Tablet Coater:The Ultimate Buying Guide In 2025

A coated tablet is the key to patient compliance!

Surprisingly an uncoated tablet can be therapeutically active– but only if the patient accepts it.

Tablet coater is mainly employed for coating the pills against reactive substances present in the environment and also from mechanical harm.

Tablet coater is also used to mask the tangy taste, odor, and appearance of drugs. This machine also prevents the decomposition of the drug and increases the chance of ingesting the pill.

If you are interested in purchasing a tablet coater or if you already own one such machine but do not know how to maintain it. Then you are at the right place! read this guidance blog- to learn about different aspects of a tablet coating pan.

In this blog, you will find about the features of the tablet coater, its operational principle, types, operation, troubleshooting, and much more.

LET’S HAVE A DEEPER LOOK!

1.What is a tablet coater?

AIPAK tablet coater

Tablet coater machine is important for patients’ acceptance of pills. This machine coats a protective layer on the drug core and prevents it from chemical and physical damage. This machine makes drugs pleasant for patients by covering drugs’ bitter taste, horrid smell, and color. Tablet coater also aids patients in swallowing drugs.

2.How is tablet coater designed?

The design of various types of tablet coaters are discussed below.

1.STANDARD COATING PAN

Below are some alternations made in the design of the standard coating pan.

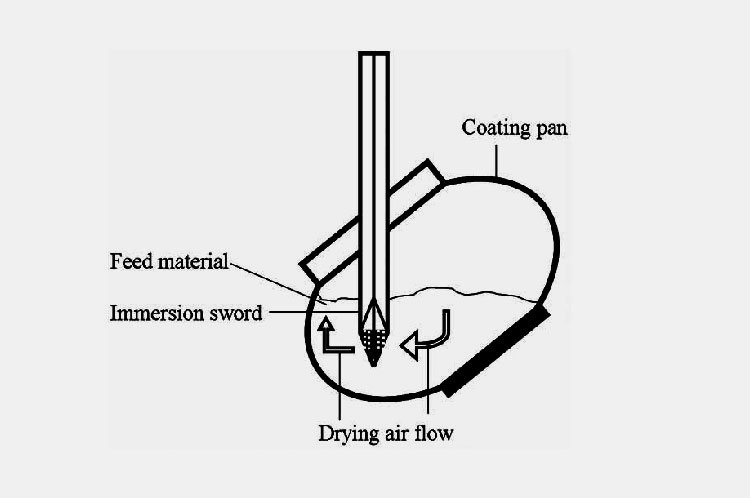

I.Immersion Sword System

For efficient drying of coated material, in this type of coating pan, heated air enters from a boring metal structure shaped like a sword. This structure is fixed in a coating pan.

Immersion Sword Smystem

II.Pellegrini pan system

This coating pan has holes that help in the even distribution of heated air on the tablet bed.

Pellegrini pan system

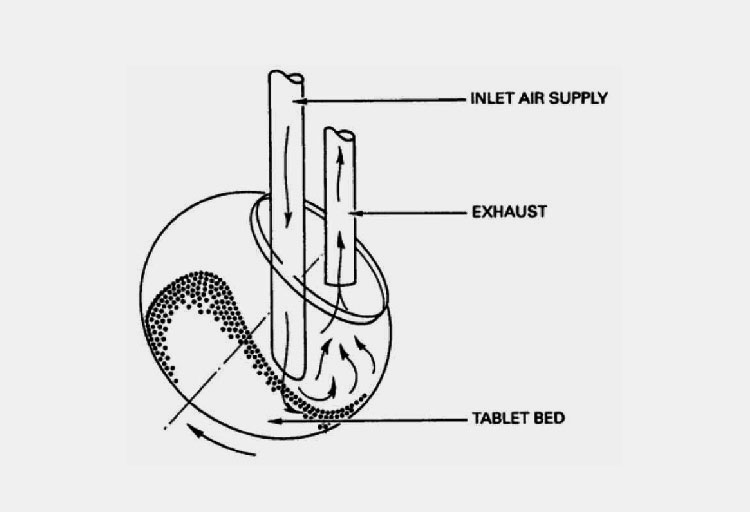

III.Immersion Tube System

In this tablet coater, a tube is submerged in the tablet drum that allows the incoming heated air. This air enters through a nozzle fixed at the top of the tube.

Immersion Tube System- Tablet Coater

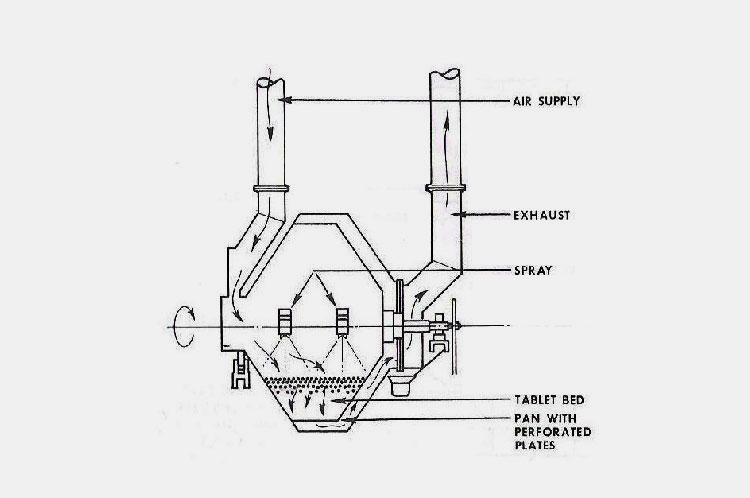

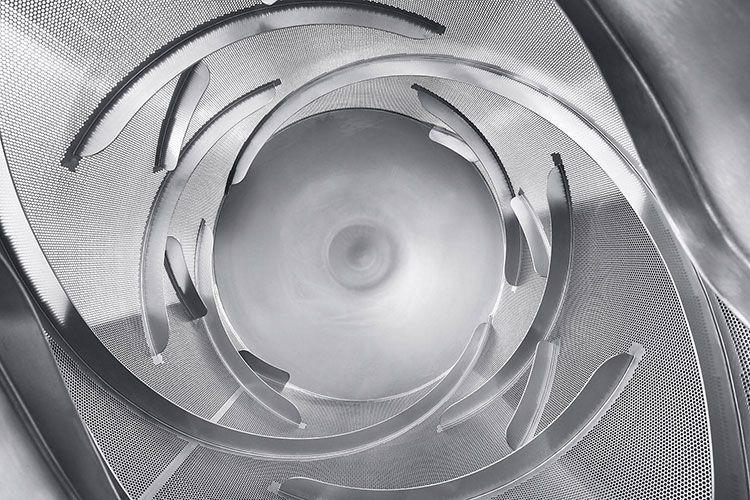

2.PERFORATED PANS

Perorated pan consists of a boring drum, spray system, loading and discharge unit, and control system. Its drum rotates on its own axis horizontally. The coating of tablets applied on rotating bed via spray nozzle present inside the drum. A perforated drum is high efficiency drum with large coating capacity.

Perforated pans of various designs are available in the markets. There are following sub-types of perforated pan system:

- Accela Cota

- Hi- Coater system

- Dria Coater system

- Glatt Coater

I.Accela-Cota

In this machine,

- drying air enters the pan,

- goes to the tablet bed,

- leaves through holes of perforated drum.

Accela-Cota- Tablet Coater

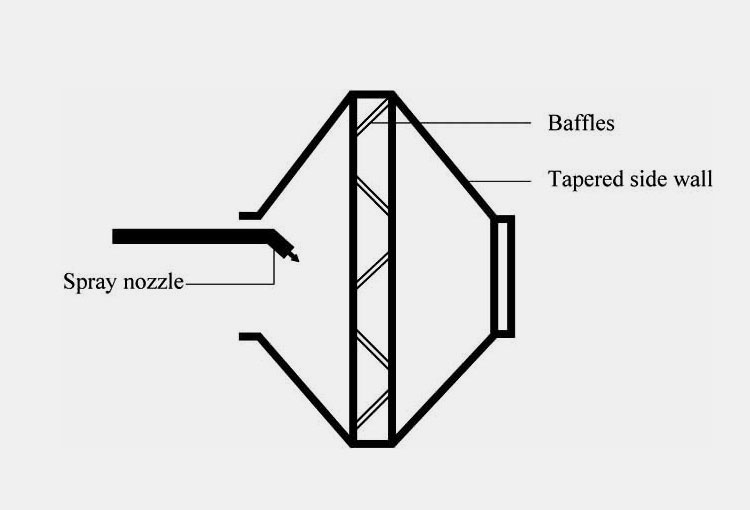

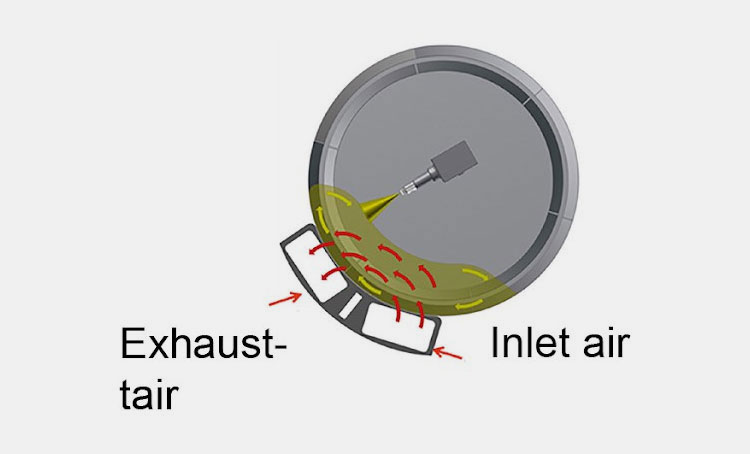

II.Hi-Coater system

Hi coater system comprised of four perforated sections that are perpendicular to each other.

Each perforation provides opening for air which is fixed at exterior of pan surface.

A dry air is introduced inside the pan via opening present on inside the periphery on the top of pan.

exhausted air is back via different air flow.

Hi -Coater

III. Dria coater

Heated air enters through depressed or hollow perforations present on the sides of the dria coater pan.

When the pan rotates, the air passes the tablet bed and goes out from the back of the drum.

Dria coater

IV.Glatt Coater

This machine is completely perforated which results in the efficient spray.

Heated air enters from inside of pan goes by tablet bed and leaves through the exhaust.

Or this incoming air can enter through pan holes for incompletely covering tablet bed.

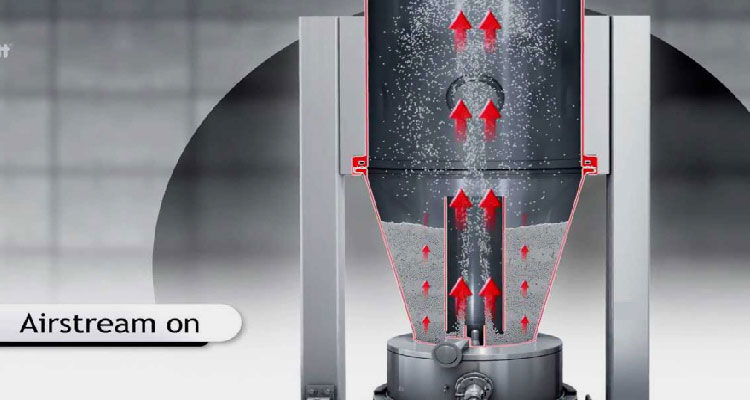

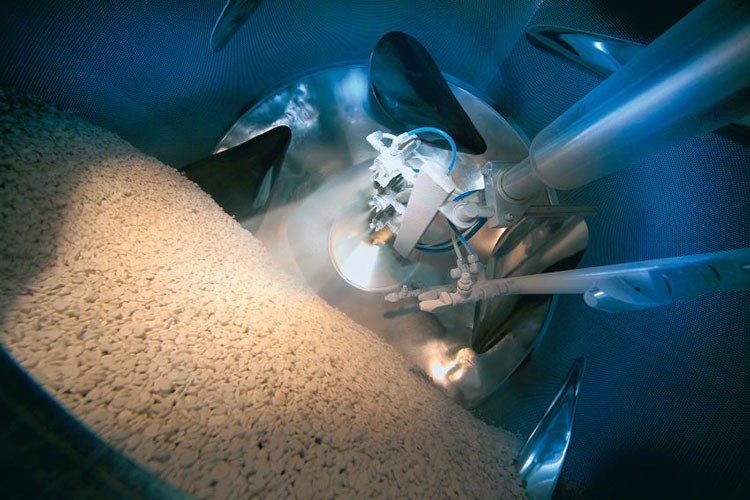

3.FLUIDIZED BED SYSTEM

Tablet Coating by Fluidized Bed System

Tablet Coating by Fluidized Bed System

This machine has four basic systems

- Airflow Management System

- Spraying

- Cleaning

- Automated Control Panel

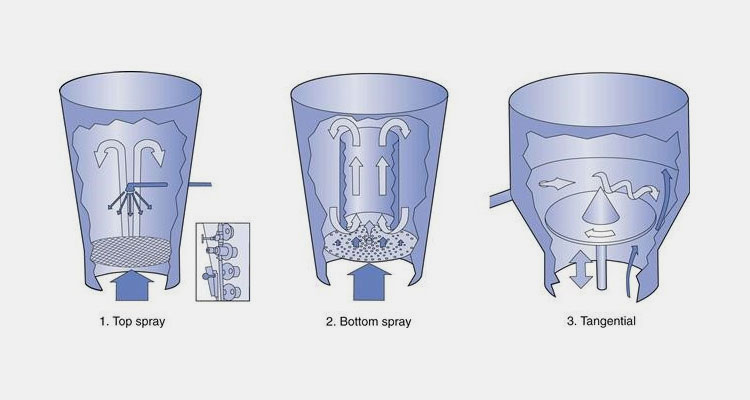

This machine comes in three spraying design configurations

- Bottom Spray Wurster

- Top Spray Granulator

- Tangential Spray (Rotary Granulator)

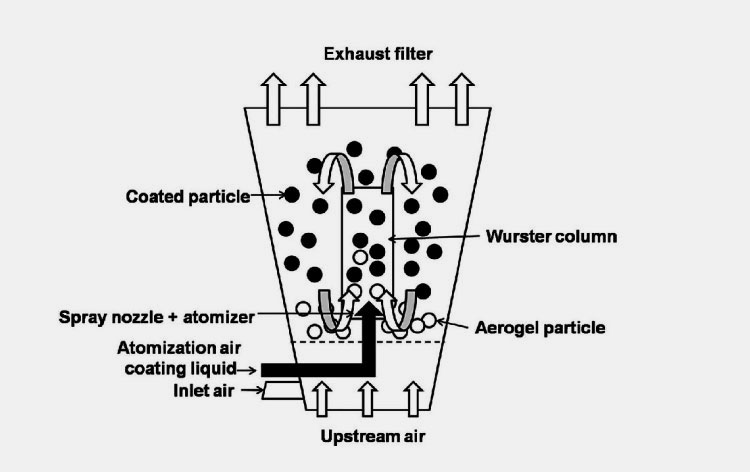

I.Bottom Spray Wurster

In this tablet coater, the coating solution is applied in the same direction as of rising tablets that in an upward direction. This is useful for coating polymers to pellets. This results in even coating and a low number of cracked tablets.

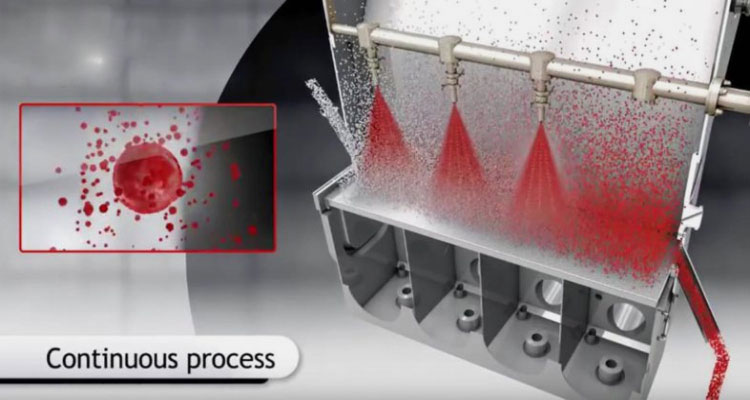

II.Top Spray Granulator

In top spray granulators, the coating solution is sprayed in the opposite direction of the rising tablets. The solution is sprayed in a downward direction. Tablets fall at the bottom of the chamber after the spray. Drying air dries the coating solution. This process of spraying is repeated to achieve the desired thickness of the coating layer. It is used for covering the taste and smell of the core drug. This spraying design does not result in even layering of coating material but is right for hot-melt layering.

III. Tangential Spray (Rotary Granulator)

In a rotary granulator, tablets are rotated at the top of the column by the rotor while the coating solution is being sprayed from the sides of the column. Tablets are shaken by the rotor to prevent sticking of the tablets. This design is suitable for coating the tablets when there are fluctuations in the batch and tablets are not of equal size.

3.What are the limitations of tablet coater?

Each type of tablet coater has its cons. Before buying a tablet coater you should consider the limitations of every kind of tablet coater and then make your selection. Disadvantages of each type of tablet coater are given below:

In a pan coating system, drying of the film is less efficient because most of the drying is done on the coating bed. This makes it difficult to apply another coating of film.

There are areas of low tablet movements in pan coating which results in an uneven coating of tablets.

There is the risk of explosion in pan coating due to leakage of volatile organic solvent vapors in the coating area. This is due to poor ventilation of incoming and outgoing air currents.

One main disadvantage of the perforated pan system is that you cannot ensure that all the perforations are cleaned after the removal of products.

It is hard to coat tablets that have powdery core and are susceptible to chipping in fluidized-bed coating systems. This is due to the coarse contact of tablets with column chamber walls.

Fluidized-bed coating systems are not appropriate for sugar coating.

Fluidized-bed coating systems cannot coat tablets in large batches.

4.Industrial uses of tablet coater are?

This machine has various applications in different industries like:

1. Pharmaceutical Industry

In the pharmaceutical industry, it is used for coating tablets by various methods such as sugar, film, and enteric coating. Due to high demand of tablet coater machine, you will find new advancement and innovations in every new upcoming machine to meet customer demand and enhance product quality.

2. Nutraceutical Industry

Manufacturing of nutraceutical items require intricate handling to preserve their active substances and delicacy. Excellent features of tablet coater offer a high degree product safety and enhances appearance for health-conscious individuals.

3. Agricultural Industry

It is also used for coating the protective layer on different agricultural products.

4. Food & Confectionary Industry

The manufacturers of foods and confectionary items such as chewing gums, chocolate, coffee beans and candies etc., strives to make their product attractive, polished, and colorful to gain customer satisfaction. That’s why tablet coater is consider as an essential tool to preserve originality and flavour.

5. Cosmetic Industry

It has application in the beauty industry for enhancing the perfume and appearance of cosmetic products.

6.Research Laboratories

Before marketing any product, test trials are mandatory. It is of well-known that every drug goes through R&D phase before commercial manufacturing. For small scale batch production mini or small tablet coaters are widely used.

5.Why is tablet coating done?

Tablet coating is done due to following reasons:

Protective film applied by tablet coater regulates the release of drug at the right time.

This film also protects the drug from an acidic stomach environment.

It also helps in containing reactive chemicals in the interior of the pills and also prevents their exposure to the environment.

This protective material also prevents exposure of the drug to oxygen in the environment, humid conditions, and harsh temperatures.

6.How many types of tablet coating? OR What are the different types of tablet coating?

Tablet coating is classified into three main categories:

1.Sugar Coating

2. Film Coating

3. Enteric Coating

1. Sugar Coating

Sugar tablet coating material involves sugar solution with blended color to give a uniform and elegant appearance.

Benefits:

1. It enhances sweetness and mask bitter odor and taste.

2. Sugar coating develops highly elegant and glossy tablets.

3. Tablets are resistant to chipping, cracking and abrasion.

4. Increase product’s shelf life and efficacy.

2. Film Coating

In film coating, polymeric solution of uniform film is coated on tablet surface.

Benefits:

1. It provides significant mechanical strength to tablets.

2. Film coating facilitates controlled /moderate release of active ingredients.

3. Protects drugs from air oxidation.

4. It efficiently masks bad small of tablets hence improve patient compliance.

3.Enteric Coating

Enteric coating provide protection to tablets core against disintegration in acidic environment of stomach due to using pH sensitive polymer that swells and solubilize when pH increases for e.g intestine.

Benefits:

1. Protects APIs against acidic environment of gastric media.

2. Protects gastric mucosa from local irritation.

3. Release drug at specific target site.

7.What material is used for tablet coating?

Tablet Coating Material:

1.Sugar coating:

Material used for sugar coating are as followed:

Sealing: seal that protect tablets from moisture. Ingredients used for sealing are, PG, shellac, zein, PEG4000 and polyunsaturated fatty acids.

Shellac

Sub- Coating: is done to form a uniform edge and improves tablet size. Ingredients used for sub-coating are gelatin, sugarcane, gum acacia etc.Acacia Gum

Syruping: is done to improve tablet surface and overcome imperfection caused during sub-coating. Ingredients used for syruping are distill water, corn starch, colorant, calcium carbonate, etc.

Polishing: it is done to improve luster and glossy appearance. Ingredients used for polishing tablets are carnauba wax, paraffin wax, volatile solvents etc.

2. Film Coating

Tablet film coating process involves following ingredients: HYDROXY- PROPYL-METHLY-CELLULOSE or HPMC, METHYL HYDROXYL ETHYL CELLULOSE or MHEC, Povidone, acrylate polymer etc.

3. Enteric Coating

Ingredients used for enteric coating are CAP – cellulose acetate phthalate, acrylate polymers, etc.

8.What are the important features of tablet coater?

Currently, there are many different types of tablet coater available in the market. You can select tablets coater that useful features for easy operation and working.

In the past, tablet coater did not have efficient nozzles for a spray of coating material. Cleaning of different parts was difficult. The tablet coaters of the past consumed a lot of power. But modern machines are equipped with different features like

They are supplied with washing nozzles.

They are equipped with a spray gun for the efficient coating of materials.

The rate of chipped and cracked tablets is less in modern tablet coaters.

They have automatic settings for controlling important functional parameters like heat, dew point, airflow, and pressure.

They conserve the coating material.

They are energy efficient.

They uniformly coat film on the surface of the tablet.

Less time is required for cleaning components of the machine.

They are equipped with automated designs for ventilation and discharge of tablets.

Large batches of tablets are processed at the same time.

Drying efficiency is also increased in modern tablet coaters.

Tablet Coater

9.What are the structural and functional components of tablet coater?

Tablet coater comes in various forms. Depending upon the type of tablet coat, its composition varies. Now let’s get some insight about various components of tablet coater.

Automatic tablet coater

A.Electric Motors

The function of an electric motor is to maintain airflow and create a low-pressure environment inside of tablet coater. These motors are also used for mixing pills. Usually, there are more than three electric motors in the tablet coater. Tablet coaters are composed of various kinds of electric motors. Electric motors are present in a contractile pump, hot air blower, air outlet, and coating bed. It is necessary to know about the rate of rotation of electric motor as this will determine the amount of power consumption of machine and ultimately the price of tablets.

B.Guide Plate

The guide plate is an agitator which helps in the smooth toppling of tablets. This toppling process of tablets allows the coating of material to tablets and at the same time, this prevents tablets from cracking and fragmenting. The small surface area of the guide plate aids in preventing unnecessary sticking of coating solvent.

C.Contractile Pump

These days tablet coaters are equipped with peristaltic pumps. These pumps have basic functions like

Maintaining steady pressure inside the machine by this return pumps are not used.

These pumps assist in the stable atomized spray. Thus, they make the spray system easy to operate and handle.

D.Control System

The control system is automated and equipped with different sensors for adjusting the operation state of the tablet coater. The control panel improves the operation of the tablet coater and maintains the safety of this equipment. These adjustment options in the control system include

Setting for adjusting speed, heat, and pressure in the machine

Documenting the operational state of tablet coater

Regulating the speed of atomized spray gun

Screen for a display of data

E.Touch Screen Panel

This technology is present in many contemporary tablet coaters. This panel has an easy-to-use brain-computer interface. This touch screen panel is present inside a case. This technology makes the operation of the tablet coater easy and impeccable.

Tablet film coating machine

F.Spray System

The spray system is the basic part of the pill coater. Without it, coating material gets wasted. It also saves the cost of manufacturing tablets. The spraying part of the tablet coater is made up of the tank, a nozzle, and propellers.

It is very important to select the right kind of nozzle that is suitable for the kind of material being coated. This process of selection of nozzle ensures optimal spray. Usually, sugar coating is done by using a rake and binary nozzles are used for spraying aqueous and organic solutions.

This system has different functions like

- It has a head for adjusting the spray nozzle.

- It makes cleaning and maintenance of spray guns easy.

- It helps in the stabilization of atomized spray.

- It stops the jamming of the spray gun.

- It prevents wastage of coating material.

- It helps in the even distribution of coating film.

G.Loading and Exhaust System

Tablets are usually loaded in the pan or drum by the means of a shaft. Some machines have a close charging system in which tablets are poured into the drum using pipes. These pipes are located in the front and upper part of the drum.

Coated tablets are moved out of the pan by two means (open and close discharge). In open discharge, a clipper is mounted on the machine and tablets move out of the drum while it is spinning. Coated tablets are moved down in a shaft and dropped into a hopper. In closed discharge, the mounted clipper moves the tablets in pipes and into an encased container.

Tablet discharge Chute- Tablet auto-coater machine

10.What are the different types of tablet coater?

Many pharmaceutical companies manufacture tablet coating machines that meet their requirements. There are various kinds of pill coater present in the market.

- Standard Coating Pan

- Perforated Pans

- Fluidized Beds

1.Standard Coating Pan

This type of tablet coater is made up of a circle-shaped metal pan that is fixed in a slanted position on a stand. This pan has a diameter of 8 to 60 inches. A motor is used to rotate the pan around a horizontal axis. This movement of the pan loads the tablets in the pan, which are passed then multiple times through the coating zone.

A spray of coating material in atomized form is applied to the tablet bed. This treatment is advantageous to the simple application of the liquid solution to tablets because it makes the coating process faster and results in the smooth dispersion of protective film.

After the application of protective film, heated air is introduced on the surface of the tablet bed and this air is flowed out from the ducts located in the front of the pan.

Standard Pan Coater- Pill Coating Machine

2.Perforated Pan Systems

The perforated Pan System is made up of a boring drum. This drum is present in the case and has a rotational movement around a horizontal axis. In this type of tablet coater, the coating film is distributed to tablets by the means of nozzles. These spraying nozzles are present inside the drum.

These machines (perforated pans) are widely used in the pharmaceutical industry. These machines used aqueous coating instead of solvent-based coating. The use of perforated pans prevents explosions due to volatile solvents. Perforated pans are used both for sugar and film coating.

3.Fluidized-bed Coating System

This type of tablet coater is also termed as ‘Air Suspension Coaters’. This type of tablet coater is different from other types of tablet coater as this uses a column chamber for the application of coating film. Tablets are suspended in column and coating solution is sprayed on these tablets. The column is heated by warm air. The flow of air is regulated. When more air enters the chamber, tablets move up in the middle of the column. These tablets then fall in the column chamber and the cycle of rising and falling of tablets is repeated. The spray nozzles present at the top and bottom of the column spray the coating solutions on tablets.

Fluidized-bed Coating System

11.How does tablet coater benefit your business?

Pharmaceutical tablet coating process is historically performed utilizing tablet pan or tablet coater. This is a large and lengthy technique performed on small to large batches may benefits your business significantly. Today, tablet coater is extensively used in chemical, food, agriculture and other manufacturing sectors.

Let’s explore how tablet coater benefits your business!

1.Quality Production Line

To achieve customer satisfaction is a prime objective of every manufacturer. Tablet coater offers the highest level of coating uniformity that improves elegance and glossy appearance to tablets. This quality improves user compliance and helps to achieve customer’s satisfaction and trust.

2.Safety and Protection

Construction of tablet coater comply with cGMP requirements; hence it is suitable for pharmaceutical and food manufacturing departments. A stainless-steel tablet coater offers exceptional safety and protection to all types of products. Furthermore, a coating application minimize chances of contamination or degradation of dosage form from external environment.

3.Good Taste Products

Tablet coater mask bad taste and odor of medicines. Not only this, in food industries tablet coater are used to enhance the flavour, color and taste of food items. The application of tablet coater makes your product more palatable to customer and increase market demand.

4.User Friendly

Tablet coater has extensive features and user-friendly operating system for beginners and leading industries. These machines are available in different languages and different levels from manual to automatic. Hence, you may choose the type of tablet coater according to suitability of production.

5.Cost- Effective

Tablet coater is simple machine that do not require many technicians to perform coating task. In a simpler word, it is economical way to enhance and improve your product in a low cost and manpower.

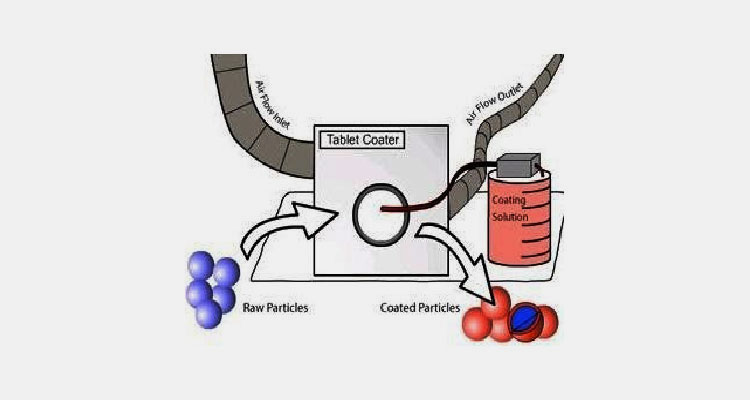

12.Do you know tablet coating working principle?

There are five main steps involved in the working of the tablet coater, these are

- Loading of Tablets

- Spraying

- Drying

- Unloading

I.Loading of Tablets

First, tablets are loaded in the rotating pan or column chamber using a chute or clipper. Some machines also have pipes for loading the uncoated tablets inside the machine.

Auto-coater Tablet coating machine

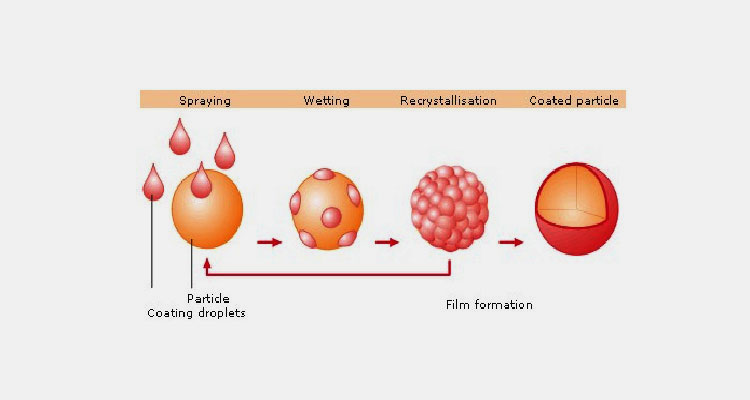

II.Spraying

In the coating pan, coating solvent is sprayed at the same time when tablets are moving on the tablet bed. On the tablet beds, tablets are being agitated to ensure the uniform coating of liquid. The spraying process results in a thin fine coating on the tablets. The spray process is applied one time for adhering film on the tablets or the spray cycle is repeated multiple times to build many layers. In a fluid bed system, tablets are suspended inside a column and spray nozzles located at the top and bottom of the chamber, are used to spray the tablets.

III.Drying

Drying of coating material is done by blowing the air on the falling tablets. Excess liquid is dried in this way. And in a fluidized bed, heated air is passed on the tablet bed to evaporate the surplus coating material.

Tablet Drying- Tablet Coater

IV.Unloading

Once coating material is dried, coated tablets are removed from the tablet coater. Coated tablets are removed by the exhaust pipes or through the shaft. These are dropped in the hopper or a closed container.

Tablet Discharging-Tablet Coater

13.How to operate tablet coater?

Tablet coating operator jobs

Press ‘ON’ the button located at the automatic control system for starting the tablet coater.

- Fill the tablet coater with uncoated tablets and coating solution.

- Switch ON the electric supply.

- Then take care to properly shut the front panel of the tablet coater.

- Load the program for coating tablets on the computer. Select input values for parameters like time, heat, and speed of rotation from the menu.

- The machine will automatically shut down when the coating process is finished.

- After the operation, perform cleaning of tablet bed and spray nozzles.

14.How to install a tablet coater?

Tablet Coater Machine- Picture Courtesy: ganson coating machine

Tablet coating machine manufacturers always recommend and offers you install tablet coater with trained and experienced staff.

- Before install visually inspect the machine to find if any damage occurs, in case of non-compliance immediately report the provider.

- It is recommended to have power supply ranges from 110 to 440 V.

- Install a tablet coater over a stable base as well as in a clean and dry area with appropriate ventilation.

- Before installing it is recommended to monitor the reducer and fill it with lubrication oil

- Ensure that all clasps are tight, and coat pan is cleaned.

- Machine wiring must be grounded well.

- The recommended electrical connection for tablet coater is ≤4Ω.

15.What are Do’s and Don’ts while operating the tablet coater?

Always wear protective equipment like gloves, goggles, masks, and protective boots to prevent releasing of chemicals into the environment.

Do not touch live wires as you can receive an electric shock.

Chemicals and coating solutions should be discarded properly as they are volatile, can use skin and respiratory irritation, and even cause sedation if inhale.

Always check speed parameters of tablet coater like ramping. If rotation speed or ramping is too high, then a defect in equipment may occur and the sample may be destroyed.

Always ensure that no chemical get leaked into the motor when replacing the aluminum foil. Discard these foils inside a contaminated waste bag and do not discard these foils in a trash of general items.

Always handle chemicals with non-inflammable tools and store them in properly ground containers.

16.What is the cleaning procedure of tablet coater?

Cleaning of tablet coater is necessary to avoid instrument contamination. Instrument contamination occurs because of two events.

- It happens due to substances used in the manufacturing of tablets.

- Environment and people also contribute to the contamination of tablet coater.

Cleaning tablet coaters of residual ingredients and detergents; is crucial for pharmaceutical industries and research facilities. This ensures good quality and safe to use products.

The cleaning procedure is as follows

Switch off all the switches for warm air inlet, exhaust pipe, and coating tablet machine.

Remove exhaust and hot-air pipes.

Close the drainage vent.

Attach cleaning bar to spray nozzles.

Switch on the pan rotation.

Pour water into the pan and add 10 ml detergent solution.

Rotate pan for 10 minutes.

Remove this detergent water and clean the inner sides of the pan with a lint-free cloth.

Use compressed air to get rid of powdery substances from spray guns.

Switch on hot air blowers to ensure drying of the pan.

17.How can we maintain tablet coater?

Maintaining procedure is very crucial for healthy life and efficient working of tablet coater. You should follow the maintenance schedule as mentioned in the machine guide. Below are few steps you can easily follow for maintaining the machine.

The coating pan must be cleaned daily after working on tablet coating. Also, oil its surface daily.

Rinse the spray gun with water daily after work. Dismantle its head and remove residual power with the help of a needle.

Tablet Coater

Check the temperature of the machine regularly to avoid process downtime.

Check for electric resistance to ensure connectivity with ground wire. Electric resistance should be under 4Ω.

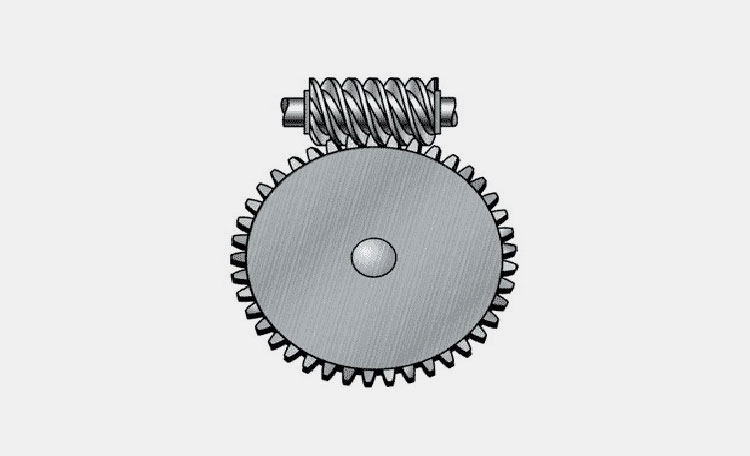

The oil-proof cylinder ring in worm gear should be replaced in 6 months.

Worm-gears

Regularly change grease oil in the gearbox and lubricating oil inside roller bears every 6 months.

18.What are the different factors on which the tablet coating process depends?

Many factors affect the efficiency of the tablet coating process. These are

Air Flow Capacity

This is an important aspect of tablet coater because air current controls the removal of water and solvent from the pill in the coating process. It is necessary for the production of tablets in dried form.

Coating Material and Airflow

Coating material compositions vary with the use of different chemicals and as well as solvents (which act as a carrier of ingredients). Airflow removes the solvents during the coating operation. If you want to increase the process of evaporation of the solvent, you will have to heat the air. But keep in mind that the amount of solvent removed during coating should be equal to the amount of coating material present.

Tablet Surface Area

It is thought that the weight of the tablets batch determines the quantity of coating material. But the application of coating liquid to tablets also depends upon the surface area of the tablets. Smaller the tablets’ less coating material is required. Conditions of the coating process are influenced by the area of tablets and their surface features.

Spray Oscillations

Various factors like the size of the droplet, velocity of spray, its distribution, and rate of drying contribute to an efficient coating of material on tablets. The efficient coating also depends upon the rate of spray and the area of bed on which coating material is being sprayed. Spray rate also depends upon the distance between nozzle and tablet bed, atomization conditions, and airflow.

Efficiency of Equipment

The efficiency of the coating process is determined by the tablet coating pan for example some coating material accumulated in pan walls makes the coating process less efficient.

19.What are the important aspects that needed consideration when procuring tablet coater?

When you are purchasing a tablet coater you should consider the following aspects such as

- Should be equipped with an automated control system.

- Should have cleaning-in-place system.

- Should be able to handle batches having different loads.

- Should have measures for preventing breaking and cracking of tablets.

- Should be complied with cGMP regulations.

- Have user-friendly software.

- Should have environment-friendly air exhaust systems.

20.What is the troubleshooting procedure of the tablet coater? What are the expected failures of tablet coater?

Tablet film coating defects most often occurred during coating process that affects

- issues with drug release

- aesthetic effects

- product stability

- cost of manufacturing

These issues are usually avoided by controlling parameters like temperature, humidity, airflow, etc. You can also encounter problems by making modifications to the tablet coater. Few important visual issues are discussed below:

Tablet Twining

This occurs when tablets stick together.

Reason

This happens due to defects in the shape of the tablet or capsule.

Solution

You can solve this problem by enhancing the rotation of the pan and decreasing the rate of spray if you do not want to change the shape of a pill.

Mottling

If you see light and dark patches on the surface of tablets, this is mottling. It is an irregular distribution of color.

Reason

It mainly happens because there is a color difference in excipient and also due to coloration of a disintegrated product of drug.

Solution

If you properly measure and formulate a coating solution, you can avoid mottling.

Edge Chipping

Sometimes tablets get broken from their tips. Dents are seen on their surface because of chipping.

Reason

Chipping is caused by the decreased inflow of warm air and by the low rotation velocity of the pan.

Solution

Care should be taken when drying tablets because over-drying tablets can make them fragile and leads to chipping.

Breaking

Sometimes tablets are split into two halves.

Reason

Breaking occurs due to excessive forces on tables when they are poured and removed from the pan.

Solution

Tablets should be handled with care when pouring and removing them from the pan for reducing damage to tablets.

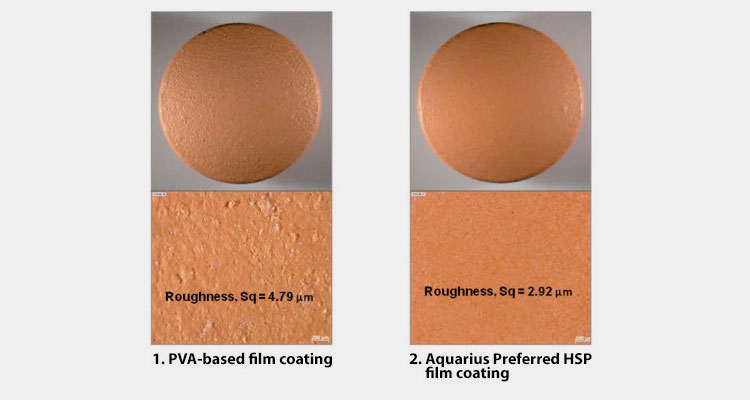

Rough Coating

Sometimes tablets get coarse coating and coating peels off when they are rubbed.

Reason

This is due to incomplete drying and over-wetting of tablets.

Solution

This issue is avoided by decreasing spray rate, reducing drying time, and using less vicious solvents. If this issue is caused by over-wetting, then increase the drying time.

Blooming

Tablets come dull in appearance right away or after some time in storage.

Reason

Blooming is because of the aggregation of some ingredients on the surface of tablets and these ingredients will become plastic in nature.

Solution

This is avoided by controlling temperature during the process of tablet formulation.

Infilling

Infilling is a phenomenon in which logos printed on tablets are difficult to discern. Sometimes spraying solutions fills the gaps formed by logos on the surface of the tablet which render them unclear

Reason

The foam droplets are protected by intagliations and they get accumulated inside these intagliations. These get set which causes infilling.

Solution

This issue is prevented by careful application of coating solution and proper mixing of a tablet with this solution.

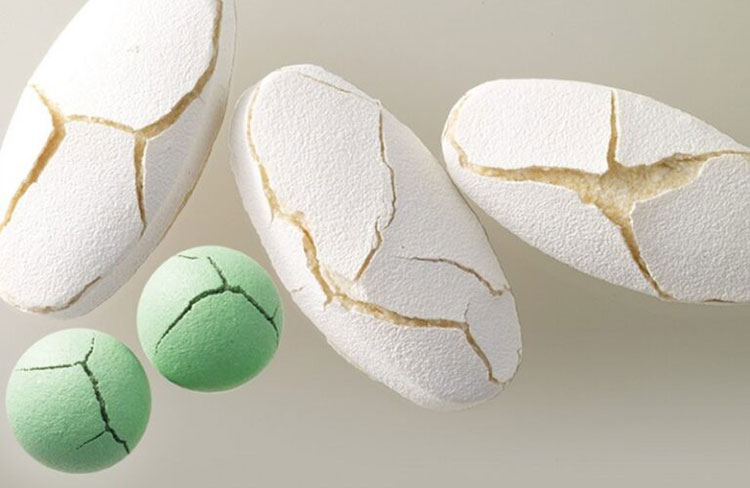

Cracking of Film

Film cracks when its application is disrupted. Cracks are seen on the tip or edges of the tablets.

Reason

This occurs because of high inside stress on film. This stress is greater than the elastic strength of the film.

Solution

It is avoided by making improvements in the formulation of tablet film. This is done by using polymers that have a large weight to increase the tensile strength of the film.

Conclusion

Tablets coaters have gained huge importance in today’s industrial and research sectors. It has applications in different fields like agriculture, beauty, pharmaceutical, and health. Using the right kind of tablet coater will save a lot of time, effort, and money. Hope you have learned about different aspects of tablet coater by reading this blog and this blog has provided you the solutions to your problems regarding tablet coaters.

Tablet Coating Machine Related Products

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine