Why Sample Testing is Critical Before Shipping Your Tablet Counting Line?

Buying machinery from overseas creates anxiety for many business owners. You worry about whether the equipment will actually work with your specific products once it arrives at your facility.

Sample testing is the only way to guarantee your production line works immediately upon arrival. By sending your specific bottles, caps, and labels to the factory before shipping, we configure sensors and guide rails to your exact specifications. This process prevents costly downtime and technical failures during the installation phase.

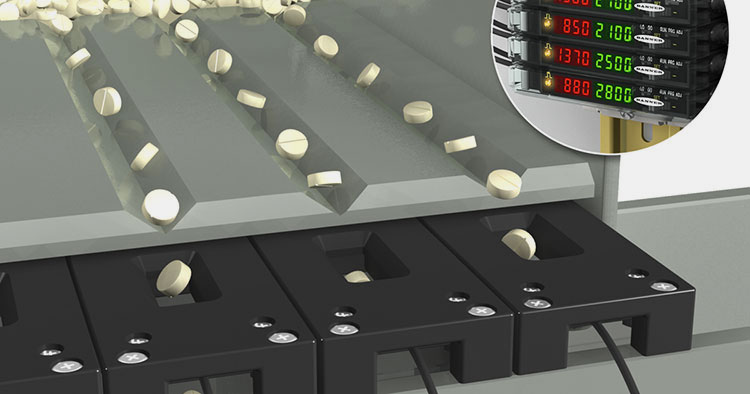

Factory engineer testing tablet counting machine with client samples

If you enjoy gambling with your production schedule and budget, you can skip the rest of this article. However, if you want to understand how we ensure a 100% success rate for our clients, keep reading to see our process in action.

1.How did we configure the right medium-speed line for a Canadian client?

In early 2025, we received an inquiry from a new client in Canada. He needed a reliable solution for counting and bottling his supplement products without breaking his budget.

We analyzed his production speed requirements and bottle sizes. We recommended a complete 16-channel line, including the APC160 Unscrambler, APC16 Counter, and APC902 Capper. This setup offers the best balance between high output and cost-efficiency for growing manufacturers.

AIPAK complete automatic tablet counting line

I want to share the details of this specific project because it represents a very common need in the market. The client needed a "medium-speed" line. He did not need the fastest machine in the world, but he could not afford a slow machine either. We held an internal meeting at AIPAK to discuss his needs. Since this was our first time working with this Canadian partner, we decided to offer a very competitive price to build trust.

We designed the line with a logical flow. First, the APC160 Bottle Unscrambler organizes the bottles. Then, the bottles move to the APC16 Channel Counting Line, which is the heart of the system. We added an L1 Material Lifter to automatically feed his capsules. After counting, the bottles go to the APC120 Cotton Inserter, followed by the APC902 Capping Machine.

To finish the product, we included an M1 Induction Sealer and the APC T1 Labeling Machine. Finally, the finished bottles collect on an 850mm Turntable. This configuration covers every step of the packaging process. It ensures that the client does not need to buy separate machines from different vendors. Everything talks to each other perfectly.

2.Can a larger bottle hopper really save you labor time?

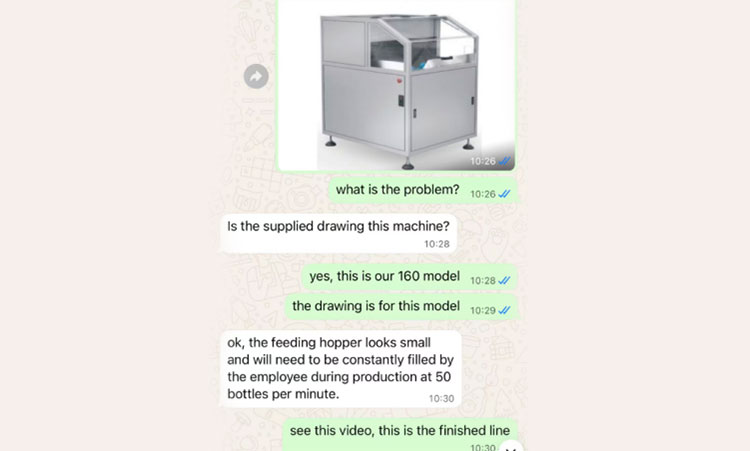

Standard machines are great, but they do not fit every workflow. During our discussion, the client pointed out a specific problem with the standard bottle feeding system.

The client felt the standard APC160 unscrambler hopper was too small, holding only 1000 bottles. He worried his operators would waste time refilling it. We agreed to build a custom hopper that holds 1500 bottles at no extra cost to solve this pain point.

Customized large hopper for bottle unscrambler request from customer

You might think that the size of a hopper is a small detail. However, for a production manager, it is a huge deal. The client looked at the specs of our APC160 Bottle Unscrambler. He saw that the standard storage bin holds about 1000 bottles. He did the math quickly. At his production speed, his operator would need to refill that bin very often. This means the operator cannot do other tasks, like checking quality or preparing boxes.

We understood his concern immediately. We are a manufacturer, not just a trading company, so we have the power to change the design. We told him, "No problem." We agreed to customize a larger material hopper for him. This new design holds 1500 bottles. This is a 50% increase in capacity. It allows the machine to run longer without human attention.

The client was very happy with this proposal. We did not charge him extra for this. We view this as part of our service to ensure the machine fits his daily reality, not just the catalog description.

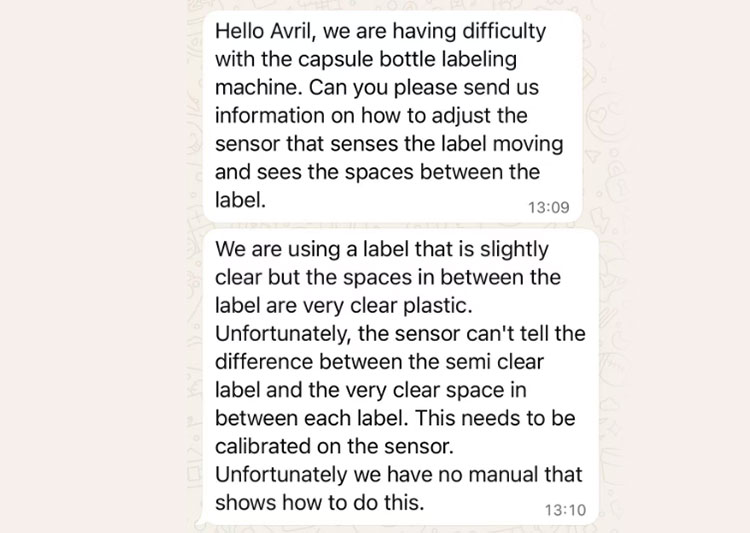

3.How do we handle the difficulty of detecting semi-transparent labels?

Labels are the face of your brand, but they can be a nightmare for machines. The client had a specific label design that caused significant concern for his engineering team.

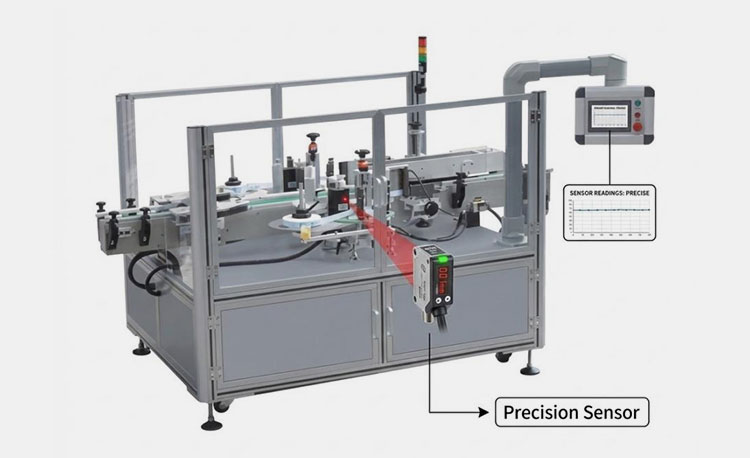

The client uses semi-transparent labels, which standard sensors often fail to detect. We recommended upgrading to the Lion Precision sensor from the USA. This high-end sensor uses advanced technology to accurately read clear materials, ensuring every bottle is labeled correctly.

Precision sensor on labeling machine

Labeling is often the trickiest part of the packaging line. The client told us his labels are semi-transparent. This is a red flag for standard equipment. Most basic labeling machines use a standard optical eye (photoelectric sensor).

These sensors work by seeing the difference in light between the label and the backing paper. If the label is clear or semi-transparent, the light goes right through it. The machine thinks there is no label there. This leads to double labeling, missed bottles, or machine jams.

Our engineers looked at the photos of his labels. We knew immediately that the standard sensor would fail. We advised him to upgrade. We recommended the **Lion Precision sensor**. This is a top-tier brand from the United States. It uses capacitive or ultrasonic technology, not just light.

It can "feel" the thickness difference of the label, even if it is invisible to the eye. The client was worried about the cost, but we explained that a cheaper sensor would waste thousands of labels. He agreed to the upgrade because he understood the value of reliability.

4.Why did we insist on receiving physical samples before finalizing the order?

Theory is different from reality. We never rely on drawings alone. We asked the client to send his actual products to our factory in China before we shipped anything.

We required the client to mail us his bottles, caps, capsules, and the tricky semi-transparent labels. We used these raw materials to test the machine physically. This allowed us to calibrate the Lion sensor and the counting channels to his exact product dimensions.

Engineer adjusting machine with client bottles

This is the most critical step in our process. Many suppliers skip this to save time. They look at the dimensions on a PDF file and say, "It will fit." We do not work that way. We asked the client to ship a box containing all his packaging materials. We needed his specific plastic bottles. We needed his exact caps. We needed his actual capsules, and most importantly, those semi-transparent labels.

Once the package arrived, we set up the entire line. We poured his capsules into the APC16 counting machine. We checked if they flowed smoothly or if they were sticky. We put his bottles into the new, larger APC160 hopper. We ran them through the line. Then, we tested the APC T1 Labeler with the new Lion Precision sensor.

We adjusted the sensitivity until it caught the edge of the transparent label perfectly every single time. We filmed this process. We sent the video to the client. Only after the machine ran perfectly with *his* items did we approve the shipment. This eliminates the risk of the machine arriving in Canada and not working.

Conclusion

The client received the machine, and it worked perfectly immediately. His business is now expanding, and he plans to order more equipment from us because we solved his problems before they happened.

Don't forget to share this post!

The Importance of Sample Testing for Counting Lines

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine