Sorting Out The Problems Of Tablet Coating Machine

The tablet coating machine is an important tablet device in the pharmaceutical industry. In the process of long term use of the tablet coating machine, there are many problems, such as electrical problems, mechanical problems, hot air system problems, exhaust system problems, etc.

If these problems are not solved in time, they will affect the effect and quality of the coating to a certain extent, and even pollute the environment.

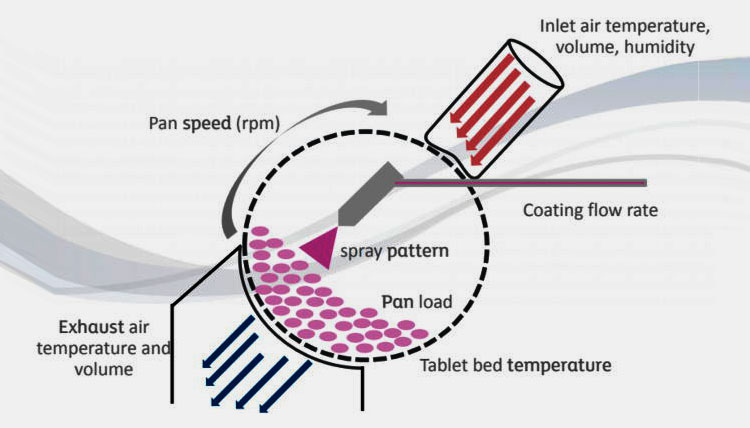

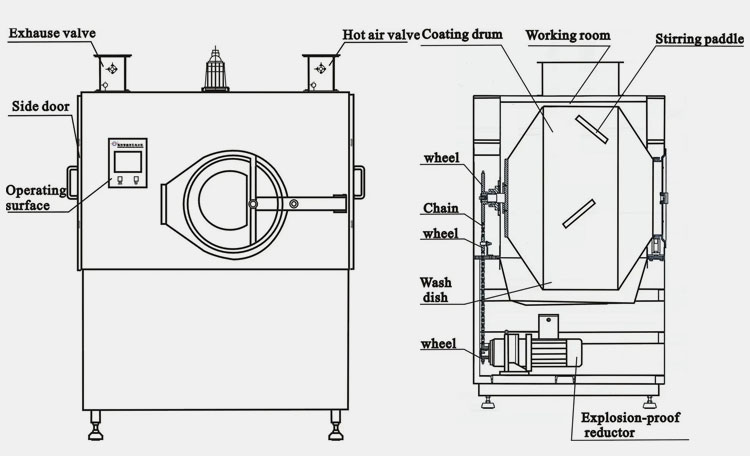

Before solving the problems, you need to know the working principle of the tablet coating machine. When operating the tablet coating machine, we usually put the plain tablets into the rotating drum of the tablet coating machine and rotate the drum clockwise.

Then add syrup to the plain tablets in the rotating drum at different times to make the sugar-coated tablet roll and rub in the rotating drum so that the sugar-coated film is evenly wrapped.

At the same time, you need to pass hot air into the drum to quickly remove the moisture on the surface of the sugar coating film, and finally get a uniform, smooth sugar coated tablet.

According to the process requirements, the process of tablet coating machine needs to control many links, such as the size of the air intake control; control the speed of the drum in a certain range; the rotary drum and air inlet heating control.

However, through the working process and control system of tablet coating machine, you may find some drawback as follows: A tablet coating machine’s control system is mostly controlled by a rely in the form of machine wiring and there are many control buttons and the space occupied by the control cabinet is relatively large.

And because there is too much dust around the production environment, and buttons are also easy to accumulate some fine dust, which may cause the tablet coating machine to have some problems and makes it difficult to clean. This may easily lead to a bind side of cleanness, affecting the medicine’ quality.

In view of this situation, from the point of view of convenience, timesaving, stability and so on, some tablet coating machine manufacturers decided to carry out the following aspects of transformation:

Adopt the PLC to substitute the relay to control the system; take the touching screen as a human-computer interface to substitute button operation; add one analog input module and one output module; the frequency converter is used to control and adjust the speed of the drum.

Frequency converter is a power control device that uses the on-off function of power semiconductor devices to transform the power frequency power supply into another frequency. It can realize the functions of soft starting, frequency conversion speed regulation, improving operation accuracy, changing power factor, overcurrent/overvoltage/overload protection of AC asynchronous motor.

Otherwise, this manufacturer also starts from the system, such as the use of touch screen, PLC and related modules, control the start and stop of each actuator; through PLC FX2N-4AD-PT module, detect and control the temperature; through the PLC RS-485 bus, the operation frequency of the frequency converter is directly modified in operation.

But even so, there are many problems that have become increasingly apparent after long-term use. For example, mechanical problems, mechanical problems are relatively numerous, such as tug wear, tug is the roller bearing parts, but also vulnerable goods.

Different manufacturers of tugs are basically the same, the abnormal situation is basically the screw off and bearing necrosis caused by the wheel, the surface nylon wear caused by the roller beat.

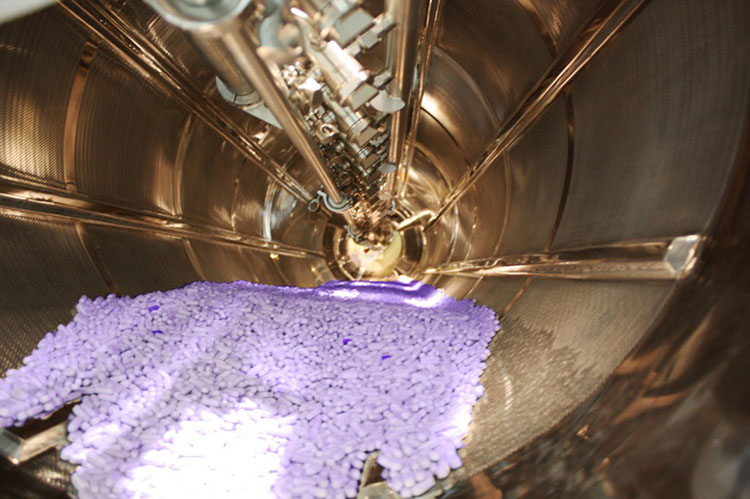

There are also many common problems with the spray guns. For example, the blockage of the spray gun is a common problem, and the formation of the blockage is mainly caused by the problems in the design of the air path of the spray gun.

Some imported airbrush guns also suffer from such design flaws. Airbrush drip, airbrush drip basically happens when you clean the gun.

Many manufacturers say that the spray gun blockage can be carried out in the way of clearing the gun, but it is actually wrong. The spray gun blockage is divided into hanging beard blockage and membrane blockage. And the gun is the process that happens when the membrane is blocked.

Another example is the spray gun pulse. The spray gun pulse is mainly caused by the peristaltic pump, and the pulse is an important factor affecting the tablet coating quality. There are many ways to eliminate the pulse, increase the pipe length of the peristaltic pump outlet, increase the adjustment structure and so on.

Uneven mixing is also a major problem. In order to facilitate cleaning, there is a large distance between the stirring leaf on the stirring shaft and the bottom of the tank in the design of the coating liquid stirring tank. If the distance is close, the stirring leaf cannot be taken out for cleaning, and there is a design defect.

According to the combing and summary of the overall system problems of the tablet coating machine, it is not difficult to find that there are still defects in the design and manufacturing of the equipment, and there are many errors in the selection process.

But now few manufacturers can provide comprehensive equipment upgrading, transformation services, resulting in a significant increase in the cost of enterprise equipment, as well as the continuous exposure of problems. Therefore, the tablet coating machine manufacturers still need to make more efforts in equipment design and manufacturing.

In general, there are various types of tablet coating machine, and with the development and rapid progress of technology, more and more products with different functions are emerging one after another.

In this context, the industry expects that in the future, the tablet coating machine will usher in more opportunities with the development of the pharmaceutical industry, and the market will continue to expand.

However, it should be noted that under the background of the continuous increase in the concentration of the current tablet coating machine industry, the tablet coating machine manufacturers need to accelerate the upgrading of innovative equipment, and pay more attention to structure, material, flexibility and product quality.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine