Tablet Manufacturing:the Complete FAQ Guide in 2024

You must know tablets are one of the most widespread and popular dosage forms on the pharmaceutical market.

However, although all final tablets may look simple and self-contained, the underlying manufacturing processes can be highly complex.

So,”Knowledge is Power”,you must get the basic knowledge about this tablet manufacturing to further well conduct your production.

In today’s guide ,I will use every knowledge to explain the great technique to let you well understand how that tablet dosage form was made out.

Let’s start directly.

1.What is Tablet?

Tablets

Tablets are hard forms of drugs consisting of drug substances generally set up with the drug excipients. shape, size, and hardness of all the tablets may vary.

It all depends on the technique to produce the tablet. Powder and granules are compressed to make the tablets.

2.What is Advantage of Tablet Dosage Form?

These are the advantages of Tablets.

Dosing Accuracy

It has high exactness level, most minimal changeability, steady and precise dosing.

Sugar Coating

Sugar coated tablets

To finish the displeasing taste of tablet sugar coating is done on the tablet it gives sugar taste to the tablet. So, anyone can easily eat that.

Production Cost

The production cost of tablets is very low when we compare it to any other drug. Color coating is used on the tablet for the identification purpose.

Safe from Atmosphere

It is sealed or covered that way it is safe from all the conditions of the atmosphere like light, air and moisture etc.

Easiness

It is easy to use, easy to carry anywhere, and easy to divide it if you want a bit of the tablet.

Manufacturing of Tablets

It is very easy and cheap to manufacture the tablet. Packaging of tablets is very cheap and easy.

Tablets are Flexible.

Different color, size, and shape of tablet -Photo Credits:Golerich pharma

Tablets are very flexible, you can easily adjust the shape, color, and size of the tablet according to your requirements.

Formulation of Substance is Easy

You can easily mix two or more substances and convert it into the tablet which is an easy process compared with drug processes.

3.Are there Any Disadvantages of Tablet Dosage Form?

Tablets do not have many disadvantages, but these are some of the cons of the tablet.

- To finish the bitter taste of the tablet. You must do the sugar coating of the tablet. This may increase the cost of the tablet, but it is not necessary to do the sugar coating.

- You cannot convert all the drug substances in the form of tablets because it may cause some problem in your digestive system.

- Some drugs are amorphous, and it is very difficult to compress it into the tablet form.

4.How Many Types of Tablet are there in the Pharmaceutical Industry?

There are many types of tablets in the pharmaceutical industry some of these are.

- Sugar coated tablets

- Compressed tablets

- Film coated tablets

- Chewable tablets

- Buccal tablets

- Layered tablets

- Lozenges

- Gelatin coated tablets

Sugar Coated Tablets

It is a type of tablet which is coated by the sugar which is used. Sugar coated is used to change the bitter taste of the tablet. It increases the weight and size of tablets.

Compressed Tablets

It is a tablet which is made by the compressing of powder and granules. It is the most made tablet. It is either in a coated state or uncoated state.

Film Coated Tablets

Film coated tablets-Photo credits:pharma excipients

It is a type of tablet which is coated by the polymer or the mixture of polymer. It takes more time to coat the polymer than the sugar coating, small and durable than the sugar coated.

Chewable Tablets

It is a tablet which is very big in size and only chews. You cannot eat it directly, you must chew this tablet before eating.

Buccal Tablets

It is a circular shaped and small sized tablet. It is manufactured that way it is only dissolved when you put it underneath the tongue. It breaks up expeditiously and gives fast medication impact.

Layered Tablets

It is a tablet which has two or more layers of powder, granules, or any other material.

It may be two layered or three layered depending on how many materials you want to fill in the tablet. Each layer has different material because it is not compatible.

Lozenges Tablets

It is a very hard sugar candy which has medicine in it. It is expected to be dissolved gradually.

Gelatin Coated Tablets

It is a compressed tablet which is coated with the gelatin. It may have been covered with one- or two-colored gelatin. It serves the same purpose as the sugar-coated tablets.

5.Why Should You Invest on Tablet Manufacturing?

Rising graph tablet-Photo Credits:kelwonareal estate

You should invest in tablet manufacturing because it is the industry, which is boosting every year, not only tablet manufacturing but the whole drug industry is boosting it is not going down because the population of the world is increasing, and every man needs medicine.

Now due to the covid-19 people are using medicine more and more so you should invest in tablet manufacturing moreover it is best time to invest in the pharmaceutical industry.

The worldwide drug market is going to reach 198 billion dollars by 2022 with a compound annual growth rate of approximately 6 percent. Patent lapse of conspicuous medications, government activities, local entrance and growth of old age people are a portion of the variables that are driving the market development. strict rules and regulations are given by the World health organization and divided markets are the components that are creating hindrance in the API market development.

6.What is the Primary Goal of Tablet Manufacturing?

Different tablets

These are some of the primary goals which every manufacturer tends to achieve.

- To form tablets that are solid and difficult to withstand mechanical stun experienced during assembling, pressing, dispatching, administering and use.

- To make tablets that are constant in weight and in medication content.

- To form tablets that are bio accessible as per sign necessities.

- To manufacture the tablets that are synthetically and stable throughout a significant stretch of time.

- To form tablets which have a great quality and do not have any flaws.

7.What is the Raw Material for Tablet Manufacturing?

Raw materials are the substances utilized in both compound combination and preparing and incorporate supports, cleaning specialists, regular solvents, and ordinarily utilized engineered beginning materials, for example, amino acids.

Excipients are substances that are utilized as fixings in drug details, for example, tablets and cases. Ordinary excipients incorporate straightforward salts, for example, NaCl, solvents, sugars, cleansers, seasoning specialists, and colors.

At the point when these materials are conveyed, they should be tried to affirm that they are sure what they guarantee to be and have not been improperly named. It might likewise be important to utilize a quantitative separative technique to show the quality and substance of chose materials.

8.How to Evaluate the Quality of Raw Material for Tablet Manufacturing?

Quality is the most important factor in any industry, but it is the major factor in the drugs or medication industry. These are some of ways to ensure the quality of material.

Ensure That You Have the Right Material.

While picking up the material for the product manufacturing there are some things that you must keep in mind in advance.

First thing that you should know about the availability of the material is how much material is available in the market.

So, if you need that material so you can easily get it. Second thing that you must know is that this material is safe for utilization and there is enough data and science that backs up.

Research about Material and Provider

Probably the greatest advance of the quality control measure is to guarantee the materials given by the provider are of the most ideal quality whenever you have ensured the item configuration is all set.

For instance, you can find out about the provider's standing and history to get a thought of how solid they are probably going to be. You can likewise associate straightforwardly with the provider and test the materials already for quality confirmation.

Checking every Supply Chain

This is the last step where you must check and access everything properly.

If there is a need for any action you must do it because after that manufacturing process starts.

If there is any problem after that it could adversely affect the quality of the item.

9.What is the Tablet Manufacturing Process?

These are the steps which include the manufacturing of tablets.

Dispensing of the Material

It is the most important step in the formulation of tablets, and it must be done under the supervision of technical staff. It is the first step every material is weighed accurately according to the formula of the dose.

Sizing of the Material

Formulation material should be in finely partitioned structure, in any case, size decrease ought to be done for better stream property and simple blending.

Powder Mixing

Mixing of a powder using a blender which suits your need and getting a homogenous solution. Excipients and medication substances are blended in a geometric dilution.

Granulation of Material

Powder particles are assembled in the form of layers, and lasting totals to deliver them into free-streaming states.

Drying of Granules

You need to dry the wet granules for the specific time span in the liquid bed dryer or plate at the temperature of 550 degree Celsius and the temperature must not surpass.

Compression of Tablets

In this step granules are compressed into different shapes like circular, oval, rectangular or any other shapes. You can put any other symbol and code number on the tablet.

Coating of Tablet

In this step tablets are covered if there is need to be to finish the unpleasant taste of the tablets. By coating the tablet, it becomes colorful and pleasant.

10.Which Factors will Affect the Tablet Formulation during the Tablet Manufacturing Process?

These are the factors that will affect the tablet formulation in the manufacturing process.

Compression properties of the Material

Distinctive pharmaceutical materials or API’s have distinctive compression properties. You should select the process that does not merge with the API’s. you should research in advance about the compatibility of API’s.

Stability of Material

Tablet formulation may change the physical and chemical stability of the API. So you should be very cautious when you are choosing the process for formulation. Ensure that the integrity of the API is not lost.

Particle Size

You should always look for the particle size of API’s before selecting the process of formulation. Different formulations have an explicit size of particle. It may require small sized or large sized particles.

Equipment Availability

There must be all the equipment available that are required in that formulation process. Check all the equipment that are required if it is not available then choose a different formulation.

Manufacturing Cost

It is the most important factor in any process to determine the cost. Look for how much this formulation costs if the cost of this formulation is high than choose any formulation cycle.

11.Which Equipment are Needed for the Tablet Manufacturing?

Different types of equipment used in tablet manufacturing. The equipment is as follows:

In Size Reduction equipment different types of things can be used to reduce the size. Like hammers, cutters, rollers and different kinds of equipment.

Balancing of weighing equipment is done by the mass weighing balance which weighs the mass in kilograms. And the electronic weighing balance which weighs the mass in milligrams or grams.

In Blending Equipment there are the devices used to blend are some different types of mixers such as DTH series post bin blenders and AIPAK HTD series bin blenders.

The Grinding Equipment include HLSG series high speed mixing granulator, GK series Granulator and other AIPAK Products.

There is also equipment for Controlling the Quality. For example, Tablet hardness tester, Tablet thickness tester, USP dissolution tester.

Spray dryer, rotary dryer and fluidized bed dryer are included in the Pigmenting Equipment.

Varnishing and Coated Machines for coated tablets include Air suspension coating system, standard coating pan and perforated pan.

The Tableting Machines include single punch tablet press and multi-layer rotary tablet machines.

AIPAK rotary tablet press machine

And finally, there is the Packaging Equipment including the AIPAK blister packing series and other related machine .

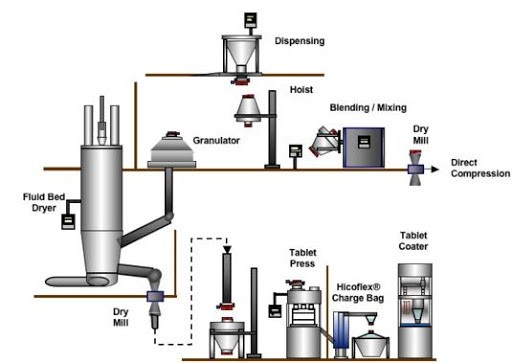

12.What are the Techniques Used in Tablet Formulation?

Tablet Manufacturing Process-Photo: pharmatips.com

Table manufacturing is not a very common method of manufacturing tablets. So, tablet producing requires a specific degree of mastery to perform the work well.

It is very important to have some certain strategies to produce tablets.

It is likewise imperative to permit the medication blend to stream openly from the tableting machine container to the passes on.

This will empower the pressure of powder blend at an extremely high pace into tablets.

The techniques which are used in tablet manufacturing are as follows:

Wet Granulation Process

The wet granulation method is used to produce the compressed tablets. This granulation method has many steps to manufacture the tablets.

So, you can get all the physical properties of tablets by the granules you are using in the granulation process.

These are the steps given below of the granulation process:

Mixing and Weighing

This is the first step of the granulation process. In this step, at very first you have to gather all the fixings that you require for making tablets.

From that point onwards, weigh all the fixings by using the weighing apparatus in the pharmaceutical.

After the weighing process you have to measure the exact amount of the ingredients used for the granulation process.

And the very important thing you should have to keep in mind during mixing that there will be no usage of any lubrication in the method.

So, this is all you have to do in the first step.

Adding of Binder Solution

This is the second step of the granulation process. In this process you have to blend all the binder solutions with some powders.

And this mixing of binder solution results in a tincture of a damp mass.

Here the step two ends.

Wet Screening

Moving on to the third step of the granulation process. This is the step where you should screen all the damp solution you made in the second step into some pellets or granules.

You will have to utilize almost 6 to12 mesh screens to form the pallets from it.

Drying of Granules

This is the second last step of the granulation process. In this step, you have to dry the wet granules by different kinds of dryers that are in your process.

So, you have to dry until the last particle of granule is fully dried by the dryer. Here the fourth step ends in drying.

Granulation Sizing

This is the last and important step of the granulation process. In this step you have to make sizes from the 14 to 20 mesh screens.

After doing this, you have to blend the dry granules with some lubricants.

In the last compress all the granules to make tablets from it.

The table manufactured by a wet granule process has some mechanical properties.

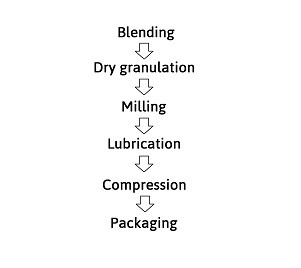

Dry Granulation

After the wet granulation method of manufacturing tablets. There is another method called dry granulation method. This method is also called the double-compression method.

In this process you can enlarge the size of the tablet and it will also upgrade the characteristics and compression of a tablet.

The Dry Granulation contains two types of methods.

- Roller Compaction

- Slugging techniques

These two methods will give you alternative output.

The first method is roller compaction. In this method the essentials used for the tablet manufacturing passes through some rollers and becomes into the shape like solid mass.

The second method is Slugging Techniques. In this method of tablet manufacturing the tablets are being squeezed or high pressed by the machine.

Furthermore, the Dry Granulation of tablets is also a step-by-step process. The steps of Dry Granulation are as follows:

Elements Weighing

In the first step, weight of the ingredients is measured. And also, you can reduce the size and weight of it in this step.

Ingredients Mixing

In this process the material of the tablets is being mixed in the mixer. To avoid the thrust of the powder you can also add half the amount of material in it.

Mixture Compression

In this step Dry Granulation, the mixture is being compressed to make tablets. In this process it’s up to you to choose the slugging method or roller technique to complete compression.

Sieving

This is the fourth step of Dry Granulation. In this step, sieving is done after the milling of the ingredient to produce some granules.

Blending and Disintegrating

This is the second last step which comes after the sieving. In this step, the remaining ingredient is again blended and also it disintegrates.

Granules Compressing

This is the last step of Dry Granulation. In this step the tablet is being compressed to make shapes and fit with the punches. The coating of tablets can also be done in it.

13.What is Tablet Manufacturing Granulation?

Dry Granulation Method-Photo credit: pharmaapproach.com

The main procedure of manufacturing tablets is granulation procedure. The granulation process has two kinds:

- Dry Granulation

- Wet Granulation

So, it is the procedure of making granules from the granulation.

Granulation process helps the combined particles of powder to make the huge size granules.

The procedure is also used for the tablet production at commercial level.

The granulation process gives access to the particles to twig strongly. This will increase the size of the ingredients used. And helps in the increasing the binding ability.

14.How can you Conduct Direct Tablet Manufacturing Compression Method?

Manufacturing of Tablets -Photo credit: pharmaguideline.com

The tablets can be manufactured by the direct compression method without other methods like granulation. This process is very easy.

This process can be done only by blending the material into the mixer. And after doing this squeezed or compressed the tablets.

The process can only be achievable if you have the material that is very consistent.

Moreover, there are some methods for direct compression. So, these methods or techniques are as follows:

- Usage of die feeders in the compression

- Usage of dry Binders in the direct compression

- By using direct compression excipients

Furthermore, the procedure has different steps to follow:

Pre-Milling

This is the first step of the Direct Tablet Manufacturing Compression Method. In this step, grind all the elements which are active.

Blending

Now, in this step, mix all the active elements with some powder and ala add some lubrication if needed.

Compression

This is the last step of formation of tablets from the direct method. In this step, you can simply compress the blended powder you make to produce tablets from it.

In the end a desired tablet is being formed by the Direct Compressed Method.

15.How to Compare Various Steps used in the Tablet Manufacturing Process?

| Wet Granulation | Dry Granulation |

| · It is the procedure of making granules from the granulating liquid.

· In the wet granulation, blending of powder is done in it with the granulating fluid to make tablets. · Wet granulation needs only the particles of powder and a granulating fluid or a strainer. · High moisture and heat sensitive compounds required for the production of the tablets. |

· It is the procedure of making granules without any helping material like solution.

· In the dry granulation, the direct compression of powder is done. · The requirement for dry granulation is the good quality powder and tablet pressers. · To avoid the destruction of active elements it is necessary. |

16.What Tests can you do to Make the Quality Control?

Quality Control Test for Tablets -Photo credit: pharmapproach.com

There are some quality tablets before using them. These tests will give the assurance that the tablets are not harmful for humans and they are antitoxic.

Before using the tablets, you have to go through from the process which is in the form of some quality tests.

So, the tablets need to follow the tests given by some authorities of the Pharmaceutical Industries.

The arrangement of tests falls under two principal classifications which are:

Pharmacopoeia

The tablet should have the test of Pharmacopoeia. Is also called the official test.

The tests are true since the testing system is in the authority compendia including the English Pharmacopeia and American pharmacopeia.

These are quality testing techniques that have clear limits which directs the levels a tablet should reach.

In this quality test, testing the substance of the dynamic fixing or unquestionably the substance of the medication.

Also, testing the heaviness of the tablets.

Then, consistency of the tablets.

So, these tests center around the substance or in vitro arrival of the dynamic fixings.

You should ensure that the substance on the fixing rundown should coordinate the substance of the tablets. Aside from that, the substance of the tablets ought to adjust to all the necessities of the authority test.

Non-Pharmacopoeia

The last test for tablets is Non-Pharmacopoeia which is also called non-official test.

These are the tests that you will perform on the tablets despite the fact that they are not on the authority compendia.

It concerns various quality ascribes that you need to assess including:

- It tests the porousness of the tablets.

- And also, the squashing ability or solidity of the tablet.

- The important one is the thickness test.

- The vast majority of these tests don't have an authority testing limit for acknowledgment and differ starting with one producer then onto the next. It might likewise fluctuate as per the plan.

- Despite the fact that the devastating strength limit was on the English Pharmacopeia, it has no restrictions set to it. it will, along these lines, stay under the non-official test.

- Quality trials of pharmaceutical tablets expect you to be incredibly sharp. Any deformity may make inconvenient impacts on the last purchaser.

- You need to play out these tests during the cycle of creation of the tablets.

- After the creation of each cluster, you ought to likewise play out a confirmation test.

17.What are the Common Problems of Tablet Manufacturing Process? How to Solve them?

Defects

There are some common problems that occur in the manufacturing of tablets. And also, there is also a solution for that problem too.

So, the common problems are:

Sticking

This occurs in tablets that have very low dissolving centered substances. These substances cut down the speed of lower and upper punch leads and weight assortment of the tablets.

It achieves the game plan of chipping and terrible surface tablets and improvement of materials on the two punches.

- Solution

Complete or fractional replacement of the segments with low liquefying focuses with high softening point substances.

Appropriately drying the granules to take out the abundance dampness.

Appropriately choosing great mixing agents.

Poor Flow

Inappropriate planning of the container.

Helpless stream capacity of the granules.

Angling or connecting of the granules at the base of the container.

Delineation or isolation of the particles by utilizing stream advancing gadgets, for example, vibrators.

Flood of the overabundance stream over the container.

- Solution

Improving the stream by utilizing glidants.

Appropriately planning the container.

Appropriately utilizing the stream upgrading gadgets like the vibrator.

Arrangement of uniform shapes and sizes of the granules.

Lamination

Lamination Problem-Photo credit pharmamanual.com

Lamination is the division of a tablet into at least two particular level layers.

It occurs due to the presence of oily material in the granules. And also due to extra usage of the lubrications.

- Solution

To solve this problem, you have to adjust your blending procedure.

Moreover, you have to use a very short amount of the lubrication an also substitute the kind lubrication if possible.

Poor Blending

Inappropriate blending of the fixings, for example, greases and glidants which are significant for legitimate punching and stream.

Lacking or inadequate blending time.

- Solution

The solution to this problem is the exact blending of the substance. The blending should be done by the appropriate blender.

Cracking

Cracking of Tablet-Photo credit: filmcoating-troubleshooting.com

The cracks come on the top and the bottom layer of the tablets. This happens because of the huge sized granules used. And due this results in the enlargement of the tablet.

- Solution

So, the solution to this problem is to use small size granules which were fit for the tablets.

And also, it will be solved by putting the dry binders in it.

Picking

Picking-Photo credit: filmcoating-troubleshooting.com

Picking is the more explicit term that portrays items staying just inside the letters, logos, plans on the punch faces.

It is due to the improper drying of granules. And also due to excessive use of binders.

- Solution

To solve this problem, you have to dry the granules in the proper way.

And to alternate the or decrease the binder.

18.How can you Package and Sort Tablets in the Pharmaceutical Industry?

Tablet Packaging Machine-Photo credit: directindustry.com

Packaging process comes after the tablet manufacturing process. So, you have to package the tablets in the right way.

The kind of packing materials that you will utilize will rely upon your own decision.

The most well-known techniques that you may use in packing the tablets incorporate blister and jug bundling.

After that you will store them in a spot with low moistness and cool temperatures.

Blister Packing

AIPAK Tablet Packaging Machine

This an overall term for preformed plastic pressing for drugs, for instance, tablets. The chief pieces of the rankle pack in the thermoformed plastic.

It has a fundamental pressing that will include the thing and hold it set up. The main fundamental fragments of the rankle packs are the opening and the lidding.

After that cover it with a discretionary packaging for social occasion all fundamental groups in a solitary spot.

It moreover has a paperboard backing or an aluminum driving foil or plastic seal. You may moreover use a clamshell which is a sort of rankle that folds into itself.

You need to use the rankle groups for unit bundling of measurements.

Bottle Packaging

AIPAK Tablet filling and bottling line

This sort of packing is useful for extremely solid tablets that can't break without any problem. You have to put the tablets in a jug which is the essential bundle.

From that point onward, you have to cover the container with a top which goes about as the auxiliary packing.

This sort of packing is useful for extremely solid tablets that can't break without any problem. You have to put the tablets in a jug which is the essential bundle.

From that point onward, you have to cover the container with a top which goes about as the auxiliary packing.

In the wake of packing the tablets in either the blister bundle or container bundle. You will put them in a tertiary bundle like boxes for mass dealing with.

19.Are there any Personnel Requirements during the Pharmaceutical Tablet Manufacturing?

Tablet testing-Photo Credit:texturetechnologies.com

Yes, there are some personal requirements during the manufacturing of Pharmaceutical Tablets.

Production Pharmacists

A production drug specialist works in an organization producing drugs. He takes orders from the creation supervisor and regulates fabricating exercises.

He additionally regulates workers, plans creation targets, and takes dynamic support in the administration job of the organization.

Manufacturing Chemist

Manufacturing Chemist is the main magazine for the drug business.

Manufacturing Chemist brings you expert improvements across all the zones of the pharma inventory network, just as thorough specialized articles, market examination and experiences into the issues forming the business consistently.

Analytical Chemist

Analytical Chemists survey the compound construction and nature of substances. Their abilities are required for an assortment of purposes including drug improvement, criminological examination and toxicology.

Analytical Chemists can have practical experience in territories as fluctuated as toxicology, drugs and legal sciences.

Quality assurance manager

Quality assurance chiefs assume a vital part in business by guaranteeing that items meet certain edges of adequacy.

They plan, immediate or organize quality confirmation programs and detail quality control strategies.

They likewise work to improve an association's proficiency and productivity by diminishing waste.

Machine operators

Machine Operator works forte apparatus to create, fabricate, amass, or move items. Keep up and screen the machine to ensure it works appropriately.

Comprehension of how machines function. Lead quality checks occasionally. Confirm satisfactory materials and supplies are accessible to finish activities varying

Investigate machine activities and yield if material

Change machine varying for changeovers, various capacities, or other fluctuating necessities of creation.

Mechanics

A Mechanic is liable for examining and fixing apparatus.

Mechanics also called Administration Experts, these experts direct upkeep examinations, screen stock, amass mechanical parts, and perform fixes. They for the most part work in carports that are inside.

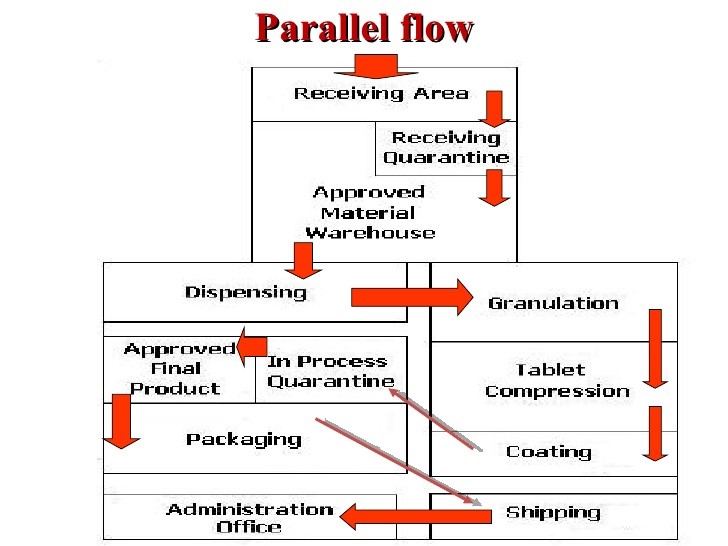

20.What is Area and Environment Requirement for Pharmaceutical Tablet Manufacturing?

Layout of Tablet Manufacturing-Photo credit:slideshare.net

Specific areas are required for the manufacturing of tablets. Without the specific area tablets cannot be manufactured easily.

Raw Material Store Room

A raw material stockroom centers around the capacity, transportation, dissemination, and get together of crude materials utilized for a producers' business.

Material coordination is fundamental for each business, so distinguishing a distribution center accomplice that rehearses legitimate capacity and the board methods is pivotal.

Dispensary

A dispensary is an office in a mechanical plant, or other association that administers meds, clinical supplies, and now and again even clinical and dental treatment.

In a customary dispensary set-up, a drug specialist administers medicine per the solution or request structure.

Production Room

Production is a very important area of the tablet manufacturing process. In the production room you can do production according to your need.

Production room has some sections like:

- Blending, Drying, Granulation

- Punching

- Plating Section

Section of Quality Control

In the Quality Control Section, you check for the best quality.

Packaging Section

The last area of the tablet manufacturing process is the packaging section.

So, the packing of tablets is done in this section. With suitable presentation and with great protection, the tablet is being packed here.

Don't forget to share this post!

Tablet Press Machine Related Products

Tablet Press Machine Related Posts

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine