Pharma Equipment Buying Guide: How Detailed Bottle & Product Specs Ensure the Perfect Tablet Counting Line Solution?

You want to start production quickly, so you ask for a price immediately. However, if you skip the details, you might buy a machine that stops working or counts wrong. This leads to wasted money and time.

A reliable tablet counting line solution requires specific data: bottle dimensions, cap types, and tablet shapes. Without these, manufacturers cannot guarantee counting accuracy or smooth capping. Providing samples and photos ensures the equipment is customized to handle your specific products without errors.

I recently received an inquiry from a client in the UK. At first, he only asked about the price and speed of a tablet counting line. He did not provide any other details. I could not give him an accurate price because I did not know his product. I asked him for the bottle size, cap specifications, and photos of his materials. At first, he felt this was too much trouble. But after I explained why, he understood. This project taught us that a good machine comes from clear details.

1.Why do I need to send you my bottle and tablet photos?

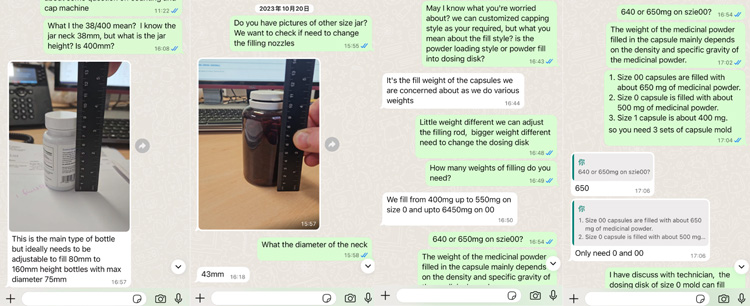

Message with the UK customer

It feels annoying when a salesperson asks for too many photos and measurements. You just want a quote to see if it fits your budget. However, guessing the specifications is the fastest way to fail in pharmaceutical manufacturing.

To build a working line, we need to know the bottle height, diameter, and neck size. We also need to know if the tablets are dusty or sticky. These details dictate the sensor sensitivity and the guide rail width of the counting machine.

When the UK client first contacted me, he just wanted a price. I had to insist on getting the details. I explained to him that "counting accuracy, material flow stability, and jamming prevention" are all strictly related to his specific bottle and material.

If I quote a standard machine for a wide bottle, but you use a narrow bottle, the pills will spill. If your tablets are dusty and I sell you a standard sensor, the machine will stop every ten minutes to be cleaned.

Here is a breakdown of why I need specific data to design your line:

| Component | Why Specifics Matter | Potential Risk of "Standard" Quote |

| Bottle Unscrambler | Needs bottle diameter and height to set the sorting disc | Bottles will fall over or get stuck in the chute |

| Counting Head | Needs tablet size and color to calibrate the optical eye | Transparent capsules or small pills might be miscounted |

| Filling Nozzle | Must match the bottle mouth diameter | Product spills outside the bottle, causing waste |

| Capping Machine | Needs the exact cap thread and height | Caps will be loose, leading to leaking or contamination |

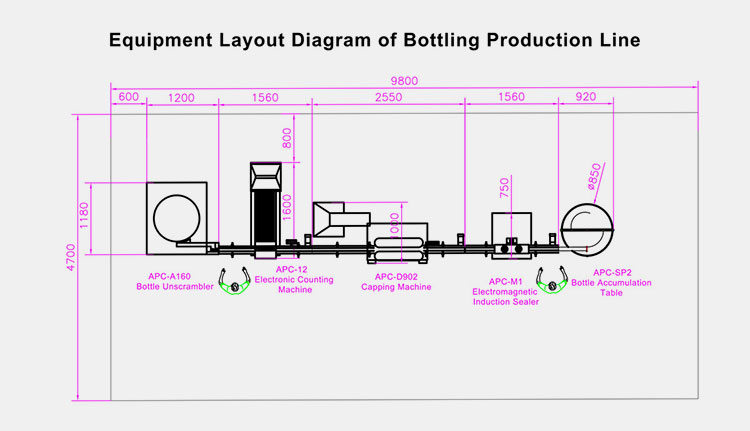

After I explained this, the client was very cooperative. He sent pictures and data. Based on this information, I made the first complete plan for him. This included a bottle unscrambler, a counting machine, a capping machine, an induction sealer, and a labeling machine. Because we had the data, we knew this equipment would actually work for his product.

2.What happens if my factory space is too limited for a standard layout?

You have the machine list, but your room is small. Standard production lines are long and straight. This can be a disaster for small workshops that do not have enough length.

Customizing the layout is just as important as the machine itself. For limited spaces, we switch from linear layouts to U-shaped or L-shaped designs. This optimizes the workflow and ensures operators have enough room to move and maintain the equipment.

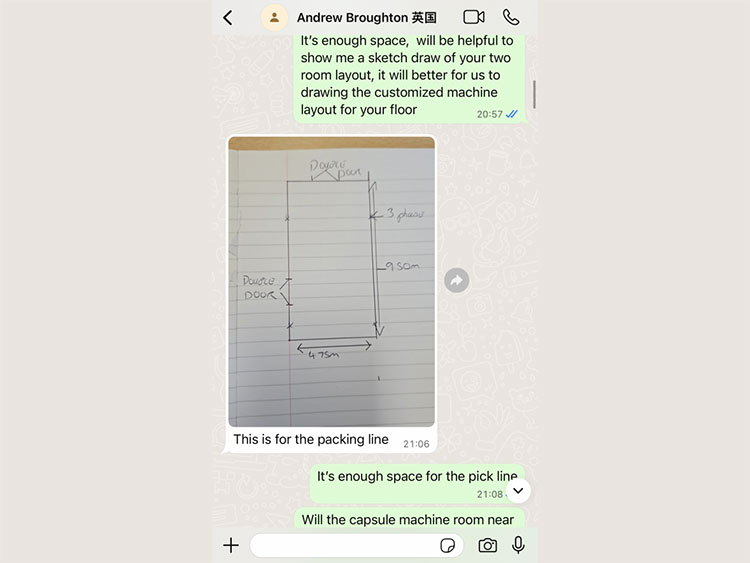

Customized tablet counting line layout design

After we agreed on the machines, I thought we were ready to sign the contract. Then I asked about his factory size. He told me the area was very small. This was a big problem. A standard counting line is long.

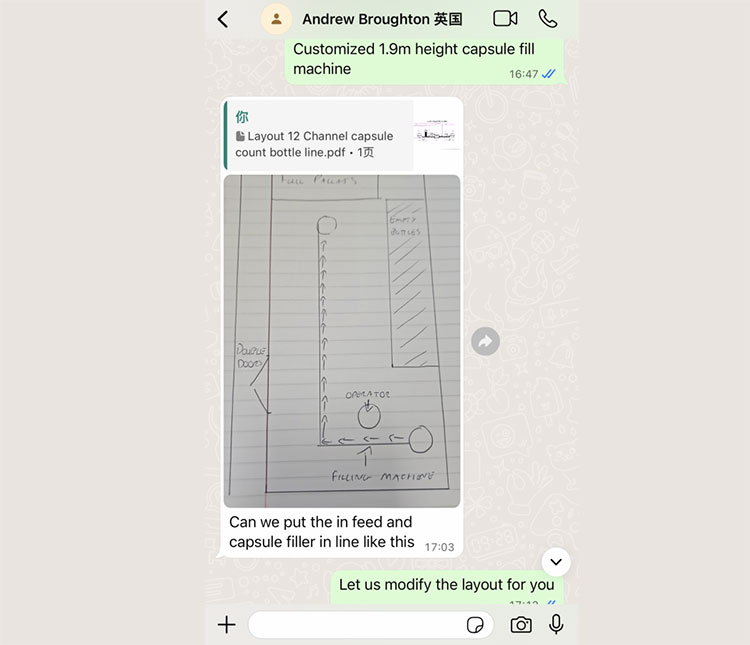

I asked for a drawing of his factory floor. Once I got it, I immediately talked to our engineers. We saw that a straight line would not fit. We had to change our thinking. We moved from a "straight-line layout" to a "compact layout."

We adjusted the order of the machines and the direction they faced. We sent the first layout drawing to the client. He looked at it and said there was not enough space for his workers to walk around. We listened and made a second change.

Then, he brought up "personnel flow." He needed his workers to move in a specific way to follow GMP rules. We made a third optimization.

AIPAK tablet counting line on customer site

This process shows why "off-the-shelf" solutions rarely work well in B2B manufacturing. We had to use critical thinking to solve the space problem:

**Analyze Constraints: We looked at the pillars, the doors, and the power outlets in his room.

**Turn the Line: We used curved conveyors to turn the line 90 degrees or 180 degrees.

**Operator Access: We ensured that even in a tight space, a person could open the machine doors for cleaning.

This was almost a "tailor-made" suit for his factory. It took time, but it ensured that when the machines arrived, they would actually fit in the room.

3.Will I receive support if the machine breaks down after delivery?

Buying from overseas is scary. You worry that once the money is paid, the seller disappears. This is the biggest fear for most international buyers who cannot fix the machines themselves.

Reliable after-sales service includes both remote troubleshooting and on-site support. We ensure our engineers have valid visas to travel immediately. We also provide video training and 24/7 online help to fix small issues before they become big production stops.

Engineer providing onsite installation service

Before the final confirmation, the client raised one last concern. He was very honest with me. He said, "I have bought equipment from China before. My biggest fear is that if the machine breaks later, there is no service."

This is a fair question. A machine that does not run is just a pile of expensive metal. I was very frank with him. I told him that at AIPAK, we are not just a trading company; we are a manufacturer.

I explained our support structure to remove his worry:

Visa-Ready Engineers: We have a team of engineers who specialize in overseas projects. They already have visas. This means if you need us, we can fly to the UK quickly. We do not need to wait months for paperwork.

On-Site Service: We go to your factory. We install the line, debug it, and train your staff. We do not leave until your operators know how to use it.

Remote Support: For small problems, you do not need an engineer to fly over. We can use video calls to guide your team. Most software or setting issues are solved this way in minutes.

| Service Type | Problem Solved | Benefit to Client |

| Installation | Machine setup and connection | Ensures the line runs at full speed from day one |

| Training | Staff does not know how to operate | Prevents user errors and damage to the machine |

| Remote Debug | Software error or sensor alarm | Immediate fix without travel costs |

This explanation removed his last doubt. He realized we were partners, not just sellers. He signed the contract. This UK project reminded me that price is important, but trust is the key. Trust comes from professional details, patience in design, and a promise of service.

Conclusion

We secured this UK order not by offering the lowest price, but by demanding detailed specs, customizing the layout for a small space, and guaranteeing reliable after-sales support.

Don't forget to share this post!

How Bottle Specs Influence Your Counting Line Solution

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine