Capsule Powder Filling Machine: The Complete Buying Guide in 2025

Pharmacists face a ton of difficulties when filling powder items.

Above all while picking the proper powder filling hardware for their particular application.

What if some contamination gets into the powder?

Have you ever imagined filling unequal amount of powder in capsules? What would possibly happen?

They need to discover filling arrangements that meet their necessities to create a sensible quantifiable profit.

For, drug enterprises filling and shutting machines is assuming a significant part.

The drug business has explicit rules and necessities regarding amount and quality.

In this guide, we will explain you all if and thats of the Powder Filling Machine. Starting from the definition, benefits, types, parts, working principal and troubleshoot etc.

1. What is Pharmaceutical Powder?

Pharmaceutical powder comprises finely divided drugs in adequate quantities. It is a dry substance made for internal and external use. The pharmaceutical powder is obtained by grinding and crushing the solid substances. It has a very smooth appearance constitutes of very small particles. The particles may range in size that varies from 10 nanometers to 100 micrometers.

Taking a dose of medication in the form of powders is more effective. Powders are easily soluble than the liquid dosage. thus, showing the effects of the medicines rapidly. Classification of pharmaceutical powders is based on the quantity in which they are supplied to the end-users. Broadly speaking, pharmaceutical powders are divided into two categories.

Bulk Powders

Bulk Powder

Bulk powders are supplied in large quantities and used as less potent drugs. The pharmaceutical powder is provided to you in the form of bulk. With the bulk, it means that a handful of powder is there, wrapped in the packet. You will now open the packet and take the prescribed dosage by using a spoon, cup, or any insufflator.

Divided Powders

Divided powders come to you in an accurate dosage that is separately packed. Most of the time, they will come to you in the wrapped form with the use of parchment and bond paper. It is a kind of traditional way of packing pharmaceutical powders. Dosages that come in divided powders form are rarely seen nowadays. Note that most of the time they are for internal use only.

Sounds easy to take the dose now. Yes! Here you just need to open that small pack and consume all of what is inside it.

Mixing of Powders

Mixing of Powder-Photo Credit: FreePic

Mixing of pharmaceutical powders seems easy to a layman but practically the powders will never mix through spontaneous mixing. There is a science behind mixing pharmaceutical powders. It needs proper processing from either of the following options.

- Tumbling

- Trituration

- Sifting

- Spatulation

Just for the sake of your understanding, imagine trying yourself mixing the two substances whose quantities are not balancing properly by you. Have you felt annoying? Yes! Similar is the situation faced by many pharmacists.

The greatest challenge faced by the pharmacist in mixing these powders is when one powdered substance is kept in relatively greater or lesser quantity than the other.

Compounding Pharmaceutical Powders

Compounding of Powder-Photo Credit: porticopharmacy

Ever have you seen the powder that becomes pasty after storing for some time? On some of the drug labels, it is written ‘store in cool and dry place’. Here is the reason. Why.

As there are many types of powders an equal number of possibilities are also there. Among those, there some powders that contain a molecule termed the water of hydration. It will make the powder texture damp and it will feel moist.

This is due to the reason that the water is released mostly after the process of trituration when mixing powders. Also, when the powder is stored in the humidity.

Instead of this, there is a need for utmost care while dealing with the deliquescent and hygroscopic powders due to their affinity with the moisture present in the air.

2. How do you Fill Pharmaceutical Powder?

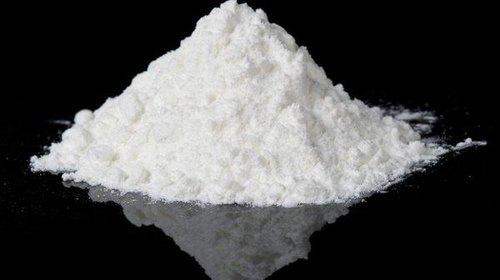

Powder Photo Credit: PharmaMachinery

With the advent of time, the pharmaceutical industry has a keen interest to employ machinery in performing certain tasks. To fill pharmaceutical powders, you have powder filling machines that are more extensively used in the food industry, pharmaceutical, cosmetic industries, and many others. The pharmaceutical powder can easily fill in the bottle or the parched bag with the help of machines. These machines come in various forms and operate at the same place of packaging the pharmaceutics.

Mostly the pharmaceutics comes in the form of granules and can be filled into bottles or plastic bags. The packaging also depends on the consumer’s preference. Packaging of the sachet is a little bit different approach. The type of packaging of the powder depends upon the nature of the powder as well.

Choosing the capsule Powder Filler Machine

Powder Filling-Photo Credit: vikingmesek

While choosing the capsule powder filler machine know that the powder comes in many forms in the industry. Some of it is present in raw form, while the rest of them are just passed from the processor are on the verge of completion. The kind of packaging will also be determined by these forms of the powders.

The powder characteristics need to be readily known by anyone going to opt for the kind of capsule powder filling machines. Powder characterization consists of the following points that are note-worthy.

- Chemical composition

- Flow measurements

- Morphology

- Density

- Particle size distribution

3. Where can you Use Pharmaceutical Powder?

Pharmaceutical Powder Photo credit: Pexels

If we classify pharmaceutical powders based on their uses then, you will see there are two main uses of the pharmaceutical powders.

For Internal Use

Bulk powders for internal use are the most convenient form of ingesting the dosage. Such pharmaceutical powders that are also named oral bulk powders are used for a variety of purposes which include bulk laxatives, antacids, oral electrolyte mixture for rehydration, and antidiarrheal medications. However, the bulk powders for internal users are not recommended for serious ailments because the exact proportion of the amount is not known.

Other pharmaceutical powders are found encapsulated into the hard plastic material. The capsule burst when reaches acids in the stomach releasing the powder inside into the body secretions. Similarly, some of the powdered material is compressed to mold it into the form of tablets. So, the powder ingested in the form of capsules and tablets is present in an adequate amount.

Most of the powders are replaced with capsules and tablets or you can say they got embedded into those two types.

For External Use

Protein Powder-Photo Credit: Vector

The rest of the other powders can be used externally only. Some of them are used to treat pimples by mixing the divided powder, most of the time, with Vaseline or any other such compound which can make a heterogeneous solution. Topical bulk powders are also applied to the skin.

Here is the list of powders that can be used for external purposes only. They include douche powders, dentifrice powders, triturates, dusting powders, and insufflations.

4. Are There Any Different Types of the Filling Powder?

Different powders-Photo Credit: healthline

Yes, there are different types of filling powders. Here is a description of how pharmaceutical filling powders are classified depending upon the types.

· Bulk powders

Bulk powders are non-potent and can be dosed with worthy precision and wellbeing utilizing estimating gadgets, for example, the teaspoon, cup, or insufflator. This restricts the utilization of orally managed mass powders to acid neutralizers, dietary enhancements, diuretics, and a couple of analgesics. Many mass powders are utilized topically.

· Douche Powders

Douche powders are recommended for the patient since a powder is more versatile than a cumbersome agreement. The equation is grown with the goal that a teaspoonful or tablespoonful of powder mixed up in a predefined volume of water gives the ideal focus. The pH normally goes from 3.5 to 5 when the arrangement is readied.

Douche powders ought to be filled in glass containers with a wide mouth. Some business douche powders are accessible in metal foil bundles, which contain the appropriate measure of powder for a solitary douche. Numerous douches are likewise accessible as a prepared unit of utilization in utensils.

· Dusting Powders

Douche powders are fine restorative although the bulk powders are expected to be clear upon the skin. A solitary restorative specialist might be utilized as a cleaning powder; nonetheless, a base is regularly used to apply as a therapeutic specialist and to shield the skin from irritation.

Bentonite, kaolin, kieselguhr, magnesium carbonate, starch, and powder are utilized as inactive bases for douche powders. Powder bases leave a drying impact, which alleviates blockage and gives a cooling sensation. All unpremeditated cleaning powders ought to be gone through a 100-200 mesh-sieve to guarantee that they won't further aggravate damaged areas.

· Insufflation

Insufflation Powder-Photo Credit: Edgepharma

Insufflations are very fine powders to be brought into body cavities. To regulate insufflation, the powder is put in the insufflator, and when the tuber is pressed, the air current helps the fine particles through the spout to the locale for which the medicine is expected. All without premeditation intensified insufflations should be gone through 100 mesh sieves. Pressurized bundles give an exquisite way to deal with the organization of insufflations.

5. Why Powder Fitness is Important in Pharmaceutical Business?

Pharmaceutical Powder

Powder fitness is important in the pharmaceutical business because a thorough understanding of the powder can only make effective products from it. The powder fitness will lead to developing clinically tested and effective medicine through efficient processes that result in the manufacturing of high-quality consistent products.

These days we have powders for inhalation, dissolution when taken intravenously and ingested as tablets and capsules. So, to develop the right product one should have the right knowledge for it.

The growing importance of powder fitness is also because the vast tools and technologies are employed these days so many challenges are faced while handling the powder. It will give you a keen understanding of which powder should pass from which machine.

Powder Fineness

Finest of the Powders-Photo Credit: fdocument

The fineness of the powder ranges from very fine to very coarse. You can easily identify the coarse and fine powder in this range. Then comes the properties of the powder flow. They are.

- Angle of response

- Segregation tendency

- Permeability

- Bulk density

- Flow rate

- Frictional strength

- Cohesive properties

Now, the operator’s job is to understand all of the above-mentioned properties of the powders and then choose the filling machines accordingly.

Free-flowing powders cannot be easily compressed, yet they are molded into different forms when the pressure is applied. Whereas, the non-free-flowing powders maintain their actual shape when the pressure is applied to them. Now, it makes sense that why powder fitness is important in the pharmaceutical business.

So, the reasons described above are enough to predict that the fitness of the powder is necessary while operating in the machine. Medical professionals expect the medicines to be highly consistent and of the best quality for the patients.

6. What is Capsule Powder Filling Machine?

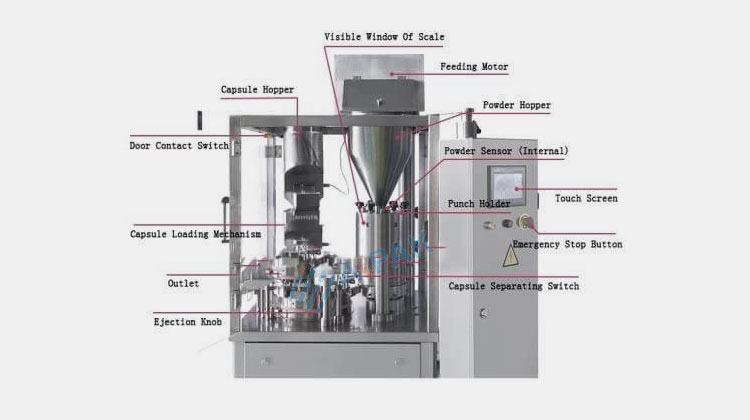

AIPAK Capsule Powder Filling Machine

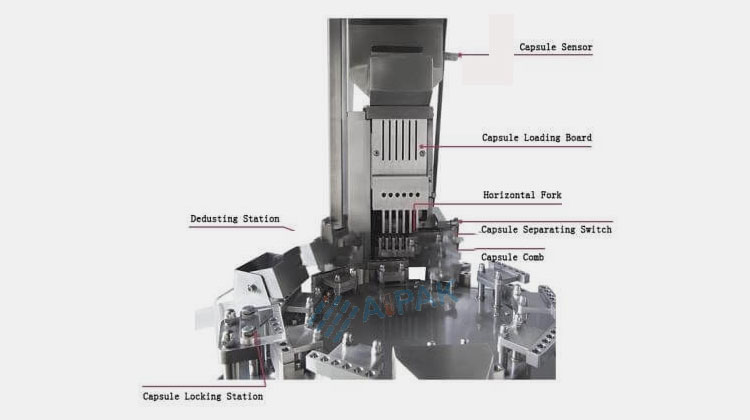

Capsule powder filling machines will assist you in processing the pharmaceutical powders that are available in different forms, particle sizes, and nature of the powder. The most commonly categorized powders are free-flowing and non-free-flowing powders. Types of machines are characterized based on design and the level of automation. These machines can provide volumetric as well as quantitative filling.

Each of the machine types handles a certain kind of powder. While some machines can process both the free-flowing and non-free-flowing powders. The next step after processing the powder is to fill it in the required packaging. Packaging also comes in various forms depending upon the powder's purposes.

Capsule powder filling machines are used in the pharmaceutical industry, cosmetics industry, food, and beverages industry. Usually powder filling machines works efficiently for dry, injectable, and sterile powder filling. Most of the machines process only one size of the particles while some of them are universal.

A dosage plate is fitted inside the machine for measuring the accurate quantity of the powder. The uniformity of the powder flow is also ensured by the dosage plate. High precision and accuracy for measuring the fills is considered to be a must have outcome for any capsule powder filling machine.

7. What are the Industrial Usages of the Capsule Powder Filling Machine?

Capsule powder filling machines are there to serve various industries. The industrial usage of the capsule powder filling machines along with the industries in which it is used is listed below. Generically forecasting this machine can be used to fill any kind of powder.

Note that, irrespective of the industry in which the machine is operating it will measure the quantity of the powder beforehand.

Pharmaceutical Industry

Pharmaceutical industry-Photo Credit: Pexels

Have you ever noticed that no matter how many bottles of medicines or packets of sachets you bring, every bottle and sachet contains the amount of medicine that is equivalent to the medicines selling even at different venues? Of course Yes!

The medicine will make you reach the powdered substance having an appropriate amount and equal to other packets and sachets as well when it is processed and packed through the powder filling machine working at the back end.

Veterinary Industry

Veternity Industry-Photo Credit: envatoelements

If you are having a pet at home, then you know that curing your sick pet through medicines is a confusing task you have performed in a while. Animals are not willing to take the syrups through spoons in a sophisticated manner. For them, pharmaceutical powders are there.

Most of the medication designed for animals are available in powders. It is because, you will mix that powder in drinking water provided to them. Filling of those medicines is also done through the powder filling machines in an adequate quantity.

Food and Beverage Industry

You may have wondered for a while that how could powders use in food and beverages. So, here is an answer to the satisfaction of your thoughts. Milk powder, all the spices, flour, coffee powders, and sugar all are filled in their respective packing with powder filling machine.

Chemical Industry

Chemical Industry-Photo Credit: chemicalspacks

Certain chemicals are filled in the glass bottles to be used for laboratory purposes. All such packaging is done with the help of a powder filling machine. In addition to this, all the aesthetic paints also pass through this procedure.

Cosmetics and Domestic Industry

Used in Cosmetics too-Photo Credit: thecosmetics

While looking among cosmetics many of the baby powders and blushes are in powdered form. It is those powder filling machines that pack the powders in packaging that comes in various sizes and shapes. Most of them are made up of plastic.

As far as domestic industry is concerned, many of the detergent powders either less or high acidic used for cleaning purposes are packed inside plastic bottles or plastic wrappers. Powder filling machine plays their part herein too.

Agricultural Industry

Agricultural Industry-Photo Credit: ipharma

In the agricultural industry all the insecticides, pesticides, herbicides, so on and so forth are filled in plastic bottles usually. Some of them are available in the form of sprays.

Firstly, the powdered substance is condensed and mixed with other elements to change its morphology. It is then packed inside the spray bottles with the help of a powder filling machine. Moreover, organic and inorganic fertilizers are no more behind in passing through this technology.

Hence, there is hardly any sector left where the final powder product does not pass through the powder filling machine. So, the quality of the powder filling machines used in the above-mentioned industries should be efficient enough. It is imperative to say that it should meet the quality standards as well.

Note: if in case the powder product you are dealing with does not fall in any of the categories of the powders described above, then you must consult with the powder filling machine manufacturer. He will surely suggest to you the machine specifically designed for the kind of powder concerning you.

8. What are Different Available Technologies in Capsule Powder Filling?

Different available technologies found in the powder filling processes and techniques are described here.

Incorporating Tools and Drive

You must decide on the right kinds of tools and drives for fixing inside the machine considering them its parts. Choose those tools that are the best fit for your machines.

Given below are the points that you need to consider while choosing the right tools.

· Weight of the Fill

Volumetric filling-Photo Credit: biopharma

The dosing systems fitted inside the machines determine the accuracy of measuring the weight of the fill. The small dosing system accounts for high accuracy with the less amount of powder holding capacity at the slower rate and vice versa.

So, to choose the best option, it is recommended to opt for the system that has multiple dosage systems installed. In this way, higher precision and accuracy are obtained even for the multiple amounts of a substance that can operate at an appropriate speed.

· Container Necks

The neck of the container should be in close conjugation with the size of the funnel. The powder-filled will then be accurate in measurement too.

· Characterization of the Powder

Every pharmaceutical powder has its unique properties. Three of them are.

- Non-free flowing powder

- Semi-free flowing powder

- Free-flowing powder

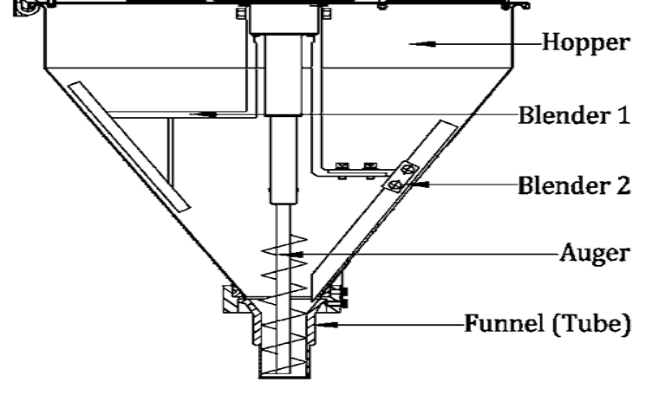

Here, the non-free-flowing auger requires a larger size auger machine for its quick filling. The machine has the potential to push all the particles of non-free-flowing powder downwards in an instant. Instead, the regulation of agitation mode will pause the machine between the fills to avoid powder from becoming more and more compact. Changing the agitation mode repeatedly will also help for the non-free-flowing powder. The use of a bigger hopper provides a more significant agitation to the non-free-flowing powders.

On the contrary semi-free flowing powders do not need a bigger auger with the hopper section. There is a chance of it getting damaged. So, choose the auger with parallel flights semi-flowing powder. There is a chance of semi-free flowing powder to bounce. To deal with it, give a little pressure from the back so that it remains within the funnel.

Free-flowing powder needs a force that stops them. In this case, using a spinner disc is highly recommended that intrudes with the path of free-flowing powder to stop it.

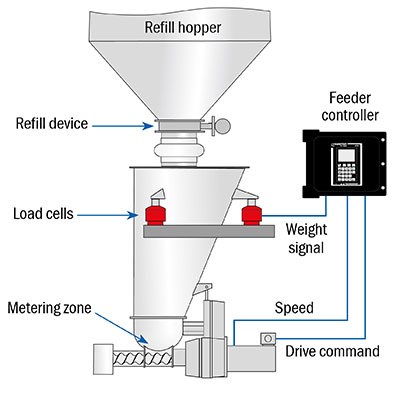

Gravimetric Filling Technology

Gravimetric filling-Photo Credit: ptonline

Gravimetric powder filling technology is best to measure the weight of the powder. This technique works under the principle termed “fill by weight”. There are certain discrepancies associated with other technological systems and are rectified by approaching gravimetric technology.

· Why Use Gravimetric Technology?

Some of the benefits of using gravimetric technology are given as under.

- Gravimetric technology can tell the actual weight of the powdered substance.

- All the discrepancies regarding the total weight of the substance are eliminated.

- The exact fill weight will remain constant even under repeated measurements.

- There will be no variability in the product density.

Gravimetric technology simply follows the three ways to determine the fill weight. These three are described next.

· Setpoint

On reaching the setpoint weight the filling of powder will be inhibited. Auger works on the principle of uniformity in the setpoint mode. Before the setpoint is reached, load cells will continue measuring the weight that is adding to the machine. However, the final setpoint is obtained after the process has been completed.

· Dribble

The auger works at the highest speed possible at this stage. However, it gets slowed down at dribble. The load cells will keep on calculating the fill weight, to begin with, the round once again.

· Feedforward

In the feedforward, the mode auger operates at the maximum speed, but it stands still while approaching the expected fill weight. The load cells here will record the static weight. The top-up fill will then be converted into a volumetric fill.

As described above the two of the procedure described above calculates the dynamic weight but the feedforward process comes up with the static weight of the substance.

Note that the above described three modes are optional and depend on the operator’s choice for which to choose. The powder filling machine will then become customized with these technologies.

Volumetric Filling Technology

Volumetric Filling-Photo Credit: Vector

The core concept of volumetric filling technology is to concentrate on the quantity of the substance to fill. The total number of revolutions that an auger takes will equal the amount of powder present in it.

If you are using either the semi-automatic or fully automatic machine, then this technique will apply to both types of the machine. Moreover, this principle is also the best fit for single and multiple auger machines.

· Linking with the Weigh Cell

The processes of the volumetric filling technology are optimized if you link it with the weigh cell. The benefits of linking the volumetric filling with the weigh cell are given here.

- The weigh cell will record the weight of the fill with great precision.

- All the unnecessary weight that seems excessive is rejected by the weigh cell.

- If the density of the change is changed in any case, then the weigh cell can effectively maintain it too.

Taking into consideration the data received by the weigh cell, the power loading device will send the substance to the filling head. Fluctuations in the number of revolutions will take place according to the weight of powder. This is the most crucial way to handle some of the tiny, weighed substances.

· Error-free Modification

Do not forget that, no matter what kind of latest technology is implemented inside the machines it could never be error-free. However, you can reduce the error rating to some extent. Make the following modifications to make it error-free.

Use an additional filler equipped with weighing devices for tare and gross weight. That way you will have two weight cells together. The former will measure the unfilled while the latter will measure the weight of the filled bottle. Subsequently, the net weight is obtained by simply subtracting the tare weight from the gross weight.

9. What are the Benefits of the Capsule Powder Filling Machine?

Pros and Cons-Photo Credit: Themoneycompany

Purchasing the machines is somewhat costly. So, finding the equipment that grants your business the value for money is the ultimate objective of purchasing the pieces of equipment. Powder filling machines benefit your business in the following possible manners.

· Gaining a Competitive Advantage

While marketing your business have you ever noticed that building brand equity and earning the loyalty of the customers are not that easy. The right fit of machinery will let you gain a competitive advantage over all your rivals in the marketplace. Best machinery guarantees you the best product.

· Cost-Effective Process

Paying the labor for carrying out the tasks of powder filling is a huge expense. Moreover, the desired outcomes could also not achieve because of the lack of precision and accuracy in the results. So, in this regard, powder filling machines prove to be very cost-effective. Eliminate all the operating as well as labor costs by using fully automatic powder filling machines.

Such compatible machines yield a long term profit for your business by inducing conversions and sales.

· Precise Filling

Precision in Filling-Photo Credit: Vector

It is also stated above that achieving uniformity through high accuracy and precision is the pre-requisite of any powder filling machine. Each bottle or the sachet of the powder should equally fill. Any ambiguity from the end of the manufacturer is avoided by adopting powder filling technologies. As the precision rate is increased, the wastage of the powder will decrease simultaneously.

· Machines Depend on the Application

Some of the powder filling machines are flexible enough to change the size of the container and its fill levels depending upon the amount of the fill. You can fill all kinds of bottles and sachet packets from a single machine. Consult you are the machine manufacturer to customize the powder filling machines for you that are suitable for your business type.

· Various Production Capacities Available

Business needs to invest wisely in the assets of the company. If you have high production demands at your place, then opt for the machine that synchronizes with your needs by investing a high amount of budget as well. However, if your production is slightly lower, then it is preferable to choose the low-capacity machinery to incorporate in your production line. The costs should not exceed the demands.

Henceforth, choosing the right kind of equipment will benefit you in profit maximization, both by facilitating the right amount of product and refraining from extra revenue allocation for the same process that could be done in the limited budget too.

10. What are the Drawbacks of Capsule Powder Filling Machine?

Apart from all the benefits that the powder filling machines offer to the business. Some of the drawbacks or limitations that you can encounter are also listed below.

· Expensive Technique

Powder filling machine is an expensive technique to adopt. Especially those machines that are used in large-scale business are relatively more expensive.

· Depends Upon Nature

The nature of powders manufacturing in one industry is maybe free-flowing or non-free flowing. The satire here is that one machine could not entertain the powders of both natures. You will have to work with separate machines. It will in turn become costly.

In addition to this, most of the machines could not operate efficiently when there come irregular sized particles present in the powder.

· Inaccurate Fills

The machines that are not equipped with the volumetric technology and the weights attached will probably not show the accurate measurements of the fill.

· Slow Operating Rate

All the powder filling machines do not operate on the same principle. Some of them are slower than others. Likewise, they are expected to deal roughly with the substance. While others are said to eliminate dusty particles when operating.

What would you probably do when you get confused in the capsule powder filling machines? It is expected that some of you will look for expert advice. So, it is highly recommended that you consult with the manufacturer of the machines. He will better guide you to go with the technology that can give you the best possible outcomes.

Note that every type of machine has its limitations and drawbacks.

11. What are the Types of Capsule Powder Filling Machine?

Types of powder filling machines are based on various categories. Three of them are listed below.

- Design type

- Automation type

- Industry type

However, if we broadly classify the powder filling machine, it will for sure fall in automation type. Based on the automation, the powder filling machine is of three types.

- Fully automatic

- Semi-automatic

- Manual

Each of them is described in detail herein.

Fully Automatic Capsule Powder Filling Machine

AIPAK NJP-7500 Capsule Powder Filling Machine

In fully automatic powder filling machines, there is an utmost use of the latest technology inside the machines. It requires very less or none of the manpower for its operations. All you have to do is to purchase the fully automatic powder filler and consider your work done. Also, the work done by the fully automated machine comes with three main advantages. They are.

- Work is done at a reasonable price because almost no labor cost is incurred at the end of the business holders.

- The results come are more concise and accurate.

- The robust system will never get tired of working day in and day out.

The step-by-step transfer of the powder from the hopper into the weigh fills and to the filling is done without intervening any human being around.

Semi-Automatic Capsule Powder Filling Machine

AIPAK Semi Automatic Capsule Powder Filler machine

Semi-automatic powder filling machines has their benefits apart from the fact that you have to get some of the stuff done by yourself while working with this type of machine. Another option is that you can convert the semi-auto to a fully automatic machine with several modifications done properly.

Some additional features possess by the semi-automatic machines include the PLC system. The PLC system enables the machine to carry out the tasks like filling of the substance and measuring the probability of the error automatically.

One of the competitive advantages that the semi-automatic machine owns is that it has greater control over the filling procedure. the person operating the machine from the back end is autonomous of adjusting the limits of weights and volumetric fillings. While the fully automated machine receives commands in the form of vibrations which they need to follow for the limits of the fill.

Manual Capsule Powder Filling Machine

Manual capsule powder filling machines require some level of struggle at the end of the operator as well. You need to manually fill the powder, check the weight of the fill, record any discrepancy in the measurement to ensure that the task is performing with precision and accuracy.

After all that process, stopping the machine to fill in it and then restarting it either from the pause or from the new start is your job.

Just for the sake of your convenience, the machines based on the automation process are described here. You will find more detailed data about certain other machines later on here.

12. What are the Parts of Capsule Powder Filling Machine?

Parts of Capsule Powder filling Machine

Before going into the details of each part of the powder filling machine know that all those parts depend upon the following characteristics.

- Model of the machine

- Design of the machine

- Degree of automation

- Use of technology inside

Below is a brief description of the parts of powder filling machines that are commonly found in almost all machines.

· Filling Motor

The filling motor is there to adjust the number of revolutions while filling. So, it can effectively manage the amount that is needed to fill the packet or the bottle.

· Mixing Motor

The mixing motor will blend the powders thoroughly with the controlled mixing speed.

· Mainframe Heads

Mainframe heads are here to prevent any damage to the machine. It forms an outer layer of protective coating.

· Level Detector

The level detector detects the levels of the powder that is about to fill in the bottles or sachets. Thus, gives equal filling in every container. They come in two forms.

- Point level detector

- Continuous level detector

· Feeding Port

Consider the feeding port as just the pathway for the powder products to pass.

· Hopper

Hopper-Photo Credit: Vtops

Hopper holds all the powdered substance that is about to fill in the container. Level sensors are also employed at that stage to detect the level of the powder. It is considered a dosing system.

· Filling Spout

Just know that filling spout is a part of the powder filling machine system. It is a component of the dosage system. It takes the powder from the hopper to pass on to fill the desired bottle or the sachet.

· Worktable

The worktable is the component of the powder filling machine that is located away from the powder processing parts. The worktable is used to place the powdered filled containers.

· Electric Scale

The electric scale will automatically measure the weight of both the filled as well as empty containers.

· Overflow Collector

The overflow collector will collect and hold all the spilled powder for some time during the process.

· Control Box

The control box is considered a locker system. Here all the power, as well as control buttons, are installed along with plugins.

Pedestal

The pedestal will provide support to the whole machine and position it in a balanced way.

· Mechanical Drive

The powder filling machine consists of a mechanical drive system as one of its parts. The mechanical drive system comes in two forms.

- Linear mechanical drive system

- Rotatory mechanical drive system

The kind of movement that the machine performs is determined by the mechanical drive system. The system further consists of some parts, they are.

- Mechanical motors

- Gears

- Conveyors

· Sensors

Sensors detect the presence of a container placed on the worktable and then the machine either stops or initiates the process.

· Control System

Control systems are handled by the operators and comes in the form of a PLC control system. A fully automatic filling machine introduced the touch screen system. While the operator controls the machine in semi-automatic and manual machine types.

· Weighers

Some of the powder filling machines have built-in weigher. It predicts the most precise levels of fills in a quantitative manner.

13. What is the Working Mechanism of Capsule Powder Filling Machine?

The working mechanism of the powder filling machine from putting the material into it to getting the finalized product that meets your satisfaction is described herein step by step. Here is a generic overview of how a powder filling machine tends to operate.

Let’s get started!

The powder is sent to fill the sachet, bottle, pouch, or any other form of a container placed on the turntables. The powder makes its way forward to reach the endpoint will be controlled by some screws commonly known as Archimedes screws present inside the machine, as one of its components.

For making the proper dosage, one component of the system is located inside the hopper, which will help the machine prepare accurate dosages of the powder. While the other part of the dosage system is seen inside the tube, it will also aid the entire process of making the dose.

After the machine has finished making the doses, the volume of the powder that it will deliver depending upon the weight is processed through the number of rotations made, at this step.

Now, this step accounts for filling the containers of different sizes and shapes with powder. The number of heads of the machine varies, and the hopper also comes in different shapes. Consider the very generic forms, which is a hopper in cone-shaped and machine with just one head.

To make the most precise doses in volume, the machine head will fit in very close proximity and adhere to the tube firmly. The drive takes a turn at a constant speed throughout the process.

The material will come up to the filling tubes with the help of rotations. That will aid in inflowing the already made dosages to the container positioned next. Know that the filling will take place step by step in chronological order. It will never be continuous.

The new pack will come at the point of the previous one after the filling takes place. The machine will then process the dose. All of it is dropped in the open container, be it a sachet or bottle. After closing the packet and moving it forward, the new round will start.

In the case of cup-shaped fillers, the rotating cup will continually fill in with the powder coming through the hopers.

Adjust the volume of the filling cup manually taking into view the total weight and the volume of the powder. This is a kind of passive arrangement for filling the cup. The cup system is good to go for the free-flowing powder. However, the powder of cohesive nature has a chance of getting glued to the walls and bottom of the cup somehow.

After that, the filling tube will empty down into the packaging of the powder.

Note that the above-mentioned procedure is for the most commonly used powder filling machines. The process may vary depending upon the type of machine you are using.

14. What are the Different Quality Standards for Capsule Powder Filling Machine?

Till now you have gained an overall perspective of various powder filling equipment. Now, here you will know about the quality standards that must be there while purchasing a machine. Make sure that the machine you purchase is designed by considering all of the quality standards, it is only then that it can operate efficiently and effectively. Those standards are listed below.

· CCC Mark

It will identify the safety compliance, developed from the end of manufacturers for the machines that make their way to China.

· ISO 313

It is supposed to set international standards for all the filling equipment manufactured worldwide.

· CE Mark

It indicates that machine will not cause any danger to health, environment, and safety.

· FDA Compliance

The machines used in food and beverage industries, as well as pharmaceutical equipment, need to abide by the standards of the FDA.

· cGMP

According to it, the manufacturing process, as well as the manufacturing machines, need to hold on the safety measures very firmly. It will be in the interest of both the organization as well as employees operating that particular machine.

· RoHS

RoHS claims that not even a single harmful particle should be seen while working with the powder filling machines.

It is also noteworthy that all the above-mentioned standards can vary from country to country depending on the rules and laws there.

15. What Points you Should Keep in mind When Buying Powder Filling Machine?

After knowing all about the basics of the machine it is also necessary that you must know about the nuts and bolts that should be looked for while purchasing the machine.

· Properties of Powder Product

Most of the powder filling machines can handle only the specific type of powder either it is free-flowing or non-free-flowing powder products. Such powders have more diverse characteristics like their stickiness, compressibility, and the size of the particles. You need to choose that machine which fits best for your product.

· Product Package

AIPAK DPP-260H1 Blister Packaging Machine

The type of container in which you are going to fill the substance should very easily fit the machine. As mentioned before that the head of the funnel should be in very close proximity to the container. So, opt for the powder filling machine that is good for your container type like bottles, sachets, etc.

· Production Demands

The production capacity of every machine varies from another. As the mechanism is also slightly different. Moreover, the fully automated machine performs better than semi-automatic and manual. So, the fully automatic is good for higher production. Considering the volume of the hopper, as well as the rotatory and inline machines have different principles. So, opt for the one that is best for your requirements.

· The Machine's Control Mechanism

some of the machines have buttons and switches for the operator to control them. While the rest of them also have digital PLC systems. Make the decision wisely by taking into view your budget range.

· Machine's Driving Mechanism

the driving mechanism of the machine depends upon the machine parts. Especially the motors that provide force for all other components to make movements.

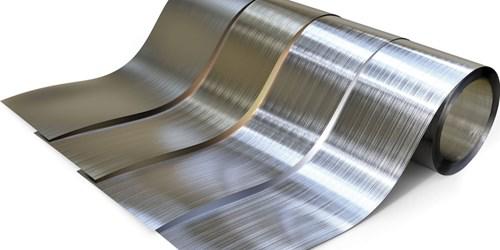

· Machine's Material Type

Stainless Steel

From your daily usage products, you might have heard that the machinery is getting corroded. To prevent the machine from rust, opt for the one that is made up of corrosive-resistant material. The rust can severely damage the contact points of the product. The recommended option is a stainless steel material. Among them, stainless steel numbers 304 and 316 are good to go.

· Machine's Accuracy

It is no doubt a difficult task to adapt a perfect machine. However, try your best to choose the one with the minimum flaws. For this, go through the specifications sheet once while purchasing. It is expected that some of the errors that are likely to occur may be listed there.

· Other Components

Consider some of the other components according to usage and quality of the machine.

The machine with the following built-in components will give you more precise results. They are.

- You must look for a larger-sized hoper to buy while buying a machine for bulk powder.

- The machines that can fill up approximately to less than 1 gram are good to go.

- The presence of sensors and timers will make the machine give more accurate and in prescribed time filling.

16. What are the Auxiliary Equipment for Capsule Powder Filling Machine?

Auxiliary equipment is all the equipment that is needed to make up the complete production line of the powder filling machines. The machines here can easily process the powdered substance both in the form of a non-free-flowing and free-flowing nature. Even the dusty and sticky materials are filled to the precision for the pharmaceutical, cosmetics, food and beverages, and agricultural industry.

· System Implementation

The whole process and the system through which the powder passes are non-hazardous for health as well as for the environment. The dust-free space will be provided for the packaging ensuring that no contamination takes place.

· Easy to Use

Here the machinery is easy to work, simple to clean and to keep up. It is ideal for huge creations just as for organizations with regular powder changes.

· Quality

Gmp-Photo Credit: superiorsuplementmfg

All the contact parts are made of treated steel following the GMP, FAD, and all other rules and regulations.

Customizable Product Line

The functions performed in the entire product line are according to the requirements of the clients. There is the following equipment that makes up a complete production line.

- Powder mixers in the form of huge mixing machines are there.

- Auger fillers can process both the free-flowing and non-free-flowing powders.

- Pouch filling machines will transfer the powders to the sachet if required.

- In custom build filling equipment, rotary systems are present to deal with any special kind of powders.

- Various quality control equipment includes weighers, detectors, and other quality control units.

- Some of the rejection units are also there if the quality of the powdered substance is not up to the mark.

- Induction sealers seal the mouth of the container in which the powder is filled finally.

- Labelers of various size that shows all the details of the substance written on it.

- For the labelers inject printers are there to make the work more efficient.

- Shrink wrapping facilitates the placing and storing of the final product. They can even assemble into one cartoon.

- Conveyors, turntables, and elevators are there to connect your production machinery with other packaging processes going on. This is to facilitate and coordinate the process going on.

Note that all the parts and components of the equipment are described in this guide in detail.

17. How to Troubleshoot Common Problems of Powder Filling Machine?

Filling a material inside the packaging is often the end of the procedure taking place in an assembling cycle. The material that has been delivered, or just took care of, in past interaction steps, is filled in the container. In any case, issues at this stage, if arise, can have intense ramifications for the entire manufacturing factory as a decline of performance at the last stage, implies that the entire product will diminish in quality.

The vast majority of the issues that are recorded underneath can be found to a typical fundamental underlying reason which is the flow of the powder.

Flow in Hoppers

The flow in hoppers right above the filling head should be very smooth and steady. Otherwise, the bulk material that is accumulated at the hopper will make the weightage calculation of the product go wrong.

· How to Solve?

The above-mentioned problem that is observed can be solved by making sure that the hopper is steep enough to make the powder flow easily. Agitators can be used in the hour of need. In addition to this small vibrators are also the better option.

Weight Control

When the filling process is volumetric, the powder that is moving into the dosing system should have accurate. The variations in the net weight of the powder are the root cause of the problem. The weight set by the end of the manufacturer is usually kept more than that prescribed on the container. This is maybe due to the bad setting of the powder in the volumetric measure.

The volumetric filling here needs to be filled all the time. Anyway, awful weight control is normally identified with the powder flow. If the volumetric dosing instrument isn't occupied constantly in a similar way, the weight will change. The unpredictable filling can be because of firm powders or awful stream in the cradle container. Another conceivable issue is to have the degree of powder fluctuating over the dosing framework, the progress of the powder is then changing relying upon the weight of the powder in the container.

· How to solve

The flowability issue can be addressed by playing on the definition of the powder to be filled or by analyzing the machine to add more guides to it

For example, instigators in containers, or little vibrating frameworks.

If it is seen that the level in the filling container is changing much after some time, it tends to be improved by changing the control by refilling the hopper and funnel.

Leakages

The fixing of the pack should be managed without powder staying in the middle of the two sides of the filling material. On the off chance that some powder is caught, the fixing won't be done accurately which will prompt some spillage pretty much high.

It can essentially aim for spillages if the sealing is not properly done. It can cause miniature spillages which will be pretty much risky for the powder in the pack. The main cause for improper sealing is that the powder while falling in the pack is producing dust if the residue has not settled at the time the jaws are closing down for sealing, at that point spillages can occur.

· How to solve

The solution to this problem simply lies in the product. The powder should not be very much dusty. Moreover, to avoid such consequences the dust controllers are also needed to install.

18. How to Maintain Capsule Powder Filling Machine?

In this advanced time, when powder filling machines are used everywhere there is a need to keep them well maintained. It is only then that they can perform their tasks efficiently and effectively. Those business who do not acknowledge the importance of the maintenance of machinery will often end up regretting the time, efforts, and the budget they have put in.

So, before time here is a way for you to get the best out of powder filling machines even after the years of buying it. It is only through the proper service and maintenance of the machine that the life span of it is increased.

Oil Lubrication

Lubricating the parts of the machinery should be done in regular sessions. Oil can be incorporated into the parts of the machine through injections. Some of the components inside the machine are not recommended to operate without lubricating them for many days. However, there are some parts where the oil may not provide any favorable outcome.

There is a need to be well informed about the major and minor discrepancies that could occur. Take, for example, the case of rotating belt, if the oil is spread all over it then there will be a chance of it getting corrode earlier than expected. So, try not to put the oil there. Likewise, the drive belt will also cause damage to it.

The machine wants lubrication after 2500 hours of work done. Note that it is just an estimated figure.

Clean Regularly

There is a need to clean the machine regular. From regular it means on regular basis. Clean the turntable to make the area for the finished products neat and clean. Also, the sealing line should be kept tidy, so that not even a single contaminated particle could interfere with the final product and alter its concentration. The free-flowing powder should also handle with utmost care and the thorough cleaning of the machine needs to be done after their processing.

Prevention from the short circuits is also ensured through proper cleaning as the electrical box present inside the machine will also be cleaned.

Maintenance of Machine

Maintenance of machine is necessary to keep up the good work for the industry as a whole. All of the screws of machines are checked periodically. The functions of the motor are also double checked this way. It is also ensured that the balance of the machine is maintained.

Anomalies in the machine will come up with adverse consequences later on. So, try to mend every part in time through minimum effort.

Conclusion

Purchasing an accurate machine that proves to be error-free while processing any kind of powder is hard to find. However, the manufacturers compete with each other to acquire such kind of machine that could generate sales of the products they made from it. To have such a machine first of all you must have all the relevant knowledge about the powdered substance that your business processes. Then choose the machine that best fits your requirements. Quality and not quantity should be the measure of your purchase.

Capsule Filling Machine Related Products

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours