Pharma Packaging: Is Capsule Counting Machine Necessary?

Packaging carry immense importance in pharmaceutical industry for the perseveration of drugs. When it comes to the packaging of capsules and tablets, counting become instrumental. For such abundantly produced capsules, there is a machine called Capsule Counting Machine.

The role of this machine is of great importance for the accurate counting of capsules and pills. It has high automation and efficient performance. It offers significant advantages in terms of convenient operation. Not only this, the machine can deal range of other products and come in different types to suit varying production needs. So, let's uncover more about Capsule Counting Machine?

1.What Is A Capsule Counting Machine?

Aipak APC-32 automatic tablet capsule machine

Capsule counting machine is a specialized equipment designed for the counting of capsules, tablets, and softgels. It can perform dual function of counting as well as filling the counted capsules into various sizes of bottles and containers. The machine is has automated technology to undertake capsules counting. It has stainless steel body which is resistant to corrosion. It maintain hygiene for such a sterile product.

2.Is Capsule Counting Machine Necessary?

Capsules counting process- Picture Courtesy: Cremer

You might be pondering about the question, is capsule counting machine necessary? So, the answer is simply yes! The use of capsule counting machine in todays era is evidently necessary. Here we have provided few reasons which will help you understand its worth!

Firstly, it is not humanly possible to keep counting abundantly produced capsules due to humans proclivity to errors. Secondly, capsules are meant to be taken by patients suffering from various illnesses. In that case, it is important that drugs must be free from contamination. Therefore, it is only possible with a machine that maintain aseptic environment for the counting of capsules.

3.What Are The Key Benefits Of A Capsule Counting Machine?

Capsule counting machine offers numerous advantages for you in terms of production efficiency, quality retention, and accuracy in counting. Some of the potential benefits of a capsule counting machine are as follows:

Convenient Operation

Capsules filling into bottles- Picture Courtesy: bellatrx.com

Capsule counting machine is best known for its simple operation especially due to its automatic technology to administer it. This feature enable the user to just observe the machine working which works independently.

Production Efficiency

Capsules falling over vibratory trays from hopper- Picture Courtesy: saintytec.com

Another key attribute of a capsule counting machine is its counting efficiency. Manually counting capsules is not only a difficult task but that also require too much time and effort. Compare to that, a simple capsule counting machine works fastly and fill up to 40 bottles in a minute.

High Flexibility

Various sizes of capsules and tablets- Picture Courtesy: Freepik

Capsule counting machine is versatile enough to count various types of capsules with different sizes and shapes including softgels and hard gel capsules. Apart from this, it can count tablets and other products such as chocolate balls and candies etc.

Precision

The machine is automatic and perform multiple tasks such as rejecting waste and detecting faulty capsules. This helps in maintaining packaging accuracy which is instrumental for pharmaceuticals.

Safety

Stainless Stell Vibratory Channels- Picture Courtesy: pppharmapack.com

Safety is an important aspect of a capsule counting machine as it deals with delicate capsules. Therefore, the stainless steel body and enclosed structure of the machine makes is more desirable for capsules to be counted in a hygienic environment.

4.How Does A Capsule Counting Machine Work?

Operating a capsule counting machine require one to fully understand its working principles. Starting frommachine setting till hopper loading capsules counting and depositing, it follows series of steps. These steps are mentioned below in detail:

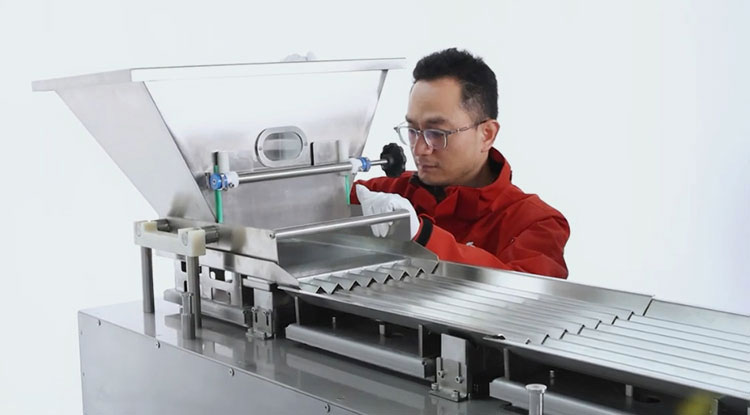

Machine Setting

Operator adjusting the hopper of the machine- Picture Courtesy: Richpacking Machinery

The initial step for operating a capsule counting machine involves the setting of machine is a necessary one. It includes tightening the screws of machine and fixing other parts such as hopper and glass windows to their concurrent location. Similarly, the operator is required to set the parameters by using a touch screen interface. The vibration speed, number of capsules to be filled in each bottle, and the speed of conveyor are all set here.

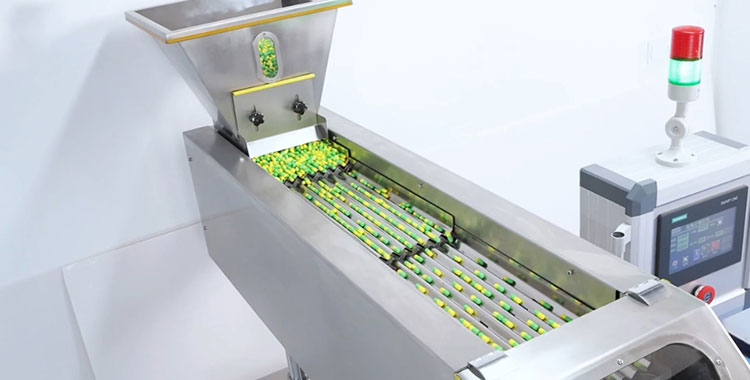

Hopper Loading

Capsule counting machine- Picture Courtesy: ceking.com

The next step is loading the hopper of the machine with adequate amount of capsules for counting. For smooth and non-stop working of the machine, a feeding system may be integrated with the main machine.

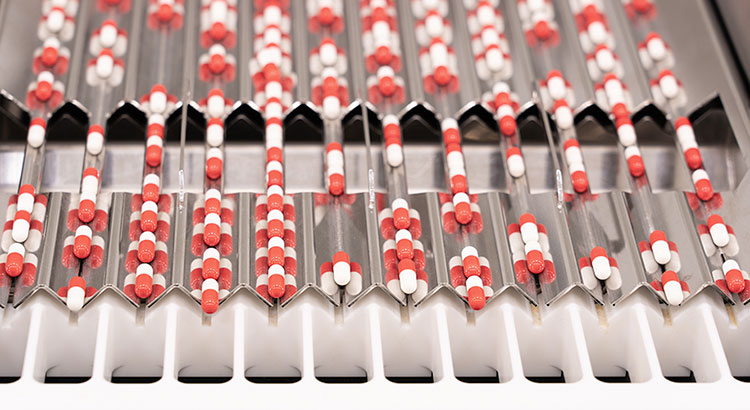

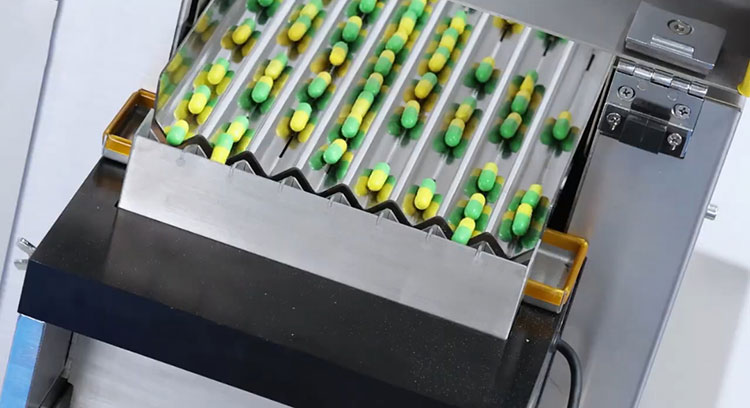

Capsule Counting

Capsule counting process- Picture Courtesy: Richpacking Machinery

Once the setting and loading of machine gets done, it is the time for capsule counting. As soon as the machine is powered on, the hopper start releasing capsules over the vibratory trays. The vibration of trays led to the scattering of capsules all around after which they are serialized in channels. Here, the counting of capsules takes place.

Capsule Depositing

Capsule depositing into compartments- Picture Courtesy: Richpacking Machinery

Moving ahead, the capsules move forward and fall into the counting compartments. As soon as the bottles reach under the filling head, the counted capsules are released from the compartments and deposited into the bottles.

Bottles Discharging

Bottles discharging via conveyor- Picture Courtesy: ceking.com

At the end, bottles filled with capsules are gently mobilized by the conveyor. In similar way, the filled bottles are discharged and moved for further packaging such as capping and labeling machine.

5.What Are The Types Of A Capsule Counting Machine?

There are different types of capsule counting machine today available in the market. These capsule counting machines vary from one another on the basis of their structure, automation level, as well as working procedure. In the upcoming paragraphs, you will know about each type in detail:

Semi-Automatic Capsule Counting Machine

Semi-automatic capsule counting machine

Semi-automatic capsule counting machine is yet another type of the equipment that combines manual and automatic features into one machine. The machine has compact body made up of stainless steel. Although, it requires human intervention for carrying out the process, yet it has advanced technological features of automatic detection through sensors. It also has good rate of production efficiency making it suitable for small to medium scale pharmaceutical and nutraceutical companies.

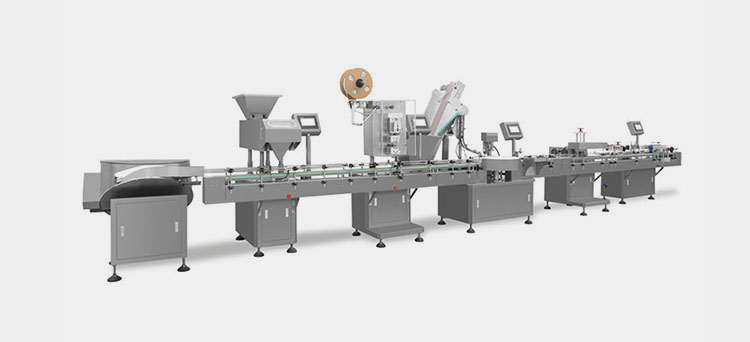

Fully Automatic Capsule Counting Machine

Aipak APC-16 High speed capsule counting machine

Fully automatic capsule counting machine has advanced technology with independent operational procedure. It is available in 6 channels, 8 channels, and even 12 channels of vibratory trays for counting abundant capsules. The machine is highly automated that hardly needs any direct human involvement. It has high production efficiency, accuracy, as well as safety features. The machine may be directly integrated with other machines to make production line. It is an ideal choice for large scale manufacturing industries.

6.What Are The Applications Of A Capsule Counting Machine?

Capsule counting machine has diverse applications due to the machine's outstanding features of customization and versatility that it can process wide variety of products. Therefore, it may be used in different industries including pharmaceutical, nutraceutical, and veterinary industry etc. Some of the major applications of the machine are as follows:

Pharmaceutical Industry

Various forms of drugs- Picture Courtesy: dailysabah.com

Pharmaceutical industry is an area where the production and processing of drugs is a daily task. These includes tablets, capsules, and tablets which need proper counting and packaging. They can be easily counted by a capsule counting machine.

Nutraceutical Industry

Various nutraceutical capsules and pills- Picture Courtesy: zimlab.in

Around the world, the use of nutraceuticals for treating diseases is now given priority over other drugs due to their low side effects and enhanced effectiveness. For this reason, micronutrients and macronutrients are extracted from food products and turned into capsules form which too require counting and packaging that can be easily done with a capsule counting machine.

Herbal Industry

Herbal medicine presentation idea- Picture Courtesy: pharmaceutical-journal.com

The herbal industry is fastly growing due to people's believe in traditional therapeutic procedures for treatment. That's why, now you can find herbal capsules, tablets, and syrups etc. For their proper counting and filling into containers, capsule counting machine is best applicable.

Veterinary Industry

Dog FMT capsules bottle- Picture Courtesy: animalbiome.vet

The machine can also be used in veterinary industry for counting and filling of capsules into containers. As the machine has enclosed environment, it can greatly helps in minimizing product waste and counting errors.

Beauty Care Industry

Gluta fair capsule presentation idea- Picture Courtesy: Nutrifactor

Among other uses, beauty care industry is one of the notable fields where softgels and capsule essence encasing vitamins, oils, and emulsions are produced. These capsules are easily counted by a capsule counting machine and filled into desired containers.

7.How To Choose The Right Capsule Counting Machine?

When you intend to choose a capsule counting machine for your business, make you don't rush and take some time to consider some factors which can ultimately lead you to a better choice. Here we have provided a list to follow:

Production Capacity

Capsules filling into bottles- Picture Courtesy: marchesini.com

The very first thing that must be taken into account when choosing a capsule counting machine is to know the production capacity of the machine you are looking for. Now, this factor depends upon your current production scale. You need to determine whether it is small scale production, medium scale, or large scale. Once you have finalized, it will be easy for you to opt for the compatible machine.

Upgradation

AIPAK APK-A100-12 low-speed automatic electronic capsule counting machine line

A machine that is easy to customize and upgrade is always considered a fascinating one. Similar is the case with a capsule counting machine. You need to check if the machine can be upgraded with time for generating more output. In the same manner, it is also good for a machine to be capable of integration with other machines for packaging such as desiccant inserting machine, capping machine, and labeling machine etc.

Quality

Quality icon- Picture Courtesy: culturewise.com

The quality of a capsule counting machine matters a lot as it has to deal with sterile medication like capsules. For this reason, it must be made up of quality materials and fully safe for processing capsules. It may be simply checked by looking into the company's certification from ISO, GMP, and FDA. Similarly, the warranty policy may also be a step towards having a quality machine.

Budget

Budget icon- Picture Courtesy: er.educause.edu

Last and the most important factor to never overlook is considering your budget. Can you afford a new and expensive capsule counting machine? Or are you running out of budget and want to pick a second hand machine from renowned company? These questions carry great importance and must be paid heed.

8.Top 5 Manufacturers Of Capsule Counting Machine?

The popularity of capsule counting machine depends upon the innovative technology and features it carries. In this way, you can find the best suppliers of capsule counting machine who dominates the expertise in introducing new features to the equipment. Here we have provided a list of top 5 manufacturers of capsule counting machine:

1.COUNTEC

COUNTEC company logo- Picture Courtesy: countec.com

Headquarter: Bucheon Gyeonggi-Do, South Korea

Company Background:

COUNTEC company office- Picture Courtesy: countec-group.com

COUNTEC is one of the world's leading company in manufacturing and supplying top-notch equipment related to drugs production and packaging. These machines include capsule counting machines, bottling machines, and inspection machines etc. The company was originated 40 years ago and since then it is working dedicatedly to build customers around the globe.

2.CREMER

Cremer company logo- Picture Courtesy: cremer.com

Headquarter: Lisse, Netherlands

Company Background:

Cremer company building- Picture Courtesy: informatiegids-nederland.nl

Established in 1949, CREMER is the globally recognized company operating worldwide for manufacturing solutions for pharmaceutical and food products. Their main equipment include counting and packaging machines which manifest highest quality. The company believes counting is a necessary step to be carried out for products no matter what. CREMER manages its clients in different countries and provide them with full support regarding machines.

3.AIPAK

Aipak company logo- Picture Courtesy: icapsulepack.com

Headquarter: Wuhan China

Company Background:

Aipak manufacturing center- Picture Courtesy: icapsulepack.com

AIPAK is a renowned company in the field of pharmaceutical manufacturing and packaging. The company has over 10 years of experience in supplying latest technology equipment including counting machines, packaging machines, and inspection machines. They have maintained global presence in over 50 countries and completed over 800 projects which shows their commitment and resilience to innovate the packaging solutions and uplift their quality.

4.PHARMAPACK

Pharma pack company logo- Picture Courtesy: pppharmapack.com

Headquarter: Guangdong Province, China

Company Background:

Pharma pack company building- Picture Courtesy: pharmapack.com

Pharma Pack Technologies Corporation was established in 2002 in Guangzhou Economic District in China. The company has global marketing and services networks in the realm of pharmaceutical packaging industry. It has been successful in supplying range of packaging solutions to customers globally. The main equipment include smart bottling packaging line, smart inspection packaging line, and secondary packaging line equipment.

5.IMA

IMA company logo- Picture Courtesy: prosource.org

Headquarter: Bologna, Italy

Company Background:

IMA company building- Picture Courtesy: archello.com

IMA is a global leader in designing and manufacturing machines for the processing and counting of pharmaceutical as well as food products. IMA is well known for entertaining the most stringent requests of the pharmaceutical market. The company has pioneered different brands under its supervision to conduct manufacturing. These include IMA ACTIVE, IMA LIFE, and IMA SAFE through which solid dose solutions, aseptic processing and freeze drying solutions, and packaging solutions are manufactured and supplied.

Conclusion

To put in a nutshell, Pharma Packaging: Is Capsule Counting Machine Necessary? is an important topic about which we have provided enough information in the above explanation. We hope that you have found this review a helpful one. Besides that, it is essential to know the benefits, working principles, and applications of a machine which is considered inevitable in pharmaceutical manufacturing. You might be interested in purchasing the machine and looking for trustworthy suppliers for which we have mentioned the top 5 manufacturers. If you are still confused which to select then Aipak is the best option. For further information contact us!

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine