Horizontal Flow Wrapper:The Complete Buying Guide in 2024

Flow wrapping or flow packaging is a technique used in different industries to wrap different type of products with a thin plastic wrap around them.

Horizontal flow wrapper used to wrap different products on a large scale to ensure safety, long life, and bacteria free items.

In this “Horizontal Flow Wrapper Guide” you will learn multiple things and key features about the horizontal flow wrapping machine.

When buying a horizontal flow wrapper these questions will help you to provide knowledge and guidance.

1.What is Horizontal flow wrapper?

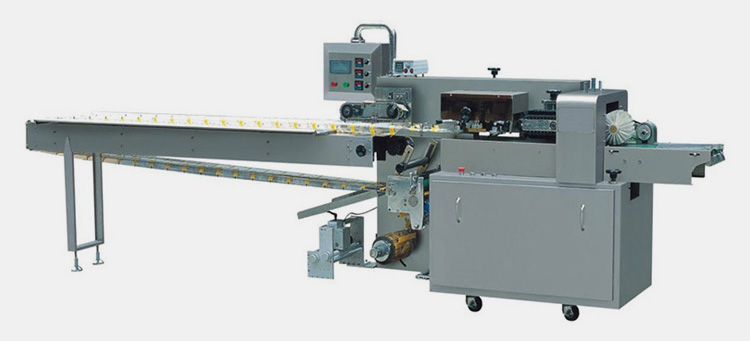

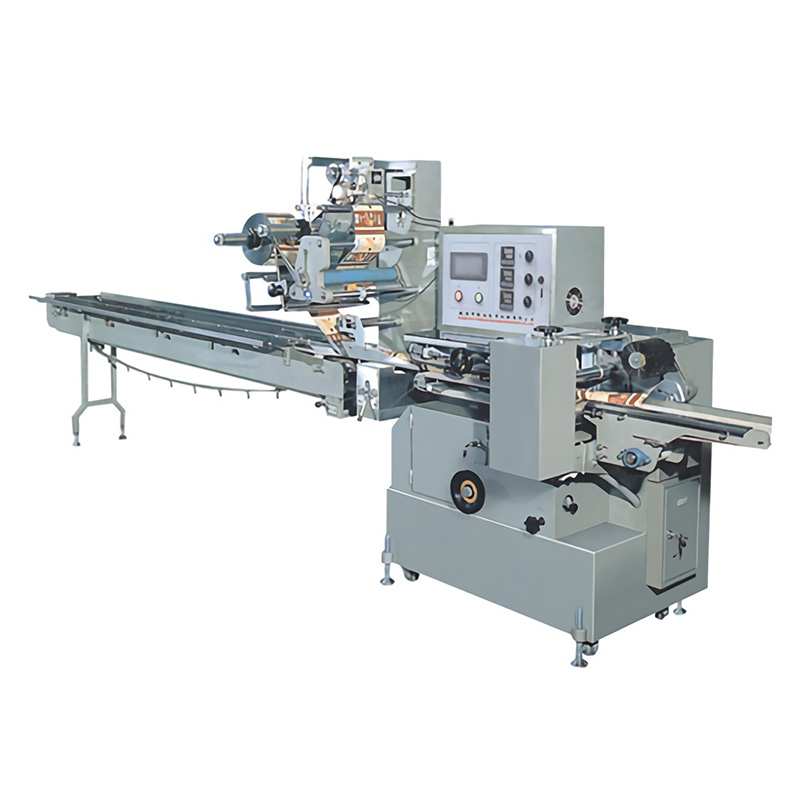

AIPAK Horizontal Flow Wrapper

Horizontal flow wrapper is one of the kinds of packing equipment used for packing different pharmaceutical items as well as other industrial items in the form of pouch or pillow.

Usually, a horizontal flow wrapper puts a wrap around the packed items in a tray form. It horizontally operates the wrapping mechanism in a flow that is why it is called horizontal flow wrapper.

Normally, a horizontal flow wrapper can perform three different tasks on a same product in a sequence such as first it will wrap the product then it will seal that warp and at the end your final product will be discharged safely.

Wrapping is considered as more secure type of packing which is more versatile and authentic for sensitive medicines or food items to make these items free from bacterial effect.

2.Applications of Horizontal flow wrapper in different industries?

Horizontal flow wrapper is an easy access for packing that can be used in multiple industries to wrap multiple items.

Some following applications of Horizontal flow wrapper are as follows.

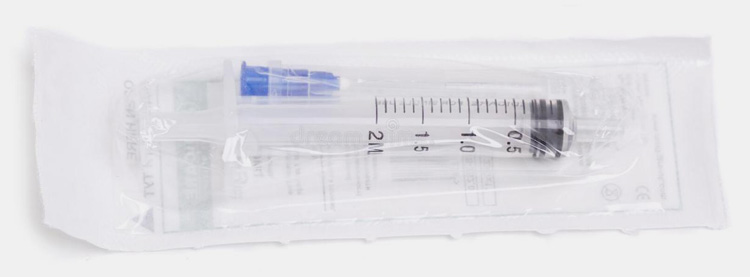

Pharmaceutical Industry

In pharma industry horizontal flow wrapping machine can works to pack different medical dosages and clinical devices such as tablets or capsules, masks, gloves etc to make them air sealed.

An easy-to-use horizontal flow wrapper in pharmaceutical packaging additionally ensures the best use of medicinal merchandise and promotes affected person compliance (for example, tablet & capsule packing and small medical devices).

It is likewise a protection whilst it makes use of unique methods, including single-dose packaging or multi dose packing and sealing (specifically in clinic setting).

To overcome the packing difficulties of different medicines AIPAK introduced innovative and smart featured horizontal flow wrapping machines manufactured & designed to fulfill your needs.

Food Industry

Horizontal flow wrapping machine is also used in food industry especially to pack different bakery products for example pastries, cakes, biscuits etc.

Wrapping bulk amount of bakery items or wrap a single item can increase the expiry rate of your product. Some other food items such as chocolate bars or other instant food items like noodles can also be wrapped successfully and quickly by using this machine.

Vegetables and fruits that we often see in the market are packed with horizontal flow wrapper to make sure you get fresh items.

Cosmetics & Beauty Industry

A report taken in 2022 suggests that after the most successful tenure of horizontal flow wrapper in pharmaceutical and food industry it is now become demanding in cosmetics and beauty care industry with the increasing rate of 3%.

Many cosmetic products such as creams, lotions, facial powder are wrapped with the help of horizontal flow wrapper to make them dust free, fresh and pure.

Protective film wrapping around the product can be very effective to make the product safe, secure, damage free, dust free and preserve it from contaminating elements.

Household Items

Flexibility of horizontal flow wrapper to work with different types of products makes it even more comfortable to be used in daily life household working as well.

Many household items can be wrapped with flow wrapper such as napkins, disposable items, wipes and sponges.

Different plastic household items that we purchase from the market are also wrapped in a plastic film that is also made with the help of horizontal flow wrapper.

Indeed, horizontal flow wrapping machine is a flexible equipment that can be used in any industry for the purpose of packaging multiple items in bulk amount at a very high speed.

3.Explain advantages of Horizontal flow wrapper?

Horizontal flow wrapper holds numerous advantages that are given below.

- Horizontal flow wrapper prevent your production from contamination

- It provides cost-effective packing at low rate

- Horizontal flow wrapping machine gives clear and attractive packing look to your products

- This machine make your product still at the same spot after the packing to make sure it remains in good shape

- Horizontal flow wrapper can pack your product by utilizing fewer resources for shipping purpose

- Definitely wrapping will increase the life cycle and freshness of your product

- A visible thin layer at the top for attraction and safety of inner product

4.What kind of material is used for wrapping?

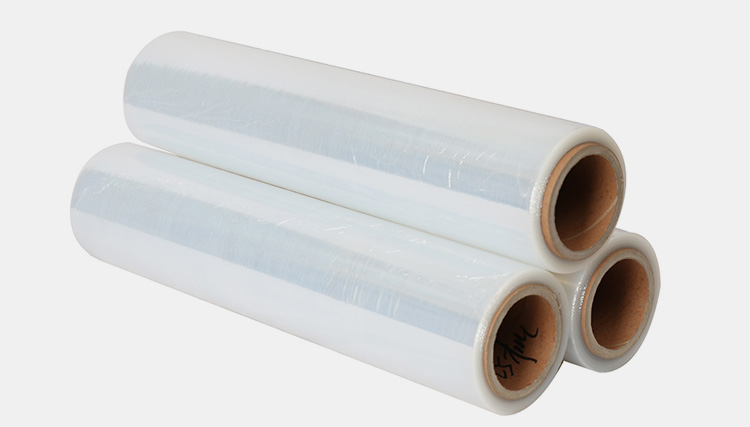

Many wrapping materials can be used in the horizontal flow wrapper but one of the most used wrapping materials is BOPP.

BOPP

BOPP is Biaxially Oriented Polypropylene used to by most of the horizontal flow wrappers. It is a thin film that gives a shinny look during the packing.

BOPP is a visible form of wrap. It provides original look of your inner packed product and very good in strength wise.

Bopp is widely used to wrap different pharmaceutical and medical items.

PE

Polyethylene is one of the commonly used wrap in horizontal flow wrappers as well as in other flow wrappers because it works well in packing multiple shape boxes, trays, cartons etc.

PE is a plastic film utilized in different packing industries. Polyethylene is not only good for wrapping with horizontal flow wrapper but it is also good for manual packing of multiple products to make them air proof.

PET

Polyethylene terephthalate is also comes from polyester family and commonly utilized in different flow rappers.

It works differently in wrapping as compared to other wrapping materials because it is not that much flexible as PE and BOPP but closely packed molecules of PET make it stronger than others.

If you want to wrap or pack different liquid containers, food boxes then PET is a best wrapping material that you can use in horizontal flow wrapping machine.

5.How a Horizontal flow wrapper works?

(Working of APK horizontal flow wrapper)

Every flow wrapper machine works in different way to pack multiple sorts of products.

Step-I

In the beginning packing products loaded in the feeding unit then packing items move towards the horizontal conveyor.

Horizontal conveyor arranges the items horizontally after which the products move in a sequence towards the forming unit.

Step-II

A forming unit holds the forming film which is first prepared in the forming box then a product enters the forming unit and flow wrapper warp the item.

After the wrapping a cutter cuts the product separately from each other. A heat sealing unit then provides a hot heat to seal the outer edges of the wrap in a manner.

All of these wrapping steps are done in a sequence so that your wrapped items do not get any damage and wrapped properly.

Step-III

After the wrapping and sealing of the products they can finally leave the horizontal flow wrap machine for further packaging in cartons and boxes.

Horizontal flow wrapper works in a sequence to simply wrap different products that we use in different industries.

6.What are the different components of Horizontal flow wrapper?

Horizontal flow wrapper machine consists on several small and large size components here are some of these important working components.

Infeeding Unit

A basic infeeding unit in a horizontal flow wrapper is used to hold the products that you want to wrap or pack. You simply feed the products in that unit, feeding can be done automatically or manually it depends on the nature of machine.

Infeeder then move the products towards the horizontal conveyor.

Horizontal Conveyor

A horizontal conveyor unit works to arrange the products horizontally in a sequence.

In a horizontal flow wrapper a horizontal conveyor arrange and control the movement of products going towards the flow wrapper.

Forming & Film Assembly

For the purpose of wrapping when a product enters the flow wrapping unit a forming unit first detects the size of the product and then made a thin film for wrapping.

Film wrapping assembly also contains several sub-components such as:

Film Reel Detector: It works to assess the real from starting point to the end point

Splice Unit: When a product successfully wrapped with the film reel it connects the next coming product to the previous filled product reel to make a chain.

Film Cutter:Film of wrap products connected to each other as a chain and to make the separation a film cutter comes into action.

Film Reel Holders:During wrapping process film holders used to hold and adjust the film reels according to the product movement.

Pushing Unit

When the wrapping is done around the product this pushing unit pushes the filled products towards the sealing unit.

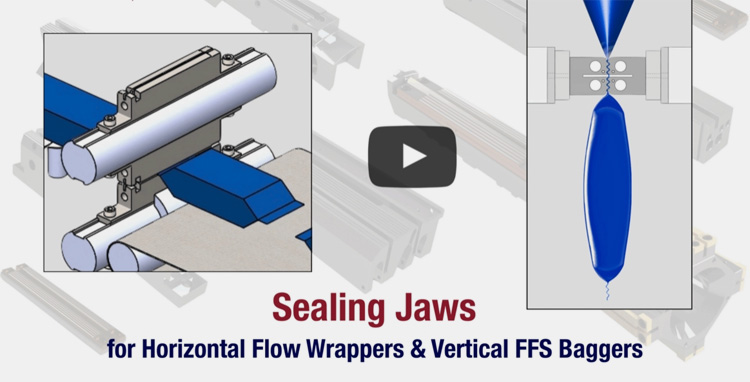

Fin Wheel

When wrapping is done around the lower and upper part of the product it tends to mat the outer edges and corners of the wrap for sealing purpose.

Rotary Sealing Unit

In this horizontal flow wrapper component a heating air is applied on the edges of the sealed wrapped item for the safety of inner product and that is how wrapped item is sealed flawlessly.

Horizontal flow wrapper works mainly through these components.

7.What are the working features of Horizontal flow wrapping machine?

APK-300C Horizontal flow wrapper

A horizontal flow wrapper machine holds multiple useful features to pack pharmaceutical as well as other industrial items in a simplest way.

- PLC panel provides you easy feature to control the temperature during wrapping.

- Flexible design of AIPAK horizontal flow wrapper allows you to adjust the wrapping size according to product.

- The flow of wrapping in a horizontal wrapper can be easily controlled by the working body.

- Highly durable stainless steel body with visual PLC panel for easy working environment at greater production rate.

- Strong jaws to hold your inner product firmly during wrapping without making any damage.

8.What kind of products you can wrap using Horizontal flow wrapper?

Horizontal flow wrapping machine is used in different industries so it has the tendency to wrap multiple products such as:

- Multiple irregular shape small size confectionary items for example candies, lollipops, and chocolate bars.

- Different types of biscuits wrapping, snacks wrapping, pizza tray wrapping, and multiple fried food items.

- You can also wrap multiple stationary items like papers in bulk amount, pen boxes, magazines and books wrapping.

- Bakery and frozen items can also be wrapped with a horizontal flow wrapper for instance bread, buns, cakes, frozen meat, frozen vegetables, pies.

- Disposable items like glass etc and other household items can also be wrapped with the horizontal flow wrapper.

There are numerous wrapping items that you can wrap with horizontal flow wrapper including some of these.

9.Important factors to consider before selecting a Horizontal flow wrapper?

Before selecting Horizontal flow wrapper machine you need to consider some of these factors.

Functionality & Purpose

Selecting any kind of horizontal flow wrapper is not difficult but you must understand and consider the functionality of your machine and purpose of having a wrapper.

Functionality means what sort of wrapping you want manual or automatic with what purpose?

Products Type

Horizontal flow wrapper comes in a specific function to work with specific product.

However, there are some horizontal flow wrappers that can work with multiple types of products wrapping but it is better to select a specific one if you want to work with specific product.

Cost

Always spend moderate amount of money while purchasing a horizontal flow wrapper and make sure you get quality wrapper within your budget.

This is called cost-effectiveness.

Design & Manufacturing

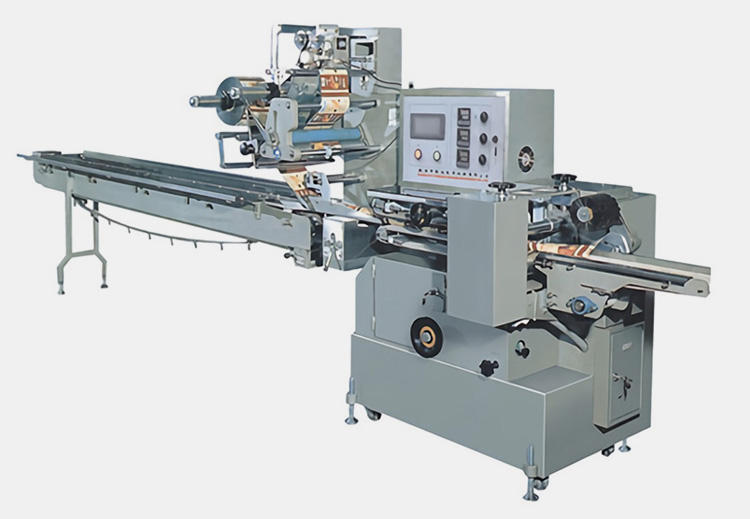

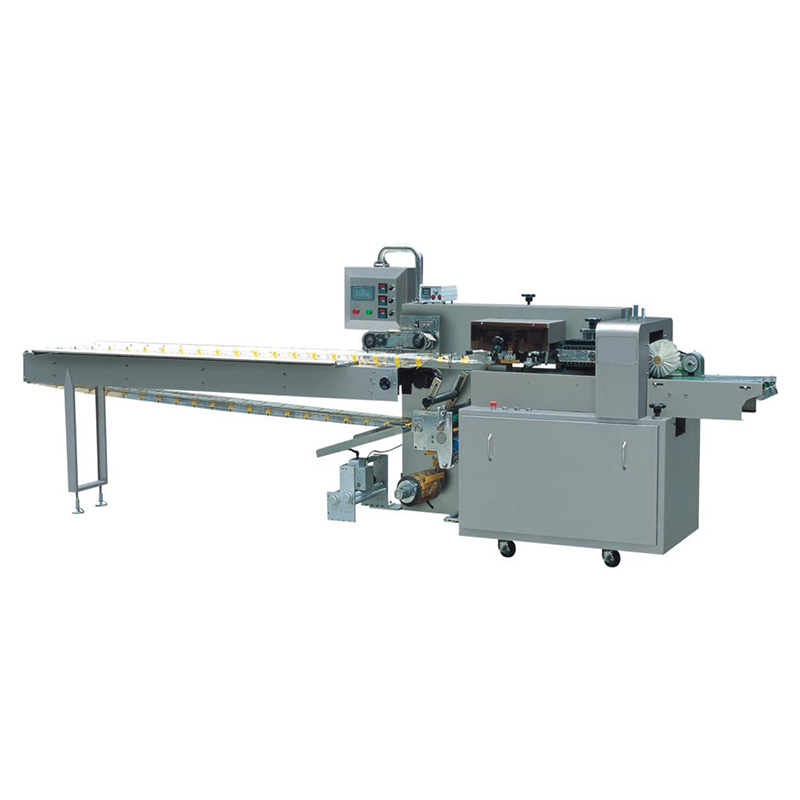

APK-350D Flow wrap machine

A horizontal flow wrapping machine should fulfill the necessary design requirements to fit perfectly with your production line.

You also need to confirm that horizontal flow wrapper machine which you select is made with the best durable material for better working and longer line run.

Size & Weight

Do not select a horizontal flow wrapper having huge size and heavy weight just select a wrapper that serves you in the best way within moderate weight and size range.

10.How to overcome problems that you may face while working with horizontal flow wrapper?

During the wrapping process with horizontal flow wrapper you might face many of the problems but do not get upset read the instructions that are given below.

Problem-1: Product Stuck

Coming from horizontal conveyor when the product enters the forming unit it may stuck in there and do not move.

This is because of slow movement of product as compared to wrapping film length in the infeed unit.

Solution: To solve this wrapping problem you can replace infeed unit and adjust the wrapping length of film.

Problem-2: Product Failed to Pack Perfectly

In the forming unit this often happens when product enter the wrapping area slowly as compared to speed of film coming out to wrap it.

Solution: Increase the incoming speed of product entering the forming unit or use small length packing film.

Problem-3: Film not feeding properly

When a wrapping film is not threaded in a perfect manner this problem might occurs during wrapping with horizontal flow wrapper.

Solution: To solve this wrapping problem you need to check & adjust the film threading properly.

11.How can you clean & maintain Horizontal flow wrapper machine?

To maintain a Horizontal flow wrap machine in its best shape you need some of these tips such as:

Lubrication

Lubrication to different horizontal flow wrap machine parts will enhance the packing ability and smooth running of the wrap machine.

Inspection

Before and after inspection of different parts of horizontal flow wrapper will help you to identify any kind of torn components and problems that happen during packing.

Inventory

Keep your inventory updated because when you face any problem about torn component in the horizontal flow wrapper it should be available to you for quick replacement.

Speed

Do not work at high speed with the horizontal flow wrapper because it may cause a problem in your forming area.

Cleaning

Keep your horizontal flow wrap machine neat and clean as it plays an important role in the proper functioning of your wrap machine.

More importantly, the forming area needs regular cleaning for better and smooth working to provide you quality packing in less time.

Working with a horizontal flow wrapping machine needs some basic and advance knowledge as well but at least you know how to handle an emergency problem.

Access the wrap machine sensibly and if you face a major problem always go for experts help.

12.Why you should choose AIPAK Horizontal flow wrapper machine?

APK-400A High speed fully automatic flow wrap machine

No doubt, there are other top companies providing Horizontal flow wrap solution but AIPAK is good in many ways let me just explain it to you.

Cost-effective Solution

AIPAK always provide different pharmaceutical and other solutions at low cost with greater working ability.

Free Consolation

You can communicate with AIPAK team and tell them your requirements and we will provide you free consolation service for better selection of your product.

High-Tech Machines

It is hard to get low cost high-tech machines in the modern day but do not worry AIPAK is here to facilitate you with modern technology wrap machines.

Quality Standard

Making a machine for pharmaceutical use or for other purpose you need to maintain quality standards set by EU & other mechanical firms. At AIPAK we always prepare a solution according to our customer requirements.

Experience Employees & Engineers

After successfully accessing your requirements our expert engineers can prepare a unique & affordable solution for your business.

13.Is it possible to customize a Horizontal flow wrapper?

In a Horizontal flow wrap machine it is possible to adjust some features of the machine but you can not customize everything in it except some of these parts like:

While packing any type of product with horizontal flow wrapper you can adjust or customize the size of wrap.

Another thing is form of wrap, sometimes you may fill a product in a square form wrap but you may require another type of form to fill another different type of product therefor, you can customize the form of pack according to your packing item.

Conclusion

Horizontal flow wrapper is a perfect equipment for you to work in pharmaceutical industry or you want to pack bakery or food items or may be something else.

Other packing equipment’s are also available at AIPAK store. If you want any packing machine or horizontal flow wrapper, do not hesitate to leave a note.

AIPAK is leading the race to provide authentic, secure and quality solutions to its customers all around the world with its great policies.

Don't forget to share this post!

Flow Wrap Machine Related Posts

Flow Wrap Machine Related Products

Flow Wrap Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine