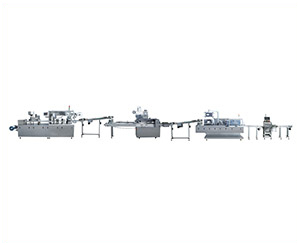

Vertical Cartoner: The Complete Buying Guide In 2025

Vertical cartoner decides the appearance of your products. Its importance is thus obvious. To choose the nice and efficient one, you needs to know its main features, working principles and so much things. And the various type on market must disturb you a lot. So how to find the most suitable cartoner?

Just follow this buying guide. It contains the hottest question on vertical cartoner, and will give you a comprehensive knowledge of the machine, guide you to choose the expected one.

1.What Is Vertical Cartoner?

With the combination of high-tech and automation, cartoner can fold, fill and seal cartons efficiently and cleanly, thus can handle products in different industries from food, pharmaceutical and so on.

Vertical Cartoner -Sourced:directindustry

According to cartoner’s way of getting products into carton, there are vertical and horizontal cartoners.

Vertical cartoner, as it names, gets its products into cartoner vertically and then operates the packaging process. For products like bottles, jars and vial, vertical cartoner is absolutely the better choice. Its flexibility makes less damage on products, thus assures the quality in many aspects.

2.What Products Can Vertical Cartoner Package?

Vertical cartoner can handle various materials and served so many different industries. And with its advantages in flexibility and compact, many products with high standard on packaging choose it.

Beverage industry

Fluid Products-Sourced: vilsv.ca

For fluid packaged in bottles, jars of vials, vertical cartoners are most suitable one for it can reduce the damage on products and contons. Its relative compact environment also assures the hygiene of products and efficiency of production. Thus it’s widely used in beverage industry.

Food industry

Bare Products-Sourced: jovialfoods

Vertical cartoner is well-suited for grains, pastas, rice, candy, powder and such bare products in food industry. After setting the amount of products, the materials can easily drop into cartons before sealing.

It omits complex steps which saved time and avoided other chance for food get affected by environment which is so important in food industry.

Cosmetic industry

Cosmetic Cartons-Sourced:pakfactory

For creams, lotions or other paste liquid usually used for beauty or health treatment, it gives them nice package which sealed paste liquid with high hygiene standard and low products waste. Thus for cream, lotion, emulsion and paste for skin use, it is the expected packaging machine.

Pharmaceutical industry

Pharmaceutical industry places the hygiene and safety in the most important place, as it is used for the human healing and curing.

Pharmaceutical Cartons-Sourced:cartonservice

It has a wide range from ampoule to blister. And its need in safe and hygiene in packaging process can all be solved by vertical cartoner. It avoids the damage on cartons and infection on products.

Electronic industry

Electronic Cartons-Sourced:luxury-paper-box

Packaging of electronic products should take the products protection in the first place. Sometimes, the settling like bubble wrap protects the damage of products in the later transportation, but in the packaging way, electronic products can be better protected for vertical machine gives the smoother packaging process.

3.What Is The Main Feature Of Vertical Cartoner?

High tech improved our living standard and working efficiency. Vertical cartoner which integrates high-tech and mechanics is absolutely the best helper in your manufacturing. Its main features can be included as follow.

High efficiency

Efficiency-Sourced: brianfaul

With the help of its high-tech, precise parts and automation of vertical cartoner, you can get your well-done products in a relative short time compared with packaging by labor or semi-auto machine.

Easy for cleaning

Easy For Cleaning-Sourced:sunriseindustrial

The stainless steel vertical cartoner adopted and lubrication system of it make it easy for clean and maintain. Thus, it saves you a lot time in cleaning, maintaining and daily checking.

Less damage

Damage-Sourced:damagemag

The special design of getting products in vertically of vertical cartoner can reduce the damage of material greatly. The saving and protecting of your material can save you a lot in money and time.

Flexibility

Flexibility-Sourced:freeicons.io

One outstanding feature of vertical cartoner is its flexibility. This special feature makes it more suitable for the fluid or bare products packaging, for it reduce the damage and saved materials for its best.

4.How Many Types Of Vertical Cartoners Are There?

There are two types of vertical cartoner. They are intermittent motion and continuous motion.

Intermittent motion vertical cartoner

Intermittent motion-Sourced:machinio

Intermittent motion makes the vertical cartoner highly efficient and flexible. The products engage in the manufacturing process by mechanic work. But as is intermittent, it can’t get products in incessantly and may waste some time.

It’s suitable for top load applications such as bottles, bags, and wrapped product. But as it’s intermittent, it needs some manage and care from labor.

Continuous motion vertical cartoner

Continuous motion-Sourced:sigmaequipment

Continuous motion is more efficient compared with intermittent one, though gets the products in without manual work as intermittent one. It wastes no time and gets the materials into cartoning process continuously. It takes higher price as it brings you more intelligence and automation.

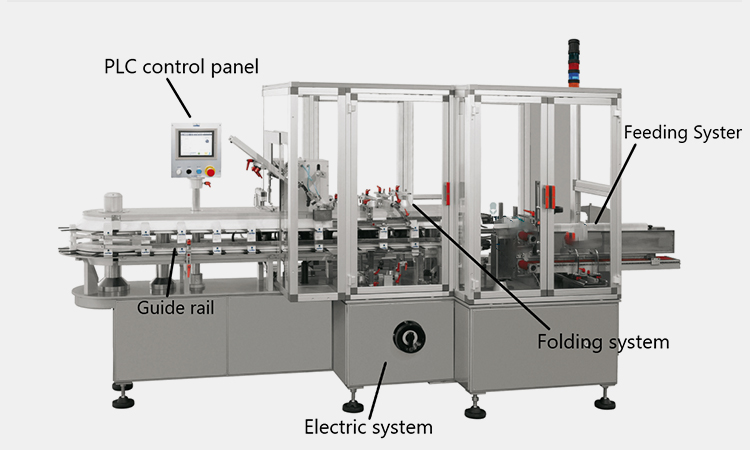

5.What Are The Main Components Of Vertical Cartoner?

Vertical cartoner integrates the process like erecting, conveying, cartoning and so on, is used to package products. And for its special design of loading process, it reduce the damage of materials greatly. They are composed by the following parts.

The Main Parts Of Vertical Cartoner- Sourced:packagingstrategies

Control panel

Control Panel-Sourced: Shenhu Packaging Machinery Equipment

PLC control center is the whole center of the machine. It’s like brain of a machine which set the important parameters and induce machine stop or start.

You can set your need like number of carton, printing, number of products per carton, sealing form and so on.

Electric system

Electric System-Sourced:udemy

As motored by electricity, the machine without electric system can not even begin the most basic process. Its nice work changes electricity into mechanical energy and lead the whole parts of machine move.

It just likes the heart of machine. Without the “blood” it conveys to every parts, the machine is invalid.

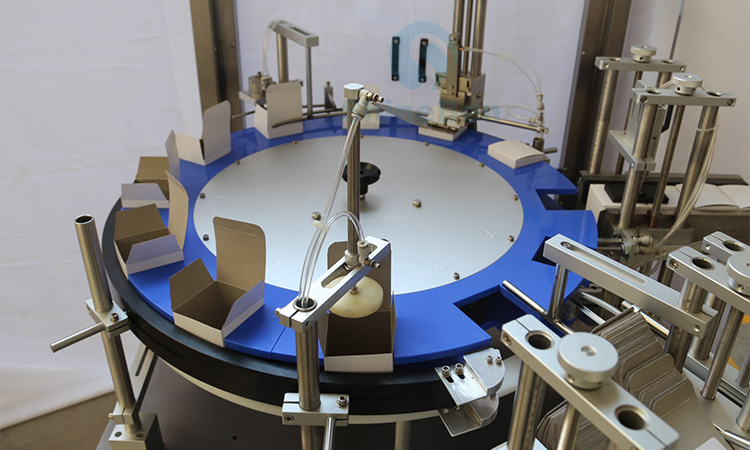

Feeding system

Vertical cartoner is different with horizontal cartoner mainly from its feeding way.

It feeds the materials vertically and in this way, the damage on materials or products are reduced to the least.

As you can see from this picture, the box parts on the right is its feeding part. The rotary structure makes high efficiency, less waste and low damage.

Carton folding system

Carton Folding-Sourced:u-packmachinery

The good folding of carton decides the appearance of your products. The vertical carton feeding system makes the smooth and tidy carton folding in a second. Whole finished by stainless steel mechanic hands, it also prove the clean and hygienic of your products.

The cartons are stored in carton room, and the conveyors which can match itself according to the size of cartons will send the cartons before the products conveyors get in.

Conveyors, guide rail and carton chute

Conveyors and guide rail play the important transporting role in the whole cartoning process. They set the whole process from ranking the materials, sending them to rail for packaging and leading the finished one to export.

Carton chute is the ending part of the whole process. It drops the carton down rather than stops it. Its existence protects the products from pilling and makes damage on machine or products for the pilling.

Vertical cartoner has its components more than the above parts, like sealing system, injetting system and so on. The nice combination of them all can drive the machine well and make good products.

6.What Is The Working Principle Of Vertical Cartoner?

Vertical Cartoner are made to packaging products and its sketchy working procedures are as follow.

How Aipak Vertical Automatic Cartoner works

- Materials get into the machine vertically and was leaded on the nearest conveyors.

- Conveyors and guide rail will guide the products into carton which is folded well by machine and waiting for the landing of products.

- The instruments or brochures are waiting between products and cartons. While the products gets into the carton, it also gets into with the help from same force.

- For some products need print the information like data or other things, it will get into the injetting system.

- After the information being printed, the sealing system will seal them well and send to the last process.

- Carton chute is the last process which lead the well-done products out without pilling in a place.

7.How To Operate Vertical Cartoner?

The operation of vertical cartoner is not difficult, you can just follow these steps.

Operating Vertical Cartoner- Sourced:shineben

- You should check power, conveyors and the condition of your machine. And also do the last cleaning for some products have high standard on hygiene.

- Don’t rush to open the machine. You should remember to put in cartons, materials or connecting it with other machine for the later dealing with well-done products.

- After the all preparation, you can settle you parameters like the number of materials, printing data and so on. Delete the formal information if necessary.

- Then you can start the machine. For emergency condition like carton struck or instruments broke, you can stop the machine in a second, by pressing the button besides the panel control.

- With all your products done and packed well, don’t forget to clean machine. The nice maintenance and careful using can prolong its lifespan.

8.What Is The Difference Between Vertical Cartoner And Horizontal Cartoner?

Vertical cartoner and horizontal cartoner are all used for packaging, their difference mainly lies on the ways products get into machine.

Vertical Cartoner- Sourced:richpaking

Vertical cartoner conveys the materials from above, in this way the damage on fluid and bare products are reduced compared with the horizontal one. And the damage on bottles, jars or vials are also cut down. Its rather suitable for pharmaceutical, food or cosmetic industry.

AIPAK Horizontal Cartoner

Horizontal cartoner gets its products in from side. For regular objects like bread, pill, candy or cake, it gives full play to its capacity. And for products which need to fit the carton well, the horizontal cartoner can give it force to make a tight fit.

9.What Should You Obey While Operating Vertical Cartoner?

Vertical cartoner machine is the giant machine with complex combination and precise parts. Thus in the operation, you must follow some specific steps for its smooth rotation.

Rules You Should Obey-Sourced:ams-nw

- You should use cartoning materials and cartons which is suitable for the machine, for vertical cartoner can handle most but not all materials. It has requirements on the quality and character of its materials.

- You shouldn’t feed broke, folded or stuck cardboard. The imperfect cardboard makes only imperfect carton, and more seriously caused the breakdown of machine.

- Operator should have a comprehensive and full knowledge of the machine and do the operation according to the instruments of the machine.

- You can’t dismantle or reform the machine, the wrong separation of it may induce the break down of machine.

- Before cartoning, remember to check the condition of machine. Is there any missing of any parts? Are the cardboards suit the mould well? If possible, give it an experiments operation and check its condition.

- After the cartoning, you can’t forget the cleaning of machine. But as it is a complex machine with so many precise components, you should do the cleaning and maintenance according to instruments.

10.What Factors May Affect The Efficiency Of Vertical Cartoner?

Vertical cartoner didn’t always perform itself according to your wants. To let it give out its best efficiency, you should pay attention to some factors.

Unsuitable materials

Carton Material-Sourced:yourboxsolution

Vertical Cartoner gets its high efficiency while dealing with the smooth and suitable materials. For cardboard that is coarse, broke and hard-folded, the speed of carton-folding is definitely reduced and caused the low efficiency of machine.

Terrible condition

Condition-Sourced: sdditionary

Vertical cartoner’s condition is affected by many factors. A machine with precise parts and perfect combination with little friction will performed better in its work.

And the machine which is maintained and cleaned regularly has less obstacles as it has no contamination and no emergent stop which is usually caused by aging, breaking or part-missing.

False operation

Operation-Sourced: vecteezy

As all parameters and process are all determined by labors, the proficient one which sets no extract process and plays the full role of machine can of course guide the machine produce expected cartons rapidly.

11.How To Maintain Vertical Cartoner?

The maintenance of vertical cartoner is not difficult as it has the lubrication system which can lubricate itself and in some way alleviate your stress in daily care and maintaining. But for the nice maintain of machine, you should also do the following steps.

Regular maintenance

Regular Maintenance-Sourced:amiraltechnologies

To keep your vertical cartoner in good condition and prolong the life span of it, the regular maintenance is essential. Regular maintenance includes daily cleaning, regular check, lubrication and so such things.

It can in some way reduce the wearing of machine and extend the new and nice condition of machine.

Remove unsuitable materials

Unsuitable Material-Sourced:linkedin

Use unsuitable carton materials makes unnoticeable damage to vertical cartoner. But the insistence of unsuitable material is a tragedy for cartoner maintenance

Materials and cartons which is too rough or robust hurt the performance of machine and affect the operation of its parts. The insisting on such materials may even scrap the machine, shorten its life span and makes irreversible hurt.

Worn parts remove

Worn Parts-Sourced:freepik

Even the best maintenance cannot prove your machine is forever new and always in its best condition. The birth of worn parts is no accident as machine operates produce worn. But if you left the worn parts with no dealing, your machine will meet the accident.

One worn part will induce the wrong fitting of your machine and more friction to its neighboring parts. Besides, the worn parts left untreated will cause contamination or unnecessary residue of former materials which can reduce the efficiency and increase the risks of products pollution.

12.What Troublesome Problems Vertical Cartoner May Meet?

Vertical cartoner may meet various troublesome problems,but not all problems need the proficient check or repairs. Here are some common problems and their relative solution.

No power up

Power Press-Sourced:flaticon

For machine does not power up, you should check the incoming power and the relative connection between machine and power.

Reset mistake

Reset-Sourced:flaticon

If your machine cannot reset the parameters, you should firstly check your writing, for the fault writing can’t be accepted by machine.

While resetting, you should also check the condition of your machine, safety circuit, opened guard doors and unstable power can all cause the reset mistake.

Sudden stop

Sudden Stop-Sourced:discoverweyburn

If you machine stopped suddenly, please check the power part. If it’s all right, turn off the machine and check is there any struck or block in carton storing room, conveyor, carton folding and feeding process.

Incorrect Carton folding

Carton Folding-Sourced:koerber-pharma

The wrong folding or imperfect folding of cartons lies on the condition of folding part. The mistakes on distance, size and combination or relative parts in folding process can affect the folding. In this condition, you should check the parts on folding process and adjust it.

Printing mistake

Print Mistake-Sourced:higherinfogroup

No print on cartons may caused by the damage or break of printer if you printer is switched on. You can check the ribbon and cable of printer.

13.What You Should Consider For Choosing The Most Suitable Vertical Cartoner?

The suitable and reliable vertical cartoner can bring you high efficiency and profits. To choose the most suitanle one, besides your budget, you should also considering the below points.

Machine types

Need-Sources:mediamath

Choose your machine according to your need. Vertical cartoner has various types, which one you need? Continuous or intermittent? It depends on your need of products type, processing speed and operating process.

Machine performance

Performance-Sourced:openclipart

The machine with higher quality in its all parts and powerful technical service can serve you better as makes better products and takes longer length of service.

Maintenance difficulty

Maintenance-Sourced:fabtechexpo

Machine with easier maintenance can save you a lot of energy in machine caring. The easier maintenance can help you perform its daily care and check easier, and thus improve the life span as well as the working efficiency of machine.

After-sales service

After-sales Service-Sourced:xtenav

The after-sales service is also an important points about the machine selecting. Choose the company which provides reliable after-sales service. It is the embody of the company strength as well as a guarantee of your machine’s quality.

Conclusion

Vertical cartoner can take you a different experience in packaging. Hope you have get your wanted information in the complete buying guide of vertical cartoner. Believe me, the outstanding performance will benefit you a lot. It’s your best choice in cartoning. Wanna know more about the machine? Contact us now.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine