Tablet Counting Line Customization: Meeting Strict URS and GMP Standards for New Manufacturers

A customized tablet counting line is a complete production system designed to meet strict User Requirement Specifications (URS). It handles tablets, capsules, and softgels across various bottle sizes. For new manufacturers, ensuring GMP compliance and providing detailed technical documentation like IQ, OQ, and PQ is essential for regulatory success.

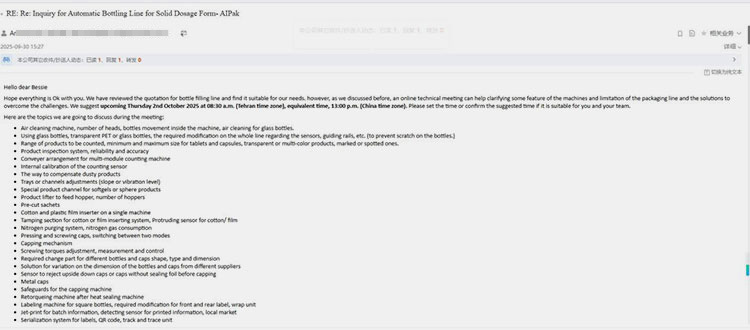

I recently worked with a health supplement distributor from Iran who wanted to become a manufacturer. This transition is challenging, and they needed a partner to guide them through the technical requirements.

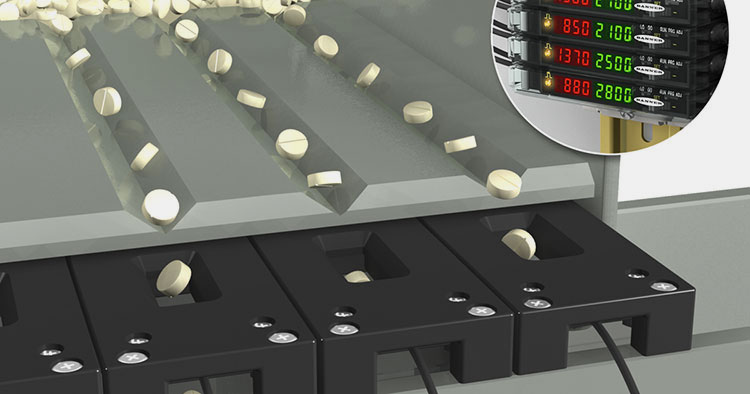

AIPAK Tablet counting line

Many distributors want to launch their own brands to increase profit margins, but they lack manufacturing experience. This client had a clear vision but needed technical support to turn that vision into a working factory.

1.How Do We Analyze the Initial URS for a Complete Counting Line?

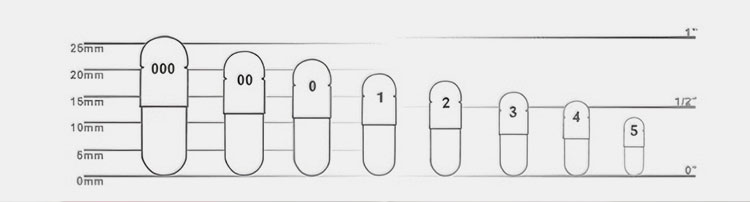

The client sent us a detailed request. They wanted to package tablets, hard capsules, and softgels. They also had specific bottle sizes ranging from 45ml to 200ml.

| Bottle volume | Bottle diameter | Height | Opening diameter | Weight without cap |

| 45 ml | 39 mm | 60 mm | 26 mm | 9.2 g |

| 75 ml | 43 mm | 74 mm | 26 mm | 11.2 g |

| 100 ml | 47 mm | 82 mm | 31 mm | 16.2 g |

| 150 ml | 56 mm | 92 mm | 31 mm | 18.4 g |

| 180 ml | 56 mm | 103 mm | 31 mm | 20.5 g |

| 200 ml | 58 mm | 103 mm | 31 mm | 22.9 g |

| Shape | Dimension (mm) | Thickness (mm) | Weight (mg) |

| Oval | 16*7.5 | 5.0-6.5 | 590-750 |

| 17.5*8.9 | 7.0-8.5 | 740-1200 | |

| 21.1*9.7 | 7.1-7.2 | 1100-1200 | |

| 19*12.2 | 7.1-8.5 | 1200-1400 | |

| 13*8 | 4.6-5.2 | 400 | |

| Round | Ø9 | 2.5-5.0 | 200-400 |

| Ø5 | 3.5 | 70-90 | |

| Ø4.5 | 2.5 | 45-50 | |

| Arc Triangle | 8*8 | 3.2 | 180 |

| Heart Shape | Ø8 | 3.0-4.0 | 200 |

| Modified Capsule | 21.1*9.7 | 7.1-7.2 | 1100-1200 |

| Table 3-Shape and size of softgels | ||||||||||||

| Model | 1 | 2 | 3 | 6 | 7.5 | 10 | 12 | 13 | 16 | 20 | 22 | 24 |

| Round | √ | √ | ||||||||||

| Oval | √ | √ | √ | √ | ||||||||

| Oblong | √ | √ | √ | √ | √ | |||||||

Various bottle sizes request from customer

We analyze the User Requirement Specification (URS) to identify every machine needed for the line. This includes the bottle unscrambler, counter, filler, capper, and labeler. We check the speed requirements and container dimensions to ensure the equipment can handle the full range of the client's products efficiently.

When I received the inquiry, I saw that this was not just a request for a single machine. It was a request for a turnkey solution. The client provided the dimensions of the bottles, pictures of the caps, and the diameter of the tablets and capsules. This information is vital. A line that handles hard capsules might need different settings than one that handles softgels.

I broke down their requirements into a specific machine list to ensure the line would flow smoothly. The complete line included the following components:

| Bottle Unscrambler | To feed the bottles automatically |

| Air Wash | To clean dust from inside the bottles |

| Desiccant Inserter | To keep the product dry |

| Tablet/Capsule Counter | The core machine for precise dosing |

| Cotton Inserter | To protect the tablets during shipping |

| Capping Machine | To seal the bottles tight |

| Induction Sealer | For tamper-evident foil sealing |

| Labeling Machine | To apply their brand visuals |

| Inkjet Coder | For batch numbers and expiry dates |

| Bottle Collector | To gather finished goods |

By listing these out and matching them to the speed requirements in the URS, I could provide a preliminary quote. I also sent videos of similar lines we had built. This helped the client visualize how their future factory would look. It is important to match the machine capability to the specific product size immediately to avoid problems later.

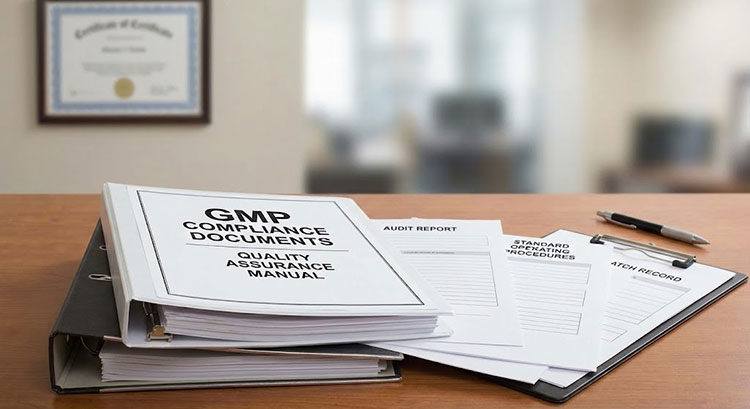

2.Why Are Detailed Technical Parameters and GMP Compliance Crucial?

The client's internal technical team reviewed our initial offer. They sent back a new, complex table. They wanted to verify every single technical parameter before moving forward.

Detailed technical parameters ensure equipment longevity and safety. We confirm contact materials, PLC brands like Siemens, and pneumatic standards. We also guarantee GMP compliance by providing IQ, OQ, PQ, DQ documents and FAT reports for validation. This transparency builds trust with the engineering team.

GMP compliance documents

The client sent a spreadsheet that was very detailed. They did not just ask "does it work?" They asked "how does it work?" They listed rows for the material of the parts that touch the medicine and the material of the main machine body. I confirmed that all contact parts are SS316L and the main body is SS304, which is the industry standard for hygiene.

They also asked about the brands of the electrical components. This is a common concern for maintenance. I assured them that we use Siemens and Schneider for our PLCs and electrical systems. These are global brands, so if a part breaks in Iran, they can find a replacement locally.

The table also covered:

| Requirement | Our Solution |

| Surface Treatment | Polished for easy cleaning and GMP compliance |

| Sensors | High-sensitivity sensors for accurate counting |

| Pneumatics | Reliable cylinders to ensure smooth mechanical motion |

| Noise Level | Kept below standard limits for worker safety |

I also confirmed that we provide full validation documents. This includes Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), along with the Factory Acceptance Test (FAT) report. This proved to them that we are a professional manufacturer, not just a trading company.

3.How to Handle Variable Packaging Needs like Desiccants and Bottle Shapes?

During the process, the client changed some requirements. They needed different desiccant types and wanted to run square bottles on the same line as round bottles.

Different bottle types request from customer

Flexible lines must handle different formats. We adjusted the quote to include both sachet and canister desiccant inserters. We also customized the changeover parts to ensure the machine handles both round and square bottles without losing speed or stability. This adaptability is key for contract manufacturers.

Round and square bottle compatibility

Customization often happens in the middle of a project. Initially, I quoted a standard sachet desiccant inserter. However, I asked the client to confirm their preference. They realized they also wanted to use canister (barrel) style desiccants. I immediately updated the quote to include a machine that could handle this specific format. It is better to ask these questions early than to deliver the wrong machine.

Later, we had a video meeting to show the machines running. During this call, the client brought up a new requirement. They planned to use square bottles in the future. They asked, "Can all these machines handle round and square bottles?"

I explained that yes, they can, but it requires customization. The bottle unscrambler and the labeling machine needed specific adjustments.

1.Guide Rails:We need adjustable rails to fit the corners of square bottles.

2.Star Wheels:The filling station needs custom star wheels to hold the square shape steady.

3.Labeling:Square bottles require a different labeling application method than round bottles to ensure no bubbles.

I updated the proposal to include these "change parts." This gave the client confidence that their investment was future-proof.

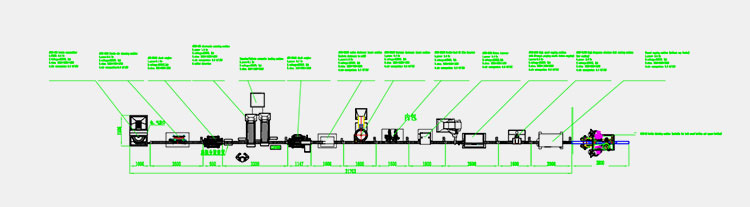

4.How Does Layout Design Help Clients with Factory Construction?

The client was still building their factory. They were worried about whether the long production line would fit into their planned cleanroom space.

Providing a linear layout drawing with precise dimensions helps new manufacturers plan their facility. We mark the length, width, and height of every machine. This allows the client to construct their cleanroom walls, HVAC systems, and power utilities around the actual equipment footprint, preventing costly construction errors.

Factory layout design from customer

One of the biggest challenges for a new manufacturer is the facility itself. You cannot build the walls until you know how big the machines are. The client did not have a finalized blueprint. To help them, I created a linear layout of the entire production line.

In this drawing, I arranged the machines in the logical order of production: Unscrambler -> Counter -> Filler -> Capper -> Labeler. I marked the exact dimensions of each machine and the total length of the conveyor belt. I also included the height of the machines.

This layout served several purposes:

Space Planning:The client could see that the line required a specific length. They decided to adjust their room dividers based on my drawing.

Utility Planning:I indicated where the power and air connections were on the machines. This helped their contractors install the electrical sockets and compressed air lines in the right spots.

Workflow Visualization:It helped them plan where the operators would stand and where the raw materials would enter the room.

By providing this service before they even signed the contract, I helped them solve a major construction headache. This solidified our partnership.

Conclusion

We successfully designed a versatile tablet counting line that met strict URS, GMP standards, and accommodated square bottles, helping a distributor transition confidently into a professional manufacturer.

Don't forget to share this post!

Tablet Counting Line Customization & GMP Standards

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine