Butter Packaging: The Complete FAQ Guide In 2024

Butter packaging is probably the most popular process of the dairy industry and it makes high demands on any material utilized for this technique. You must have realized that high greasing resistance is required against ultra violet light and humidity.

Before you grab butter packaging in the supermarket, there is indeed a series of processing to confirm the good quality of the product. Nevertheless, it is the packaging which is responsible for the attracting the consumers. Have you ever wondered what kind and how this packaging is made? Let’s read the blog!

1.What Is Butter Packaging?

It is an approach by which block of butter is placed in jar, tub, dish or tray and sealed by lidding or wrapped in aluminum or butter paper for trade, distribution and storage. Butter packaging may consist of dosing, wrapping, and sealing processes.

It is done to packaging butter in suitable containers having different sizes, form, and appearance to fulfill the needs and gratify the preference of patrons.

By packaging butter products their shelf life can be improved and their texture, flavor, and freshness is preserved.

2.Why Butter Packaging Is Important?

Butter packaging upholds the quality of butter and prevents their melting and hardening. Moreover, it prevents the exposure of butter to direct sunlight and assists in maintaining desired temperature of butter. It is essential due to several reasons for instance:

Maintain Product Integrity

The taste and smell of butter is changed when it absorb chemicals from environment. Thus packaging is necessary for preserving the product integrity.

Improve Shelf life

Packaging is suitable barrier against moisture and oxygen which can otherwise react with fats in butter and cause their rancidity. By offering protection against these environmental agents packaging has hand in improving shelf life of butters.

Prevention of Weight Loss

Butter is composed of water and oils which on high temperature vaporize resulting in weight loss. But butter packaging prevents evaporation of oils and water.

Brand Appeal

Butter packaging is integral in product differentiation on retail shelves. Brand owners often use original and innovative packaging to stand out on grocery stores aisles and to catch the eye of their customers at first glance.

Marketing and Communication

Attractive designed butter packaging plays a significant role in advertizing brand. Moreover, food labels on butter packaging tell consumers about benefits and nutritional value of packaged butter.

3.Where Do You Use Butter Packaging?

Butter packaging has gained popularity since its advent now this packaging has found its use in different fields for instance:

Dairy Products

Multiple dairy products such as margarine, cheese, ghee, yogurt, cream, butter and milk is packaged inside butter packaging for minimizing the chance of their contamination. Butter packaging aids in preventing the spoilage of these products by foreign odors, moistures, and air.

Frozen Items

Since butter packaging has high wetting strength, it is routinely employed in packaging and wrapping of frozen items such as meat, seafood, giblet and fish.

Food Trays and Molds

Thermoforming food trays and molds used for holding ready-to-serve meals are often manufactured using laminated aluminum foil butter packaging. Due to its excellent bending and forming properties, these foil materials are easily molded into diverse shapes.

Packaging of Food Products

Butter packaging is majorly employed in food industry for wrapping variety of food items such as chocolates, stock cubes, confectionary commodities, yeast, soup, etc. These packaging materials have superior impermeability to intrusion of air, moisture, and chemicals.

Personal Care

Use of butter packaging in personal care industry offers several advantages such as water impermeability, heat insulation, and air protection. It is used to packaging soaps, hair wash, tooth paste powders, wet pipes, etc.

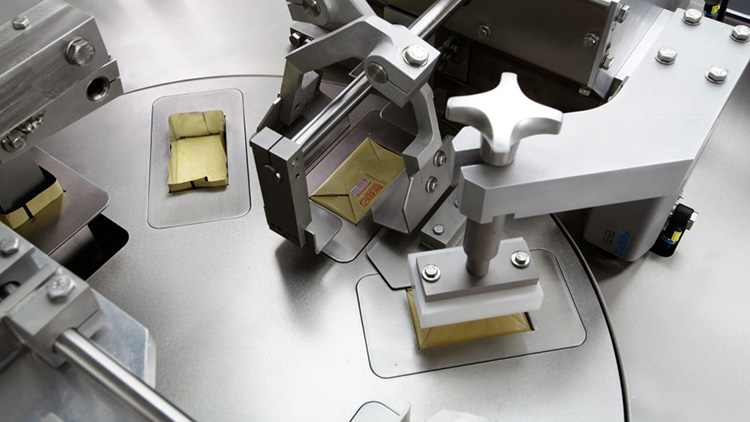

4.What Are the Steps Of Butter Packaging?

Butter packaging is a complicated process requiring great deal of care and synchronicity. Some steps involved in butter packaging are:

Container Preparation

In this step, containers tubs or trays are loaded on the conveyor or in case of butter wrapping; the film material is unwound and cut into rectangular or square shaped sheets.

Butter Loading

The butter from processing machines move into collecting hopper by channels or are directly loaded into hopper by operators. This butter is then moved into dosing unit via pipes and screws.

Butter Dosing

The packaging wraps are transported to filing unit where they are loaded into holding areas as a box. Dosing pipes put butter block into sheets box or pipes can place butter into tubs or trays.

Sealing

Folding of these filled sheets is carried out by tucking in top and bottom ends and afterwards central flaps are closed. Pressing units then press the raised sides of package. Lids are placed on the mouth of tubs and trays for their airtight sealing.

Cartoning

After sealing, packaged butter is placed inside corrugated carton boxes for bulk storage and shipment.

5.What Is the Best Butter Packaging?

Brand owners use wide variety of materials and packaging styles for protecting their butter products. However, aluminum wraps and HDPE or PP tubs are best for packaging butter.

Often butter has certain tawny taste because butter has absorbed odors from foods in surrounding. Aluminum laminated foils prevent the penetration of undesired smells. Thus for preserving flavorful taste of butter, it is packaged in aluminum packaging.

Tubs thermoformed by PP and HDPE are ideal for their convenience and reuse. These tubs wrapped in paperboard sleeve have minimal UV exposure therefore butter packaged in these containers has longer shelf life.

Small flap on lids assist in easy opening and resealing of container. Overall design and shape of these containers are tailored for offering customer best experience.

6.Why Is Butter Packaged In Paper?

Various forms of butters such as block, stick, and rolls come packaged in paper like packaging. Butter is made of oils and fats which are quite greasy and prone to leakage.

By wrapping butter in specialized paper usually treated with wax or silicon, brand owners can stop the leakage of oils from packaging. The paper is impermeable to water and oils.

This is of convenience of buyers since greasy butter soil their hands. Moreover, it makes self-servicing easier.

7.What Are Butter Packaging Materials?

Numerous kinds of butter packaging materials are used by brand owners for upholding nutritional quality and flavor of butter. Some packaging materials are discussed below:

Butter Paper or Parchment Paper

It is mostly widely used material for butter packaging. It is formed by treating plant based cellulose with sulfuric acid and zinc chloride and afterwards this processed paper is coated by silicon. Moisture and fats cannot move across this paper material.

Cellophane

This material is formed by regenerated cellulose. It is thin clear sheet that has minimal permeability for air, fats, moisture. It is good for inhibiting growth of bacteria.

Plastic

It is good barricade against environmental chemicals such as oxygen and water. It has high tensile strength and is readily available at low cost rates. It has weight-cutting advantage and is ideal material for storing butter products. Plastic is used for making butter wraps, trays, tubs, and jars.

Aluminum Foil Laminate

0.009 mm thick aluminum foil is processed with lacquer on external surface for giving butter protection against rusting and corrosion. It provides barrier against moisture, gas, and UV light. It has low penetrance against unwanted smells thus can maintain the taste of packaged butter.

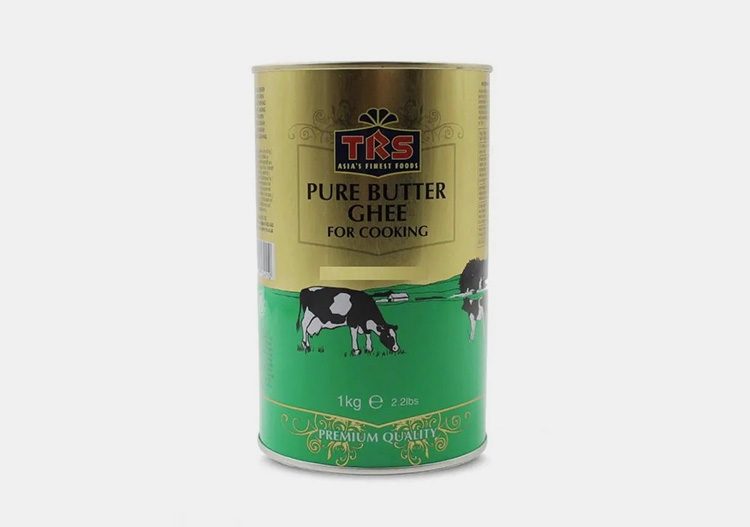

Tinplate

This metal is durable, ductile, and malleable and is often employed for manufacturing cans for packaging dairy items like butter.

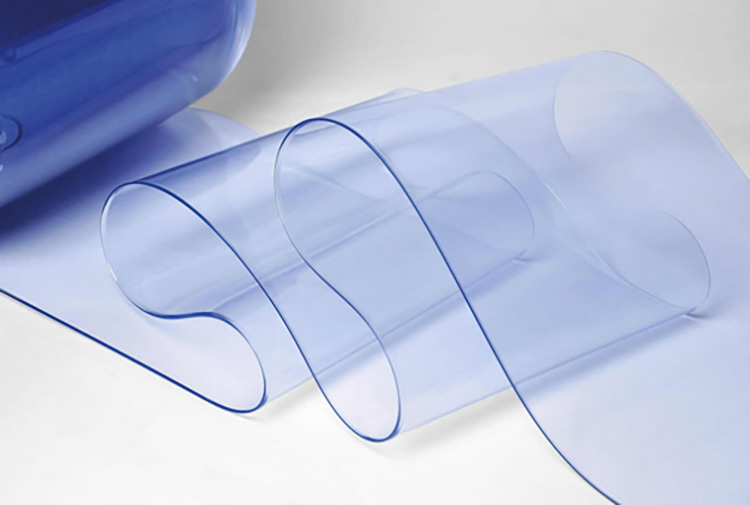

8.What Type Of Plastic Is Butter Packaging?

Butter packaging employs vast variety for plastics so that butter products can safely arrive at homes from packaging plants. Few types of plastic used for butter packaging are:

Polypropylene (PP)

These plastics are used for making tubs and trays. Most options of PP containers are heat resistant so can be used in microwave. Moreover, they are suitable for refrigerating and freezing butter. These are unbreakable and can be reused for storing other foods.

High-density polyethylene (HDPE)

This plastic type is used for packaging large amount of butter in heavy duty trays and buckets. They are more tensile strength than PP plastics and are more flexible.

High-impact polystyrene (HIPS)

It is quite brittle and is used as copolymers in butter packaging wraps with aluminum and parchment paper. It is shiny, clear, and has good printing capabilities.

Polyvinyl Chloride (PVC)

PVC has superior resistance against oil and grease. Furthermore, it is low priced and durable. However, this material is difficult to recycle and negatively impact environment.

Polyethylene terephthalate (PET)

This kind of plastic has high tensile strength and increased toughness. These are highly suitable for creating butter trays, wrapping films and jars. They provide packaged butter protection against deteriorating effects of heat, moisture, and air.

9.What Are Requirements Of Butter Packaging?

Superior barrier materials are needed for packaging of food with high fat content. Butter packaging is challenging in this respect. Combination of various materials is required for optimizing butter packaging. Some important requirements for butter packaging are:

Absolute Grease Barrier

Packaging should be completely grease proof for preventing the leakage of grease from container that can otherwise create mess in surroundings.

Wetting Strength

It should have resistance against moisture since water vapors in environment promote growth of bacteria.

Oxygen Protection

Butter packaging must be impervious to oxygen molecules because latter can react with fats in butter and cause their rancidity. This rancid butter is unsafe for eating.

UV Light Fortification

Materials in butter packaging should not transmit light. UV light can promote oxidation of oils in butter that lowers its shelf life.

Non-toxicity

Butter packaging materials should not be composed of non-toxic materials that can pose risk to human health.

Low Metallic Content

It should have low metallic content as metals increase butter fats degradation.

10.What Are Butter Packaging Styles?

Butter can be packaged in a variety of ways, including in containers. Containers are typically made of plastic or glass, and may have a snap-on or screw-on lid to keep the butter fresh. Jars are similar to containers, but are usually made of glass and have a screw-on lid. Tubes are typically made of plastic and have a screw-on cap at one end. Their packaging style include:

Butter in Stick Packs

Butter is packed in individual sticks, typically in a cardboard or plastic wrapper. These sticks are often sold in packs of four or eight and are convenient for measuring out specific amounts of butter for baking or cooking.

Butter Packaging In Tubes

Butter packaging in tubes is a method of packaging butter in which the butter is extruded or pushed out of a tube, similar to toothpaste or other similar products. This allows for easy dispensing of the butter and can help to reduce waste, as the butter can be easily pushed out of the tube without breaking or crumbling.

Butter Packaging In Sachets

Butter packaging in sachets refers to the method of packaging butter in small, single-serving portions using small plastic or foil packets. This type of packaging is convenient for consumers as it allows them to take a single serving of butter with them when they are on the go or to portion out their butter usage more accurately.

Butter Packaging in Buckets

Butter is packaged in a plastic or ceramic bucket, usually with a screw-on or snap-on lid. This type of packaging is convenient for spreading butter on bread or using it as a spread.

Butter Packaging in Cans

This type of butter is whipped to incorporate air, making it lighter and fluffier. It’s often packaged in a tub or can and is convenient for spreading on bread or in baking.

Butter Packaging in Cups

This type of packaging is also very commonly seen. The basic material used is plastic. As we know that plastic is a very sustainable and easy to work on material and also the printing of brand name is easy. It is light weight and water proof.

Butter Packaging in Rolls

A block of butter is rolled out, wrapped in plastic or parchment paper, and then chilled. This type of packaging is often used in high-end restaurants or bakeries.

European-Style Butter Packaging

This type of butter is made with a higher butterfat content and is typically packaged in a foil or wax paper. It’s often used in baking and cooking because of its rich flavor and texture.

Pouches for Butter Packaging

Printed and trendy stand up pouches r are a good way to present the product. They can store a large quantity of product occupying a smaller space on grocery shelves. They are designed with either re-seal slider or zippers.

Heat Sealed Aluminum Butter Packaging

The aluminum foil paper is designed differently. The inner side that is in contact with butter is a fat resistance protective layer. This protective layer is made up of an ethylene copolymer that functions as protective lacquer that repels grease. The other side, the side facing outwards is just an aluminum foil.

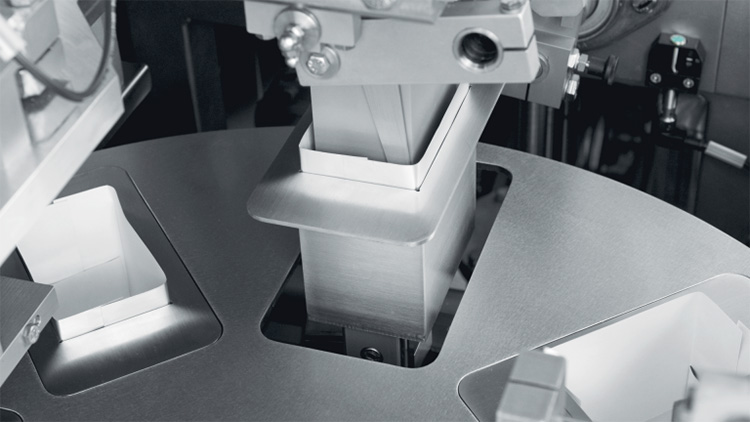

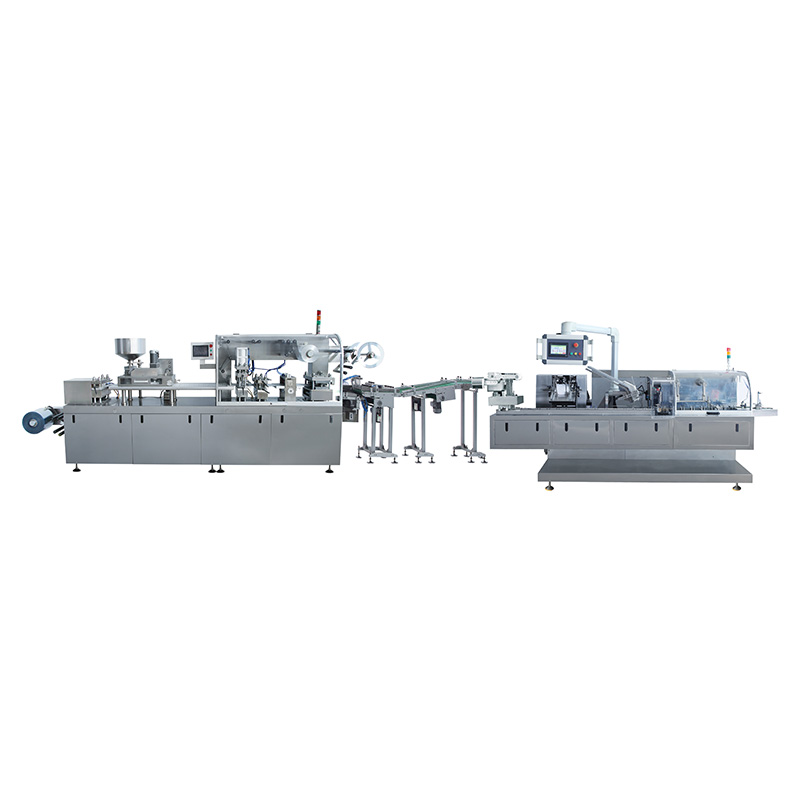

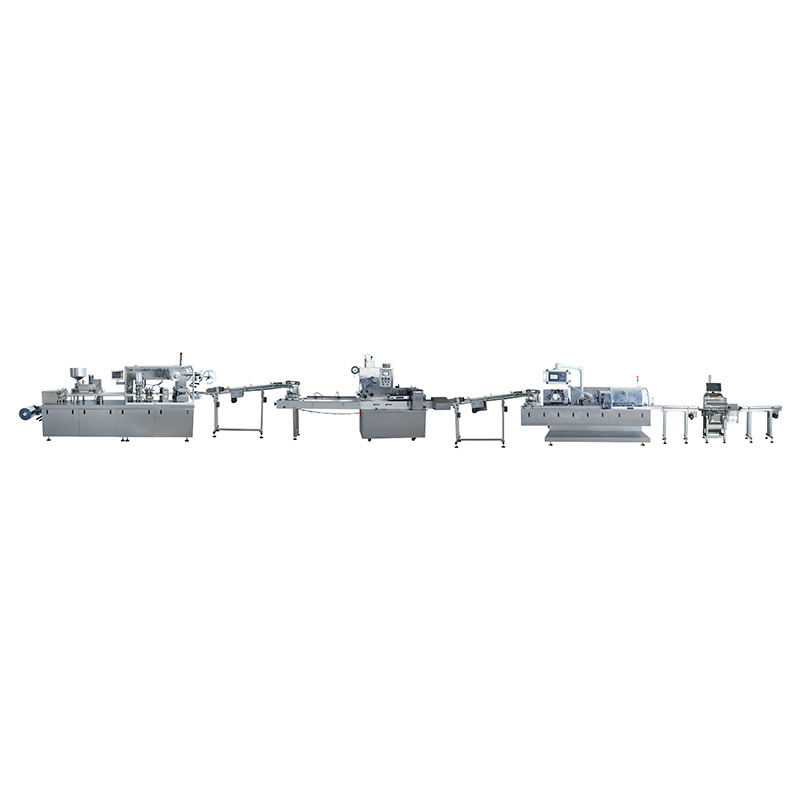

11.What Are Butter Packaging Machine Types?

There are several types of machines that are used for butter packaging.Some machines may include additional features such as automatic filling, weighing, and counting, to streamline the packaging process. The selection of the machine should be based on the production volume, packaging format, and specific requirements of the butter manufacturer. Let’s have a look!

FLOW WRAPPING MACHINE FOR BUTTER PACKAGING

These machines are used to get a flow-wrap format that involves a continuous sheet of film. A flow wrapper, also known as a horizontal flow wrapper, is a type of packaging machine that is commonly used for packaging products such as butter. The machine works by:

- Forming a continuous tube of packaging material, usually a plastic film, from a roll of material. The butter product is then fed into the center of the tube.

- The tube is sealed around the product to form a package.

- The package is then cut to the desired length and the excess material is discarded.

- The machine typically uses heat sealing to seal the package and may also use ultrasonic or impulse sealing.

CUPS FILLING MACHINE

Tubs and cups filling machine has ability to fill butter, margarine or other spreads into pre-made cups or tubs with delicate covering of aluminum foil and or lid. The machine is featured with rotary filling functionality. The working of equipment is described as:

- Product is feed into the hopper that is equipped with two auger options.

- Using HMI touch screen, cups from storage is picked and adjusted in rotatory holders. Upon moving, a pre-cut dose filled in cups soon after exposing to UV radiation for sterilization.

- Heat sealing is done followed by lid covering.

- Tub is transferred on conveyor for collection once filled and sealed.

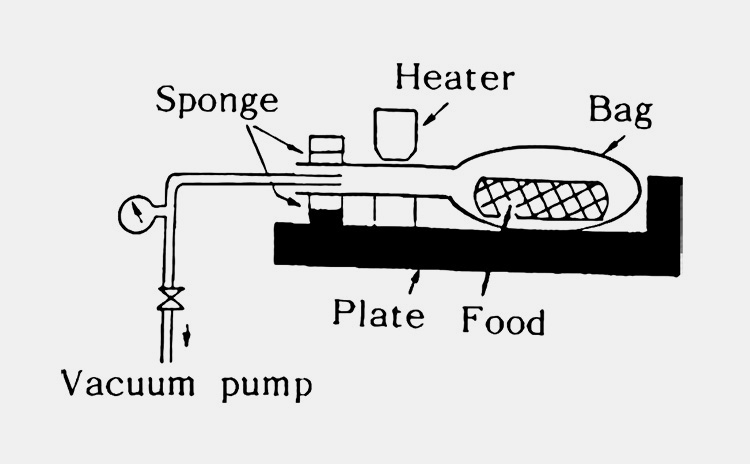

VACUUM PACKAGING MACHINES FOR BUTTER PACKAGING

Vacuum packaging machines work by removing the air from a package and sealing it in order to extend the shelf life of the product. The following is a step-by-step explanation of how vacuum packaging machines work:

- The butter is introduced in a packaging material and the open end of the bag is inserted into the vacuum chamber.

- Inside the vacuum chamber, a vacuum pump is used to remove the air inside and outside of packaging material.

- As the air is removed, the pressure inside the chamber drops, and the bag collapses around the butter.

- Once the desired level of vacuum is reached, the chamber is sealed and the butter is packaged.

- The vacuum packaging process can also include an additional step of using heat-sealing to seal the bag and to ensure the safety and freshness of the product.

- The packaged butter can now be stored for a longer period of time without spoilage. The vacuum packaging process removes the oxygen that causes food to spoil and bacteria to grow, extending the shelf life of the butter.

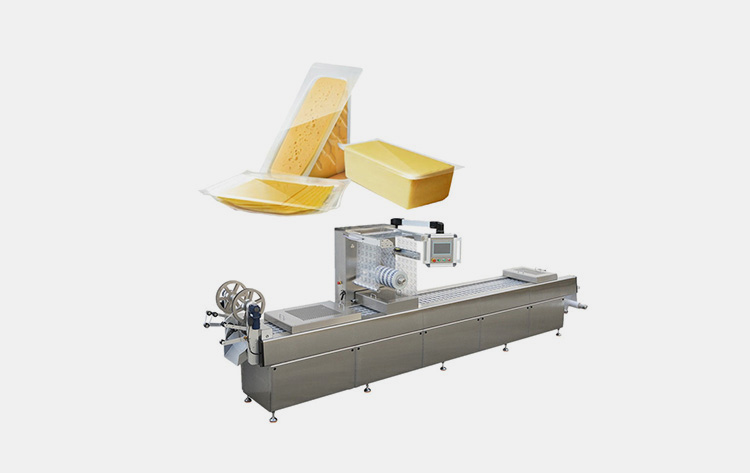

HORIZONTAL FORM FILL SEAL MACHINES FOR BUTTER PACKAGING

A horizontal form fill seal machine (HFFS) is a type of packaging machine that creates a sealed package by forming a tube of packaging material (such as plastic or foil) and then filling it with the product (such as butter) before sealing it. The process typically involves the following steps:

- A roll of packaging material is fed into the machine and passed through a set of forming rollers, which shape the material into a tube.

- The tube of packaging material is then moved to a filling station, where butter is dispensed into the tube.

- The tube is then sealed at the bottom to create a package.

- The package is then cut to the desired length and discharged from the machine.

- The machine can be adjusted to package butter in different sizes and shapes.

STICK PACK MACHINES FOR BUTTER PACKAGING

- Stick pack machines are used for packaging products such as butter in small, narrow packets or sticks. The working principle of these machines typically involves several steps:

- Product preparation: The butter is first prepared and placed into a hopper or feeder that feeds the product into the machine.

- Forming and filling: The product is then extruded or formed into the desired shape and size of the stick pack. The formed product is then filled with the appropriate amount of butter.

- Sealing: The filled stick pack is then sealed on both ends to ensure that the product remains fresh and protected.

- Cutoff: The machine then cuts the stick pack to the appropriate length.

- Print date: Stick pack machine also print date of manufacturing on the package.

- Counting and packaging: The finished stick packs are counted and packaged for shipping and distribution.

- Overall, stick pack machines are designed to be fast, accurate, and efficient at packaging products like butter in small, convenient sticks.

VFFS FOR BUTTER PACKAGING

VFFS (Vertical Form Fill Seal) packaging machines work by taking a roll of flexible packaging material (such as plastic film), forming it into a pouch or bag shape, filling it with the product (in this case, butter), and then sealing it to create a finished package.

- The process begins with the roll of packaging material being unwound and fed into the machine.

- The material is then heated and formed into a tube shape by a set of forming jaws.

- The butter is then dispensed into the pouch through a filling nozzle.

- Finally, the pouch is sealed at the top to create a finished package.

- The entire process is automated and can be done at high speeds.

SACHET BUTTER PACKAGING MACHINE

Sachet butter packaging machines are machines that are used to package butter into small, single-serving packets or sachets. These machines typically use a combination of mechanical and heat sealing processes to package the butter.

The working principle of sachet butter packaging machines typically involves several steps:

- The butter is first placed into a hopper or container that feeds the butter into the machine.

- The butter is then extruded or pushed through a nozzle or die, forming it into the shape and size of the desired sachet.

- Next, the butter is placed into a heat sealing chamber, where it is sealed using heat and pressure to create a secure and airtight seal.

- Finally, the sachets are cut and packaged into boxes or bags for distribution.

TUBE FILLING MACHINE FOR BUTTER PACKAGING

A tube filling machine is a diversified equipment tend to fill high capacity butter product in a shorter time. It has ability to precisely fill the butter into tube no matter what viscosity it has. The working of tube filling machine is mentioned below:

- Filling tubes are positioned automatically onto holders attached on a turntable.

- Upon rotation it faces the filling nozzle where a specified concentration of butter is filled into tubes.

- Sealing is done at the edges of tube’s bottom via heating jaws.

12.How Do You Package Butter For Export And Shipment?

For shipment and export purposes, fresh butter is packaged as blocks having of 25 kg. Large blocks are placed and wrapped in polythene or butter paper or foil.

These wrapped blocks are then loaded in cartons made of corrugated fiberboard or cardboard. The cartons are also lined with wax or paperboard inserts to prevent moisture and gas ingression.

Tin cans are also used for packaging small amount of butter. Tin cans are ideal for reducing exposure of butters to UV light and keep butter from melting at temperature lower than 12°C.

Sometimes for export, butter is palletized and shrink-wrapped for decreasing damage to butter.

13.How Long Does Butter Last In Butter Packaging?

If the expiry date of dairy items like milk, creams, and yogurt has passed, they will taste off within couple of days but this is not the case with butter. It can be used up to 1 month pass its expiry date.

Butter can lose its flavor and quality but it takes more time to do so than you think. With time, butter particles will deteriorate due to culprits like oxygen, light, and temperature. This will give bad flavor and smell to butter.

Keeping the packed butter in refrigerator improves its expiry date from 1-3 moths. However if you put butter in the freezer, you can increase its consumption life by 1 year.

14.Which Is Better? Butter Paper VS Wax Paper?

Butter paper and wax papers are both kinds of packaging and wrapping papers. Sometimes these are interchangeably used but there are significant differences between these two papers.

| Butter Paper | Wax Paper |

| Heat Resistance | |

| It does not melts or ignite in baking oven therefore it is used for lining baking sheets. | It has found its use in many fields however; wax should not be put in ovens for baking since it can catch excess flames. |

| Price | |

| It is more expensive than butter papers. | It is reasonably price. |

| Coating | |

| This type of paper is generally coated with silicone for giving it heat resistant properties. | Wax papers are produced using paraffin or soyabean wax. |

| Non-stick Nature | |

| Parchment paper does not stick to surface. | Due to their waxy coating it can stick with surface. |

Both these types of papers have their own advantages but butter papers are best for baking and cooking purposes due to its grease proof and non-sticky nature. These are widely used for packaging of foods items such as dairy products and frozen goods.

Conversely wax papers are best for wrapping and packaging fatty food and for protecting chopping boards against raw foods such as fishes, onion, and meat.

15.Can Butter Packaging Be Recycled?

Recycling of butter packaging is generally depended upon the brand of butter and the materials used for its manufacturing. Nevertheless, it is extremely difficult to recycle this packaging

Butter packaging is formed by cellulose type paper, foil, and silicon. It is processed with silicon after its production from plant cellulose which affects recyclability of butter packaging.

It can be partially decomposed by microbes however; on decomposition it releases chemicals harmful to environment and humans.

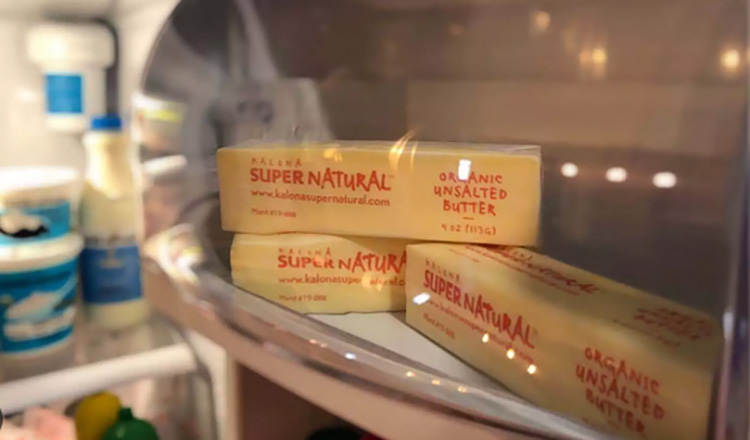

16.Does Packaged Butter Need To Be Refrigerated?

It is universal truth that packaged butter should be kept in refrigerator for preventing its spoilage. Milk and cheese go bad if left for more than 1 day in open air. However, unlike its other dairy counterparts, it is safe to leave butter on your counters.

Most people keep their packaged butter at room temperature since it is easier to spread warm butter on toast. Packaged butter can last few hours or even days without being refrigerated.

The reason behind its superior resistance is minimal carbohydrate and protein content which can otherwise lead to bacterial growth and molding.

However, ensure that butter is placed in proper packaging and at cooler temperature of less than 21°C so that it is safe for use without its refrigeration.

Conclusion

Brand owners are in continuous struggle for innovating their butter packaging so that their packed product has improved retail life. Grease imperviousness and high moisture resistance are two must have features of butter packaging. Butter packaging is available in unique and distinct packaging styles for instance stick, block, roll, trays, tubs, and jars for attracting customers at first glance. Hope you have learned about different aspects of butter packaging by going through this FAQ. For further information you can consult our customer care service.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide, tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine