Pharmaceutical Packaging Design: The Complete Guide From Concept to Compliance In 2025

Are you a pharma manufacturer? Are you launching a new drug or upgrading your existing product? Designing pharmaceutical packaging must be your initial concern. As pharmaceutical packaging design is just not about appearance, but it also relates to the safety, compliance, branding and patient convenience.

This guide is created to satisfy your curiosity related to pharmaceutical packaging design. You get to learn about so many things that help you in choosing the best option for your product. You are going to discover about privileges, types, material, packaging machines, and important considerations of pharmaceutical packaging design. Let’s read to learn!

1.What is pharmaceutical packaging design?

Pharmaceutical Packaging Design

Pharmaceutical packaging design is a crucial, technical and creative process of crafting containers for pharmaceutical products. This process ensures the safety, stability, integrity and compliance of tablets, syrups, injectables, or ointments etc. during shelf life and transportation.

2.What are the privileges of pharmaceutical packaging design?

Pharmaceutical packaging design is regarded as integral process in pharma industry. When product arrives after going through production process, it needs an appropriate and efficient packaging to remain efficacious, safe and compliant. Let’s discuss the privileges of pharmaceutical packaging design!

Preserving product safety and stability:

Preserving Product Safety & Stability

Do you know how drug reaches you in safe and stable form? It’s an effective pharmaceutical packaging design that keeps product protected from moisture, light, oxygen and contaminants. It does not only shield during storage but also prevent physical damage during transportation. It has contribution in increasing the shelf life expectancy and chemical stability.

Keeping product compliant:

Keeping Product Compliant

Do you know pharmaceutical packaging design has the role in keeping your product compliant? Yes, it supports the regulatory compliance and helps to adhere to the guidelines of FDA, WHO and other important regulatory bodies. You easily get to meet labeling requirements and market demands. The last thing contributing to above benefits is you stay away from legal troubles.

Facilitating patient safety & convenience:

Facilitating Patient Safety & Convenience-Picture Courtesy: Sensire

A contemplative pharmaceutical packaging design is more than a blessing for a patient. It has clear labeling and instructions that minimizes the chances of medication errors. It comprises of child-resistant closures that can prevent unwanted accidents but easy for adults to use it. It apparently has all features that boost patient’s convenience.

Building product’s good impression:

Building Product’s Good Impression

What thing attracts you the most in a drug product at first sight? It’s the appealing and easy to comprehend pharmaceutical packaging design. An ideal pharmaceutical packaging design has custom color schemes and typography. It keeps maintaining consistent brand identity which builds trust and product recall in consumers.

Enhancing counterfeit resistance:

Enhancing Counterfeit Resistance

In pharma world, counterfeiting causes a lot of damage to manufacturers and patients. A thoughtful pharmaceutical packaging design incorporates tamper-proof seals, holograms, and serialized tracking. These features safeguard consumers and enhance counterfeit resistance.

Optimizing supply chain efficiency:

Optimizing Supply Chain Efficiency

A perfect pharmaceutical packaging design comprises of such characteristics that optimizes space saving in transport and storage. It has barcodes that promotes quick scanning and traceability. It also shows compatibility with automated packaging line.

Improving market reach globally

Improving Market Reach Globally

When a pharmaceutical packaging design has compliance with regulatory standards either local or international, it enhances links with diverse regions. The market accessibility and global reach of product increases robustly.

Ensuring eco-friendly goals:

Ensuring Eco-Friendly Goals

It is one of the important trends of pharma industry to promote sustainability in their packaging. An environmental friendly packaging is capable of reducing material waste and promotes recyclability. Such pharmaceutical packaging design uplifts brand image and ensures eco-friendly goals.

3.What are the types of pharmaceutical packaging design?

The medicine you are holding in your hand is present in its relevant packaging. This pharmaceutical packaging design is basically categorized in to primary, secondary or tertiary. Every type has its own function in keeping drug safe and effective. Let’s get to know about different pharmaceutical packaging and their purposes!

Primary pharmaceutical packaging design:

Primary Pharmaceutical Packaging Design-Picture Courtesy: The Pharma Education

This is the packaging in which drug is enclosed, showing its direct contact with the drug. It is created to safeguard the drug from contamination, chemical instability and physical damage.

| Pharmaceutical packaging | Purpose |

| Blister packaging | These packaging are chosen for tablets or capsules. They protect drug from moisture, light and air exposure. |

| Bottles and jars | You can find solid, liquid and suspension drugs in the bottles and jars like syrups, tablets or capsules, or nutritional powders.

You get this packaging with child-resistant caps. |

| Ampoules or vials | You can see injectables or nutritional supplements in the form of ampoules or vials.

They are highly precise, sterile and tamper evident. |

| Sachets or pouches | You can get powders, granules or single-dose liquids in sachets or pouches. |

| Pre-filled syringe | You often see ready to use injectable products in prefilled syringes. This packaging gives you precise dose control and reduces contamination risks. |

Secondary pharmaceutical packaging design:

Secondary Pharmaceutical Packaging Design

Secondary pharmaceutical packaging design is intended for branding and extra protection. This also contributes in shielding packaging container from chemical or physical factors. It is helpful in prolonging the shelf life of product. Let’s have a look on secondary pharmaceutical packaging and their purposes.

| Secondary pharmaceutical packaging | Purpose |

| Cartons | You often see medicines are packaged in folding boxes. These boxes are called cartons. These cartons contain labelling which provides important information to the consumer at first sight. Barcode is also present that helps to enhance traceability. |

| Sleeves | You can spot extra labeling or branding wrap with packaging drug to facilitate the consumers. This is known as sleeves. |

| Shrink wraps or over wraps | You can observe drug products with shrink wraps or over wraps in the pharmacy. Such packaging is intended for tamper-evidence and protection. |

| Leaflets | You mostly find a paper with medicine you buy. This is called leaflet. This piece of paper contains detailed information about the drug like doses, indications, contraindications etc. |

Tertiary pharmaceutical packaging design:

Tertiary Pharmaceutical Packaging Design

This kind of pharmaceutical packaging design is helpful in bulk handling and transportation. You find them using for shipping, storage and distribution.

| Tertiary pharmaceutical packaging | Purpose |

| Corrugated boxes | When you want to transport a bulk quantity of pharmaceutical products, you use corrugated boxes. They are suitable for large scale shipment. |

| Pallets and stretch films: | Stretch films are used to wrap and secure pharma products on pallets for the purpose of storage and transportation. |

4.What machines are employed for pharmaceutical packaging designs in pharma industry?

The machines that are employed for pharmaceutical packaging design are known as packaging machines. These machines are regulatory compliant and have integral role in production of pharmaceutical industry. These machines are picked up on the basis of

Form of drug (solid, liquid or semi-solid)

Packaging design (bottle, vial, blister pack or cartons etc.)

Machines for solid pharmaceutical products:

In this topic you get to know about machines that are used to package powders, tablets or capsules.

| Packaging machines | Purpose |

| Blister packaging machine

AIPAK Blister Packaging Machine |

Blister packaging machines is used to package tablets or capsules in blister packs. |

| Tablet filling machine

AIPAK Tablet Filling Machine |

Tablet filling machine is suitable for packaging tablets and hard or soft capsules in to bottles and jars. |

| Sachet filling machine

AIPAK Sachet Filling Machine |

Sachet filling machine is helpful in packing powders or granules in sachets or pouches. |

| Lyophilized powder vial filling line

AIPAK Lyophilized Powder Vial Filling Line |

Injectables that can be antibiotics, hormones or nutritional supplement are packed in vials in lyophilized powder form to avoid instability.

Lyophilized powder vial filling machine is employed to fill powder drugs in vials. |

| Powder filling machine

AIPAK Powder Filling Machine |

Powder filling machine is used to pack powder pharma products like antibiotics, nutritional supplements etc. into bottles and jars. |

Machines for Liquid pharmaceutical products:

Here you are well informed about the packaging machines employed for syrups, suspensions and injectables.

| Packaging machines | Purpose |

| Bottle filling line

AIPAK Bottle Filling Line |

Bottle filling line is used to fill and cap syrups and suspensions in to bottles. |

| Liquid vial filling line

AIPAK Liquid Vial Filling Line |

This liquid vial filling machine is ideal for filling and sealing sterile liquid formulation like antibiotics, steroids, antifungals, pain killers, hormones, and nutritional supplements etc. into vials either made from glass or plastic.

It endorses the high precision, sterility and potency of drug. |

| Ampoule filling line

AIPAK Ampoule Filling Line |

Ampoule filling lines has the function of filling and sealing the single dose of liquid drug product in to ampoules.

It ensures the dose control and aseptic conditions during whole process. |

| Eye drop bottle filling machine

AIPAK Eye Drop Bottle Filling Machine |

Eye drop bottle filling machine is used to fill and seal eye drops, ear drops or nasal drops in to dropper bottle.

Sterile conditions are maintained throughout the operation. |

| Prefilled syringes production line

AIPAK Prefilled Syringes Production Line |

This machine is employed to fill and seal the prepared liquid formulation in to syringes.

It maintains precise dosing and sterility. |

| BFS bottle production line

AIPAK BFS Bottle Production Line |

BFS bottle means blow-fill-seal bottle. This container is suitable for liquid formulations either drugs or vehicles for drug formation.

BFS bottle production line fills and seals the drug formulation into a bottle in a continuous process. This ensures high sterility of product. |

Machines for semi-solid pharmaceutical products:

In this topic, you get the information about machines used for semi-solid pharmaceutical products like ointments, creams, gels or suppositories.

| Packaging machine | Purpose |

| Tube filling machine

AIPAK Tube Filling Machine |

Tube filling machine is capable of filling semi-solid pharma products in to aluminum or plastic tubes. |

Machines for secondary packaging:

These machines are utilized to secure secondary packaging like leaflets, cartons etc.

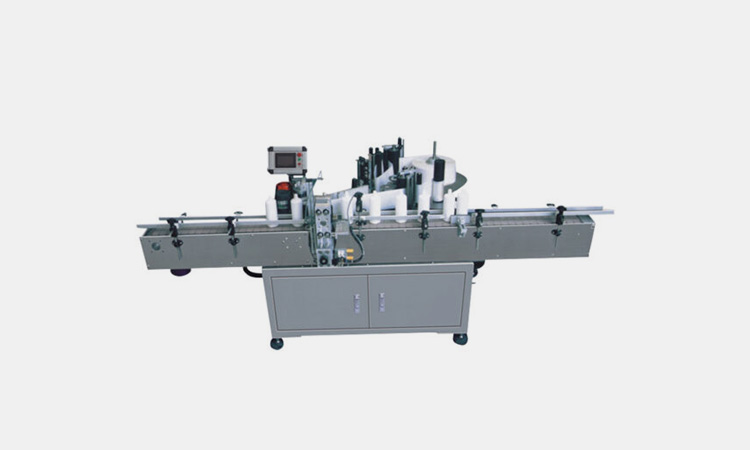

Labeling machines:

AIPAK Labeling Machine

Labeling machines have the key function of applying labels on different packaging containers like vials, bottles, ampoules etc. This equipment is integrated with primary packaging machines to ensure correct labeling of pharmaceutical products. Labels contain important information about drug, expiry date and barcodes. Labeling machine applies labels in different ways and most common way is to apply the printed label on containers.

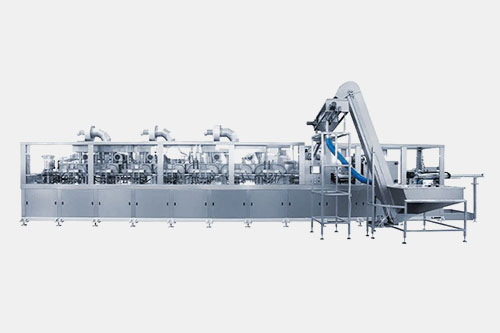

Cartoning machines:

AIPAK Cartoning Machine

Cartoning machines are utilized to close the packaging container in to relevant sizes of boxes. These boxes are in printed form, contains integral information about the pharmaceutical product. This machine is also capable of inserting leaflets with the drug product into the cartons.

5.What are the important considerations when choosing pharmaceutical packaging design?

Pharmaceutical packaging design is a lot more than the container. It shows connection between the drug, regulator and the consumer. It needs to be created in perfect way as it endorses the product quality and patient safety. This topic tells you about important considerations of pharmaceutical packaging design to help you get the desired one for your product.

| Important considerations | Information |

| Product compatibility

Pharmaceutical Packaging Design Should Be Product Compatible |

Your pharmaceutical packaging design must have product compatibility. Suppose you are producing antibiotics for oral use then you should opt for glass bottles for packaging your product.

It should be capable of protecting the product from mechanical damage, environmental factors and contaminants. The material you are using for packaging design must be competent to the product type. Like borosilicate glass is used for vials or ampoules. The packaging design should be suitable for storing and transporting the pharmaceutical product. It must have ability to endure the chemical and physical factors. |

| User-centric design

Your Pharmaceutical Packaging Design Should Be User-Centric |

Your pharmaceutical packaging design must be easy to understand and consume.

It must have arthritis-friendly caps and large fonts for old patients. For some packaging, children resistant closures are necessary to avoid accidents. It should have tamper proof seal to ensure patient safety. |

| Sustainability

Material Of Packaging Should Be Biodegradable Or Recyclable |

Sustainability is counted as a regulatory and consumer expectation.

The material used for your pharmaceutical packaging design should be biodegradable or recyclable. |

| Regulatory compliance

Packaging Design Must Have Serialization And Anti-Counterfeiting Features |

You have to make sure that your pharmaceutical packaging design should be aligned with local and international pharmaceutical laws like FDA, EU, and WHO etc.

It is requisite that your packaging design contains mandatory information, dosage, batch number, expiry date and manufacturer details. Your design should have serialization and anti-counterfeiting features to avoid trouble in future. |

6.Do you know about innovative pharmaceutical packaging designs?

Do you have an idea about innovative pharmaceutical packaging designs? It relates to the development and application of new technology and concepts in packaging designs of pharma products. This innovation brings safety, effectiveness, sustainability and patient-friendliness towards pharmaceutical packaging. Let’s explore innovative pharmaceutical packaging designs:

Smart & connected packaging:

Innovation in pharmaceutical packaging design has brought so much convenience for consumers. Along with advanced engagement, it merged the technology with packaging that combats counterfeiting. You can see the use of smart & connected packaging that is discussed below:

NFC-enabled blister packs:

NFC-Enabled Blister Packs

In this packaging design, NFC (near field communication) chip or tag is embedded in blister card. You can tap the blister pack with an NFC enabled smartphone and this chip introduces you to a secure digital platform, which contains crucial drug information like dose, expiry, authentication etc.

QR code linked packaging:

QR Code Linked Packaging-Picture Courtesy: Digital Link

This pharmaceutical packaging design contains QR code that helps patients, pharmacists or other healthcare workers to get the reach towards relevant information by just scanning that QR code.

Time-temperature indicators:

Time-Temperature Indicators

These are smart devices that told you about the time conditions or temperature that have potential to influence the quality, safety or effectiveness of product.

Bluetooth-enabled pill bottles:

Bluetooth Enabled Pill Bottles

These are the smart pill containers that have blue tooth sensors. Every time you open the lid, this information is sent to the paired app or cloud server. This app can tell you dose times and send reminders if dose is not taken.

Compliance-boosting designs:

Compliance-boosting designs facilitate the patients to take correct drug with right dose and on right time.

Calendarized blister packs:

Calendarized Blister Packs

This packaging design is based on blister pack, in which each cavity is labeled with a day and time of day.

Push through plus peel off hybrids:

Push-Through Plus Peel-Off Hybrids

This packaging design is a type of blister packaging that merges the push-through and peel-off methods of opening in a single design.

Integrated dose counters

Integrated Dose Counter

This packaging design involves the integration of a mechanical or electronic counter with the packaging container. Each time you use the container, it advances the counter by one unit.

Patient-centric accessibility:

Patient-centric accessibility is defined as creating the packaging containers, labels and delivery systems that enhance the ease of use, clarity and patient safety of any age, abilities and literacy level.

Ergonomic caps:

Ergonomic Caps

These caps are helpful in opening and closing the medicine easily and safely. These are designed for elderly people or patients with limited hand strength. These are also known as arthritis caps.

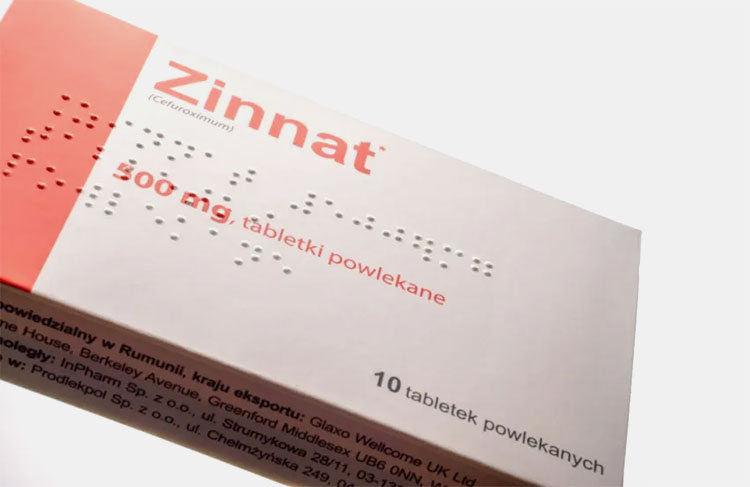

Large print or braille labels:

Large Print Or Braille Labels

Packaging contains large, high-contrast fonts, braille for visually impaired and pictograms for less educated consumers.

Color coded systems:

Color Coded System

This is referred to the use of different colors for highlighting important information. For example, using distinct colors for morning, afternoon and evening doses that makes regimen easy to follow.

Sustainability:

Efforts are made to bring more environmental friendly pharmaceutical packaging designs that can offset the carbon footprints of pharma industry. The material used in making of such packaging is biodegradable or recyclable.

Mono-material blister packs:

This indicates the use of single recyclable material (plant based plastic or aluminum) in the creation of blister packaging. This feature can make the process of recycling much quicker and easier.

Biodegradable pill bottles:

Paper Pill Bottle

These are the medicine containers that are made from plant-derived material. This material can include plant based polymers, bacteria-produced polymers, blend of starch with polymer or paper cardboard.

Reduced-plastic sachets & stick packs:

Reduced-Plastic Sachets

These are the small dose packagings that are made from biodegradable material instead of conventional multilayer pouches. Plant based polymer or paper is used for making of sachets and stick packs.

High protection designs:

Such pharmaceutical packaging design ensures the complete protection of pharmaceutical product from chemical, physical or environmental factors.

Active packaging:

Pill Bottle With Desiccant

This packaging design contains a proper system that shield the pharmaceutical product from moisture, temperature, air or microbes. This design ensures safety and stability of product. For example, integration of desiccants into bottle caps or blister cavities can save the product from moisture.

Tamper-evident closures:

Tamper-Evident Closures

This packaging design is made for keeping the product safe. Such features help to manifest it visually or physically clear if medicine container is has been opened, altered or interfered before reaching to the consumer. Examples include the use of breakaway closures, heat shrink plastic wrap around container etc.

Anti-counterfeit tech:

Anti-Counterfeit Tech

This relates to the complete system integrated in pharmaceutical packaging to verify the drug authenticity, avoid imitation and safeguard the supply chain from fake or substandard drugs. Example includes the use of holograms, invisible inks, micro-text orienting etc.

Specialized delivery formats:

Such pharmaceutical packaging design is created to ensure that the drug is reached to the patient in most effective, protected and easy way.

Unit-dose stick packs:

Single Dose Stick Packs

This delivery system consists of slim, elongated pouches that have single-serve and pre-measured drug product. The drug product can be powder, granules or liquid formulation.

Pre-filled syringes & auto-injectors:

Auto Injectors

The ready-to-use formulation either vaccine, biologic or insulin is filled in syringe by the help of advances filling machines. This packaging ensures precise dosing and minimal contamination risk.

Dual-chamber syringes & vials:

Dual-Chamber Syringes

Medicines like antibiotics etc. requires mixing before administration. Dual chamber syringes and vials comprise of two portions that contain drug and vehicle separately. Prior to administration, drug is mixed in vehicle, which ensures its potency.

7.What are the future outlooks for pharmaceutical packaging design?

This topic educates you about the predicted trends, possible changes and developments expected in pharmaceutical packaging design. Let’s dive in!

| Smart, connected & data-driven packaging

|

Smart packaging refers to the use of IoT (internet of things) technology. This technology will facilitate the patient to get important information about the drug product.

This packaging will have integration with QR codes and NFC chips for tracking and traceability. Counterfeiting is biggest threat in pharma world and to prevent this issue holograms, micro text, invisible inks or block chain tracking will be introduced. |

| Patient-centric & accessibility focused

|

Pharmaceutical packaging design will be altered to get more patients friendly. For example braille will be introduced on packaging labeling so that blind consumers can read the information.

An ideal pharmaceutical packaging design is created to avoid challenges that relate to the consumers like over dosing, medication error etc. |

| Sustainability & circular economic

|

Greater adoption of plant derived polymers, biomass blisters and reusable delivery systems will be made possible in future.

In order to ensure the sustainability in pharmaceutical packaging, some important measures will be taken like Increasing the reach of people to sustainable materials. Promoting green technology and train people about using it. Giving awareness about benefits of sustainable material and hazards of environmental pollution. |

| Personalized & on-demand packaging

|

This refers to the facility of creating customized pharmaceutical packagings that are made particularly for an individual or batch produced only when needed. |

| Enhanced protection for complex drugs

|

This packaging design is suggested to keep the complex drugs like biologics, high potency medicines and other sensitive dosage forms protected from environmental, chemical and physical threats.

This will be achieved by promoting Active packaging Temperature control packaging Light-blocking containers High-barrier materials Tamper-evident seals Secondary protective layers |

| Regulatory-driven innovation

|

Regulatory-driven innovation manifests about bringing advancements and changes in packaging design, material and technology according to guidelines suggested by regulatory bodies such as the FDA, EMA, WHO etc. |

Conclusion:

Pharmaceutical packaging design is not only about presenting the drug in appealing way. But it manifests the product safety, regulatory compliance, patient trust and market success. Any negligence in choosing the correct pharmaceutical packaging design can cost production disasters and consumers’ life. Are you willing to get more aware about pharmaceutical packaging design? You can visit AIPAK for relevant information at any time!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine