additionally, it permits them to know the substance of the food or refreshment that they're purchasing.

Also, it's thus that utilization of this machine is more predominant in this industry.

4.How many types of Automatic Labeling Machine are there?

In this segment, that is why, I need you to read some of these kinds of programmed labeling machines which you're probably going to go over.

Clearly, this will result into good for you to settle on the correct buying choice and guarantee that you get what suit your requirements.

So, below mentioned are some of the major type of automatic labeling machines

Horizontal wrap labelers

This is the kind of automatic labeler which is regularly utilized for marking compartments or things which are fairly shaky and circular.

It is hardware worked to apply pressure delicate mark naturally onto generally round types of thing which can't pass on upstanding on the transport.

Horizontal Labeler

You place the things on an even roller which then runs them through that is called as a wrap station.

This kind of programmed labeler is ideal for you in the event that you are an agreement packager or producer that serves markets encompassing the biotech, drug or pharmaceutical, individual consideration, and makeup.

Vertical wrap labelers

It is likewise another kind of programmed(Automatic) labeler that is normal in market these days.

It is typically utilized for various items and things including those which are marginally tightened, stable square and rectangular shapes.

This machine administers pressure-delicate names with outrageous precision.

It accompanies probably the best highlights, for example, stepper engine drive for mark and auto speed changes.

Furthermore, this machine likewise accommodates halfway and full making of the label it among the most well known choices around.

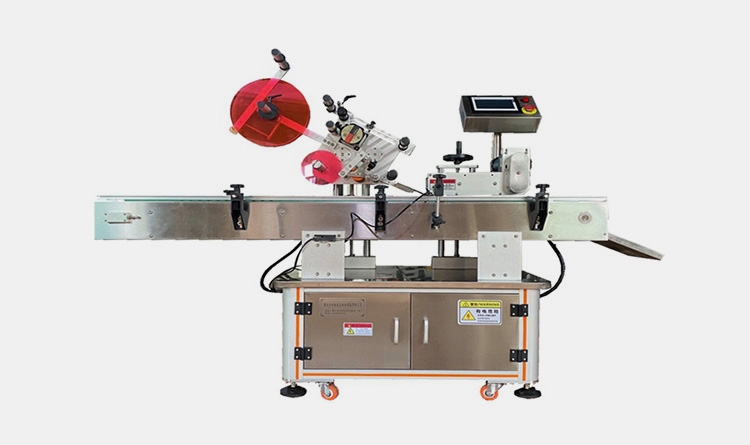

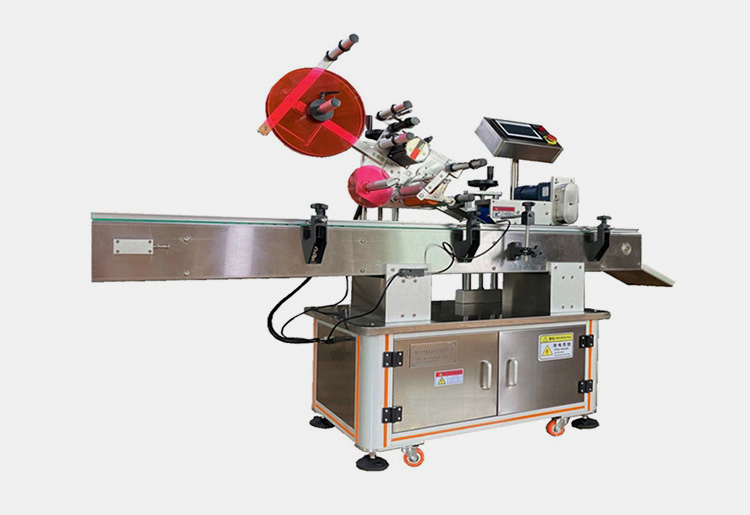

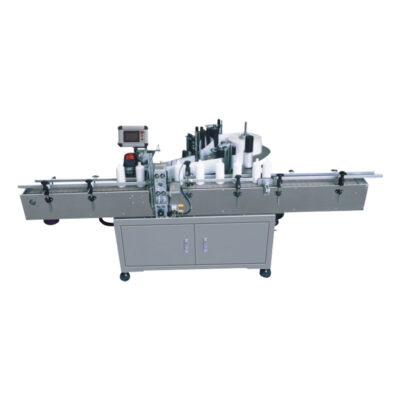

Back and Front labelers

It is additionally among the generally utilized sorts of auto or automatic labelling machines over a wide scope of ventures.

You utilize this gear to put labels on a both sides of something, or in certain occurrences, including some change.

Front and back marking machine

The plan of this labeler is obviously to assist with obliging different oval compartments or flat sided.

Furthermore, is that you should decide to add a discretionary third or fourth implement as a method of giving zero vacation labeling.

It is in any case imperative to comprehend that bottles for this situation likewise should be steady enough as a method of protecting stumbling while moving items to transports.

Top Labelers

Top Labeling Machine

It is apparently the most-adaptable sort of programmed marking machine or automatic labeling machine that you can actually have around.

You can be used for the labeling of wide scope of items of different applications including gadgets, pharmacological and also edibles items too.

Top labeling machine is easy to work with and it does work by putting the board or spot on the highest point of the item which passes.

Also, before the finish of the cycle, you'll have a fine and great label on the specific thing or item that you are labeling .

Top and base labelers

It is additionally another normal and famous kind of automatic labeling machine or programmed marking machine which you need to think about.

In numerous occasions, it is constantly utilized for labeling things or items which need both top and base labeled.

Top and Bottom Labeling System

For example, you may need to put an UPC mark on the base and simultaneously place an item name on top of the items.

One beneficial thing with this unit is that it gives setups which you may decide to use for a wide scope of holders, for example, cases, bottles and cartons.

Custom marking utensil

So this is a sort of implement which you alter as the end client to coordinate the particular setups which you require.

There are cases where the organization machine may not really fit your requirements.

So you should simply only change the different settings and different types of designs to make it workable for it to be viable.

There are a few occurrences, notwithstanding, that the organization makes these vital changes as a method of making similarity.

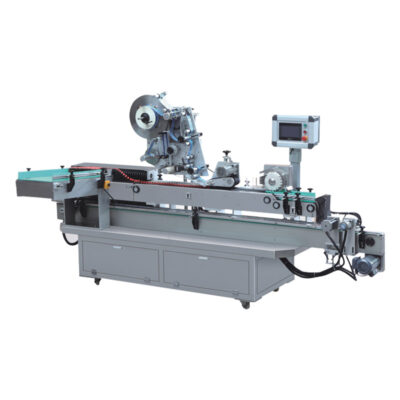

Print and apply labelers

This is a kind of programmed marking machine or automatic labeling machine that gives great naming or labeling requirements to your items.

It is ideal for standardized identifications, high-goal messages, beds, pictures on cases just as therapist wraps among others.

Print and Apply labeling Machine

The majority of the models of this kind of labeler additionally include unrivaled innovation which helps in exact position of marks on the bundle even at high speeds.

A print and apply labeler can fulfill all labelling requirement with respect to production line and profitability.

Depending on your application type of the automatic labelling machine

It is additionally quite important to to comprehend that very a few machines of labeling likewise come dependent on their particular applications.

Obviously, this is fundamental since it makes it fairly simple for you to decide the specific kind to choose relying upon your need of the application.

So we should take dive right into the details of these sorts dependent on the applications and see the change that every one of thees automatic labelling machine offers;

Automatic labeling machine for Tins/ Cans

Similarly as the name recommends, this is a sort of programmed labeler utilized for putting marks/labels on surfaces of jars or can.

The sort of label may fluctuate just as the areas of the printing place on the surface of the can.

It has been advised that when searching for one, you must be choosing the one that is most recent innovations to achieve high speeds and accurateness in the labelling.

This kind of machine is essential in case you're fabricating items that are bundled on jars, for example, soda pops and different refreshments cans.

Along these lines, it gets judicious to guarantee that you investigate them acutely to choose the best one which meets your requirements suitably.

Labeling machine for bottles

It is additionally another basic kind of labeler that you're almost certain to run over.

This type of the labeling machine is reasonable for marking bottles of various items moderately fats and viably.

The uniqueness of this type of the machine is that it gives you the opportunity of customising the labels on the bottles which is very unlikely to happen in the other type of the machine.

They do come in various sizes and limits with some intended for business creation of thousands of containers for every day.

Then again, others are intended for little scope creation/ production, yet all will in general work in pretty much a similar aspect.

The automatic labeling machine for cartoning and boxes

This automatic labeling machine has both names the boxing as well as the cartoning machine.

Just as the name recommends, this could be used for applications most of the time for the boxes and carton labeling.

It is useful in putting marks on the different segments of the container just as the determinations of the specific item in the crate.

This automatic labeling machine you can use in a wide scope of enterprises including pharmaceuticals, safety , and makeup among others.

It includes an appropriate speed, obviously relying upon the model you're thinking about, yet as a rule, the greater part of them are very simple to work with.

Automatic scanning bar code labeling machine

Indeed, this one alludes to the naming machine which you can use for printing different sorts of scanner tags for different components.

A portion of these components incorporate delivery marks, gear labeling, item labelling and parts following among some more.

The substance of putting standardised identifications on various things is to assist you with seeing item subtleties, to notice if you have enough stock left to not or if you require more inventory or not, and deals finish whenever coordinated.

Vial Automatic labeling machine

This is the kind of marking machine explicitly intended to name vials generally in the drug and corrective industry.

A remarkable component with respect to vial marking is that it requires generally fast and elite naming frameworks.

Ampoule automatic labeling machine

Horizontal Ampoule Labeling Machine

Above all else, you need to realize that an ampoule alludes to a generally little fixed vial utilized in many happenings to keep the samples safe.

So we have machines which regularly are utilized to apply labels or marks on ampoules naturally.

The proficiency of this machine is likewise subject to the particular model that you lean toward just as the limit among different subtleties.

As should be obvious, we have a serious a few sorts of automatic labeling machine to browse.

It can be hard and be interesting to decide the specific one which you need.

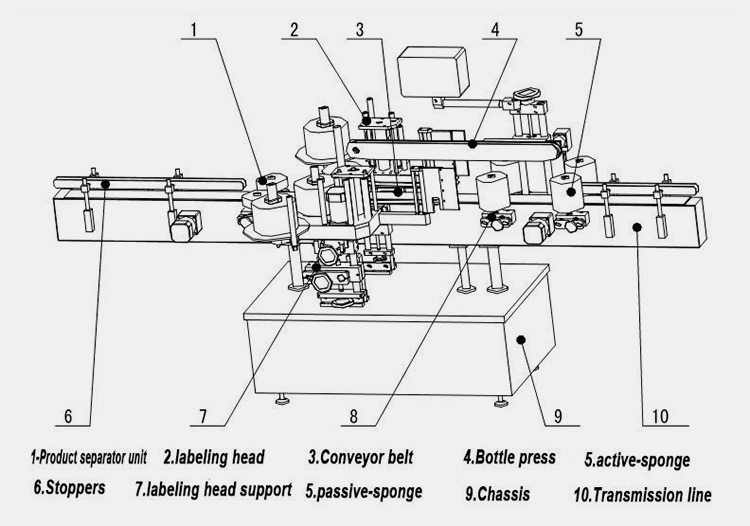

5.What are the Main Components of Automatic Labeling Machine?

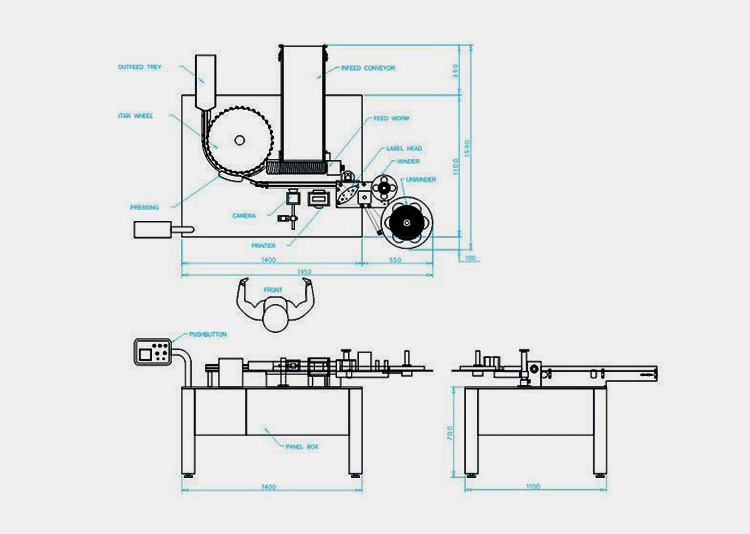

Component of Automatic Labeling Machine

So, this part is none other than the key components of the automatic labeling machine.

Labeling head

This an entire unit which highlights different parts.

It is in different occasions known as labeling applier, and its fundamental capacity is to put the names/label on the outside of the thing or holder.

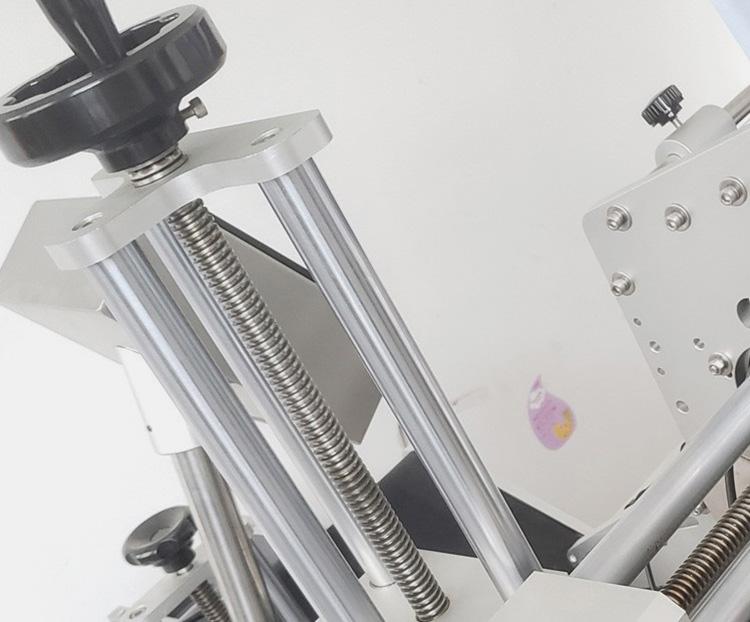

A portion of the parts which make up the labeling head incorporate these;

Drive roller

This is obviously the workhorse of the labeling top of any auto labeler.

It works by pulling the web backing subsequently beginning and halting or stoping with each marking grouping.

The majority of the drive rollers are moderately comparative in all the auto-labelers.

The main contrast maybe may emerge from the way it is driven and halted.

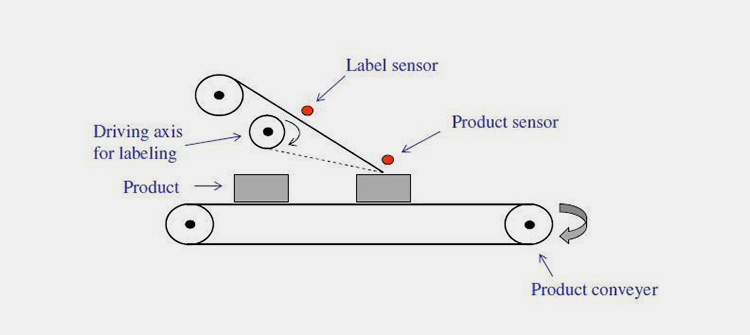

Label sensor

This part helps in recognizing the holes that exist between names as a method of controlling the framework to start a name stop succession.

It includes an electro mechanical switch in certain models and a capacitive sensor which you need to change when changing name stock.

Chassis

Just like the human skull to include every part of the body. An automatic machine also need a frame like body to hold each and every part of the machine in it.

This alludes to the base edge of the machine which shapes the underlying structure which some way or another looks like a square.

It assumes a basic function in the general working of this machine since it offers help for the wide range of various segments and parts.

So, some of the key factors should be kept in the mind.

The majority of the frame of this hardware is made of hardened steel material to give the vital soundness.

Plate or Tray

It is the one that takes them into the machine for the process.

The majority of the plate are situated on the upper side of the machine obviously for simple access and taking care of the marks.

It is additionally made of tempered steel material which is significant in light of the fact that it makes it is repellent to a wide scope of components like synthetics and troublesome atmosphere.

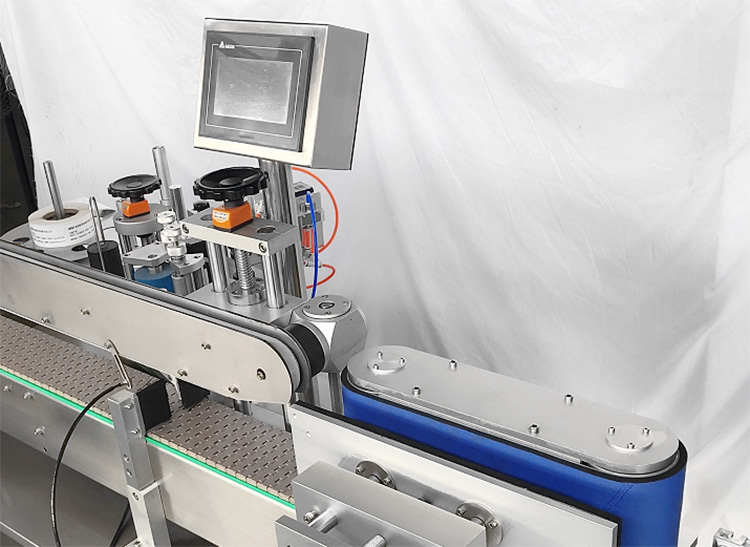

Conveyor Belt

Standing on the airport waiting for the luggage you always get through the conveyor belt. Same is the function of conveyor in the automatic labeling machine. It takes the label to the place where it should be.

It moves the material in a pivoting movement which makes it simple for it to interact with the outside of the thing.

Conveyor is key part of the machine, and it accompanies various settings to permit you to sort out the requirements that you need to accomplish during labeing/marking process.

Touch Screen Panel

Just like a mobile screen touch panel.

By using this panel you can have access to the different control on the machine.

This part of the machine makes it simple for you to screen the advancement and different modules spinning around an automatic labeling machine.

It is likewise important since it makes it simple to decide all the capacities and different settings of the machine as a method of accomplishing effectiveness.

Motor

By using the electricity this is an electric part that assists in running the machine by changing over electrical energy into mechanical energy.

The limit and size of the engine regularly differ starting with one model then onto the next.

Yet, it has always been suggested to investigate this part when buying an auto labeler on the grounds that it decides execution in a meaningful manner.

Strip plate

The substance of this part is to isolate the backing of the paper from the label.

It works in a way that the web breaks strongly over the strip plate as the mark proceeds in an orderly fashion.

Dancer's arm

The part of this segment is to help in permitting smooth marks to begin.

It keeps web strain just as going about as a brake for halting the web loosen up move from overloading.

Controls

All things considered, since this machine is automatic, you would anticipate that it should have however many controls in the machine rather than handling them manually.

Truly you need to comprehend the different controls of this machine and the impact they have on any capacity.

This machine can be controlled by the switches, and in certain examples, some are controlled by the touchscreen.

Touch Screen Panel

So you need to realize which catch plays what work and the simplest method of accomplishing this is by perusing the client manual.

So these are the couple of yet key segments of an automatic labeling machine.

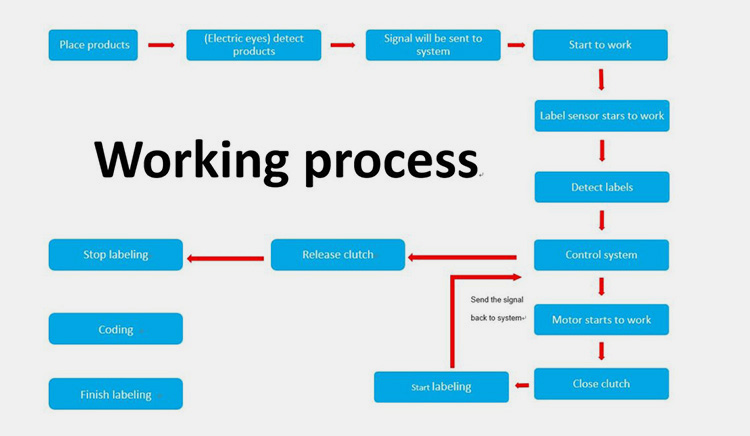

6.How does Automatic Labeling Machine working?

This is pretty much the simplest of the operation.

Working Principle of Auto Labeling Machine

- Pick suitable settings for the machine through the HMI touchscreen control board

- Set up your label at the right place

- Guarantee material or holders you need to label are in the correct segment

- Run the labeling process

- Screen the cycle by means of the HMI control board

- Survey things/items are being marked

Having said that, allow me to take you through the working principal of the automatic labeling machine.

Working of Principal

Container/Items/ Feeding phases

An automatic machine uses an alternate system to take care of material into the labeling system.

A few machines utilize a vibration system to take care of things onto the belt, that takes them into the labeling station.

Station of the labeling

In most of the cases, if the label has the right information and already printed before hand.

Indeed, some come when they have been sliced to the correct size.

Labeling Machine Work Station

This will rely upon the plan of the machine.

Regularly, the items feeding system and label of frameworks are sync together.

It is to guarantee the pace of the feeding of the both labels and items will be the exactly same.

Here, the in-feed frameworks guarantee right separating of the holder you need to label.

Framework wheel hauls labels in a rotating development. Simultaneously, the name/label is extricated to the reel, causing pressure for the following label.

The machine dispense, taking into consideration their application on the holder framework. Obviously, this is because of a computerized sync between the name and compartment feeding framework.

Machine applies the marks of the label at a already decided position on the things.

There are machines that print the marks on the compartments. Obviously, they will print all data including the batch number too.

Simultaneously, the machine has sensors that recognize if the labels have been applied appropriately.

Removing things after labeling

Automatic labeling machine will remove the label items.

Additionally, at this stage, you can investigate the eventual outcomes to guarantee they fulfill the correct quality guidelines or not.

Auto marking machine has a basic and simple working rule and cycle.

Keep in mind, there could be varieties with regards to various phases of the working guideline of programmed labeling machine.

Try not to stress, it always come with a user manual.

Truth be told, good companies offers both installation as well as training pf the machine.

7.What can you Label through the Automatic Labeling Machine?

As prior referenced, automatic labeling machines are intended to apply marks to an assortment of items, compartments, bundles, bottles and so forth

These machines can stick names to an assortment of surface materials, for example, aluminum, plastic, glass, fiberglass, steel, and so forth.

8.What Factors do you need to Consider when Buying an Automatic Labeling Machine?

All things considered, as I referenced prior in this guide, finding the good and most reasonable auto machine that meets your requirements can be troublesome.

Unexpectedly, the numerous points that you need to consider when purchasing this machine are what makes it this difficult.

In this part, I need you to take into the deep insight of the vital points to investigate before making any buying.

Plan and Development

The second you'll start your quest for this type of machine, regardless of whether on the web or in the market, you'll notice that they come in different plans.

What happens is that each producer needs to be novel as a method of drawing more customers for buying their designs.

How a machine is planned and what is there development procedure does matter a lot.

Some plans may very well be to interest the eye while others may help upgrade the proficiency of the machine.

When all is said in done, it is fitting to quantify your requirements and decide the correct plan which suits the equivalent.

Auto Labeller Designs

This will help guarantee that you achieve the best outcomes.

Consumption of the Power

It is likewise another central perspective which you need to keep focused at whatever point you're choosing an ideal auto labeler.

The main point here is that most of the new innovative technological machines have a special system. It helps in saving the energy.

Yet, you must be sharp enough to feel the differnece since this innovation does not come in every type of the machine.

So to play it safe, guarantee that you check all the previous ratings of the machine if you are buying an online machine.

Additionally, remember that power utilization of a machine can likewise settle on the nature of labeling or perfectness of the machine.

Consequently, you should be cautious when investigating this specific factor.

Profitability and Innovation

All things considered, for this situation, it basically implies that you need to monitor the adequacy of the machine in accordance with the related innovation.

Nowadays, particularly for auto products, it would be by one way or another hard to compromise on the innovative part of the product.

Also, in many cases the innovation of the machine is the thing that fundamentally directs the degree of efficiency of the machine.

So it is fundamental to choose a machine that includes all the basic specialized necessities for appropriate working and better outcomes.

Shape and Size

It is pretty much comparable or identical with plan and development.

Hence, you additionally need to understand that the machines size is essential with regards to deciding the reason of the labeling machine.

Like for example that you're going for business creation or enormous scope labeling, at that point maybe you'll require a moderately huge automatic labelling machine.

However, for smaller scale of the production, you'd need a to have a modest sort of machine as long as it is viable.

Additionally, you need to pick the size and shape of the machine relies on the space you have for placing the machine.

Specialized detail of programmed marking machine

Specialized determination of programmed marking machine

The main thing is to guarantee that the size of the machine you select affect the quality of the your labeling system.

Labeling Spool

This alludes to a round item where the marks are twisted to apply to the separate surfaces.

Labeling spool is a significant component in the auto labeling machine particularly with regards to estimate.

By this, I imply that you must be distrustful with the size of the labelling spool that the machine accompanies.

Likewise guarantee that you go for one which has a spool that is very simple to stack with the label for better time management.

So, related to this we are done.

Rejection

Rejection is always a chance in any kind of production that is why we always have the tolerance level.

Indeed, when managing a labelling machine, you must be aware of the way that rejection is always on the way.

In any case, there is always a standards pre defined if machine does not have that setting it will definitely reject the label.

In fact, this perspective is constantly controlled by the standards of the machine which has a method of dismissing terrible quality label.

So when looking for one, guarantee that you do a test to sort out how it's rate and method of dismissal happens.

Production Duration

This alludes to the length that the machine makes a to be out of move or inaccessible for use.

This machine typically works consistently.

So there is a likelihood that sooner or later, it will some way or another slower.

Indeed, this is pretty much justifiable.

Be that as it may, the worry, for this situation, should be the means by which successive it eases back down.

Obviously, a machine with successive and expanded download is superfluous for this cycle, particularly for business production.

Along these lines, you should guarantee that you cautiously investigate this to decide the best one since it influences the quality and proficiency of labeling items.

Label Putting Frameworks

With the on going innovation, distinctive auto labelers models accompany a wide scope of label putting frameworks.

So as a client, it is upon you to choose the specific framework you'd want to use on your items dependent on the labeling.

In many occasions, you would locate that a specific machine can apply up to multiple frameworks.

Hence, all you require in such occasions is just to change the settings appropriately.

label putting framework besides is an essential component that you ought to never neglect to consider when looking for an automatic labeling machine.

Similarity with Different Machines

Indeed, as I referenced prior on, a labeling machine must be incorporated with a few good points to make it powerful.

You'll see that they use a type of programming as a method of ensuring productivity.

Hence, this software is that you need to ensure is viable with other gear that you'll be utilizing in the marking cycle.

The similarity of that software, just as different parts of the activity, is basic in the general execution of the auto labeler.

In any case, the instrument itself likewise should be viable with other available equipment that you'll conceivably interface with it to finish the cycle.

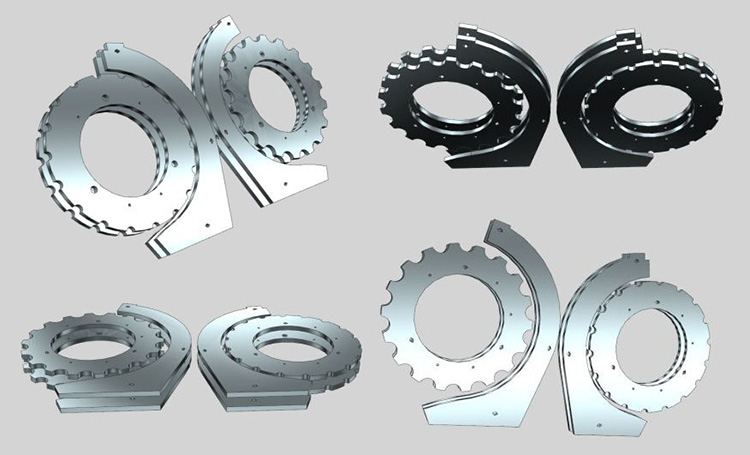

Change Parts

Labeller Change Parts

The another part of the automatic labeling machine which needs to keep in mind is changing of the parts if something wrong happens.

You must know about the way that sooner or later in time there are parts which will destroy thus need to be changed.

Furthermore, that is the motivation behind why it's significant that you go for a model which has the majority of its change parts promptly accessible.

Moreover, these parts ought to likewise be anything but difficult to fix which becomes huge particularly when you're in an activity.

With the goal that you don't need to stop the labeling running process for long to fix the parts in like manner or need to look for help from a specialist.

Ease of Usage

Last but not least is the ease of the usage.

Of the multitude of components that you should never disregard while choosing an auto labeler is its simplicity of activity when utilizing it.

You can have a high grade automatic labeling machine, yet it can be of no use for you.

What I'm attempting to state here is that for each buy choice that you need to make, consistently guarantee that the machine is easy to use.

Here I do end the thinks you need to consider before buying part.

9.What other Auxiliary Equipment is needed to cooperate with the Automatic Labeling Machine to form a Complete Line?

Complete Tablet Counting Line

Auxiliary equipment cooperates with the other parts of the automatic labeling machine and run it perfectly.

These are following parts for the complete line;

Un-scrambler

A Bottle un scrambler is to scatter the material in an order and keeps the bottles arranged on the belt line to match up with the necessities of high automatism.

Desiccant insert machine

A desiccant inserter on the other hand is a machine used for automatic handling framework to replace the past manual operation.It can naturally cut the belted desiccant and put the desiccant pack into the bottle precisely and expediently.

Counting machine

An counting machine is a sort of machine reasonable for the counting the numbers of tablets, granules and capsules.

Capping machine

A capping machine where as is a closing machine or bolting machine. It is a instrument that utilized for screwing and easing the covers of plastic bottles,glass bottles after sub stacking.

Induction sealing machine

Lastly, you have a sealing machine is a gadget utilized for fixing holders loaded up with bundles. It is important to seal the bundling holders for safety of the items, keeping up the nature of the items and dodging the deficiency of the items.

10.What quality standards should Automatic Labeling Machine compline with?

Truly. Aside from guaranteeing quality and solid development, marking machines should satisfy certain guidelines for quality, dependability and execution.

These standards are set by the business and each producer should meet them when creating labeling machines.

They incorporate;

- Current great assembling rehearses (cGMP)

- ISO accreditation quality principles

- CE quality norms

11.How to troubleshoot common problems of Automatic Labeling Machine?

| Troubleshoot Automatic Labeling Machine | ||

| PROBLEM | CAUSE | SOLUTION |

| Labels Curling Away from Bottles | Excessive adhesives

Poor wiper action Poor label stock Not enough adhesive tack |

Keep glue film down to operational minimum

Adjust compression Stiff dry labels, wrong grain direction Use a tackier product |

| Failure to Pick Label out of Magazine | Transfer mechanism is nor appropriately contacting labels

Back pressure is low |

Adjust machine

Adjust magazine |

| Spotty Adhesion | Bottle surface contaminated

Excessive coating on surface |

Clean the surface

Check the surface |

| Labels Falling off | Container too hot or too cold

Poorly treated or over coated surface |

Select proper adhesives

Check bottle and select proper adhesive |

| Staining and Discoloration of Labels | Thin label stock

Oil or grease from machinery |

Use thinner, glue fill or change label stock

Check and clean the machine |

| Labels Tearing in Machine | Wipers or rollers are dirty

Thin labels |

Clean

Use heavier label |

12.How to maintain Automatic Labeling Machine?

Regular Maintenance

How ordinary should the maintaining of your label tool be? This relies upon two components:

The Working Environment

Your work area assumes a function in the activity of your label applying. After some time, the area where you place your machine might impact. A messy or wet climate can cause additional problems for your machine.

Recurrence of Usage

How regularly do you utilize the automatic labelling machine? In the event that the machine is run continually, at that point you should keep the maintinnace all the more regularly. To decide the sort and frequency of normal maintenance, counsel about the machine and read the manual or talk about the machine's support team during establishment.

Keep it Clean

- When you utilize the label tool, take care and do the effort to clean it.

- Clean the dust and residue off the machine often.

- Check the machine for any adhesives.

- On the off chance that you locate some adhesive develop, clean it with glue removers and afterward catch up with Isopropyl liquor to eliminate any buildup.

- Continuously promptly eliminate any name stuck on the drive roller.

Conclusion

Labeling is one of the main innovation and fundamental in drug ventures.

Labeling is an expected as a guide both for clinical professionals and patients.

It will help the misusing of the customer.

It is very clear that the need and utilization of automatic labeling machine in the manufacturing business is fundamental.

It is additionally certain that the sorts and uses of these machines likewise change relies upon different components.

Automatic Labeling Machine Related Products

Automatic Labeling Machine Related Posts

Automatic Labeling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling MachineCartoning Buyer's