How To Press Pills?

Unscrewing the cap of bottle and releasing pill to administer has passed through multiple transition i.e., powder to aesthetic compact dosage.

Pill is oftenly prepared by combined forces of punches and dies, these’re responsible for uniform distribution and maintaining a mutual relation of excipients and active ingredients.

Yes, press pills is not just a technique but involvement of good equipment is essential to bring good outcome.

In this article, we’ll emphasize valuable discussion about ‘How to Press Pills’. Moreover, this process include multiple factors you must consider to make your own.

Read on to know:

1.What is History of Press Pill?

In ancient times, Egyptians were used to prepare hand made little balls. These were composed of medicinal extracts combined with honey or grains. Following them, Greece did the same; a roman author Pliny who termed these little pellets (Pills) as Pilule.

The dose of pellets was undoubtedly inaccurate. With the development of modern sciences and technology, more powerful techniques and dose estimation ways were implemented. The needs of these measuring dose were considered as essential to protect wellbeing against undesirable adverse effects.

The emergence of press pill became mandatory to achieve uniform dose distribution and compact formulation till end user.

It was William Brockendon, who invented Press Pill machine first time in 1843 and granted this patent for developing lozenges and using pressure dies.

This popular device was stimulant in the era of production sciences where not only medicines were manufactured but various supplements as well.

Today, press pill can generate pills of various sizes, shapes with often embossed marked identification of your brand. Now, more than 2/3rd of solid dosage formulation is basically manufactured in the form of tablet pills. This technique has intricately maintained the production balance in required formats.

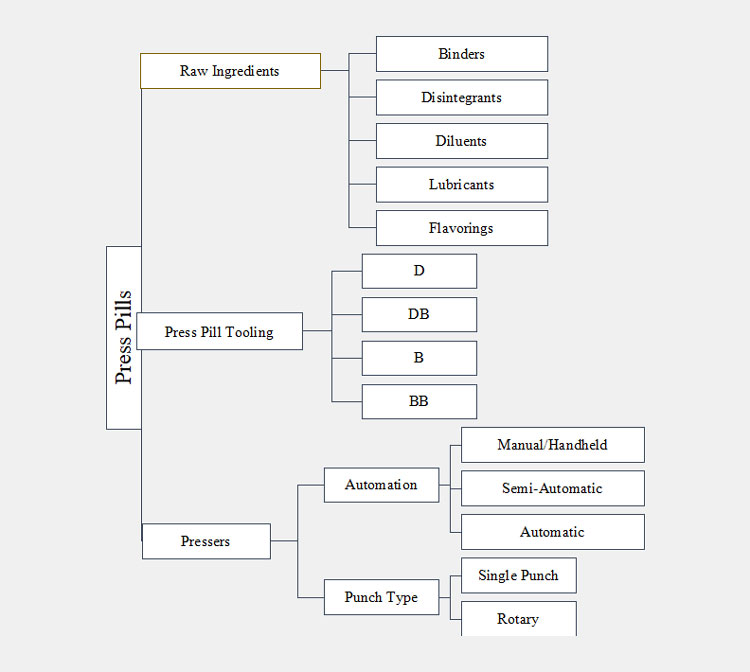

2.What are Materials required for Press Pills?

RAW INGREDIENTS

Making pill is not just compressing the powders into tablet, but their manufacturing requires estimation of various excipients that ensuring good quality product.

The excipients are inert; they do not potentiate any positive or negative effect on performance of active ingredient or shelf life of the pill. But they help to make an integrate formulation. For example:

Binders

Binders are entities that promotes the rigidity of the pill- because we need something that firmly stick the molecules of the pill’s ingredients, and binder perform this job very well.

Binders are of two types, known as wet and dry binders. Simply, wet binder needs water to stimulate the task whereas dry binder works by direct compression.

It is reported that binders can make 2 to 10% of total volume of the pill. If concentrations of binders are too low, it results in breakage or softness. Similarly, a high concentration can form a rigid formulation or may affect equipment functionality.

Common Wet Binders

Sucrose,

Gelatin

Starch and

Polyvinylpyrrolidone (Povidone)

Common Dry Binders

HMPC or Methylecellulose (HPMC)

Polyethylene Glycol

Disintegrants

The role of disintegrants is significant when you swallow the pill; it is added to dissolve the ingredient it reaches the active site. This breakdown process is known as disintegration. Disintegrator works in many ways; dissolves in contact with water either by up taking water molecule or absorbing and breaking them down via swelling.

A harder pill with increased compression and high binders molecules will simultaneously require more amount of disintegrators to break them inside the body.

Common Disintegrants

Sodium Carboxy-methylcellulose

Starch

Cellulose

Sodium starch glycolate

Diluents

These are also known as fillers. If the volume of pill is too small for e.g one milligram; fillers are added to make up the volume for easy handling and administering task. An ideal weight of any pills varies from 50mg to 500mg.

Again, these are inert in nature having no therapeutic activity, but they may penetrate into the active ingredient and absorb them so lowers their optimum concentration. Hence it is necessary to study the interactive behaviour of fillers prior using them.

Secondly, assessing solubility is crucial as sugar fillers can rapidly solubilized in water as compared to cellulose derivates that delays the release of active ingredients. Therefore, these factors should be ignored.

Common Diluents

| Lactose

Glucose, Or sucrose Sorbitol, Mannitol HPMC, And some inorganic chemicals such as calcium hydrogen phosphate. |

Glidants

They’re known as antiadherent; mean they improve flowability of the powder and minimizes the chances of stickiness during manufacturing. During production, glidants are incorporated into the mixture before press pill. They’re presented either hydrophilic or hydrophobic in nature, you must assess its properties before using them. A required concentration of glidants in pill ranges between 0 to 1% w/w to reduce the friction or improving ingredients flow.

Common Glidants

| Silica (colloidal silica)

Magnesium stearate Talc Starch |

Lubricants

It performs similar function as glidants, it facilitates smooth press pill procedure allows easy filling, compression and ejection for every batch. They’re added up to 5% in pill formulation; due to hydrophobic in nature, it may affect disintegration ratio if used in excess.

Pills are prone to stick at the edges of die and difficult to eject from it, or heat generation during compression also cause this problem. That’s why, lubricants significantly release formed pills without exerting much force or risk of stickiness. Thus, glidants and lubricants combinedly improves the flowability.

Common Lubricants

| SSF or Sodium stearyl fumarate

SLS or Sodium lauryl sulfate Stearic acid Polyethylene glycol |

Flavorings Agents

An important components added in pill mixture to mask unpleasant taste of chemicals or odors. They’re especially added for formulation belonging to peads or older population to increase patient compliance.

Common Flavoring Agents

| Strawberry

Peppermint, Vanilla Sweeteners |

PRESS PILL TOOLING

Press pill tooling play a significant in the making of pill. When designing a pill, you must keep dies and punches in your mind. They’re known as compression tool or pill tooling.

To cater pharmaceutical industry these tooling is presented with diverse range and shapes.

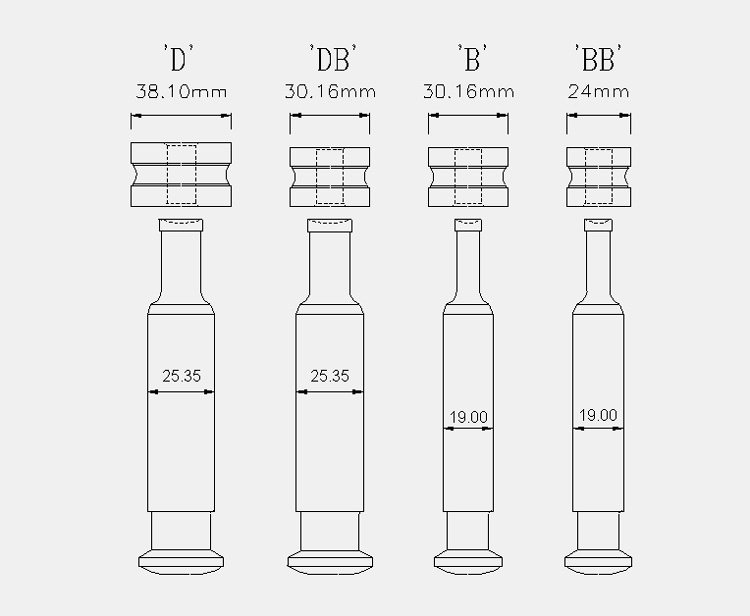

There are two standard of tooling used globally.

Tableting Specification Manual (TSM)

This is exclusively used in the United States and represented by American Pharmaceutical Association for tablet designing and pressing. Their measurement is represented in inches and imperial units.

Euro- Standard (EU)

This is primarily utilized in Europe as well as across the globe. They’re based on ISO 18084 standards.

| Work Length | Barrel Diameter | Die Diameter | Die Height | ||

| Euro-Standard | B | (133.6 - f) ±0.01 mm | 19 mm | 30.16 mm | 22.22 mm |

| D | (133.6 - f) ±0.01 mm | 25.35 mm | 38.1 mm | 23.81 mm | |

| BB | (133.6 - f) ±0.01 mm | 19 mm | 24 mm | 22.22 mm | |

| DB | (133.6 - f) ±0.01 mm | 25.35 mm | 30.16 mm | 22.22 mm | |

| Tableting Specification Manual (TSM) | B | (5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm | 0.784 inch / 19 mm | 1.1875 inch / 30.16 mm | 0.875 inch / 22.22 mm |

| D | (5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm | 0.998 inch / 25.35 mm | 1.5 inch / 38.1 mm | 0.9375 inch / 23.81 mm | |

| BB | (5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm | 0.784 inch / 19 mm | 0.945 inch / 24 mm | 0.875 inch / 22.22 mm | |

| DB | (5.250 - f) ± 0.002 inch / (133.35 - f) ±0.05 mm | 0.998 inch / 25.35 mm | 1.1875 inch / 30.16 mm | 0.875 inch / 22.22 mm |

Both of these standards are represented with sizes D, DB, B, and BB types. Additionally, they’re also represented by as TSM19 and TSM1’ where 19 and 1 demonstrates the outside diameter of punch barrel.

D Tooling

These tooling is commonly used for pills with larger diameters. They are capable to produce pill with up to 25mm size.

DB Tooling

These are similar to D tooling but the diameters range between them.

B Tooling

This tooling generates pills of nominal maximum round size up to 16 mm in both EU and TSM.

BB Tooling

This is similar to B tooling in punch length and diameter but die diameter varies between them.

TYPES OF PILL PRESSES

The types of press pill is categorised into two parts: Based on automation (handheld, semi-automatic, and automatic) and based on punch types (single and rotary).

Based on Automation

Handheld Punch

This press pill is a game changer for those who wish to make their own pill at home. Additionally, this machine is also applicable for commercial use but for small production, such as R&D or business entrepreneurs who want to develop a new supplement.

An ultimate production solution where the entire operation is performed manually in a wide range of shapes and designs. This machine is portable, small, and cost-effective with a small set of die.

Semi-Automatic Press Pill

An electric as well as hand operated machine, suitable for small industries or production batches with or without electric power. This machine is single press, can press various type of pills such as effervescent, sugar, or standard pills. in this machine, you can adjust filling depth as well as thickness.

Automatic Press Pill

With multiple punch, an automatically operated press pill is highly suitable in a large production batches. A PLC controlled machine that offers highly sophisticated operation in no time. From pressing till ejection, machine won’t ask any external helping hand. A high volume production sequence is carried out by auto-analysis, adjustment and powder depth controlling.

Based on Punch Type

The punch type of press pill is almost similar in every machine, but they are slightly different when it comes to the number of punches. For e.g.:

Single Punch Presses

This type of press pill is also termed as ‘single station press’ or ‘eccentric station press’.

This is a very simple machine that is equipped with an upper and lower punch and a die.

Working

It works by moving the upper punch while the lower punch remains stationary.

An upper punch exerts compression force over a lower punch for producing pills. This machine working is known as ‘stamping’ due to its hammer-like movement.

Multi-Station/Rotary Presses

As its names indicate, there is a number of multiple tooling stations installed in the turret. Upon movement of turrets; upper and lower compression rolls move up and down that produces a uniform and compact set of pills in a bulk. In this type of press, an upper and lower punch move simultaneously.

Working

The whole process takes place in the rotational movement of turrets hence known as the rotary press. The primary aim of this machine is to achieve pressed pills in large quantities. Moreover, there are various sizes and designs of punches available that helps you in creating pill of various shapes and dimension.

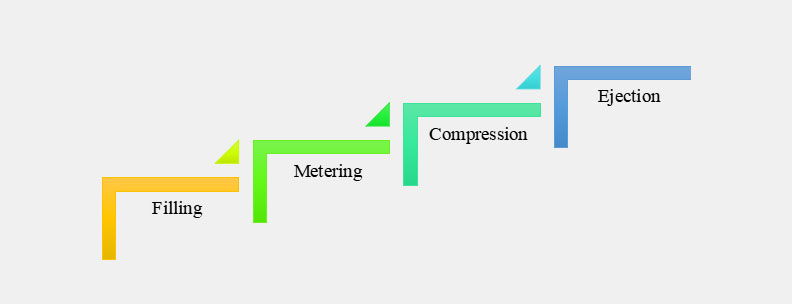

3.How to Press Pill?

The pharmaceutical industry or large-scale manufacturing plants usually employ semi-automatic or automatic pill presses. These machines produce a large number of tablets in a short time.

Hydraulic pressure is exerted by the movement of punches to convert granules into solid pills.

Unlike handheld machines, pill compression in this equipment is carried out in four steps.

Filling

First, the granules are loaded into machine hopper. The lower punch is pushed down for creating space in die cavity. The feeder is placed on top of die cavity from feeder the granules move down into the die tooling for compression.

Metering

In this step, excess material is expelled from the die tooling. Desired weight of granules in die is depended upon the level of lower punch.

Upward movement of lower punch at the metering stage pushes out surplus granules out from die. This is essential in maintaining required volume of granules in die tooling. Excess material is taken out from the die table by swipe blade.

Compression

This step is executed by the movement of punches that are in turn controlled by the of cam track.

At compression stage, the upper and lower punches move within large wheels called pressure rolls. Lower cam track raises lower punch while upper cam track pushes upper punch down consequently these punches exert force for granular compression into tablet.

The thickness of tablet is depended upon the distance between both punches. If punches have large space between them then resulting tablet will be softer and thicker. Conversely, less distance between punches produces harder and thinner tablet.

Ejection

It is as the name indicates at this stage the newly formed tablets is removed from die tooling. At beginning of this stage, the upper punch is moved back and is positioned above torrent. Then lower punch is lifted upward which sequentially push the tablet from die cavity to the top and out of tooling.

Afterwards, scrapper is employed for expelling tablet from die table to collecting bin.

Conclusion

Whether handheld or mechanically press pill; it requires series of steps to follow, for e.g. choosing material, punch size, batch size etc., How to Press Pills article is a brief overview of certain phases that you must know when designing them. For Equipment Procurement or Information, we suggest Contacting our Experts Team Now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours