What Is The Difference Between Cartoning And Case Packing

When you do shopping in market, you may be aware of the different cases, cartons and packages on shelf, truck or trash can. People’s awareness of getting products great packaging has became better and make a series of actions to protect the products. You can thus see the different package of different size, material and shape.

In so much different packages, you may be aware of the cartoning and case packing. They share the similarities as they play the same role as protection and appealing, but there also exists difference.

Do you know their difference between cartoning and case packing? Have you ever learned about their pros and cons? Would you like to know their different needs in material and machine? Come on and follow this post, you may get the best answers in cartoning and case packing!

1.What Is Cartoning And Case Packing?

You can’t find the products without package. Even the most ordinary or cheap products have the packaging. And most products don’t have just one layer of packaging, the primary and secondary packaging are widely used in manufacturing. Their combination benefits products protection and transportation.

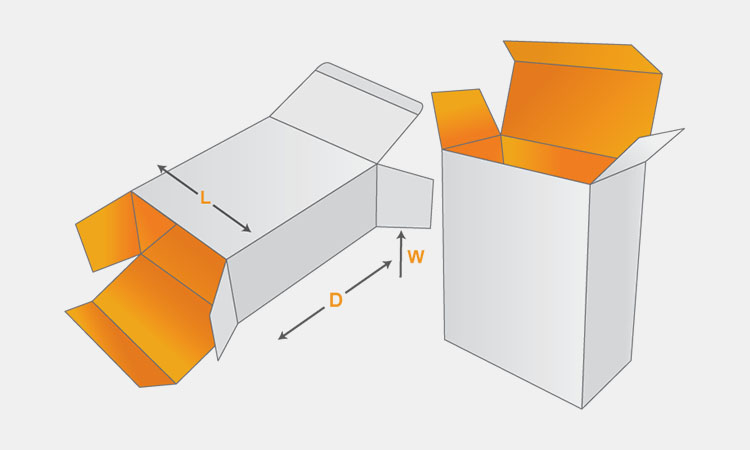

Cartoning-Sourced:massmanautomation

Cartoning contains the process as forming, filling, sealing cartons and making the primary look of products which is usually displayed in market shelf. It is the closest packaging for products and gives the products the direct protection. Besides the basic packaging, sometimes, it also needs to fulfill the work like filling brochures.

Case Packing-Sourced:insitepackaging

Case packing can be used interchangeably with cartoning. It uses the prepared case directly and saved the process of case making. Its main process is filling the case with packaged products. Usually the last process, it plays the important role to protect the products in transportation and benefit the transporting process.

2.What Are The Types Of Cartons And Case Packages?

Products varied as well as packages. With the standard of good products and package improved, you can find the various types of cartons and case packages on market.

Types of cartons

Cartons can be divided according to its different shapes and style.

- Slotted box

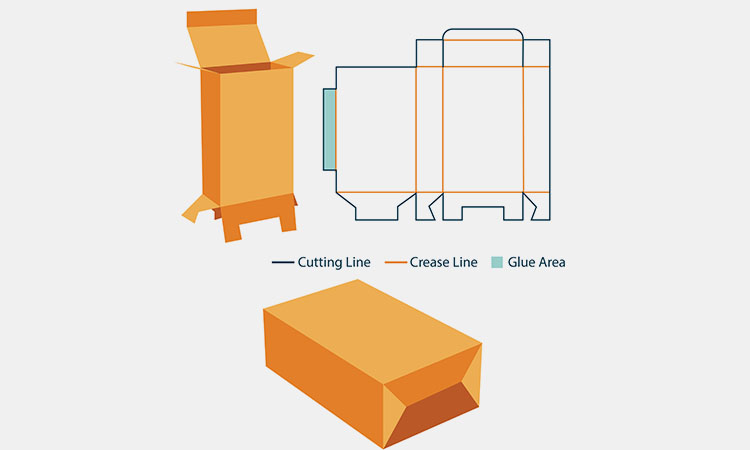

Regular Slotted Box-Sourced:crownpack

Slotted box is the most common types of cartons. Their four out flappers on its two bottom side are the half length of container and thus meet closely when shut up. They have various size and can fulfill the different need and uses in different field. For carrying large size products, it’s a good choice.

- Half slotted box

Half Slotted box-Sourced:emballagesboxpack

Similar to slotted box in its main features, half slotted box has only one open side which makes it easy to get and fill products. Its size and material can all change to suits need of manufacturing.

- Lock bottom box

Lock Bottom Carton-Sourced:conquestgraphics

Also called 123 bottom box or bottom lock boxes, it can carry heavier products as the bottom flaps are pushed into each other and thus formed stably. It is well-known for its advantages like secure and efficiency, but it also has the disadvantage like takes longer to assemble.

- Seal end box

Seal End Carton-Sourced:qinprinting

The seal end cartons are side-seamed fold and designed especially for high-speed setup of products. They have tuck flaps fold inward and side panels feature sealed end. It proves the security and can be widely seen in food industry like cereal packaging and so on.

- Hanger box

Hanger Box-Sourced:stock.adobe

Hanger box is an ideal packaging choice for your product has the need on showing or displaying. One side of it are normally closed,while the other side has a small hook. It’s suitable for small and light products like, electronic products, healthcare products and beauty products.

- Gable top box

Gable Top Box-Sourced:pactivevergreen

Gable top box is usually be applied in food industry, especially for food like milk, juice and so such drink. It adopted multi-layered cartons and a plastic cap on the top of the carton to facilitating drink or pouring.

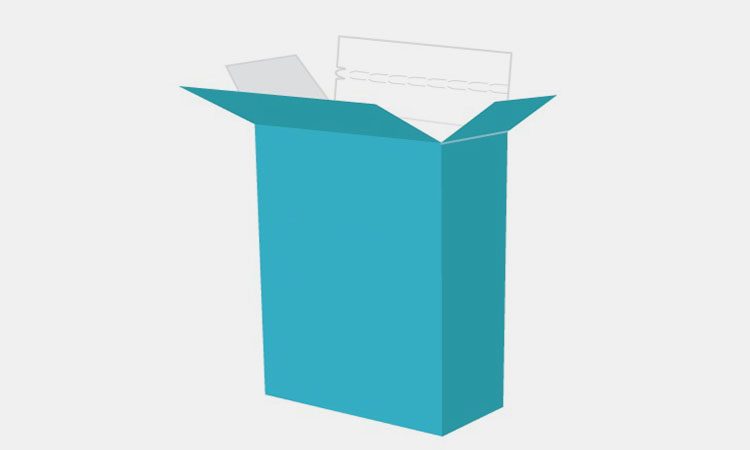

- Tuck top carton

Tuck Top Carton-Sourced:boxagency

Tuck top carton has it combined with two flaps. They are fold over each other and lid attached to one another perpendicularly. The special assembling way make it a tight combination. This carton can be opened in either side and thus rather efficient.

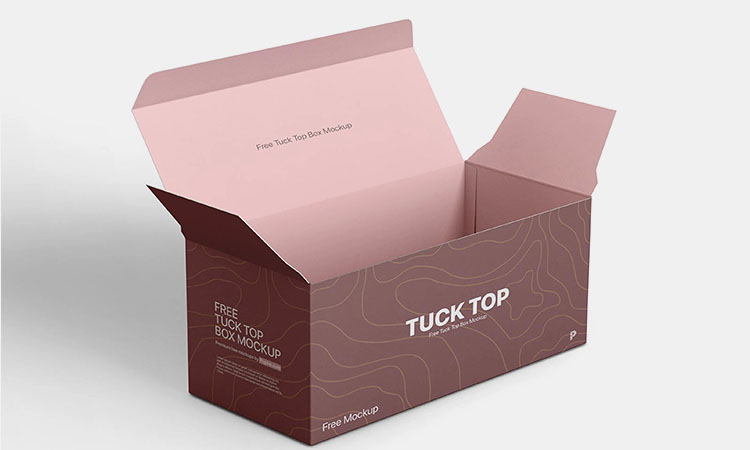

- Straight tuck end box

Straight Tuck End Box-Sourced:anycustombox

Straight tuck end box is also a common types of cartons which has its top and bottom closure panels attached to the same panel. The two sides make products handling easy and convenience.

- Reverse tuck boxes

Reverse Tuck Boxes-Sourced:packagingheights

The reverse tuck box is pretty similar to a straight tuck. Their difference lies in that reverse tuck has two closing panels but fold in opposite directions. This makes reverse tuck box more tight and waste less materials.

Types of case packages

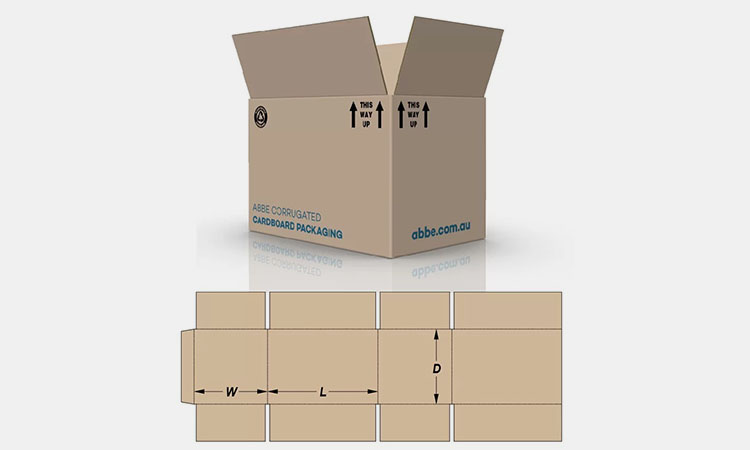

- Regular slotted container

Regular Slotted Container-Sourced:abbe

The RSC also called as knock-down case is the most common box style. It formed like slotted box and is used wildly. It is popular for its features like cheap, large volume and handy.

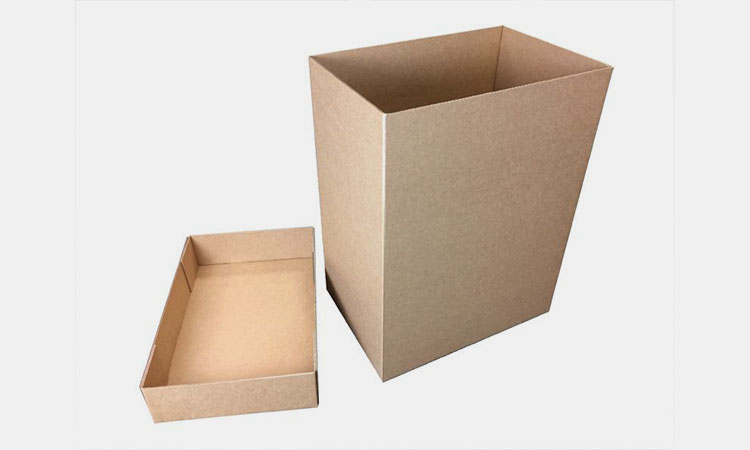

- Half slotted container

Half Slotted Container-Sourced:cactuscontainers

Similar like regular slotted container, half slotted container has only its bottom flaps and its top uncovered. The lid covered the top is slightly larger over the outer edges of your container.

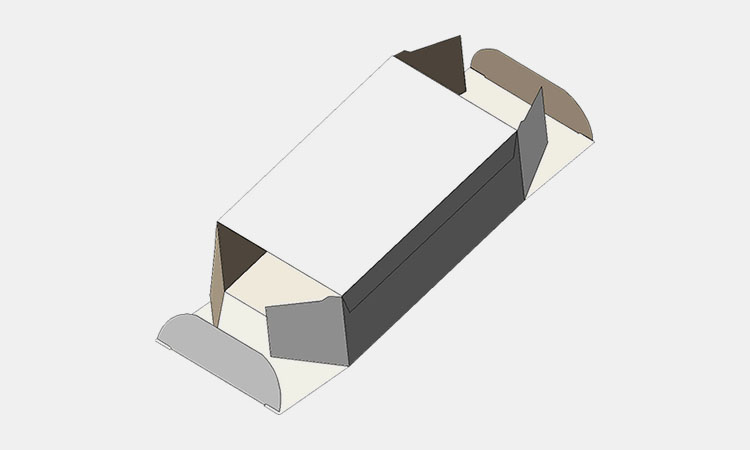

- Wrap-around

Wrap-around Case-Sourced:hollandpkg

Wrap-around case is made of a flat piece of paperboard. It formed and sealed around the products. It usually closed with glue and particularly designed to fit the dimension of their products.

3.What Is The Difference Between Cartoning And Case Packing?

Cartoning and case packing, though share the same goal of protecting products, are still different in many aspects like application and material use.

Application

Cartoning and case packing are all applied to products but its main purpose and application are different.

| Points | Cartoning | Case packing |

| Field | All industries need packaging in cartoning and case packing. | |

| Protection | l Products get a long-time protection from cartons until it being used by customers. Cartons company it in transporting, storing, and shelf-life. | l Case packing protects products mainly in the transporting and storing process. |

| Propaganda | l Cartoning needs to make the necessary propaganda by adopting attractive colors, shapes, appealing appearance and information. It should take this role as customers get to choose products on shelf from their looking. | l Case packing’s main purpose is protecting and benefiting transporting. It didn’t have the request to propaganda and attract customers. |

| Closure | l Cartoning does better in closure as for products like bread, biscuits, pills and medicines which has a higher standard and stricter request in protection and hygiene, the cartons it applied must accomplish its need like avoiding dust, damp, light. | l Case packing should also close the case well to protect the products. But the request on closure is much lower as it didn’t take the responsibility to give the close to protect the feature of some products. |

| Stability | l To conform to packaging design and products feature, the cartons can be various shape and their stability also varies. | l To fulfill the primary roles as protecting, case packing should first take stability into its first concern. |

| Material | l Cartoning adopted varied material according to product features, propaganda need an so on. | l Case packing restricted its material choice in paperboard, wooden and plastic. The primary concern of its material lies in its holding ability. |

| Size | l Cartoning has different size according to its type. | l Case packing also different size with type, but it usually bigger than cartoning as it take the roles to integrate and make bulk. |

Material use

Material in cartoning and case packing share the similarities as they are all used for packaging, but the distinct usage of different package decides its different use in materials.

- Cartoning

Different cartoning material-Sourced:cn.vitaweishi

Cartons, as the primary package, serves products from bottles, cans, to bags. Thus, it has a wide range of materials usage from plastic pouches, paperboard, corrugated box and rigid box to wooden box. The different use comes from the different preserving or propaganda purpose. But, the paperboard is the most frequently used one.

Material use of cartoning takes appearance, preservation and protection of products into serious consideration.

- Case packing

Case Packing Material-Sourced:timberpackingcases

Case packing, as the secondary package, has its main working principle as protection and transporting. Thus the material used for them is mostly plastic, wood or paperboard which are stable enough for transporting and sturdy enough for products protection.

Its further choose depends on the specific need of product, like the fragility, space-need and so on.

4.Cartoning Machine VS Case Packing Machine

Cartoning machine and case packing machine, though do the same work as packaging, has definitely different working process for their different purpose on packaging. Its type ans working principle reveals its different directly.

Machine types

Cartoning and case packing machine are two different machine and has different types.

- Cartoning machine

Cartoning machine can be divided as vertical and horizontal according to different way products gets into cartoning process.

Vertical And Horizontal Cartoner-Sourced:richpaking

Vertical cartoning machine as it names, gets the products in vertically, while horizontal one gets into products horizontally. The vertical one can reduce the damage on this process and thus particularly suitable for jars, bottles or vials. Horizontal cartoner gets its products in from side and suits most products and can make products a tight suit of cartons.

- Case packing machine

A type of packing machine-Sourced:mftecno

Case packing machine can be divided as horizontal load, top load, bottom load and tray packing. Different types serves different products need. Horizontal load is the most common and efficient one. Top loading packing machine is suitable for the bags, pouches, and cartons, and for all kinds of products especially frozen one.

Bottom loading packing machine is used for high-weight and fragile products. It can give careful hand and package to products. Tray packing can ensure the security of products from its best efforts for it has the low to high packing speed and gives tight packaging.

Working principle

Though types of each machine varied greatly, each working principle didn’t varied a lot.

Cartoning machine

Working Cartoning Machine

- Cartoning machine has the products gets into it from vertical or horizontal way.

- Products gets into the guide rail and is guided to the cartons which is folded well before filling.

- The instruments or brochures are waiting between products and cartons to get into carton.

- After being filling well with products, instruments and so such things, the products will get printed and be sealed.

- The well packaged products will be leaded out from guide rail until carton chute.

Case packing machine

Working Case Packer

- Case packing machine has its products in from various ways according to its machine type as top or bottom.

- After products gets into the machine, a mechanical arm will gets the set number of products into the prepared case.

- And the case get filled with products, it will be leaded to next process and be sealed well.

- The last process is the well packaged case being leaded by rail guide out the machine.

5.What Are Pros And Cons Of Cartoning And Case Packing?

The invention of cartoning and case packing take great convenience to packing process. But the two different kind of machines have its own advantages as well as disadvantages.

Pros of cartoning

Cartoning has the below advantages.

Pros-Sourced:trading-education

- Security

As the first package, cartoning needs to take the responsibility to protect the products from the damage coming from heat, damp and bacteria. Cartoning can make the hygienic and safe working environment.

- Efficiency

Thanks for development of mechanism and science, you can get your wanted products with just some setting of parameters. Machine’s efficiency is several times bigger than labor. There will be no wrongs like missing products, instrument, printing or sealing on a package.

- Employee safety

Cartoning machine didn’t put all its energy on making good cartons, its packaging lines and mechanical system provide a relative safe environment and prove your workers safety.

- High quality

Cartoning has a precise working process and can provide the cartons in high and same standard. It avoids the uneven and unqualified packages. The products produced in this way keep your products always in high quality.

Pros of case packing

Case packing has the below advantages.

- Strength

For products with large size or large weight, the case packing machine can give out its strength from electricity and fill the large and heavy products in case quickly and securely.

- Accuracy

Machine-leaded manufacturing shares the high accuracy as it conforms to the command of programme and finished all work by settled machine. There will be no case while your products gets over filled in one case or in wrong case.

Cons of cartoning

Cartoning and case packing aren’t share only advantages.

Cons-Sourced:pestleanalysis

- Hard maintenance

Be combined with so much complex parts and precise instruments, their maintenance work is a big project. You should have the instruments and specific knowledge for its cleaning and maintaining.

- Limited application

You can use cartoner to make packages. But the material and size of them are defined, for some specific material, product or size, it’s not available.

Cons of case packing

- Large size

Their efficiency is accomplished by the mechanism, thus the large size is unavoidable. It also unmoving. The case packing has a larger size compared with cartoning which handled package while the former handle the bulk of package. You must have a spacious, stationary and clean place for its operation.

- Technical support

To operate the huge and sophisticated machine and match the machine with different sized case and products, you should have the technical support. Besides, to have a nice maintenance of it, you also need to know the tech which needs time and money.

6.Which One Is Important? Can They Combined Together?

Cartoning and case packing are necessary in current manufacturing work as no products can get on shelf without packaging.

Importance of cartoning and case packing

Importance-Sourced:vecteezy

As the cartoning has a closer contact with the products, it takes the primary roles of protecting products from the attack like damp, dust or light. It also takes the main role as appealing and information providing as it is the first thing people see while having a view on market shelf.

While the case packing, its main purpose is to fill the case with products for better transportation and protecting. The special setting inside the box can prevent shaking and colliding on the way transporting. And the carrying way like transporting the products in bulk can save a lot strength and improve working efficiency.

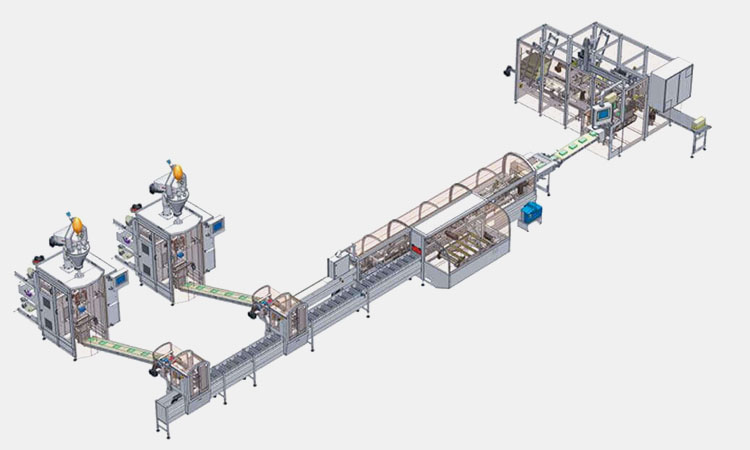

Combination

A Type Combination Of Cartoning And Casepacking-Sourced:rovema-na

Instead of waiting the packaged products pilling up and take to case packer, you can just use the rail to conjunct these two machines. The suitable combination can give you a big convenience as it saves the extra work like carrying and settling.

But in combining, you should pay attention to the conjunction size and settling. It should suits the size of two machine and do no harm to two sides. Besides, the conjunction material and tech should suits the operation of the two machine.

Conclusion

Cartoning and case packing play an important role in your overall manufacturing. What is the difference between cartoning and case packing, you must have your own answer and have your own plan of using the two in your products production. If you have any question about the two different machine, don’t hesitate and contact us!

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine