Horizontal Cartoning Machine: The Ultimate Buying Guide In 2024

In the pharmaceutical sector, the primary concern is product safety, efficacy, and potency. A carton machine does this job perfectly! A horizontal cartoning machine is an integral component of packaging lines with broad application in various production fields.

Our objective is to provide you with significant information about the horizontal cartoning machine. Keep Reading!

1.What is horizontal cartoning machine?

Horizontal cartoning machines also referred to as horizontal cartoners or end-off cartoners, are the type of packaging machines that form cartons for storing the products. The main purpose of cartoner is to shape, close, fold, and seal the cartons.

This equipment introduces products in cartons from lateral sides and creates the box from blank stacks.

Horizontal cartoning machines have high production output and are used in various industries like food, personal hygiene, and pharmaceutical to meet ever-growing packaging needs.

2.What are the prime applications of horizontal cartoning machines?

A horizontal cartoning machine is a versatile piece of equipment for fulfilling the packaging needs of almost every kind of industry. Some applications are stated below:

Pharmaceutical Industry

These machines play a major role in packaging every product from ampoules to vials, from blisters to strips, from pills or oral suspension in the pharmaceutical industry.

These machines also assist in preventing the counterfeiting of drugs. The feature of anti-counterfeiting is embossed in a carton. Drugs cannot be moved out without damaging cartons.

Food Industry

A horizontal cartoning machine is useful to pack an assortment of foods like a desert, milk powders, sugar, coffee, cereals, and prepared meals in carton boxes. The main purpose of this packaging is to keep food fresh and prevent it from getting spoiled by environmental elements. The food packaging is also essential in inhibiting the growth of microbes and preventing dust contamination.

Chemical Industry

Packaging of chemicals in cartons does not allow harmful exposure of these chemicals to the environment. Bottles and packs of chemicals like fertilizers, paints, glues, detergents, lubricants, oils, cleaning agents, laboratory reagents, and many others are packaged in cartons for safe shipment and delivery.

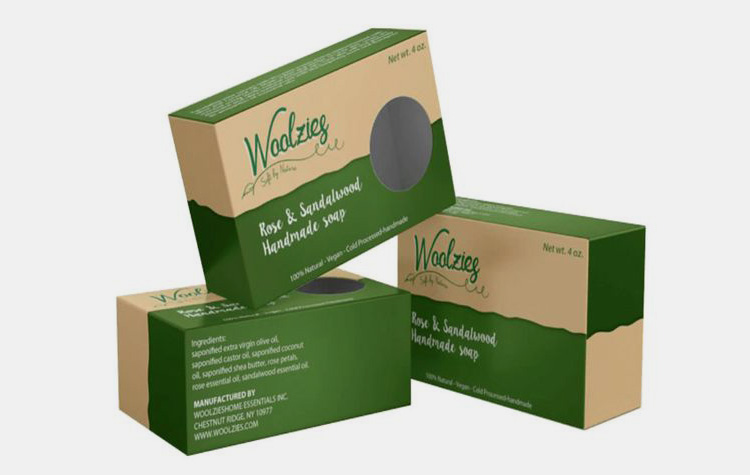

Personal Hygiene Industry

A horizontal cartoning machine has a significant role in the packaging of various personal hygiene products like soap bars, lipsticks, dyes, sunscreens, dental care products, foundations, lotion, etc. These colorful and attractive carton designs, popular in the personal care industry, make the products secure and aid in catching customer attention.

Electrical Industry

In the electric appliance industry, a variety of items like batteries, plugs, flash drives, blubs, charges, circuit breakers, etc. are packaged in cartons for their safe delivery to markets.

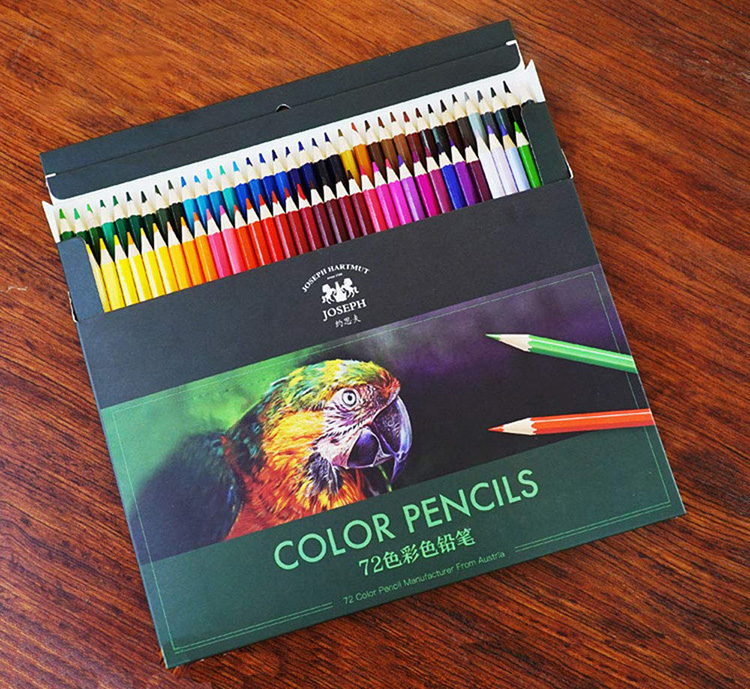

Stationery Industry

Different stationery goods like pens, pencils, rulers, note pads, books, and staplers, are packed using horizontal cartoning machines for safekeeping.

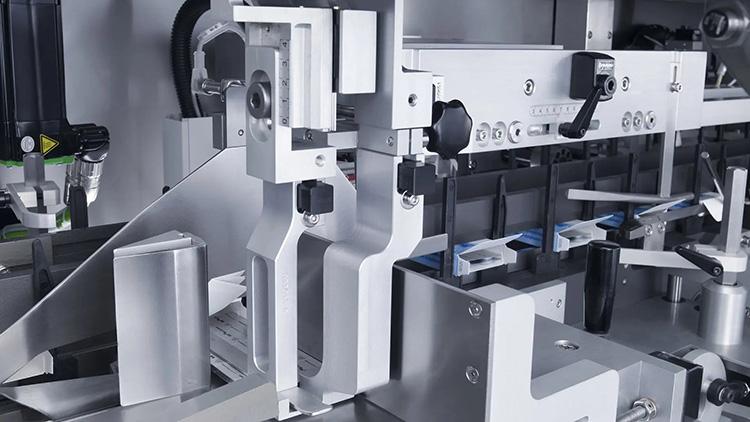

3.What are the main components of a horizontal cartoning machine?

A horizontal cartoning machine is consist of various kinds of electric, mechanical, and power-driven parts, which work as a unit for packaging jobs.

Some of these key parts are discussed below:

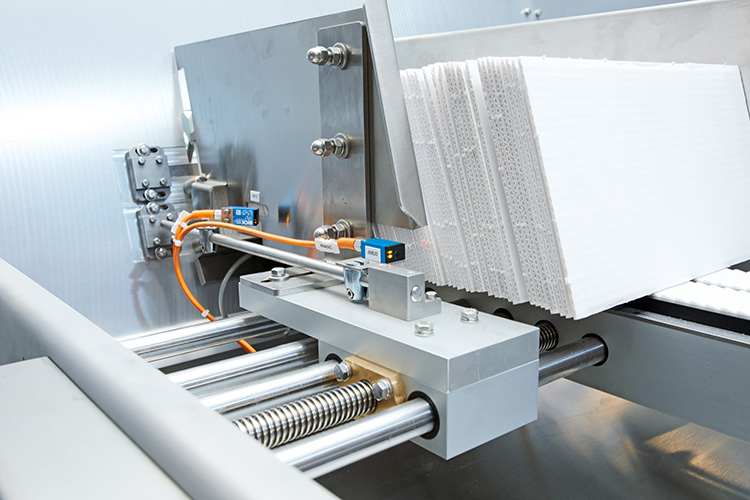

Carton Magazine

This part has a stack of flat carton boards for pickup by carton assembly system. The magazine has servo-driven belts for holding cartons at an accurate inclination in the throat. The throat does not allow flat cartons to fall out of a magazine.

Carton Pickup Assembly

Single flat cartons are pulled out of the magazine throat by the arms in the carton picker. This arm takes cartons down to guide feed and lugs, where a flat carton is opened using pressure.

Product Feeding System

Leaflet and Product Loading

Some machines are equipped with an automatic product loading system that places products directly in the pockets of the cartoning machine. The products are passed onto conveyor belts to be placed inside cartons. Feeding mechanism has a different design based on the type of product. For instance, a turntable is for bottle loading on the conveyor. In horizontal cartoning machines, the materials to be packed are placed in cartons from the sides.

Carton Closing Unit

This system has gun nozzles for spraying hot melted glue along small planes to carton sides. After some time, this melted glue solidifies and glues two flaps- upper and lower- of the carton.

Leaflet Feeding

The components supports prefolding the flat sheet leaflet, booklet, or manual into the carton.

Carton Discharge Chute

The closed carton is ejected by the pressurized arm located at the discharge chute. The discharged belts aid in ejecting closed cartons from the machine.

Electric Devices

These consist of the main power and gear motor.

The main power switch is the hub of machines, where various electric circuits are present for supplying vital power to every part of the machine.

While gear motors are essential in the movement of bearings, chains, belts, and conveyors. These motors are usually enclosed and present in the lower section of the machine.

PLC Control Panel

This part is regarded as the brain of the machines as it controls and regulates every function of the horizontal cartoning machine. It is an intelligent touch screen interface for programming and planning every aspect of the operation. The most important feature of this component is to provide self-diagnosis in case of failure or error in operation.

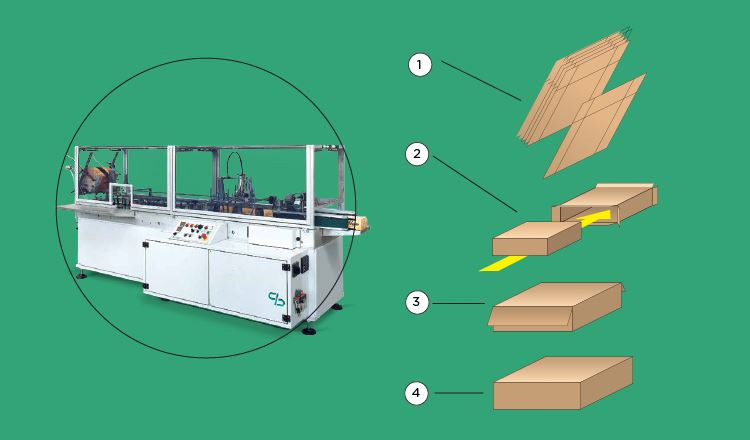

4.What is the working principle of horizontal cartoning machine?

Loading

With the help of a guard rail and pushing plates; the cartons are transferred to the machine box entrance.

Introducing Empty Cartons

The guard rail and push plates open the box followed by sucking up and closing the bottom of the box with air pressure. The cartons are introduced into the loading area with the help of a conveyor belt at the correct angle.

Filling or Loading Section

At the same time, two adjacent movable clamps will emerge from below to clamp the edge of the carton in the front and rear direction; to open the box at a right angle and move ahead to the filling area. The product will be loaded into the carton.

Leaflet Insertion

Along with the product’s loading, the movable clamps simultaneously insert the leaflet into the carton. Upon receiving the product and leaflet, the conveyor moves forward to the next step.

Folding and Sealing

Soon after filling; the machine will fold its ears into the left and right sides of the guide rail by rotating motion. Also spraying glue is used to fix the carton.Note: Push plate and cam-coupled motors support the folding of the carton ears. You can choose to glue seal or staple them varying on the type of product you intend to secure.

After cartoning; the machine checks the integrity of the packaging and separates the rejected and accepted cartons.

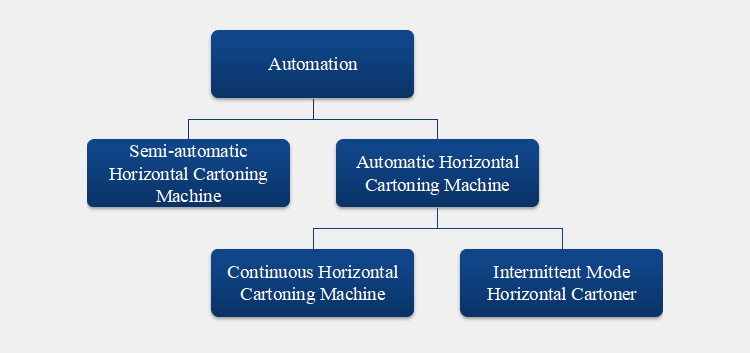

5.What are the various types of horizontal cartoning machines?

Classification of Horizontal Cartoners

Horizontal cartoning machines are available in various forms in markets. These have different design styles but broadly horizontal cartoning is classified into two categories on the basis of automation.

Semi-Automatic Horizontal Cartoning Machines

The products are packed in the cartons manually by the operators on the semi-automatic machine. Although, manually packing simplifies the machine operation but considerably decreases the production efficiency. In comparison with automatic, this machine operation is more arduous and necessitates the presence of many operators to complete the task.

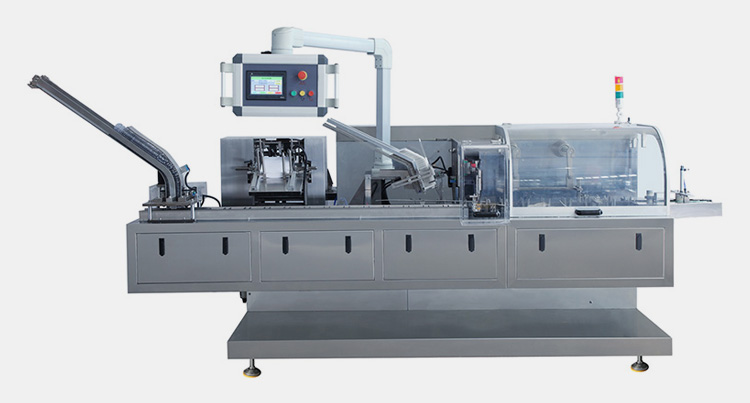

Automatic Horizontal Cartoning Machines

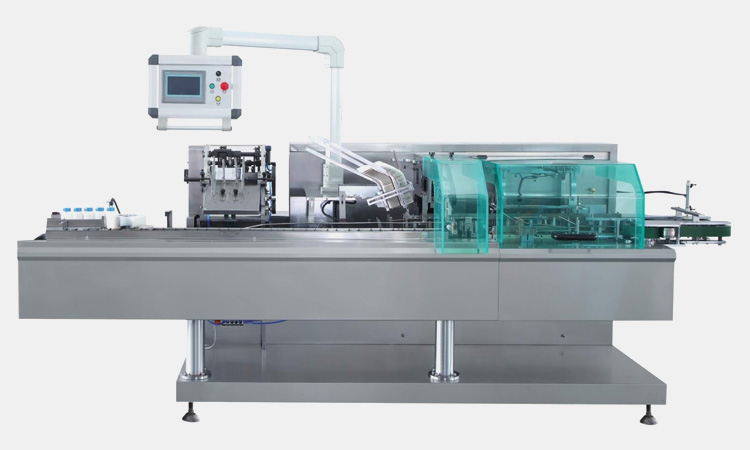

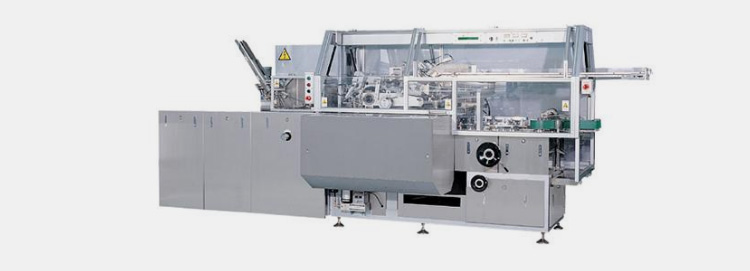

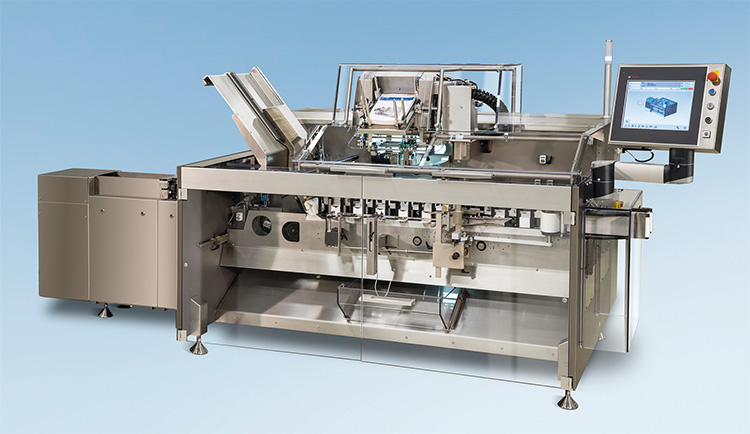

Horizontal Cartoning Machine

These machines are equipped with advanced technology for feeding products that prevent unnecessary human intervention. This equipment has sensors for inspecting and identifying any defect or damage to the carton, therefore assisting in maintaining high-quality levels. Also, the packaging speed of automatic horizontal cartoning machines is much more than semi-automatic horizontal cartoning machines.

Automatic Horizontal Cartoning Machines are fitted with a variety of components such as

- Printers

- Folding Assembly

- Brochure Feeding Units

- Gluing Devices

On the basis of motion, there are two kinds of automatic horizontal cartoning machine.

Continuous Horizontal Cartoning Machine

These machines are employed for the packing of fragile and delicate solid items. The movement of parts, for instance, feeding system, carton transport chains, and rod eyes are perfectly synchronized resulting in high production output.

Intermittent Mode Horizontal Cartoning Machine

The construction of these machines is similar to that of continuous horizontal cartoning machines but these two machines differ in the degree of speed.

6.What are the differences between continuous and intermittent horizontal cartoning machines?

| Continuous Horizontal Cartoning Machine | Intermittent Horizontal Cartoning Machine | |

| Speed | The machine has highest working speed. | Intermittent mode horizontal cartoners are 150 times slower than continuous ones. |

| Production Line | These are high speed machine packing 60 to over 400 cartons per minute | These cartoners package around 180 cartons per minute. |

| Breakage | The machine operates without stopping during packing cycle. | These machines stop during operation so box cycle can take place. |

| Packaging Style | The packaging of various products with various shapes and sizes are not catered. | It can run the packaging of products in various sized and shaped cartons |

7.What are the advantages of a horizontal cartoning machine?

Horizontal cartoning machines are extremely popular in various industries. These machines are crucial in keeping products safe and secure during shipment as well as preventing their pilferage.

Some key advantages that horizontal cartoning machines bring to your business are listed below:

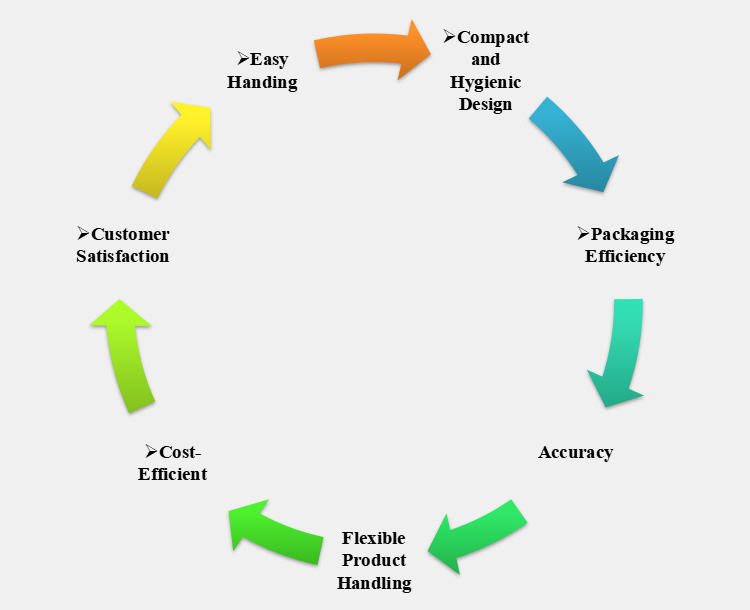

Compact and Hygienic Design

This feature ensures rapid and easy installation, thus making efficient use of open space and resources. Hygienic construction made of stainless steel provides contamination-free packaging and ensures the stability of these machines.

Packaging Efficiency

These machines achieve high production efficiency in a relatively short period and operate at high speed consequently packing many cartons in a few minutes.

Accuracy

Manually loading products can be cumbersome and tiring as well as time-consuming. By using these machines, you can save your employees from this laborious task. The rate of packaging error is considerably lower using a horizontal cartoning machine.

Flexible Product Handling

Multitasking is a major characteristic of horizontal cartoning machines; as these machines can pack various kinds of products in one carton. Also, these machines can package a variety of commodities with easy alterations of parts.

Cost-Efficient

Investing in horizontal cartoning machines is exceptionally lucrative as these machines lower the chance of human error in packaging that helps the low-budget company. These machines also cut down product wastage which also adds to their profitability.

Customer Satisfaction

Customer satisfaction is the key reason for generating high revenue. By using horizontal cartoning machines you can consistently produce extraordinary packaging results which aid in attaining customers’ endorsement of the safety and quality of your packaged goods.

Easy Handing

Horizontal cartoning machines are easy to operate and require little to no human intervention. These are also used for diverse packaging purposes with the quick part changeover. Compact design with easily disassembled parts allows for trouble-free accessibility and maintenance.

8.How to maintain horizontal cartoning machines?

Preventive maintenance of horizontal cartoning machines is necessary for their smooth and efficient running performance. Failure in adhering to a proper maintenance schedule can cause increased downtimes and damage to the machine.

Some maintenance hacks are detailed below:

| Daily | Inspect for wear and tear in vacuum cups, lines, and pumps. Clean the machine of any product residues and debris. Examine the filter system and air pressure. Use an anti-static plastic agent for cleaning transparent covering. Fasten any loose bearing or screws. |

| Weekly | Lubricate all the moving parts of the machine with a suitable lubricant. Correct pressure in the air regulator. Properly tighten chains and belts in order to attain appropriate tension. Examine pipes for air leaks. |

| Monthly | Replace the vacuum generator with a clean system. Check for damage in rod eyes and joints. Lubricate all the chains. |

9.How to troubleshoot a horizontal cartoning machine during operation?

Sometimes, problems arise during the smooth operation of the horizontal cartoning machine, but you can easily fix them by going through the following tips.

| PROBLEM | CAUSES | TROUBLESHOOTING |

| Side Corner of Cartons are Damaged | Top Rails are rubbing the cartons. The vacuum setting for carton feed is not accurate. |

The clearance between top rails and cartons must be less than 0.8mm. Correct the vacuum setting for carton feeding. |

| Wrinkles on Cartons Sometimes you see wrinkles on the surface of cartons. |

The height of the top rail is too low Transport belts are very tight. |

Adjust the level of the top rail. Loosen any tightened transport belts. |

| No Glue No glue is applied from glue nozzles. |

The glue guns are clogged. The air setting for the glue nozzle is turned off. Glue gun solenoids are damaged. There is glue buildup on the guide plate. |

Clear the clogged guns. Turn on the air setting for glue nozzles. Replace worn-out gun solenoids Remove excessive buildup from the guide plate. |

| Double Cartoners Two cartons are picked by picking assembly. |

Cartons in the magazine are not stacked properly. There are too many cartons in the feed throat. Cartons can be glued together. Carton feed timing is incorrect. |

Properly stack cartons in magazines. Fix the number of cartons in the throat. Check for gluing of cartons. Adjust the feed timing. |

| Reduced Machine Steadiness If a machine is running for a long period, it may face issues with stability. |

Servo Systems are faculty. | Replace the faulty servo system for the smooth running of the operation. |

| Folding of Leaflet The instruction manual is not properly folded. |

The gap between the fence board and folding rod is large causing the jumping of the paper. Debris is present in the fence board producing paper blockage. The paper is shrunken and twisted. Folding rods are damaged. |

Adjust the screws to remove the gap between folding rods Remove the dust and debris between fence boards. Use flat well-shaped paper. Replace old folding rods. |

10.What are the packaging types of a horizontal cartoning machine?

The packaging types of horizontal cartoning machine are as follows:

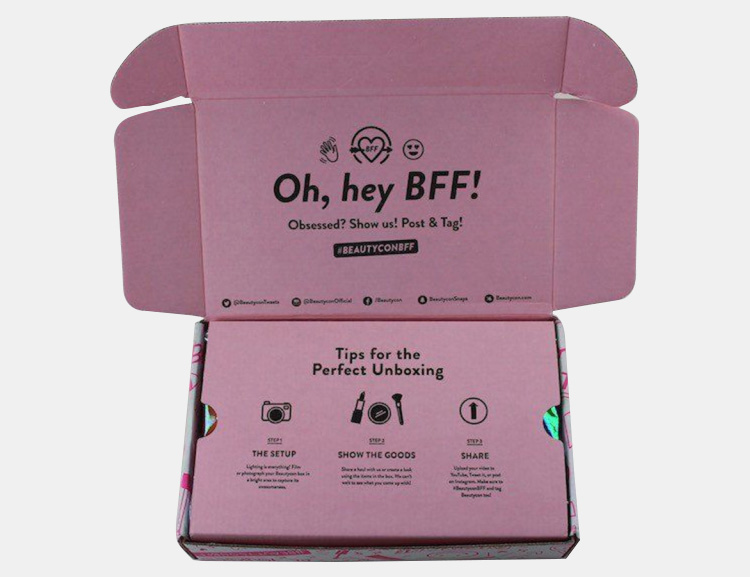

Cartons with Custom Cut-Out

This is a design element that shows content inside the carton. The cut-out is formed within the cut die.

Carton with Thumb Tab

Thumb tabs are spherical cutouts done on the main panels of the carton to facilitating an easy opening.

Straight Tuck Carton (ST)

Straight tuck cartons are commonly used for a variety of industries. The top and bottom of the closure panel are fixed to the same panel. It is folded from front to back in the same direction.

Reverse Tuck Carton (RT)

Reverse tuck boxes are almost comparable to straight tuck cartons, except for the closing panels. One closing panel is fixed to the back of the carton while the other is attached to the front.

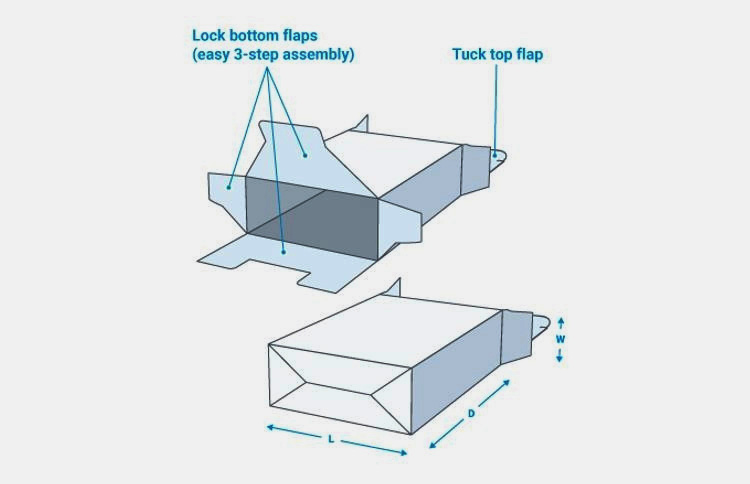

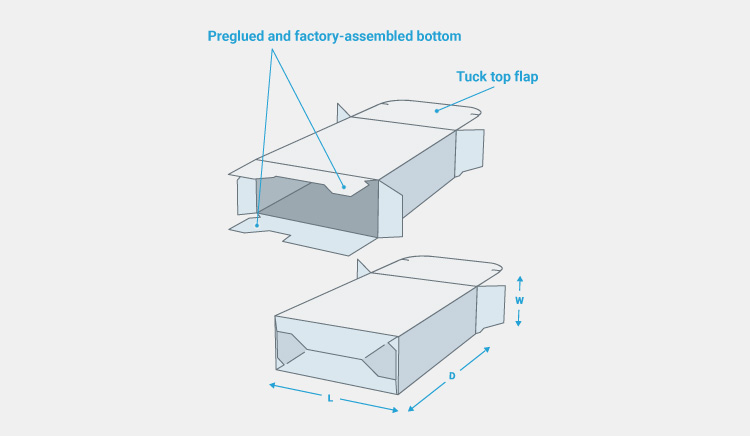

Lock Bottom Carton

This is also known as a 1-2-3 bottom carton where the carton is specially designed to hold heavier products. The bottom flaps are overlapped with each other forms a sturdy base.

Crash Bottom Carton

They are suitable for holding heavy items and are referred to as an auto-lock bottom carton or, auto-bottom cartoner.

Carton with Insert

An insert is a piece of paperboard that is being cut and glued to support the product (s) with a carton.

Display Cartoner

This type of carton packaging has two purposes; to protect and display the content.

Sleeves Cartons

A carton with no ends wraps around the product adding a high level of customization.

Holster Carton

A holster or half carton where the top is entirely opened without closing tucks.

11.Why horizontal cartoning machine is important to the pharmaceutical industry?

Seldom does any pharmaceutical manufacturing industry is existing without carrying a cartoning machine. To enter the competitive pharma market, a horizontal cartoning machine holds numerous importance. Some of them are:

Insertion of Medicine

A horizontal cartoning machine is used to insert a blister of medicines with a prescription leaflet. This phase is very important for the pharmaceutical production sector as the leaflet is essential.

Delicate Medicine Packaging

A horizontal cartoning machine is suitable for packaging pharmaceutical unit doses dispensed in glass containers like ampoules, vials, and glass jars.

Drug Security

A horizontal cartoning machine ensures the flexibility to fold and insert products in one machine as well as peace of mind that the product has not been tampered with.

Convenience

The pharmaceutical production sector works day and night. Through remote diagnosis and immediate fault correction without requiring a technician; a horizontal cartoning machine is capable to save time and money.

Identification

Printed cartons are easy to identify; you don’t need to identify each product by opening the packed inside the carton. Simply read the information of medicines written on the carton.

Contamination Free

Contamination is the most important factor to consider for pharmaceutical products. A horizontal cartoning machine is ideal to deal with medicines that ensure the diffusion and permeation-free product packaging.

12.What are the future trends of horizontal cartoning machines?

Owing to awareness and health-promoting food consumption, there has been an increased demand for cartoning machines as cartoners offer maximum safety in packaging. The production surge of fast-moving consumer goods has led to the induction of an excessive number of horizontal cartoners in industries.

The market of cartons is predicted to have a soaring surge of US$ 3.02 billion by 2029 from US$ 2.26 billion in 2019, showing the highest CAGR of 3.8%. The horizontal cartoning machine will have superior market expansion over other kinds of cartons. due to its flexibility to accommodate numerous kinds of products.

13.What are the tips for selecting the best horizontal cartoning machine?

People often struggle when it comes to choosing the right kind of equipment for their production. They quite frequently get overwhelmed by numerous assortments of equipment.

Below mentioned are a few tips- equally applicable to both small and big companies- for choosing the proper horizontal cartoning machine for your business.

Type of Product

Consider the type of product, you are packaging before buying the cartoning machine. If you are dealing with solid products packed in a square or rectangular-shaped cartons; then a continuous horizontal cartoning machine would be best for your manufacturing line. Intermittent motion horizontal cartoning is most suited for packaging bottles, jars, pills, trays, etc.

Budget

Your goal should be to enhance your production capability while minimizing production coat. Analyzing your present needs and profit from investment can set the budget range for purchasing semi-automatic or automatic horizontal cartoning machines.

Production Speed

Production speed is determined by the fact whether you have online packaging (instant packaging) or offline packaging (present in inventory; you need to ship out daily, weekly, or monthly) business. Be realistic in estimating your production volume and future needs, because you may find yourself purchasing an expensive horizontal cartoning that is unfit for your existing needs.

Loading Mechanism

It is a crucial factor, often overlooked when investing in horizontal cartoning machines. Before buying equipment, first, check how carton picking technology works and see if this mechanism is compatible with your material.

Carton Material

Search for good and reliable carton material when buying a horizontal cartoning machine. This impacts carton handling. Carton design and gluing patterns are also of prime importance. Always test carton material with your product in the manufacturer's facility.

Reliable Supplier

After, deciding on machine design and budget, make a list of suppliers, which deal in your particular niche. Narrow down the list by manufacturer’s experience as well as by visiting their facilities. Your definitive objective should be to choose a supplier with whom, you have a level of comfort and trust.

Conclusion

The horizontal cartoning machine is the most sought machine in the category of secondary packaging machines. Investing on this machine will boost your existing packaging capability and aids you in generating more revenue. For more guidance or product's quotation, give us little details. Our high-tech experts will contact you to provide free consultation.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine