Film Coating VS Sugar Coating

The coating is the earliest pharmaceutical practice utilized to mask the unpleasant taste and smell of tablets, capsules, and granules. The Tablet coating market is predicted to gain US$ 969 million by 2025. There are two main kinds of coating used for oral solid dosage: film coating and sugar coating. Each of these forms of coating has its own reasons for application and benefits.

In this informative guide, we will highlight the differences between both these types of coating. You will learn about their dissimilarities in their appearance, speed, process,

Let’s start this instructive blog!

Ⅰ.Film coating VS Sugar Coating

a) Film Coating

Film coating is defined as the process that involves the application of a thin and uniform layer of polymer formulation on the surface of different types of medication such as capsules, powders, pills, etc.

This coating is applied for aesthetic purposes and to prevent deterioration of inner drugs due to environmental elements.

b) Sugar Coating

Sugarcoating is the process in which a thick and hard sugar coat is spread over the surface of tablets. It is mostly done for purpose to improving the bitter harsh odor and taste of tablets.

It is a traditional technique of pharmaceutical coating and has been in use since the 19th century.

i.Appearance

a)Film Coating

- Film coating maintains the original shape and form of the tablets. These coatings are not glossy as compared to sugar coating.

- The thickness of the film coating is about 20-100 µm.

- Logos and break-lines are easily visible on the surface of tablets.

b)Sugar Coating

- Sugar-coated pills are rounded and smooth in form having uniform color and shiny. These tablets are polished and glossy in their appearance.

- The coating thickness is about 0.5 mm to 20 mm.

- It is not possible to see logos and crack-lines on the surface of sugar-coated tablets.

II.Advantages

- a)Film Coating

- Weight

There is minimal weight increase during the process of film coating approximately about 1-2%.

- Formulation Flexibility

Film coating has huge formulation flexibility as it employs a wide variety of materials and coating systems.

- Variety of Oral Dosage Forms

Film coating is applied to a wide variety of medications like tablets, capsules, granules, pellets, powders.

- Visual Marking

Logos and company marks can be visually discerned with a film coating.

- Diabetic Patients

Film-coated tablets and capsules are appropriate for diabetic patients.

- b)Sugar Coating

- Swallowability

Sugarcoating helps in swallowing large tablets.

- Flammable Materials

The materials used in sugar-coating are non-flammable and do not pose the risk of explosion.

III.Disadvantages

a)Film Coating

- Flammable Ingredients

The organic solvent employed as vehicles during film coating is quite flammable and can cause an explosion. Such as ethanol, methanol, methylene chloride.

- Toxic Substances

The solvent used in film coating are toxic and pose a serious health hazard to operating personnel.

b) Sugar Coating

- Weight

There is a considerable increase in the weight of the tablets about 30-50% after the application of sugar coat.

- Embossing

It is difficult to emboss sugar-coated tablets, so identification is printed on the tablets.

- Diabetic Patients

Diabetic patients cannot take sugar-coated tablets as these tablets increase blood sugar levels.

Ⅳ.Ingredients

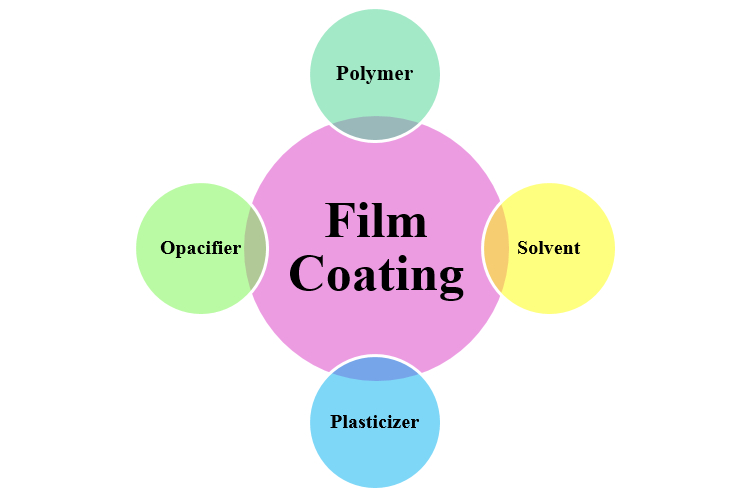

a)Film Coating

Different materials used in film coating are

- Film Former/ Polymers

These materials are the main component of film coating and impact the characteristics of the film. These materials improve the aesthetic characteristics of tablets and provide resistance to medications against light, oxygen, and heat.

Some polymers are Hydroxy Propyl Methyl Cellulose (HPMC), Polyethylene glycol, Acrylate polymers.

- Solvents

These substances are used to dissolve the polymers. These solvents aid in the spread of film on the exterior of tablets. Some solvents used in film coating are water, acetone, ketone, and alcohol.

- Plasticizer

Plasticizers such as glycerol, coconut oil are employed to alter the characteristics of the polymer. These substances enhance the film adhesion and viscosity of film formers

- Opacifier

These opacifiers like titanium oxide, talc, magnesium oxide is applied to mask the main color and to provide light protection.

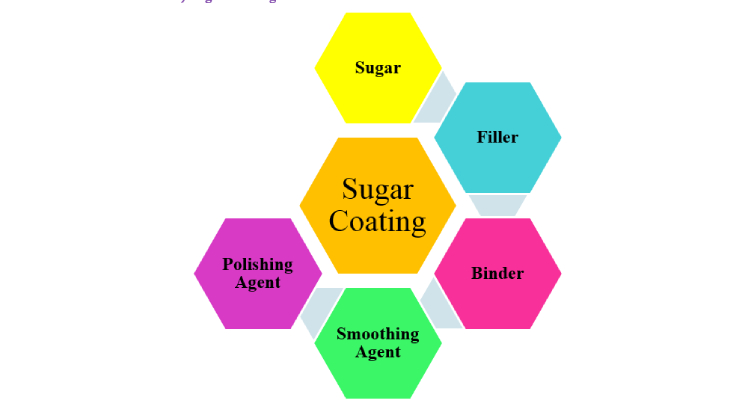

b) Sugar Coating

Materials used in sugar-coating are

- Sugar

As the name indicates sugar such as sucrose, sorbitol, and glucose are the main components of sugar coating. The concentration of sugar syrup in the coating is about 50-60%.

- Fillers

These materials maintain the form of a coat and increase its mass. Examples of filler are talc, corn starch.

- Binders

These materials improve the strength and elasticity of the sugar coating. These include polyvinyl acetate, starch, and agar.

- Smoothing Agents

These materials like syrup and acacia gum act as the lubricant and smooth the coat exterior.

- Polishing Agents

Polishing agents such as carnauba wax and beeswax increase the intensity and reflectivity of the coloring dye.

Ⅱ.Steps Involved in Film Coating VS Sugar Coating.

a)Film Coating– A Single Step Process

Film coating is a single-step and less time taking process than sugar coating. Usually, it takes about 1.5 to 2 hours to apply film coating. For instance:

- Spraying: is done onto the tablet to deposit a thin film layer around each tablet.

b) Sugar Coating- A Multi-Steps Process

Sugarcoating is a multistage and time-consuming process as it takes about 8 hours or longer for the application of sugar coating. The following steps are:

- Sealing is done to prevent the tablet from humidity. It acts as a moisture barrier and hardens the surface of the tablet.

- Sub-Coating: acts as a good substrate for smoothening of a tablet.

- Smoothing: Smoothing the color and surface of the tablet.

- Coloring: enhances the appearance of the tablet and gives a finished form.

- Polishing: produces a glossy characteristic.

III.Which Coating is More Popular Among People Nowadays? Film Or Sugar Coating?

Among three basic tablet coating (sugar, film, and press coating), film coating is widely applicable and popular technique used for oral solid dosage form. In pharmaceutical industries, film coating is significantly preferred over sugar coating as it solves various complications that encounters during manufacturing procedure, transportation, storage as well as therapeutically.

For instance,

- Film coating forms a protective barrier to prevent APIs against humidity and light.

- Film coating are more stable than other coatings.

- Film coating is most popular as it can controls the releasing pattern of the drug such as, site of action, rate, and period.

Whereas sugar coating is conventional process closely resemble to coating of confectionery products. This method of coating was extensively used in pharmaceutical industries in late 19th century. Now all newly manufactured coated products are film coated instead sugar coated often for many reasons such as:

- Easy and fast process

- An adaptable controlled release

- Cost effective

- patient compliance, etc.

Conclusion

Coating plays a significant role to achieve the desired properties in the oral solid dosage form. Recent advancements, such as processing, ingredients, and equipment have developed a substantial improvement in this technology. However, current trends in the coating have supported ‘aqueous film coating’ due to their extensive applications, low chances with environmental concerns, and high availability of coating materials.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours