Pills Press Machine:The Ultimate Buying Guide in 2025

Could your pills manufacturing machine be working harder for you?

Could you make an upgrade production process?

Could you enhance the quality of your pill’s products?

Be it in the pharmaceutical or cosmetic industry, pill press machine is always considered as the most significant and preferred tool to utilize for manufacturing products.

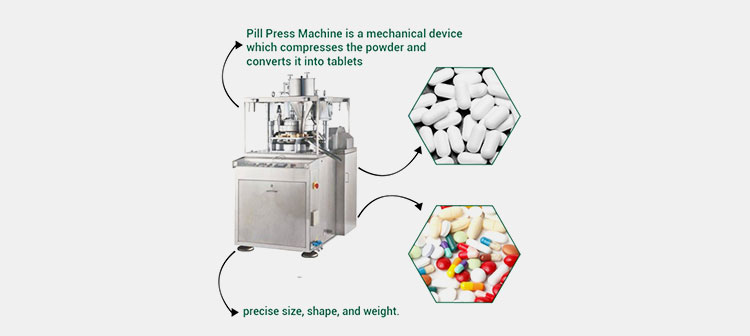

Accelerate your pharmaceutical Pills Manufacturing to Improve QualityPill press machine is a technical device that is driven to compress the powder particles that convert them into a compact tablet form with a precise volume, shape, and weight.

Pills press machine from various categories always employs with the same working principle of compression.

As the pharmaceutical sector is constantly focused on improving the optimization of operational equipment, a high production pill press machine should not be an exception. There are advanced pharmaceutical facilities launching all the time and they are implementing innovative technologies that the industry has to offer.In this article, we will look at excellent options that will enable you to increase production efficiencies by investing in pill press machines. Also, we will discuss the Back to Basic approach for the pills press machine.

So, Here We Go!

1.Do you know what exactly a pill press machine is?

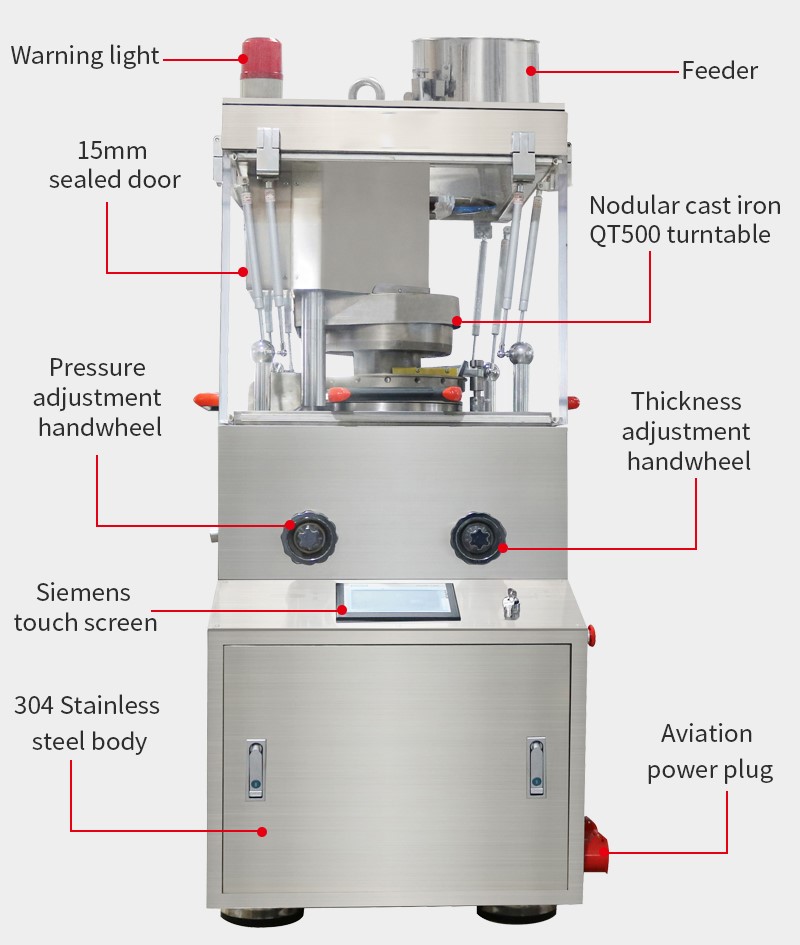

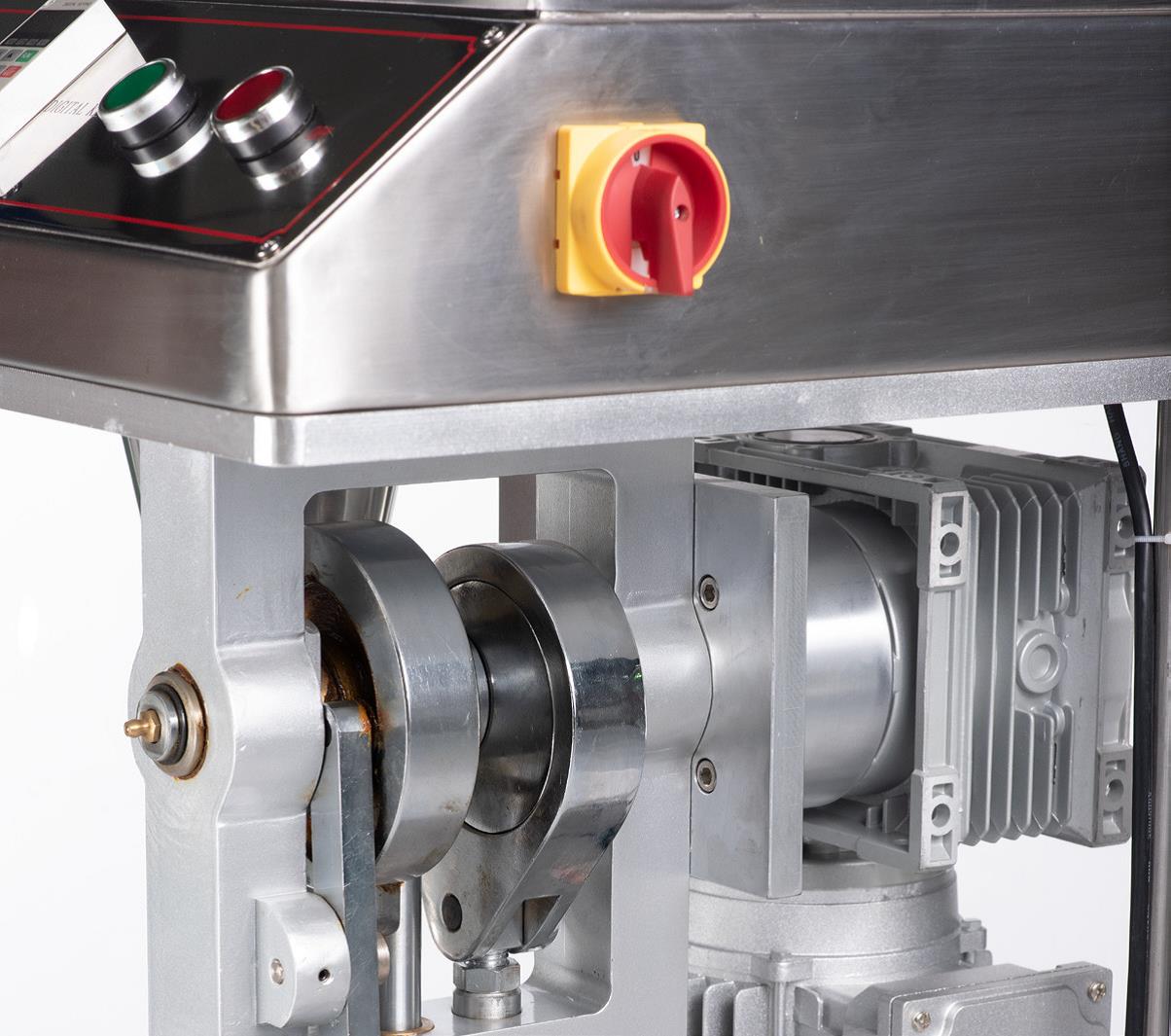

AIPAK pill press machine

Pill press is a traditional machine, broadly utilize to transform powder into a compact tablet form of uniform size and weight.

This machine is also termed a tableting press machine.

Pill press machine allows pharmaceutical, nutraceutical, agricultural, cosmetic, and other industries to manufacture a variety of small or large batch of pills.

Originally pills press machine is conceived as a tool for pills development and manufacturing. The pill press machine is comprised of a die mold that allows the powder to hoard entirely and gives them a shape and marking on pills.

There has been a constant improvement in the ‘pills press machine’.

Initially, the pills press machine was used to be a hand-driven device as compared to today’s where it is operated by an electrical system.

The constant need for development for pills press machines was required due to the high demand for pills as there was a massive increase in pathological scenarios in the healthcare unit.

So, the high demand for pills required a higher production ultimately more tweaks in the technology.

2.What is the working principle of a pill press machine?

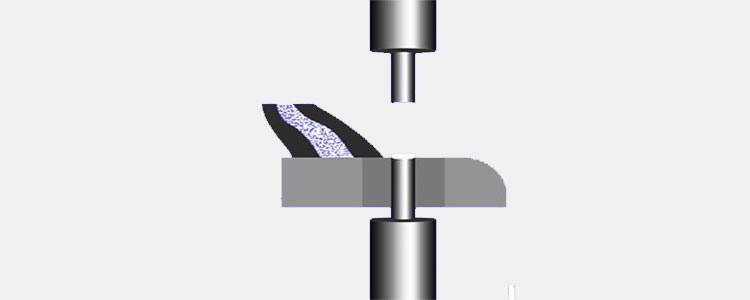

The main working principle of the pill press machine is based on compression of an upper and lower punch of die hole or a station. Hydraulic pressure is playing an essential role.

External pressure is transmitted by static fluid in all directions. It is also possible to increase predetermine forces as needed for the formation of pills.

3.What are the classifications of pills press machines: Which Pills press machine you should buy?

It is always overwhelming when you are going to select the right machine, but you cannot decide which machine will work best for your requirement.

Because there are uncountable pill press machines available in the market.

So, it is important to know the classification of the pill press machine.

There are two basic types of pills press machines for e.g., single station and multi-station pill press machines. Let’s see their quick informative summary.

Single Station Pill Press Machine

A single station pill press machine or you call it a single punch or eccentric press machine.

This is the simplest version of a press machine that uses a single tool station that contains a die along with pair of upper and lower punches.

This machine is driven manually as well as a powered operation. The compression force of a single punch pill press machine is exerted by an upper punch whereas a lower punch remains immovable.

Hence, it is nothing to say wrong if this motion is kind of hammering on the lower punch. This compression of upper punch within a die roll results in the formation of a tablet within a die cavity.

So, choosing a simple or complex die structure is essential when you are expected to lower the degree of counterfeits.

Single Station Pill Press Machine

This machine is basically meant for small-scale production purposes mainly used for Research and development and clinical trials.

Multiple Station Pill Press Machine

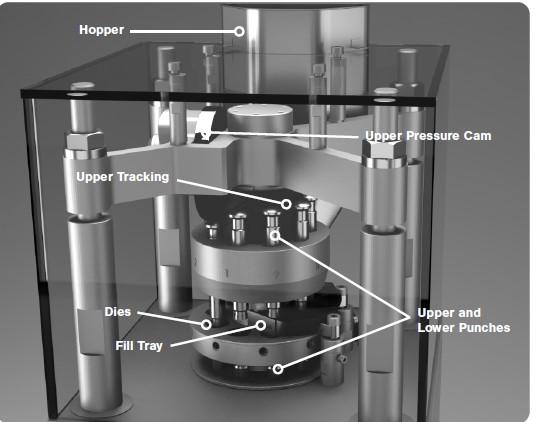

AIPAK multiple station pill press machine

A multiple station pill press machine or you can term it a rotary press machine. A multi-station pill press machine is the most likable and popular machine in the large industrial sector such as pharmaceutical, nutraceutical, etc.

The reason behind its popularity is

- high efficiency

- high production,

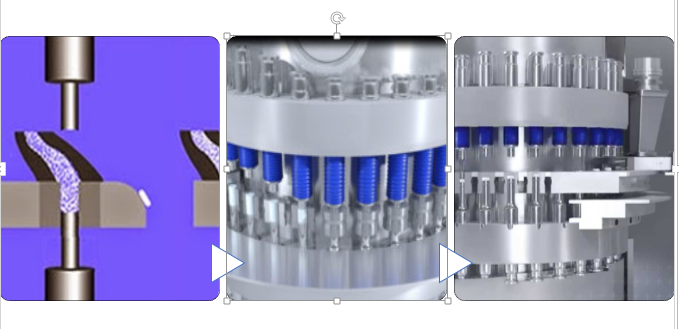

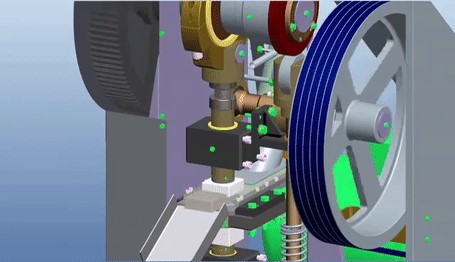

- cost-effectivenessThis machine comprises a head that holds die with upper and lower punches. The lower punch of the multiple-station pill press machine is continuously in a rotary or angular motion (spinning around an axis of its own).

Its name rotary is coined due to rotating pills assembly (dies, upper and lower punches).

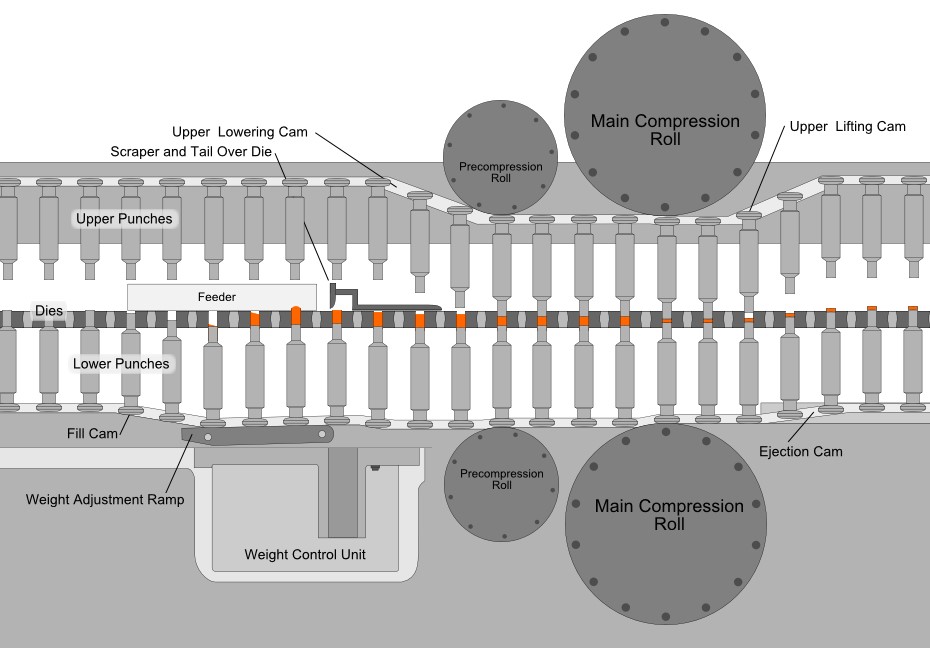

Assembly of rotary pill press machine- Pill press machine

During the operation of the multiple station rotary press machine, the head of the machine rotates which leads to the motion of punches up and down. A fixed cam track controls the process of compressions such as filling and ejection.

An example of rotary motion- Pill Press Machine

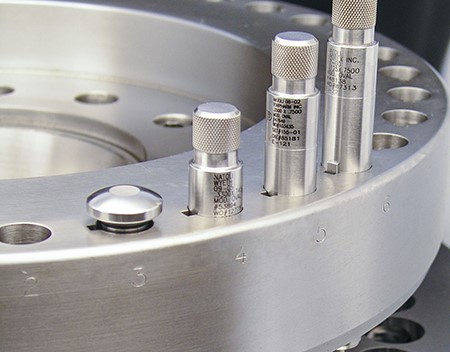

A segment head that holds both upper and lower punches is known as ‘Turrets’. Furthermore, a portion that holds a die is known as a table die.

Pills Press Turret

4.What are the basic components of a pill press machine?

Indeed, the Pill press machine is comprised of a number of complex components. But we will focus on simple and basic components of single and multiple punch pill machines.

Part of pill press machine

Here we go!

The principal components of the pill press machine are as followed:

1) Top Cam

The Top Cam guides the punches’ movement. For instance, as the wheel of a single punch machine is operated the Top cam withdraws the upper punch from the die cavity.

Top Cam- Pill Press Machine

2) Hopper

The hopper is a siphon/channel that retains the granular or powder material. This feeding material is poured prior to the process of tableting or compression.

Hopper can be filled either mechanically or manually following the process of pill pressing before it moves into the Boot to be compressed.

Hopper- Pills Press Machine

3) Boot

Boot accepts feeding material from the hopper to the compression tooling and ejects the pills. Boot fills up the Die bore with powder mixture and moves finished product out of Die bore before next refilling material is introduced into it.

Boot- Pill Press Machine

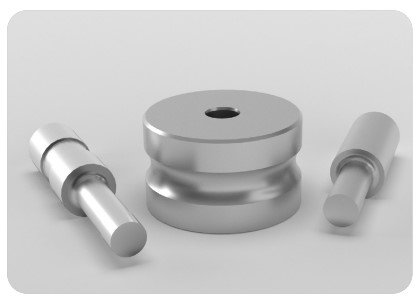

4) Die

A die cavity that allows powder granules or mixture into it. This is a part of the Tooling of pills press machine (die, upper and lower punch) that makes up a cavity for which powder is pressed and forms a shape.

Die cavity determine the following factors

- Diameter of pills

- Size of the pills

- The thickness of the pills

Tooling- Die- Upper Punch and Lower Punch- Pills Press Machine

5) Upper Punch

An upper punch is part of die assembly, that moves downward within the die body to convert pressure into powder material available in a die cavity.

6) Lower Punch

A lower punch that retains the materials and compresses them within a die cavity. After compressing powder material into pills form, a lower punch is pushed upward to eject the pill. The pill is then pressed out of the way by the Boot to make it ready for the next pill compression.

7) Upper and Lower Tracking

The upper and lower tracking guide the Tooling of the pill press machine.

8) Fill Tray

The Fill Tray delivers the pills materials towards Die bores and pushes pills into the discharge chute.

9) Discharge Chute

The discharge chute receives a final finished form of pills after ejection into a collection bin.

Pill Press Machine

10) Programmable Logic Control System

A pill press machine is a continuous automatic machine for compacting and pressing raw material into pill form. Pill Press machine is designed to manage speed, depth of filling, and thickness of pills by continuous monitoring system based on a computed customized program using PLC control system.

5.What are the advantages of a pills press machine?

The pill press machine is very profitable equipment that offers the following advantages.

- The pill press machine is very simple and easy to operate.

- If you consider the dimension occupying capacity of the pill press machine, then you will find pill press machine occupies lesser space and offers a robust design.

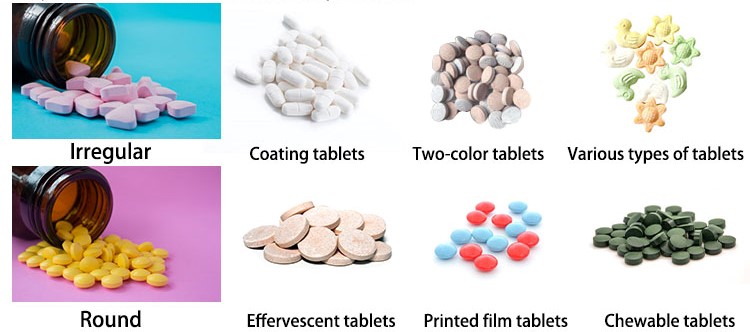

- Pill press machines offer pill manufacturing in many shapes, designs, and sizes.

- From small batches (single station) to large batch (multiple stations) production, pill press machines are always suitable to meet your requirement.

PLC control system- Pill Press Machine

- If you consider a rotary or multiple-station pill press machine it is a highly efficient tool that is cost-effective than a single station pill press machine.

- For a continuous product such as more than 8000 to 200,000 pills per hour. A multiple station pill press machine is recommended and beneficial to give 100% excellent output.

- The pill press machine is a highly consistent and accurate machine due to various automated features that lower the chances of human error.

- A PLC system-controlled pill press machine can manage the hardness, thickness, and various parameters required for pill press processing.

6.What is the production line of the pills press machine?

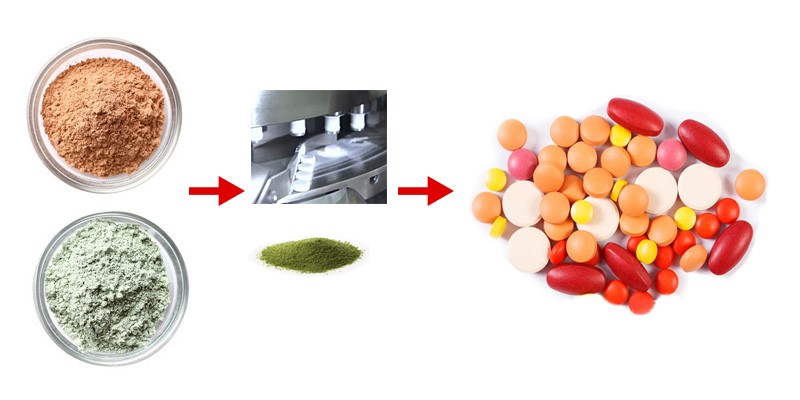

The production line of the pills press machine is comprised of four prime stages. Such as,

1) Filling

In this stage, raw material is filled into a position of pill compression station. This raw material is already treated with wet or dry granulation using a roller compaction machine.

The purpose of using roller compaction is to obtain well-defined granular material of suitable size for final formulation. The final preparation is then combined with other components to yield a homogenous blend. This blend is then poured into a pill press machine.

The granulation material is overfilled on the turret (die table) that ensures a complete volume is filled into a punch die cavity.

2) Metering

In this stage, an overfilled material is removed from compressing machine. Thus, exact weight is achieved for compressed pills. The exact weight of pills is managed by the height of the lower punch of the die known as a metering cam or dosage cam.

Metering- Pills Press Machine

3) Compression

As its names shows, high compression within a die. This step of pill compression involves bringing upper and lower punches getting closer that ultimately exerts compression to create a pill. The distance between upper punch and lower punch determines the thickness and degree of hardness of the pill. For instance, the level of closeness of punches can define either pill is thin or hard. If punches are farther then a created pill would be softer and thicker and vice versa.

Compression Process- Pills Press Machine

4) Ejection

After punching, the tablet is discharged from the die. In this stage, an upper punch gets withdraw from the die cavity and moves above the turret table, while a lower punch moves in the die.

This results in the pushing of pills upward to the top surface of a die cavity. A scarper or take-off blade then pushes a tablet off from a die table into a collection bin.

Production Line- Filling- Compression- Ejection- Pills Press Machine

Video Credit- IHolland

7.What are the versions of the pill press machine?

The basic version of pill press machines is as followed:

1) Manual Pill Press Machine

2) Semi-Automatic Pill Press Machine

3) Automatic Pill Press Machine

1) Manual Pill Press Machine

A manual pill press machine is the most powerful and efficient pill press machine suitable for R&D and healthcare clinics. This is the simplest version contains a single station press for pill manufacturing. You can use this machine by hand operation for pressing raw material to convert them into different shapes, sizes, and weights of uniform pills.

Manual Pill Press Machine – photo credit- IndiaMart

2) Semi-Automatic Pill Press Machine

A semi-automatic pill press machine is a highly advantageous machine that can be electrically driven or by hand crank when an electric power supply is not available.

Semi-Automatic Pill Press Machine- Photo Credit- MIC

Like other machines, the semi-automatic pill press machine is also constructed of stainless steel with a smooth surface that yields high productivity. Moreover, you can use a variety of dies with options of adjusting the depth, thickness, and hardness.

Different Shapes of Pill Can be Manufactured- Semi-Automatic Pill Press Machine

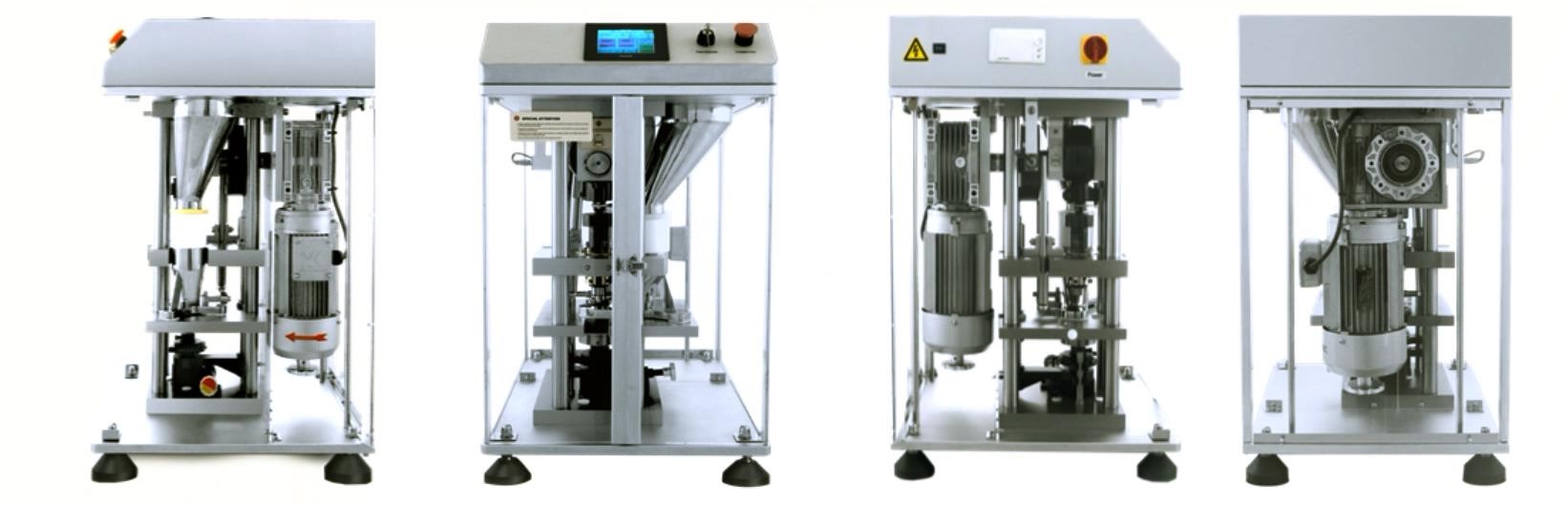

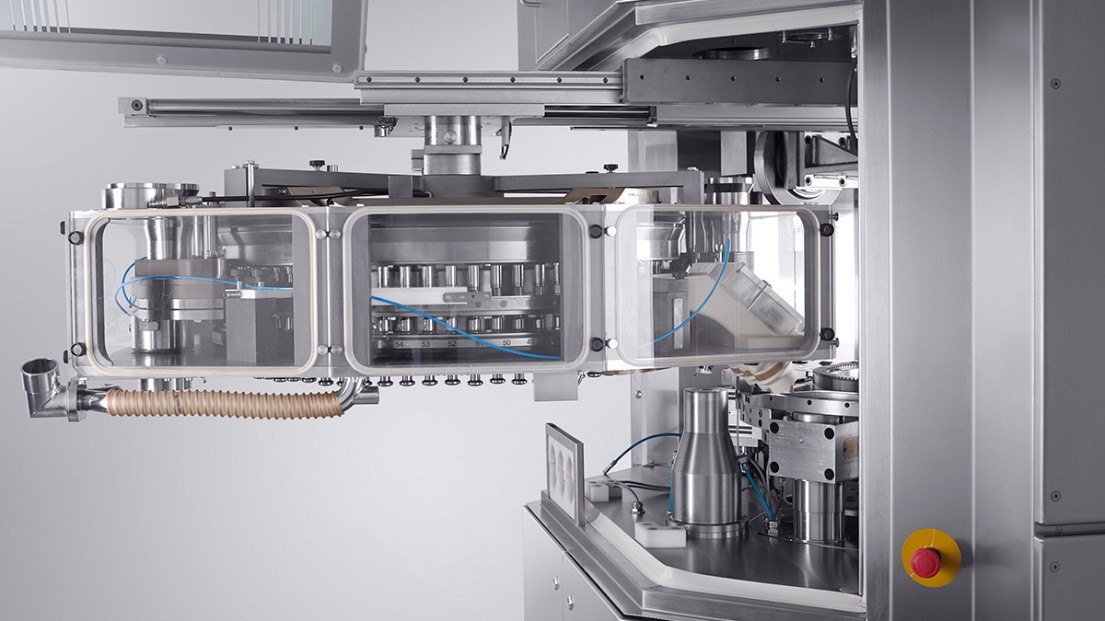

3) Automatic Pill Press Machine

AIPAK automatic pill press machine

The automatic pill press machine is a highly stable and most efficient form of pill press machine ideally used for large-scale pills production.

An automatic pill press machine is available in a single press, or continuous press for pressing granular material into pills formulation.

The automatic pill press machine has an enclosed system and is made up of stainless steel that is fully GMP complied equipment.

The automatic pill press machine has various impressive features related to processing, cleaning, maintenance, and product finishing.

Furthermore, due to the enclosed system, the automatic pills press machine allows maximum products safety and protects your products from cross-contamination.

8.What are the industrial applications of pills press machines?

The pill press machine is ideally suited for a wide range of industrial applications such as:

1) Pharmaceutical Industry

The role of pill press machines for the development and manufacturing of pharmaceutical products is unquestionable. Pill press machine has widespread applications in this sector.

A pill press machine is extensively utilized in the formulation and making of various shapes and sizes of pills.

Pill press machine, a user compliant machine that allows smooth and rapid production line considered the most suitable equipment for running a large-scale production unit.

Pill press machine offers superior automation, high-level consistency that permits modern ergonomic aspects that fulfill the demands of pharmaceutical applications.

2) Food and Confectionary Industry

The pill press machine is applicable in the food industry and confectionery industry for the manufacturing of either fruity flavor pills with added fruit powder, natural flavor, or chocolate pills that kids enjoy the most and much more.

A pill press machine is specifically designed to yield a safe, high-speed production for making food items for the small or large production unit.

Food industry -Pill Press machine

3) Nutraceutical Industry

Nowadays, nutraceutical products are the most preferable and attractive form of medication that is easily accessible without requiring a prescription.

Many of you believe that this is the safest and most natural mode of medication.

This is true!

Nutraceutical Pills- Pills Press Machine

If you compare previous data, you will assess a gradual increase in the production revenue of nutraceutical items. For instance, antioxidants, vitamins, dietary products, etc., many of them are available in the form of nutraceutical pills.

Hence, the increased demand for nutraceutical pills necessitates pill press machines. Pills press machine offers streamline production for a wide range of nutraceutical items to meet the market requirement for nutraceutical pills.

4) Veterinary Industry

Have you ever observed how a home with a domestic pet is beautiful? Or how do farmers prevent their animals from disease, cure sickness, and even reduce their pain?

This is all about a veterinary industry that manufactures unlimited veterinary medications to protect animals from various pathologies.

A pill press machine is of prime importance that supports the veterinary community by high ongoing medication production. The pill press machine assesses the product behavior, proper measurements, and production speed that helps in attaining a final finished form of pills.

Veterinary Pills- Pills Press Machine

5) Chemical Industry

Many chemicals in research or scientific laboratory are dispensed in the form of pills. These pills might be hazardous or safe that depends upon the nature of a substance.

The pill press machine is an essential equipment of pill manufacturing that is extensively used in the chemical industry. You can use a manual or rotary pill press machine that is based on your production capacity of chemical pills. Thus, a pill press machine offers a secure, precise, and secure manufacturing of chemical pills with lesser chances of error. Examples of chemical pills are PBS, buffer, or pH pills.

6) Agriculture Industry

The pill press machine is consistently progressing in the manufacturing sector of an agricultural system. Pill press machine plays an important role in the manufacturing of pesticides, insecticides, or growth-promoting pills.

9.How to operate a pills press machine?

The operations of the pill press machine have three basic steps which are filling the hopper, condensing the powder, and expelling the pill.

- Filling the Tooling (Upper Punch, Lower Punch, and Die)

- First dry powder is dispensed into the hopper.

- Hopper transfers these materials into the Boot of the machine.

- If the hand wheel is rotated manually then Top Cam is moved to remove the Upper Punch from the Die.

- But if the machine is operated automatically then the Gearbox of the machine starts the working of Top Cam which removes the Upper Punch from Die.

Pill Press Machine- Photo credit- GEA

- Condensing the Powder

- After packing the powder in Tooling components, Tom Cam forces the Upper Punch into Die and Lower Punch.

- Then these two punches apply high pressure to compress the powder.

- Expelling the Pill

- After the condensing of powder, Top Cam pulls out the Upper Punch

- Lower Punch is drive up to release the pill.

- The boot of the machine then forces the pill out of the path so that machine is ready for manufacturing the next pill.

10.How to manage and maintain a pills press machine?

Maintenance is necessary for a long and healthy life of a pill press machine. Cleaning and lubricating machine parts help in the proper operation of the machine.

General Maintenance

- Grease points should be properly maintained and lubricated.

- It is important to use the proper amount of lubricant as a surplus lubricant can leak into tablets.

- Proper oiling and drying of parts of the machine should be ensured before restoration of the machine after cleaning.

- Loose nuts and screws should be checked incessantly before and after operating the machine.

- If a machine is not operated for more than a week, then Tooling components should be stored in a sealed container and should be enclosed with lubricant.

Lubrication

Properly greased machines have long-lasting operational life. It is vital to greased machine parts as they can get jammed resulting in serious problems. These steps should be followed by proper lubrication of the pill press machine.

- First, apply the finger-sized amount of grease to Boot Timing Cam sides. The boot Timing Cam runner and the Lower Drift Pin Assembly Timing Rod runner should be properly lubricated.

- With the help of a grease gun smear the grease on Top Cam.

- Afterward, rub the grease on Upper Drift Pin Assembly.

Lubrication Schedule

- Tooling Heads should be lubricated with assembly paste after cleaning.

- The gearbox should be greased with 460 Grade Worm Gear Oil weekly.

- Top Cam, Boot Timing Cam, and Upper Drift Pin Assembly should be lubricated after manufacturing 50,000 tablets and cleaning with NLGI Grade 2. These should be lubricated when not in working for a long time.

Lubricating parts- Pills Press Machine

Cleaning

It is very important to clean properly the machine parts like Hopper, Tooling, Boot, and the base. These get rusted and contaminated if not clean of surplus powder which gets drip into these parts.

Removing Parts for Cleaning

- First Perspex Doors should be opened and then with the help of the Allen key, the Ejection Tray should be removed.

Set of Allen Keys- Pill Press Machine

- Extract Hopper upwards from the top part of the machine.

- Then use Allen Key to loosen up the Boots screws.

- Detach Boot Bolt and spring from the bottom of Boot.

- Use Allen key to slack the Boot Timing Bar Extender from Boot.

- Afterward, undo two bolts from the lower end of the Base Plate by using a 17mn wrench.

- Extract Boot and Boot and the Base Plate.

- Let down Upper Drift Pin Assembly by machine rotating the machine manually.

- By using wrench undo Upper Punch Locking Nut but keep Upper Punch Drift Assembly in position by the second wrench.

- Release the Upper Punch physically.

- Pull out the Die from the center of the Base Plate. Use a hammer to softly tap the Die for its extraction.

- Use Allen key to undo Lower Punch's bolt with an Allen key and extract the Lower Punch.

Cleaning- Pills Press Machine

Clean the Base

- Remove powder and debris from the base with a vacuum.

- Spray cleaner on the Tooling area and base.

- Wash the cleaner with water.

- Dry the base with a clean cloth.

Clean the Parts

- For each and every part of the machine, first, immerse them in the soapy water. Wash every part separately for proper cleaning.

- Use a clean cloth for properly removing dust particles from the machine parts.

- With the toothbrush, get rid of hard-to-remove debris. Soft cloth and soft pipe cleaner should be used to clean the tooling area.

- Arid machine parts right away after rinsing the soapy water from machine parts.

- A clean cloth is sanitized machine parts after drying.

11.What are the common unavoidable problems that occur with pill press machines? What are the possible solutions to deal with them?

Sometimes, it is really difficult to manage unavoidable problems that occur during operation. These problems not only affect your production line but also affect time and cost.

Troubleshooting during pills manufacturing

Therefore, it is recommended to be fully aware of each component and operating procedure of the pill press machine. Because it will let you know troubleshooting with failure of pill press machine.

Fortunately, there are some key points that will assist you if you are facing a problem with the pill press machine.

For instance:

1) Pill press machine freezes/ Pill press machine Locks up

The possible cause of freezing or locking up of pill press machine is

- Movable or greasing parts may be dried

- Excessive pressure on Upper Drift Pin Assembly

- Pressing started with an upper punch at a low pointThus, you just need to regularly oil or grease the movable parts. Furthermore, rotate the Upper Drift Pin Assembly counterclockwise that will allow moving of the pill press machine. Also, before initiating the process adjust the upper punch at the highest point. That will allow easy movement.

2) Abnormal/ Knocking Sounds

The generation of abnormal sound from pill press machine may be due to:

- Collision of upper and lower punch with die

- The upper drift pin assemble is off

- Upper Drift Pin Assembly is not dropping off onto the powder filling stage

Pill Press Machine

For this, loose and readjust the bolts correctly to align the upper and lower punch. Furthermore, adjust the upper punch till it becomes aligned to Die ‘bore. To deal with the improper dropping of the upper drift assembly, you must check the powder filling between the lower punch and the die.

There must be enough clearance in lower drift pin assembly that allows dropping of upper pin assembly smoothly.

3) Heavy Resistance During Operating Pill Press Machine

Indeed, sometimes you feel your machine is not working smoothly either it works by using some effort. This problem might be arising due to:

- High friction, dryness, or uncleaned or locked areas.

Therefore, as we mentioned earlier application of greasing and oiling on particular movable components may lower the chances of generating sounds, resistance, and freezing of this machine.

4) Powder May Stick on Upper Punch

Indeed, this is a very common problem which you encounter during processing. This problem arises due to:

- Unadjusted punch pressure

- Abnormality with machine

- Issues with the mixing of granular powder

For this, you must rotate the Upper Drift Pin Assembly in order to adjust the punch pressure. In case of abnormality in machine behavior, you must contact the machine supplier. Before initiating the process, you must adjust your pill formulation, because it will assist the smooth running of pill manufacturing.

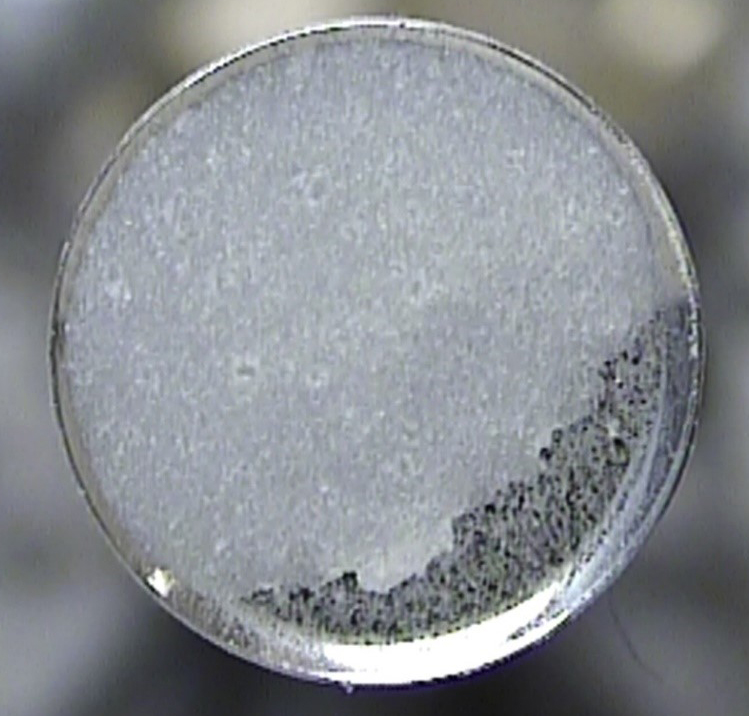

5) Cracked Or Broken Pills

Cracked or broken pills are a very common problem that occurs during manufacturing. Indeed, it is the most upsetting, time, and cost spending problem. This problem might be due to:

- Excessive pressure

- Poor formulation and ingredients

- Inadequate material feeding into Boot

A possible solution to deal with this problem is to adjust pills formulation and usage of significant-quality ingredients. Apply firm presses and assess proper material feeding into the system.

6) Soft or Inconsistent Pills

You always do not get desirable outcomes, sometimes you get soft pills or inconsistent weight.

The possible issue of this problem might be due to:

- Inadequate pressure exerted

- Too little punch force

- Poor mixture

The possible solution to this problem is to reformulate and adjust the ingredients and formulations. Furthermore, rotate the Upper Drift Pin Assembly clockwise to allow smooth flow and ideal punches. If the pills press machine makes the perfect pill, then the problem will be with your mix. Therefore, always check your formulation before replacing the die or the Tooling of the pill press machine.

12.Do pills press machines conform with international quality standards?

This is well known that every piece of manufacturing equipment relevant to the pharmaceutical, nutraceutical, or food industry must require quality standards for industrial products. The pills press machine is following certain certifications such as:

1.cGMP Compliance

cGMP is the certificate that ensures pill press machine is high-quality equipment that fully demonstrates the compatibility with assigned standards for the manufacturing of pills. Thus, it is considered as a trusted and the most demandable well-produced equipment. The entire making up of the pills press machine is done by stainless steel. Consequently, it offers a significant level of sanitation and safety.

2.CE Certified

CE certification, which is a machine manufacturer's privilege concerning about product that meets assigned quality standards by European directives and regulations.

The designated guidelines are related to machine safety and performance prior to selling in European Union or EU.

3.FAT test

Pill press machine comply with FAT or factory acceptance test protocols. FAT test verifies that recently constructed and packed machine meets relevant responsibilities.

Furthermore, these certificates define the working procedure of this machine is highly validates and provides all specification to customer.

4.ISO Certified Machine

A pill press machine is considered as an assigned manufacturing machine that meets industrial quality- assurance and standardization.

5.FDA Compliant

The pills press machine is an FDA-compliant machine that certifies as a highly robust, safe, effective, and properly constructed form of equipment with no false factors.

13.What are the important consideration factors involved in purchasing pills press machines?

When you are going to purchase a pill press machine, you must consider certain important factors that will allow getting the right choice for your production scale.

- Your Production Capacity

Manufacturing output is always determined by considering production capacity which is firmly related to motor, station, and type of Tooling.

Because motor determines the speed and station of pills establish the number of pills you will get in one go.

Based on this factor it is good to determine production capacity before opting for a pill press machine, and you will get satisfying results.

- Considering your Budget

To run a successful business, you consider your cost estimation. This is well known that a high-level pill press machine must be very expensive. If you are running a small-scale pill production then we will recommend you go for a custom pill press machine or single punch tablet machine.

Furthermore, please try to purchase pill Tooling in your budget. If you purchase Tooling and pill press machine from different vendors, it will certainly affect your budget and assembling problems.

- Always opt for a Competitive Vendor

The strength of suppliers is customer satisfaction. They will always provide you pre-sale and post-sale cooperation.

They will give you useful services, suggestions, and tools that you require with cleaning, maintenance, or installation packages.

Then, you must look for a competitive, experienced, and loyal manufacturer of pharmaceutical equipment. - Power Consumption

There are various pill press machines that are dealt with power consumption independently. For instance, the power consumption of manual, semi-automatic, and automatic pill press machines is different.If you are considering those pill press machines that can consume low power consumption and yields more production, then you must assess power expenditure before purchasing the machine.

Conclusion

We hope this informative blog related to pill press machines has helped you a lot.

Now, it will be easier for you to distinguish the most suitable option of pill press machine for your production. Either you are planning to purchase a pill press machine for large-scale production or small-scale clinical trials. The huge competitive market of pill press machines will offer you the best variety that will meet your requirements. Hence you can handle a wide range of pill production with simplicity.

Tablet Press Machine Related Products

Tablet Press Machine Related Posts

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine