How to Choose the Most Suitable Tablet Coating Machine?

You may have known that film coating is a common step in tablet manufacture that can improve product appearance, organoleptic properties, and facilitate swallowing.

And functional film coats can also be used as a part of the product’s stabilization strategy and to modify or delay drug release.

Then some of you may begin to wonder as a beginner, how to choose the most suitable tablet coating machine to coat your tablets.

That is, you must have a clear understanding of all the tablet coating equipment in the market now and identify their working principle and coating process or technique.

Then it will become easy for you to choose the most suitable tablet coating machine to fulfill your special coating process.

Now, Let’s go to the main topic of the subject directly.

1.Types of Tablet Coating Equipment

Do you want to buy a Tablet Coating machine?

AIPAK Tablet coating machine

But for a common person question arises: what is the purpose of Tablet Coating machines?

So, you use tablet coating machines to coat the surface of pills and throw a thin layering of film.

These appliances operate based on an easy theory of using the coating elements with the shape of a method to the pill’s collection within the bed which can flow perpendicularly or parallelly.

A consistent float of warm air enables the vaporization of the soluble material used. The coating is similarly dispensed to the pills via motion by the bed.

There are numerous kinds of tablet coating machines presently with the marketplace today.

The 3 primary sorts are

- Standard coating pan

- Fluidized bed coating system

- Perforated pan coating system

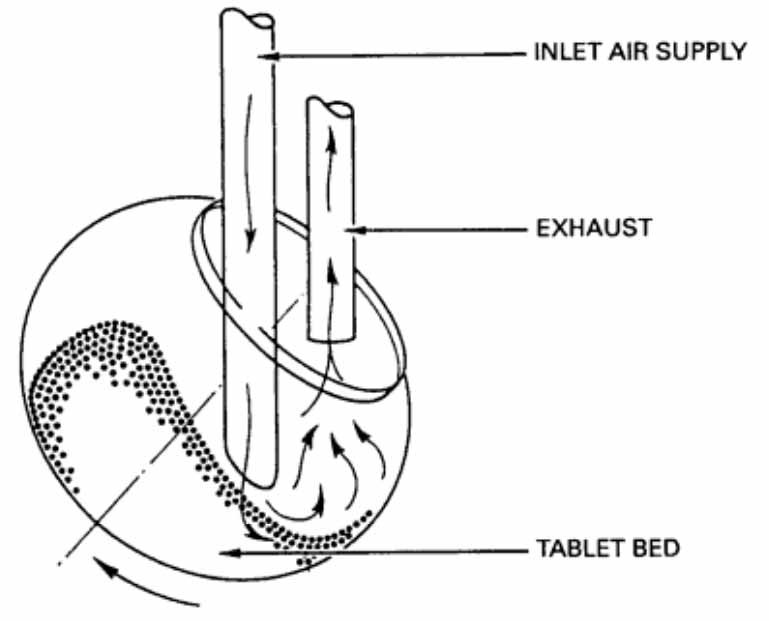

1.Standard Coating Pan

An essential part of this cycle is a round metal pan or skillet that is somewhat inclined on a top stand. The skillet or pan is ordinarily turned by an electric engine.

During the tablet covering measure, a bunch of tablets or capsules is stacked into the metal container or pan, and it is set to turn.

This movement makes the tablets twist around the inside of the container.

The covering materials of the tablets are used or applied by an atomized shower into the container. The reason for the shower is to apply and convey the covering film all the more uniformly.

Starting here, there are different potential alternatives for drying the tablet bed. They all essentially utilize various strategies for drying or warmed air by using a diffuser or arrangement of tubes.

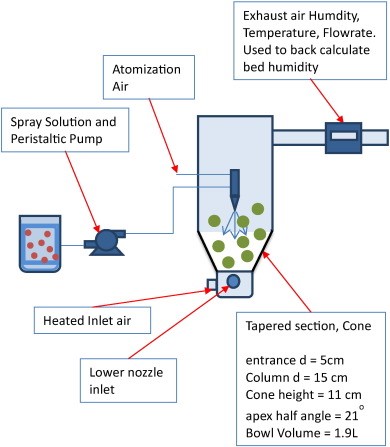

2.Fluidized Bed or Air Suspension Framework

With a fluidized bed coater, the coating of the tablets includes a vertical chamber.

Fluidization of the tablets is performed by a segmented flow of air from the base driving the tablets upwards in the chamber.

The tablets stream to the highest point of the section prior to the base and returning the air returning to return up.

The showered coating is constrained through spouts or nozzles at the base as the tablets travel around the chamber. Numerous tablets are slight and inclined to chip or fractioned.

This makes the air suspension framework a particular answer for tablet coating as the tablets affect one another and the tablet chamber ordinarily during the cycle of the coating.

Fluidized Bed or Air Suspension System-sciencedirect.com

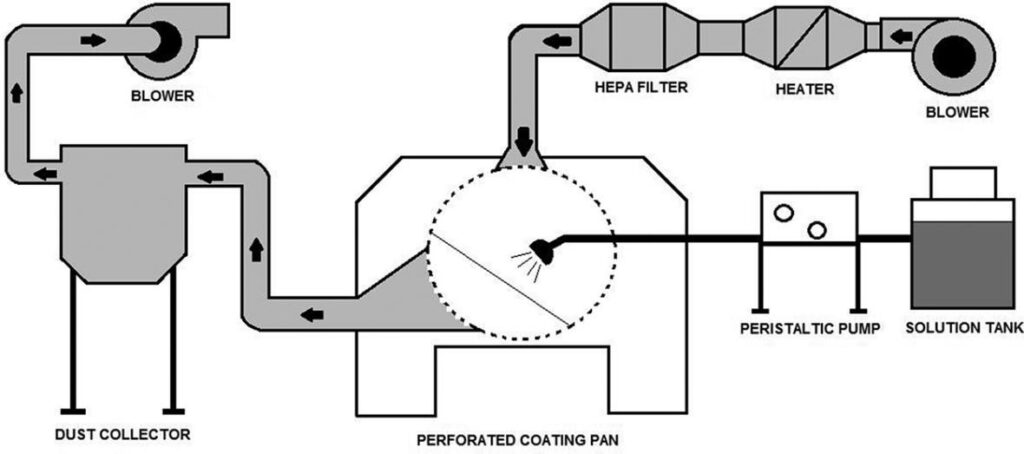

3.Perforated Pan Coating/Covering Framework

Perforated Coating Pan -Photo Credit:Degryuter.com

This technique is offered by the tablet coating machine we give at AIPAK

The cycle comprises a completely perforated drum turning on a horizontal hub. The entire framework is encased.

The covering of the surface is being applied by a shower bar spout or weapon situated inside the middle of the drum.

You will be offered choices like outer external shower and free control for example and atomizing of the air.

With our Accela-Cota framework, the drying flow of the air straightforwardly to the drum and goes through the tablet bed prior to being delivered through the holes in the drum.

Perforated drums are among the most famous determinations in the latest drug industry.

A considerable lot of the tablet coaters from us likewise accompany the comfort of interchangeable drums to lessen the opportunity of contamination coming in and give quicker batch changeover times.

2.Various types of Tablet Coating Machines Working Principle

Now, you can have a brief description of their difference and functionality below:

1- Standard Coating Pan

Metal Pan

These kinds of tablet coating machines consist of a circular metal pan that is leaned on a bench top stand whose diameter lies between about 15 and 200 cm (6 to 80 inches).

Electric Motor

An electric motor is also placed there so you can rotate the pan whenever you want. A large number of tablets are stacked into the pan which is about to revolve.

After the loading of tablets in the pan, you can start the electric motor which will force the pan to rotate and this revolving movement causes the drugs to fall into the pan.

Spraying in Atomized

The coating solution is implemented to the revolving pill bed with the aid of using spraying in atomized shape, it will help you to produce a quicker and greater equal distribution than without a doubt launching it as a liquid.

You can increase the drying efficiency of the pills by using the following

A- An immersion sword

In this system, through a permeated metal sword that is submerged in the bed, the parching air is distributed.

B- Use of a baffled pan and diffuser

The baffled pan can be used which helps you to distribute parching air over the through the layer of the tablets homogeneous.

C- An immersion tube system

The setup includes the tube which distributes warm air via spray nozzle while it is plunged in the bed earlier.

2.Perforated Pan

Permeated Drum

This type of Tablet coating machine system includes a partial or complete permeated drum that rotates on its horizontal axis, the complete gadget being picketed in a secured housing.

Drying Air system

The drying air is led to the drum with the help of this equipment, moving via the pill bed, and is launched via the pores inside the drum.

Exhaust

Same as the Accela-Cota system in the Driacoater, channels are incorporated into the drum for guiding the delivery and exhaust air to the drying air wall as fortifying elements.

Then it is added via a void location positioned in the drum’s periphery.

The drum revolves the dip into the pill bed during the process of parching, and parched air passes up via and with the air draining out via the back of the pan fluidized the pill bed.

This type of structure uses fully permeated drums, it provides us the function which shows extraordinarily quick procedure times and mixes most spray quotes.

Air Glides

The horizontal technique air glide lessens the disturbance with the nozzle region and consequently additionally contributes to a super coating result.

The Glatt Fischer and the drum structure foils, blends & defends the product at an identical time, making a completely even and surprisingly incredible coating.

The perforated pan coating system

Spray Nozzle

The layering mixture in all types of permeated pan structures is carried out via spraying nozzles that might be placed in the drum.

This type of tablet coating machine has a systematic coating potential, and it drained the pill bed more successfully than different methods.

3.Fluidized Bed/Air Suspension System

Fluidized bed coaters are also very common in the pharmaceutical industry as a tablet coating machine.

Chamber

It is composed of the chamber which is often a vertical cylinder.

Air Flow

Through a column of air flowing in an upward direction from the lowest centre of the cylinder, the process of Fluidization of the pellets is completed.

The capsules with the middle point flow in the upper direction in the air float and fall externally and in the down direction to the chamber wall, re-getting into the air circulation from the lowest portion of the column.

Spray Nozzle

For introducing the coating answer spray nozzles are placed with the backside and pinnacle of the chamber.

The pill’s center is not so strong and is at risk of scraping and chipping making it tough to coat the pill even below the most useful conditions.

This is because of the hard pill to pill effect in addition to the pill chamber contact.

3.Various types of Tablet Coating Machines Coating Process/Technique

1.Sugar Coating Machine

The cycle of sugar-coating which has its birthplaces in the sweets industry is maybe one of the most seasoned drug cycles still present.

The cycle includes the testimony of fluid sugar arrangements onto the outer surface of the center tablet.

Coating a surface with the sugar-coated material includes numerous means subsequently it requires insight and sometimes explains the machine too.

In spite of the fact that the stages vary starting with one producer then onto the next, Normally a sugar coating cycle includes the accompanying phases:

- Sealing

- Sub Coating

- Smoothing

- Coloring

- Polishing

- Printing

2.Film Coating Machine

Framing polymeric material on the tablet center and normally it is a very thin layer on the surface of the tablet that is called film coating.

This process was presented during the 1950s as an enhancement for the general process of the sugar coating.

AIPAK Film Coating Machine

Film covering has demonstrated fruitful because of the numerous points of interest offered, including:

- Negligible weight increment something like 2–3%

- The critical decrease in preparing times

- Ability to incorporate natural solvents whenever required

- Expanded cycle productivity and yield

- Expanded flexibility in the decision of film-shaping polymers

- Improved protection from chipping of the covering

Film covering can likewise be utilized to cover different plans including cases, dabs, granules, drug powders, and gems. A shower atomization method is all the more regularly used.

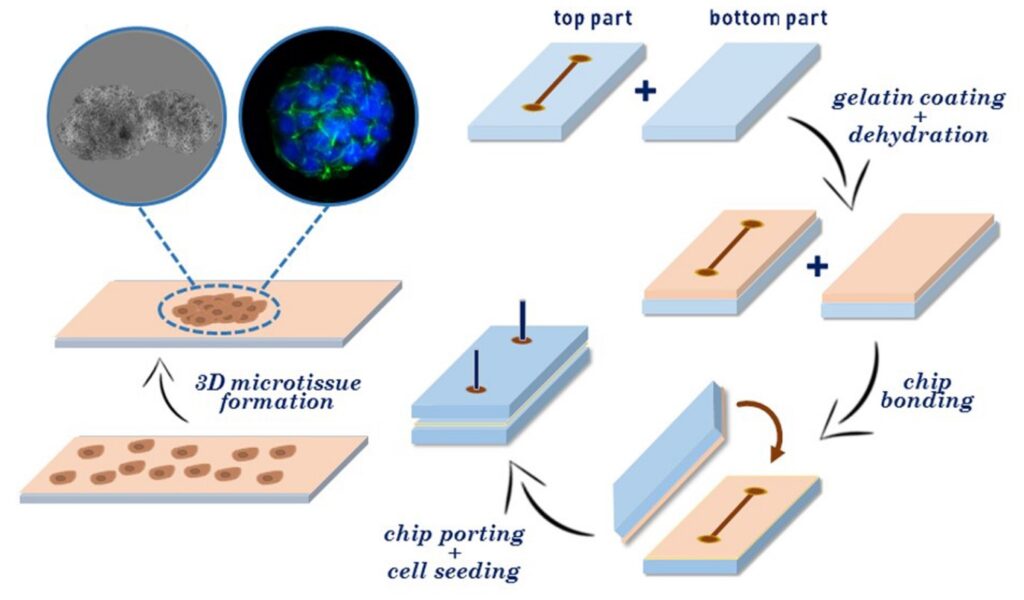

3.Gelatin Coated Tablets

If you ever had the Jell-0?

On the off chance that there is, it is gelatin. Gelatin is a sort of protein got from the fractional hydrolysis of collagen.

Gelatin Coating Process -Photo Credit:MDPI

It is found in creature parts and contains amino acids, which are the 'building squares' of proteins. Gelatin is utilized to frame the gel cap, which is a container formed tablet with outside

4.Enteric Coated Tablets

This covering gives a gastric corrosive safe covering for tablets with a corrosive touchy part.

On the off chance that a tablet is to be invested in the small digestive tract, along these lines, the tablet should be founded on stomach corrosive and arrive at the focused zone where there is no causticity, yet gradually assimilated.

Ecentric Coated Tablets

Such tablets ought not to be squashed or bitten to dodge the danger of harm because of response with stomach corrosive.

5.Pressure Coating Tablets

It includes compacting granular particles in a dry cycle around a preformed tablet utilizing exceptional hardware.

Compression Coated Tablets

It is more uncommon than the others and comprises an external sheath and an internal center.

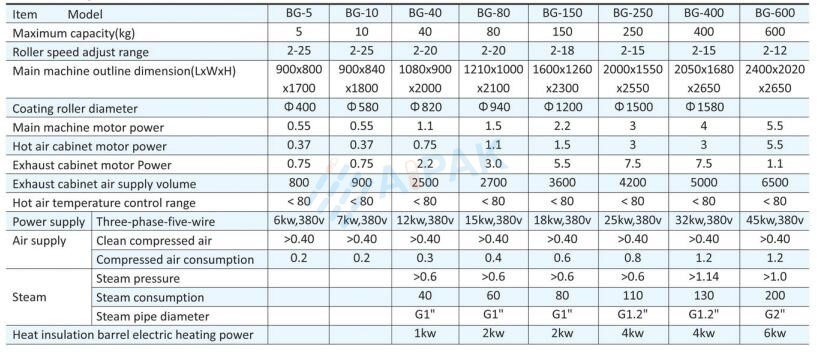

4.Various types of Tablet Coating Machines Specification

Nowadays, because the conventional sugar coating not only takes time, however additionally it can’t assure high-satisfactory results and is not labor-saving, so with the rapid improvement of the pharmaceutical industry, tablet coating has grown to be a trend, whose performance is likewise a lot faster.

Tablet coating is to spray a layer of a particularly strong mixture of polymer, solvent, plasticize, and colorant at the center layer through a sprayer, and as a result one or numerous layers of continuous, long lasting, dense, and functional coating film form.

Below defined are the few Specification of the general tablet coating machine.

Conclusion

In recent decades, the coating of tablets has been a challenge of notable developmental attempts aiming to make sure and elegantly of the satisfactory tablet dosage form. Look for the below defined factors of the tablet coating machine.

Safety Factors

Safety factors of those coatings in human beings are nonetheless to be disclosed for that reason further studies in health and safety components of those technologies will make sure the commercialization of those technologies in the medical industry.

Latest Technology

Concerning the particle movement, heat and electricity transfer, film distribution, drying performance, and non stop processing remarkable changes have come to significantly broaden this technology.

Advanced Techniques

However, in coating techniques, revolutionary change and achievement of similarly constructional enhancements seem to depend upon correct analytically gear and advanced techniques for procedure modeling and control.

High Satisfaction Production

In this regard, accomplishing the most appropriate production performance and excessive product high-satisfactory nonetheless stays the first-rate task for future studies.

Spray System

You ought to guarantee the shower framework has not many dead spaces to help the scattering of the dissolvable.

Ensure the splash framework is programmed, and fan air can be controlled effectively, perhaps from outside the container.

Proper Supply and Temperature

The pan ought to have a sufficient stockpile of cycle air that will encourage the proficient drying of covered tablets.

The framework should have the option to keep a thin temperature scope of between 30 to 70 degrees centigrade.

Additionally, with this machine, keeping up the dew point is simpler – inside a scope of 10 to 20 degrees centigrade.

So that’s why You should take some time to assess the system.

But after having all of the above know-how it’ll be a wonderful assist in making the better choice regarding the fine equipment which you should buy.

This is the best manner your attempt can pay off.

Tablet Coating Machine Related Products

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours