Technical Process Exploration Of Tablet Coating Machine

Tablet coating machine is an energy-saving, safe and clean mechatronics equipment which can be used for organic film coating, water-soluble film coating, slow and controlled-release coating of tablets, pills and candies. A tablet coating machine is suitable for pharmaceutical, chemical, food and other industries.

In recent years, with the improvement of GMP standards, product quality and equipment requirements management have been improved. At present, the traditional coating machine on the market will be gradually replaced by the new tablet coating machine.

The tablet coating machine

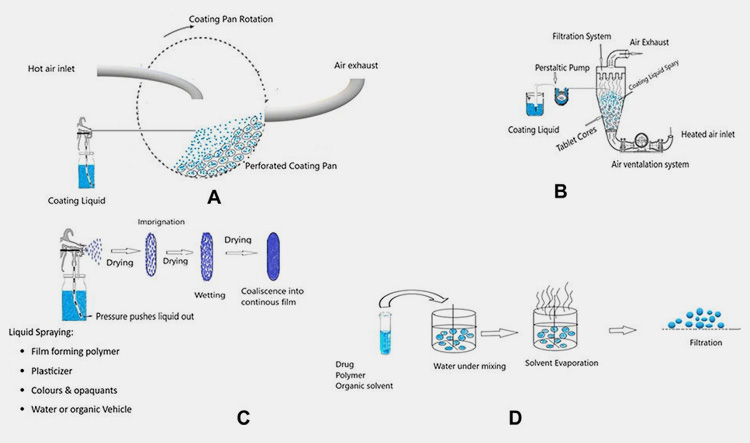

The tablet coating machine was born in the 1940s, it was first produced in the pharmaceutical industry. Its working principle is: the coated core is controlled by the programmable control system in the roller of the coating machine, so that it can continuously, continuously and repeatedly make complex trajectory motion.

In the process of movement, the control system can be programmed to control, according to the requirements of the process sequence and parameters, the medium is automatically sprayed on the surface of the core by spray gun in the form of mist.

At the same time, the hot air cabinet provides 100,000-level filtered clean hot air, which penetrates the gap layer of the chip core. The sprayed medium on the surface of the chip core fully contacts the hot air and gradually dries.

The exhaust gas is discharged from the bottom of the roller through the air duct by the exhaust fan after dust removal, so that the chip core forms a solid and smooth surface film.

The main purpose of the tablet coating machine is to improve the appearance and easy to identify, cover up the bad odor, easy for patients to swallow, reduce gastrointestinal reactions, control drug release, change the drug release curve.

At the same time, it can also avoid moisture, light and air to increase the stability of the drug. Compared with sugar coating, it has the characteristics of short production cycle, less material and strong anti-wetting ability.

In the coating process, according to the different solvents, which can be divided into water-soluble coating process and organic solvent coating process.

Film tablet coating machine

Film tablet coating is a new type of coating technology, which refers to the relatively stable thin molecular coating film on the core.

The film tablet coating technology can be widely used in tablets, pills and granules, especially for the traditional Chinese medicine tablets with strong hygroscopicity, easy cracking and patchy, which shows its superiority. It can be seen that the role of pharmaceutical film tablet coating is becoming more and more important in the field of medicine.

Medical film tablet coating technology is largely developed from sugar-coating, but compared with it, medical film coating has the advantages of good quality, quick drying, less pollution, low cost, wide application and so on.

Although the film coating material is expensive, the total calculation is not higher than the cost of sugar-coating because of the small amount, the saving of labor (1 ~ 2 operators), the need for less plant and equipment (only a standard factory and a coating pot), and the saving of materials and energy.

And in the process can reduce or avoid dust in the workshop, is conducive to environmental protection and labor protection, and can prevent pollution in the workshop, in line with the GMP clean requirements.

Water chestnut type tablet coating machine

Water chestnut type tablet coating machine is a kind of equipment for sugar-coating and film coating on the outer surface of Chinese and western medicine pieces.

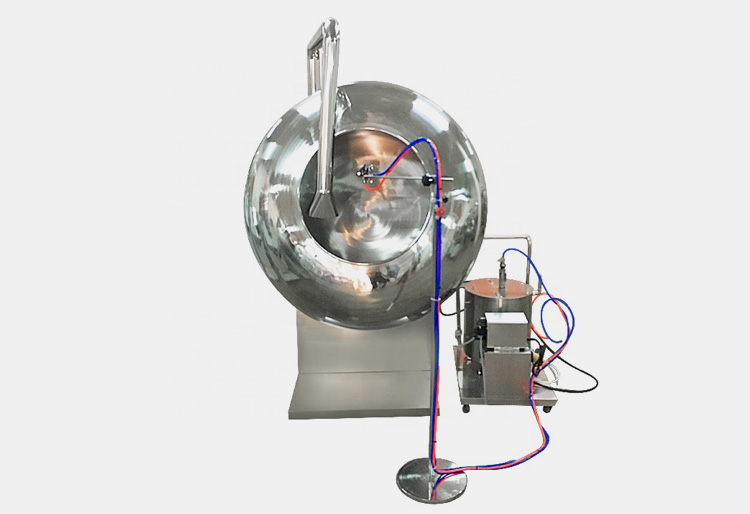

It is a new type of equipment which integrates strong current, weak current, hydraulic pressure and pneumatic, and transforms the original ordinary type sugar-coating machine.

It is mainly composed of main engine (original sugar coater), controllable warm air system at normal temperature, automatic liquid and gas supply spray system and so on.

The main motor can be controlled by frequency conversion, which is used spray coating materials onto the surface of the tablets with a high atomizing spray gun automatically controlled by electrical appliances, and at the same time the tablets move in a continuous and complex trajectory in the coating pot.

The coating liquid was evenly wrapped on the tablet core, and the controlled warm air in the pot was used to dry the tablet at the same time, so that the tablet surface quickly formed a firm, fine, complete and smooth surface film.

The water chestnut tablet coating machine has the advantages of simplicity, easy operation, one-sided smoothness, brightness, delicacy, saving auxiliary materials, easy maintenance and so on. It is an ideal equipment for experiments.

Intelligent tablet coating machine

With the development of intelligent technology, intelligent coating machine comes into being. The equipment is improved on the basis of the coating machine, more widely used.

It is reported that the intelligent tablet coating machine of the new technology has the ability to coat 0.2kg, 1kg, 3kg, 5kg, 8kg and 13kg with the same machine, which greatly improves the practicability of the coating machine in research.

The control system composed of PLC and HMI is reasonable in design, flexible in programming, which can adapt to different pharmaceutical process needs, reliable in work, stable in performance, and meet the requirements of GMP.

The various process parameters of the intelligent coating machine are all digitized, more controllable and convenient to analyze the production data and optimize the production process.

It mainly includes air inlet and exhaust temperature, humidity, air volume, wind speed, coating spray pressure, flow rate, sheet bed temperature, etc. Moreover, the modular conversion between various batches is particularly convenient and only takes 5 minutes.

The industry professionals predict that the tablet coating machine industry will continue to develop towards intelligence, energy saving and centralization in the future.

Therefore, only by investing more effort, continuously strengthening study and research, investing in technological innovation, and improving equipment level, the tablet coating machinery manufacturing companies can meet the needs of the industry and promote the new development of the tablet coating machine industry.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine