Cartoner: The Complete Buying Guide In 2025

Wanna buy a reliable cartoner, but don’t know how to choose? An efficient cartoner is essential for the pharmaceutical manufacturers. A good one can not only improve the quality of the products and give the good first impression to consumer, but also save a lot for manufacturers in power, labor and time.

Are you confused by so many different types of cartoner? Then you must check this buying guide of cartoner which will give you a comprehensive understanding about the different types of cartoner, its working principle, maintenance, disadvantages, power and so on, and lead you to choose the most suitable and reliable one. Come on and have a look!

1.What Is Cartoner?

AIPAK Cartoner

Cartoner is mainly used to package products into a carton. This machine which integrates light, electricity, gas and machinery, unleashes its talents in efficiency and completion in packaging.

Cartoner doesn’t restrict itself in carton packaging. With the high-tech, it can also handle the packaging of blister plate, small round bottle (tray), etc. Thus it helps a lot in packaging in food, pharmaceutical and electronic industry. All in all, any things packaged in container needs cartoner.

Various Products Cartoner Produce

A nice packaging gives your customers good first impression, and decides customers’ judge and products’ reputation. Thus a cartoner which produces high-quality and good-looking packaging is essential for you.

2.What Is Cartoner Used For?

Cartoner is mainly used in packaging products. It can accomplish a series of process, like erecting, closing, folding, filling, sealing and so on depending on your purpose of the packaging.

AIPAK Working Cartoner

Cartoner has wide application. It can be seen in pharmaceutical, food, cosmetic, and many other industry for packaging products. Now, let me introduce you the different application of cartoner in different industry.

Application of cartoner in pharmaceutical industry

Cartoner For Pharmaceutical Use -Sourced: gznovelpackaging

In pharmaceutical industry, cartoner are used to package a variety of products, like capsules, bottles, blisters, bags, ointments and so on. The machine’s high efficiency and reliability make it a valuable helper for pharmaceutical manufacturers.

Besides, the present packaging function of cartoner makes it impossible to get the medicine out without tearing up the whole package. The unique anti-counterfeit function it provides solves the troublesome problem which disturbs many patients and pharmaceutical manufactures.

Application of cartoner in food industry

Cartoner in food industry-Sourced:cartonservice

For food that didn’t have the proper packaging, a little shaking may destroy food in the process of transportation or change it tastes as not sealed well.

And more important, microbial and dusts that cover on food in the process of packaging can change the food quality and more seriously, can induce the change which may cause food-poisoning.

Application of cartoner in cosmetic industry

Cartoner Of Cosmetic Industry-Sourced:vipyidian

Cosmetic industry involves products like, toothpaste, soap, facial mask, face cream, lipstick, paper towels, sanitary napkins and so on.

For products of this kind, the anti-counterfeit function of it protects your brand’s profits. Besides, the cartoner can judge and pick out the products that are not qualified automatically.

Last, for products in electrical, entertainment and plastic industry, cartoner also plays a non-replaceable role in the manufacturing.

Cartons Of Different Industry -Sourced: zeepackaging

3.What Material Can Cartoner Handle

Cartoner can handle various materials of products and packs from ampoule to hardware fitting.

Packages Of Different Products

As you have known, the cartoner served so many different industries, it of course handles different materials according to the different needs of industries.

Cardboard

Usually, the cartoner produces cardboard packaging box and this kind is also the most popular one, as card paper is widely used in every industry.

Coated paper

Coated paper is majorly used in cosmetic industry, because it is eye-catching with the attracting feature and poly-tropic color.

Board

The thin and easy-folding board are designed for the packaging of special products, like chocolate, tea or wine, which can show the special feature of products.

The machine can also handle the package materials, like plastic, PU leather, or even canvas for tea, wine, medicine, gift and so on.

Various products-Sourced:moonlightcreative

4.What Are The Advantages And Disadvantages Of Cartoner?

AIPAK Cartoner

The cartoner which is the combination of automation, high-tech and mechanization, of course endows great help to manufacturing, but it also has its shortcomings. There is a conclusion about its two sides.

The advantages of cartoner

Advantage-Sourced:canvasgadget

- Efficiency

The advantages of cartoner is obvious, as it’s efficiency reduce the cost of manufacturers and improve the quality of products.

- Clean

Cartoner also creates a relative clean and safe environment for package production. The hygienic standard is easier to prove, for it’s easier to control machine’s variation compared with labors.

- Reliable

And for brand and producer, quality control of products shows costumers your profession and decides in some way their impression on your whole products.

The products whole packaged by labors is not only short in efficiency. Their uneven works which is hard to unified is also hurt your products reputation.

The disadvantages of cartoner

Disadvantage-Sourced:dreamstime

There exists disadvantages of cartoner of course.

Large size

The machine’s large size and occupation decides its excess needs in place and condition. It is not moveable. Thus,a spacious, stationary and dry place is obvious the best environments for the machine operation.

So your factory should have such environment for the smooth use and outstanding performance.

Maintenance

For a machine combined technology and machinery, it needs regular examination and daily care which also time consuming, and requires much support from the experts of this machine.

Limited on application

Cartoner can be used for package most products on market, but not all. For special or specific products, it may not suitable for your use.

5.How Many Types Of Cartoner Are There?

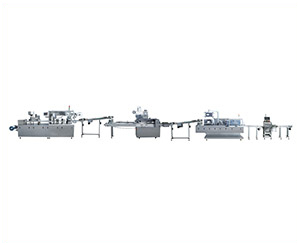

Cartoner is different according to its automation, packaging way, sealing forms, packaging shapes and so on according to different purpose and different packaging ways. Below are the classification of it.

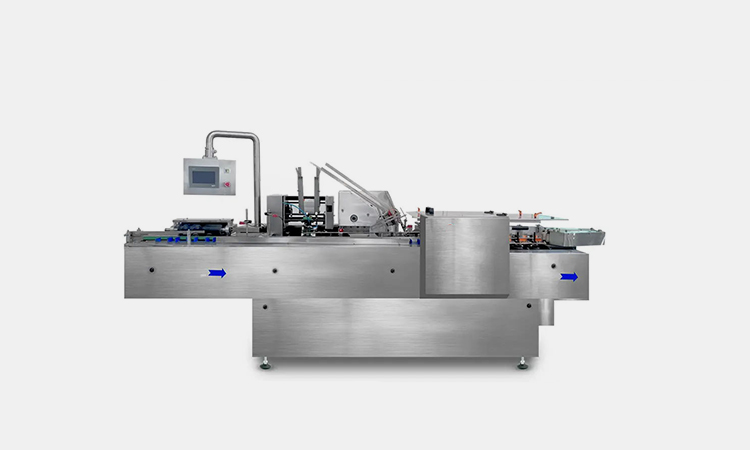

Degree of automation

The automation degree classified cartoner into semi-automation and fully-automatic.

- Semi-automatic Cartoner

Semi-automatic cartoner gets its name as it needs labor’s assistance to complete its process. Besides packaging, it can also sealing labels or heat shrinkable wrapping. For industries like food, daily necessities, chemical industry and medical hardware, it’s rather suitable.

Semi-Automatic Cartoner-sourced:jochamp

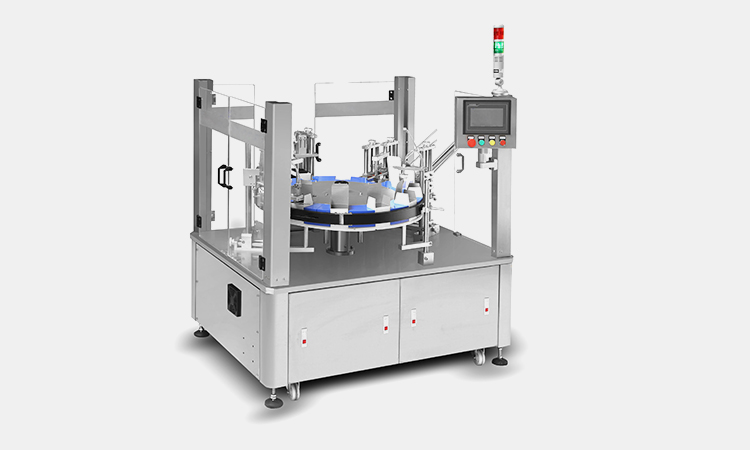

- Auto-automatic Cartoner

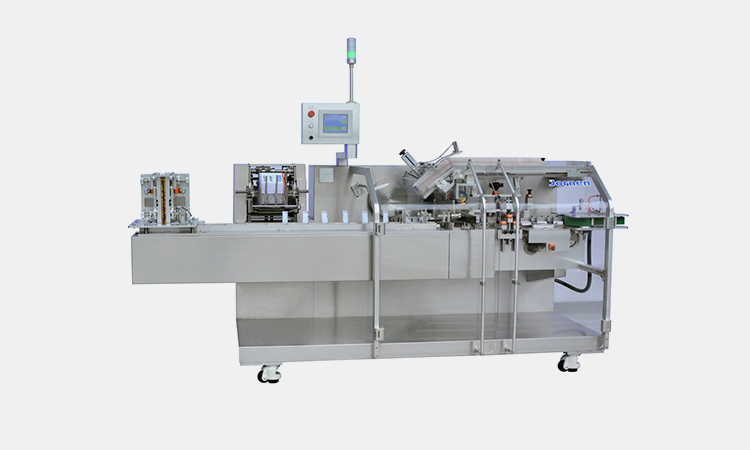

AIPAK Auto-Automatic Cartoner

Auto-automatic cartoning is more intelligent. It saved the excess work like picking out damage or empty package, thus proves the completeness of the whole process and increase the efficiency.

Auto-automatic cartoning can be further divided as intermittent automatic and continuous automatic according to its speed and working motion: the former adopts circular rotation, the later linear reciprocating motion.

Packaging way

The packaging way induces the way products insert into the carton. There are horizontal cartoner and vertical one.

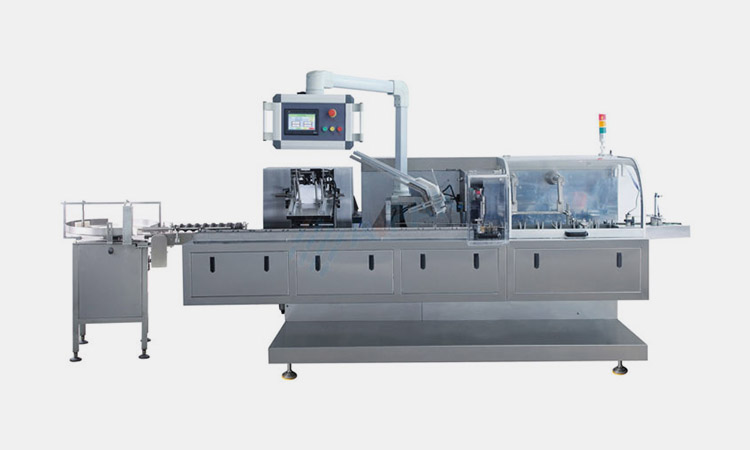

- Horizontal Cartoner

AIPAK Horizontal Cartoner

Horizontal cartoner gets its name as it packages products pushed into it horizontally. For solid regular objects, like biscuits, bread, blister medicine and moon cake, it is more proper.

- Vertical Cartoner

Vertical Cartoner -Sourced:Boom Packaging Machinery

Vertical cartoner, as its name, gets its products vertically. For bottles, jars and vials, it dose a better job compared with horizontal one, and thus are more suitable in cosmetics, food and pharmaceutical industry, as the vertical inserting way take lower risk of products damaging.

6.What Are The Components Of Cartoner?

The Whole Picture Of Cartoner- Sourced:maharshi

Cartoner exerts its performance with the combination of its every parts. The lack of a part would delay the whole process.

Cartoner is mainly composed by the following parts:PLC control panel, electric system, automatic lubrication system,carton feeding system,injet spraying system, conveyors, guide rail and carton chute.

PLC control panel

PLC Control Panel-Sourced: Shenhu Packaging Machinery Equipment

PLC control panel is the center of the whole machine, just as the brain of human. It takes in charge of the carton number, electric, gas printing, and functioning of machine.

In all, it manipulates the whole process of cartoning and parameters setting. When gets into any trouble, it will also alarm. It’s the control center of machine.

Electric system

AIPAK Electric System Of Cartoner

Electric system controls the main power of machine, which changes electricity into mechanical power and makes the whole machine move. The electric system thus played the essential connecting role. Only with it, can cartoner work and make packages.

It usually set at the bottom of the machine where is space-saving and low-interference. Connecting with other supporting axis, it transits the products into cartoning place.

Automatic lubrication system

AIPAK Automatic Lubrication System

The less of lubrication may dry your machine and even shorten its lifespan in serious condition, as the moving section and its electric device needs regular lubrication to bring smooth operating.

Its automatic lubrication system makes contamination which brings up by humidity and moisture have no way to form, and makes the maintenance of machine easier.

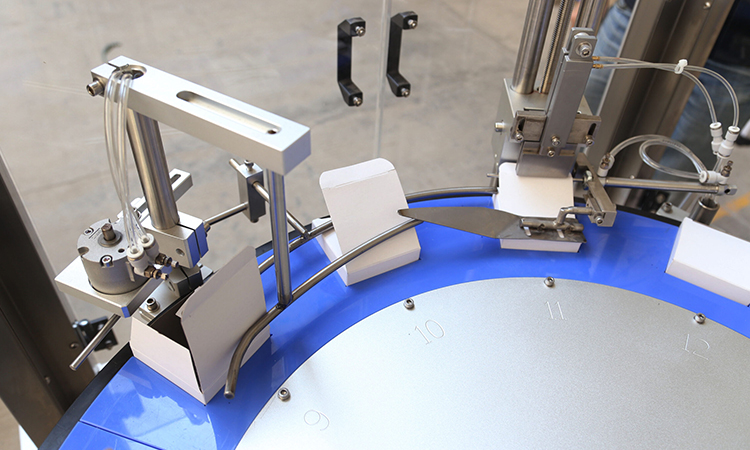

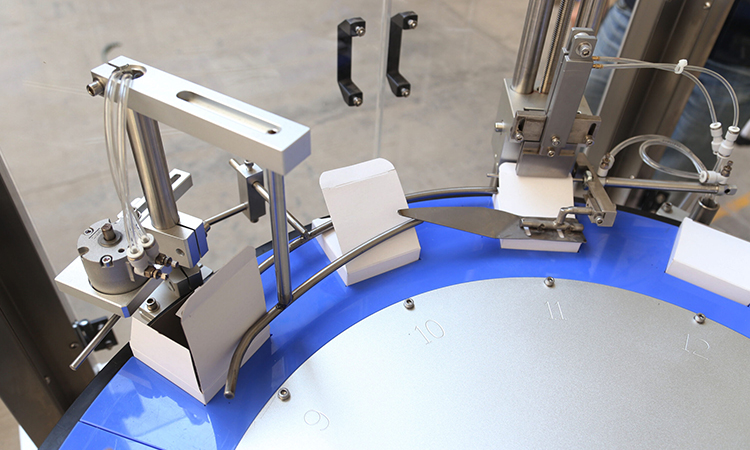

Carton feeding system

AIPAK Carton Feeding System

The main parts of carton feeding system are press device, carton storage room, leaflet feeding, conveyor belt.

The cartons which stored in carton storage room is suck by the pneumatic system to cartoning process. The leaflet and then products, in the middle of the process will send the leaflets into carton . After being sealed and send to the end by carton chute, the whole carton process is finished.

There exists a press device in front of the storeroom to stop the machine in the condition of blocking or deforming in the sucking process.

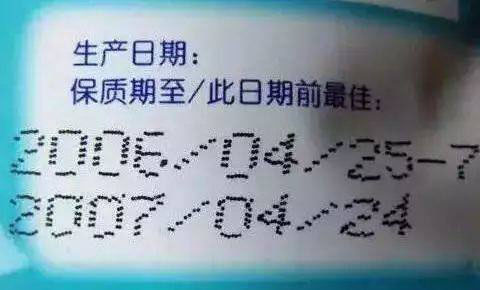

Injet spraying system

Information Made By Injet Spraying System

The sealed carton didn’t mean the whole finish of the cartoning process, injet spraying system will print the product information, like manufacturing date, expiry data and so such information to endow you customers the useful information to use the products.

Conveyors, guide rail and carton chute

AIPAK Guide Rail And Carton Chute Of Cartoner

Conveyors, guide rail and carton chute are like the transportation system of cartoner.

From the above parts, you have known the importance of conveyors in feeding and packaging. The guide rail drives the cartons move to next section and makes it follow the process. In the end, the carton chute drops down the cartons and avoid piling of cartons.

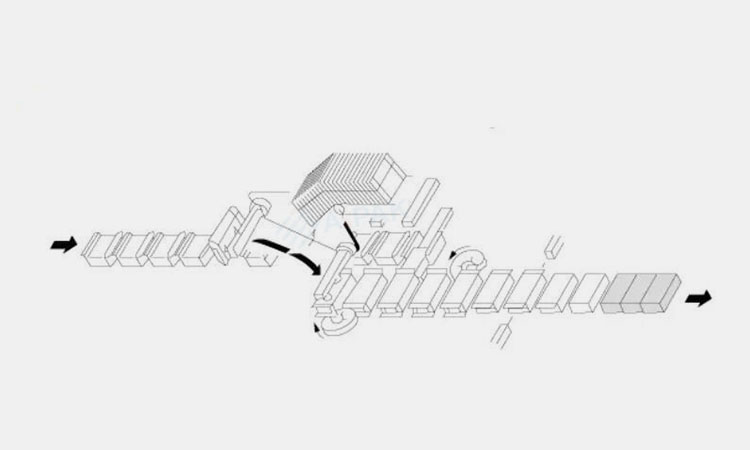

7.What Is The Working Principle Of Cartoner?

AIPAK The Inner Structure Of Cartoner

Cartoner is designed for packaging, thus its main process is lower the carton box, open carton box, insert products and sealing cartoning box.

Its detailed working process can be included into following steps.

- First, the prepared cartons are sucked from the carton storage room and be folded well waiting for the products get in.

- After been filled with leaflets, brochures or straws in according to the purpose of the products, it begins the filling process of products.

- While getting all materials in carton prepared, the injet spraying system will print products information, like manufacturing data and expiry data, on the planned location.

- The last step of the cartoning isn’t sealing it. After a carton gets all ready, carton chute will lead cartons drop down which avoid pilling. And the cartons at this moments are stack in the big box and be sold or transported in this way.

8.How To Operate Cartoner?

AIPAK Cartoner Parts

The good operating of cartoner needs the all-round knowledge of cartoner, and as you have viewed the main components and working principles of the machine, now let’s get into its operation strictly.

- You should turn on the power switch and put cartons and instructions on designated spot.

- Please get to the screen and log in. Remember to delete the former products’.

- You should setup relative parameters of this products, like size, feature and information for injetting.

- Save all your confirmed information and begin the machine.

- You should prepare for holding the falling cartoners on carton chute.

- You can turn off the machine for emergency by pressing the button beside panel area.

- After packaging, you should clean conveyor, panel and chain.

9.What Factors Affect Cartoner Efficiency?

Cartoner- Sourced:sedpharma

Cartoner with same size or appearance may show different performance and efficiency. The choose of a high efficient cartoner can save you a lot. Here are some factors affecting the efficiency.

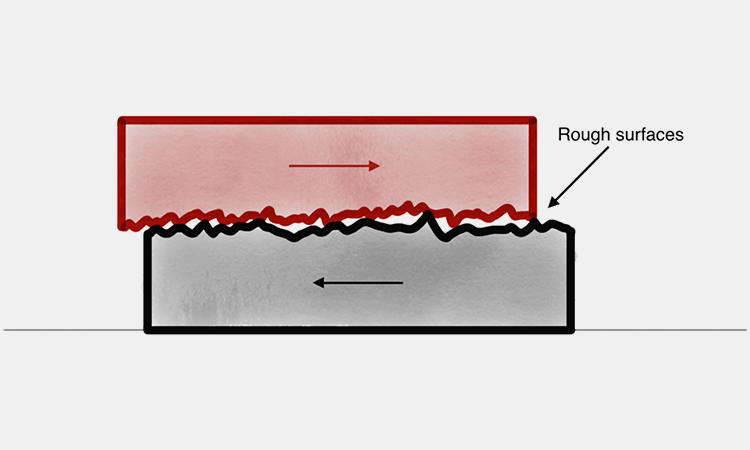

Imperfect components

Friction-Sourced:physics.stackexchange

Machine with precise parts and assembly produces less friction and works more smoothly and rapidly. While the machine with inferior components and contamination for improper maintenance are of course less efficient.

Coarse material

Product’s material-Sourced:openaccessgovernment

For products which is made by hard or coarse materials, it cause more time in folding, conveying and other processing, for its high friction and hard quality take more time.

Lack of cleaning

Machine cleaning-Sourced :weeverapps

Machines lack of cleaning are easy to get stuck by residues left from before packaging and contamination for less lubrication and rinsing.

10.How To Maintain Cartoner?

AIPAK Cartoner Maintenance

A nice maintenance of cartoner can prolong its life span and induce it to generate its largest value in carton packaging. To maintain it well, please follow below maintaining tips.

Settling environments

You should place it at a dry, flat and spacious place. The moist and narrow place will not only affect the efficiency of machines and cause contamination which delay or even damage the packaging process, but may hurt labors in operating.

Regular examination

Regular Examination-Sourced:ink

The regular examination and check of cartoner can help prolong machine’s life span and increase the efficiency, while the machines lack examination may face the hidden problems in operation.

Careful maintenance

Last but not least, remember to clean it regularly. This can protect machine and prove the quality of you products, as the cleaning rinse of the remnant of last cartoning may affect the properties of this batch.

Turn off the machine in cleaning.

11.What Troublesome Problems May Cartoner Meet?

AIPAK The Troublesome Problems Cartoners May Meet

Cartoner can improve efficiency greatly, but the problems leaved unsolved could also cause the delaying of manufacturing process. Here are some troublesome problems you should pay attention to and their relative solution.

Cartons cannot be drawn down

Working Cartoner- Sourced:shinebenmach

If cartons cannot be drawn down, while all parameters are settled well. You should check whether the cartons are put in order and whether they are pasted together. Sometimes the air pressure of suction head could also cause this condition.

The sudden stop of machine

For the interval and sudden stop of machine, you should firstly check the power and motor system. Besides, the shortage of cartons can also cause the sudden stop of machine. In this case you should add the materials and restart machine.

Errors in carton-folding and instruction

AIPAK Cartoner

Card-folding mistakes

Sometimes, card board didn’t make carton after it being sucked. In this condition, you should firstly turn off the machine and check whether the card is too hard.

If not, then check the position of god rod of carton box, small hook, suction head, carton delivery track and box feeding.

Instructions settling mistakes

For the false settling of instructions, you should check various components connected with this parts ,besides to check the completeness of paper.

The wrong match, height, position and gap of relative components can all cause mistakes in instruction filling.

12.How To Choose The Most Suitable Cartoner?

A Type Of Cartoner -Sourced:jornen

The choose of you machine makes a big difference to you later manufacturing and business development. To choose the expected one, you should consider your requirements besides budget.

Requirements for products

Various Products-Sourced:boxesgen

Your cartoner should first serve the requirements of you products. Semi-automatic or auto-automatic, horizontal or vertical? It depends on the needs and function of you products.

Performance of machine

Performance-Sourced :brooksgroup

The performance and machine design are also a big point. You should ensure the high-quality of its all parts and technical service support it can provide.

Machine size

The size of machine should also be measured and considered seriously, as the inappropriate one can’t fit you factory well and may cause continuous problems.

Conclusion

Cartoner is easy to use, operate and maintain, the application of an efficient and reliable one profits your factory a lot. Aipak cartoner is absolutely a good choice. Wanna know more? Contact us now!

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine