5 Topics To Discuss With Your Packaging Line Integrator

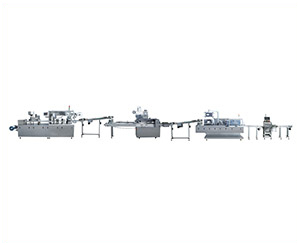

Creating a robust packaging line with efficient packaging quality is not an easy task to attain, while many companies must try their best to offer amazing goals themselves and oftentimes, they achieve the exact goals they look for.

We suggest you recruit packaging line integrator to get proper machine layout, features, energy consumption, and associated dynamic concerns.

In this article we’re going to discuss 5 topics to discuss with your packaging line integrator that you must know. Without further ado let’s jump into the main topic!

1.What is Packaging line Integrator?

Packaging line integrator is the business which works closely with its patrons to fabricate customized and efficient packaging line for their manufacturing plant.

They assist their collaborators at every step of packaging integration such as in helping them to select suitable packaging automations for their packaging line or guiding them to understand energy requirement of machines.

Manufacture hires packaging line integrator for sole purpose of building top-notch packaging plant. Implementation of various equipments, technology and instruments is an important part of packaging integrator’s job.

Integrators ascertain every piece of hardware and software perfectly aligns with packaging goal of industry. Moreover, they are involved in properly installing and setting up machines so that packaging line operates without any hiccups.

2.The importance of Transparency to Packaging Line Integration

Transparency and honesty is essential part of any client service. These values practiced during dealings boosts the investor confidence in supplier. Openness and communication goes a long way in establishing rapport between clients and service providers.

When a buyer offers money to purchase equipment or service it means that he relies on the supplier to deliver the top quality solution.

It is necessary to certify the transparency of your packaging line integrator since this investment is worth millions of dollars. Selection of experienced and reliable integrator has positive impact on your packaging organization.

For beneficial collaboration the best course of action is to have sincere and honest conversation with potential integrator.

You should discuss potential ideas involving your end products with contractors and detailed account of stringent regulation imposed your potential plant should be communicated to them.

3.Top Five Topics to Highlight during Packaging Line Discussion

Structure of Packaging Line

It is imperative that you should convey your consideration to integrator. This will help in construction packaging line that is optimized to your plant environment.

Manufacturers have the desire to assemble such packaging lines which use the space and labour resource effectively and additionally deliver superior quality results at the end of the day.

For this purpose, you should give the complete overview of several aspects associated with your production such as floor space, voltage, raw material consumption, ventilation, etc.

When designing packaging line, direction of material consumption and product transport should be kept in mind. For instance, if you have flow-through line meaning materials and products go to opposite sides of line then you must ask the integrator for assembling in-line packaging.

On the other hand if both raw materials and packaged goods come and go from same side of plant then you should go for u shaped packaging line.

Financially Strong Integrator

Working with monetarily strong integrator is very helpful in managing your own financial budget. These integrators offer creative payment contract with which you can easily handle your pecuniary resources.

In this way, you will control your investment budget. This is particularly useful in case of incidence of unpredictable disruption business world.

They will ensure that you will get monetary gain from your investment instead of other way around.

Furthermore, integrators can their own business model to help you in choosing right investment and guide you through financial difficulties. Financially strong integrator also prevents cost overruns and keeps the finances under control.

Proof of Previous Experience

The best way to determine the integrity of potential integrator is to ask them about their previous projects and skills. Not every integrator is experienced in integrating packaging lines.

You can determine the integrator compatibility with your project is by asking them their mechanical, electrical, programming and automation skill set.

An experienced integrator can understand your requirements regarding features and components of equipment and assist you in making choice.

Previous customer reference is another way to verify transparency of integrator. The reviews of their past patrons, vendors, OEM, and suppliers will aid you in selecting reputable integrator.

Moreover, by asking question about their work history with integrating coordinator you can conveniently find out designing capabilities of latter.

Besides this, you can also find out about efficiency of integrator under pressure and how well they cope upon facing adversity.

Original Equipment Manufacturer (OEM) Program Management

You can consult with your packaging line integrator if you did not build your OEM supplier base. Integrator goes through every OEM present in packaging business and aids you in picking trustworthy and right OEM for your packaging line.

The choosing criteria for OEMs should be their ability to provide suitable machines that fulfil your packaging challenges and are profitable for your business.

It is best to take into consideration integrator opinion about OEM. If you pressure them on working with certain suppliers which former does not trust then they probably will increase their charges or change contract to safe themselves from risk.

After deciding on OEM, it is responsibility of integrator’s managing team to track record of equipment supplies from OEM and bargains manufactures for appropriate prices.

Contract Demands

Always negotiate the contract demands with integrators before signing the contract. For instance, discuss the timeframe of project and deadline with integrating company.

It is important to talk about terms such as OEM selection procedure and compensation for contract breach. Signing on conditions such as liquidated damages can put integrator at risk.

Learning about your protection clause is essential when approaching the contract with integrator. It is imperative to meet-halfway between expenses and risk.

For this purpose review the strength and weaknesses of your manufacturing line. Always check capabilities of your installation engineers and whether your management can track and supervise shipment.

Consider risks linked with performing these tasks in-house and ask your integrator at what conditions will they take charge of installation and shipment.

Conclusion

Packaging line integrator makes the experience of assembling packaging plant hustle free. Before hiring integrator, establish the transparency by asking them about their work experience and past projects. Discuss your requirements for packaging lines and negotiate contract terms before signing the agreement with integrator. If you have confusion regarding the role of packaging line integrator then you can contact our 24/7 helpline.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine