What Are The Most Common Problems Of The Tablet Coating?

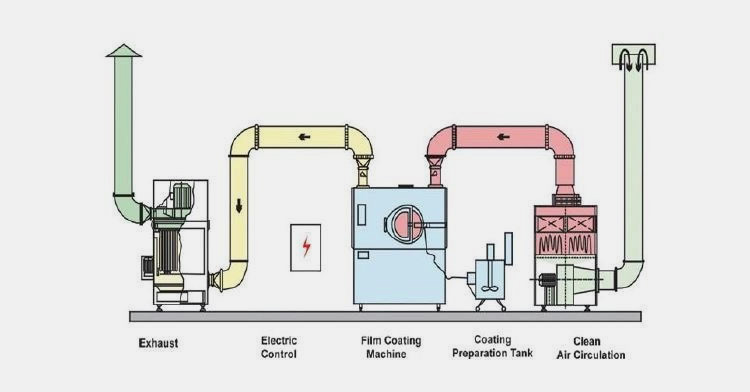

All operations of the tablet coating machine are completed on the touch screen of the computer control panel, and the operation panel is fully sealed light touch man-machine interface, reliable and stable performance.

Under the action of the linear guide plate agitator, the sheet core turns over smoothly and exchanges frequently, which eliminates the phenomenon of the sheet core falling from the height and colliding, solves the debris and the knock edge, and improves the yield.

The upper surface of the guide plate of the tablet coating machine is narrow, which eliminates the adhesion of excipients on its surface, saves excipients and improves the quality of drugs.

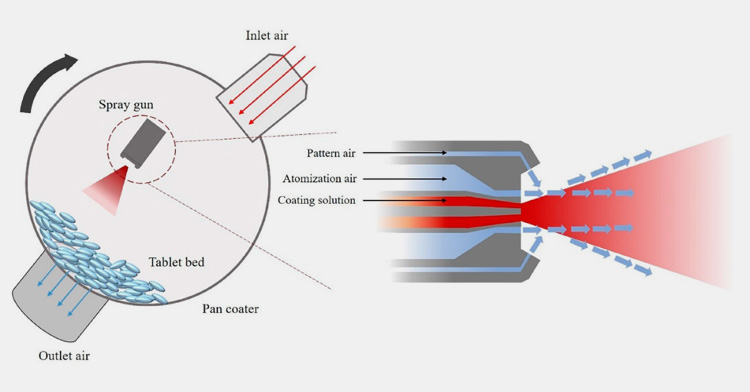

Working principle of tablet coating machine

Through the pot body clockwise, make it in the pot rolling and sliding friction grinding. Through people poured into the sugar powder, make sugar powder evenly distributed on all white pill, accompanied with the electrothermal blower, air outlet stretch goals for heating, at the same time passing a hot air blower to inner pot to remove tablet surface moisture, and degradation sugar coating tablets.

Characteristics

First, the control system composed of PLC and HMI is reasonable in design, flexible in programming, which can adapt to different pharmaceutical process needs, reliable in work, stable in performance, and meet the requirements of GMP.

Second, the plain tablet under the action of streamline guide plate agitator, smooth turnover, frequent exchange, eliminate the plain sheet falling from height and collision phenomenon, put an end to debris and knock edge, improve the yield.

The upper surface of the guide plate is narrow, which avoids the adhesion of dressing on its surface, saves dressing and improves the quality of medicine.

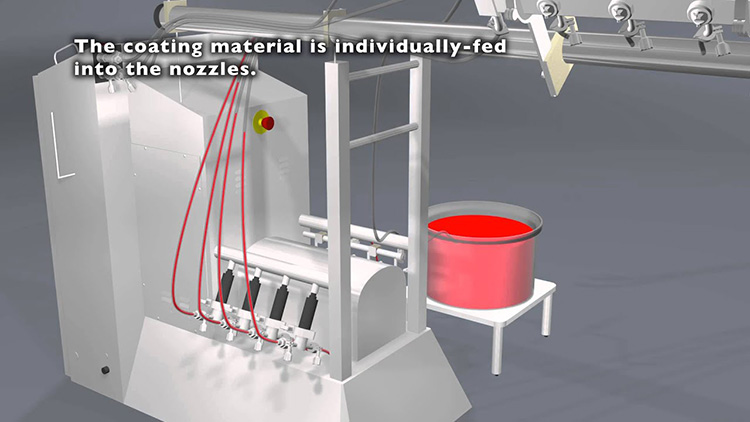

Third, Constant pressure variable peristaltic pump, eliminating the return line. The rotary radius of the roller changes with the pressure at any time, and the output slurry and spray amount are automatically balanced, which stabilizes the atomization effect, simplifies the spray system, prevents the spray gun from blocking, saves dressing, and is simple to clean with no dead angle.

Fourth, it is specially designed and manufactured for coating. The spray gun is made of uniform atomization, large spray surface, universal adjustable nozzle is not affected by the amount of loading. Spray gun blocking cleaning mechanism, can make the coating continuous, shorten the coating time, save the coating dressing.

There are more problems in the mechanical part of the tablet coating machine, which specially include the following points:

Tug wear

The Tug is the bearing parts of the roller is vulnerable goods, different manufacturers of tug are basically the same, abnormal situation is basically the screw off and bearing necrosis caused by the clamp wheel, surface nylon wear caused by the roller beating.

The front part of the tablet coating machine

Most of the tablet coating machines have a round door structure in front. The round door is divided into left and right doors. The spray gun rack is installed on the right door. The distance between the door shaft and the bracket of the right door is long, so there's basically a fixed screw in the middle.

However, in long-term use, the door shaft of the door equipped with the spray gun rack appears to tilt, resulting in the hanging of the entire spray gun rack. Especially in the coating process, the distance between the spray gun inside and the drug is close, that is to say, the distance between all the spray guns and the drug surface is not the same, which directly affects the coating quality.

Due to the tilt of the gun rack, the round door can not be closed effectively, and directly affects the negative pressure inside the coater cavity. The long-term negative pressure is not accurate, which directly affects the quality of the coating.

Spray gun blockage

Spray gun blockage is a common problem, the formation of the blockage is mainly caused by the design of the spray gun air path. Some imported airbrush guns also suffer from such design flaws.

Uneven mixing

In the design of the coating liquid stirring tank, there is a large distance between the stirring leaf on the stirring shaft and the bottom of the tank in order to facilitate cleaning. If the distance is close, the stirring leaf cannot be taken out for cleaning, and there is a design defect.

Wind speed and volume

The previous automatic and efficient coating machines basically have no device to detect wind speed and air volume. Some of them are equipped with wind speed and wind meter, but only the wind speed can be seen. The air volume needs to be calculated.

Matters need attention

First, each addition of liquid or powder should be evenly distributed.

Second, each time the liquid is added and evenly distributed, the solution should be fully dried before it can be added again. The viscosity of the solution should not be too large, or it is not easy to be evenly distributed

Third, powder coating is often used in the production of mixed slurry method, that is, powder suspension in the adhesive solution, added to the rotating tablet, this method can reduce dust and simplify the process.

Fourth, After coating, the finished product must be dried at low temperature (preferably air dried) and constantly turned.

Fifth, avoid exposure and high temperature drying, otherwise it is easy to make pills oily and discolored. After the air device is opened, it is forbidden to plug the air outlet with your hands or other things to avoid damaging the blower.

In the future of the development of machinery, the tablet coating machine equipment with the development of pharmaceutical industry will usher in more opportunities, the market will continue to expand.

However, it should be noted that in the context of the increasing concentration of the current coating machine equipment industry, the coating mechanism manufacturing enterprises need to accelerate the upgrade of innovative equipment, and pay more attention to the structure, material, flexibility and product quality.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine