How to Ensure Counting Accuracy in Tablet Counting Machines?

In pharmaceutical and nutraceutical production, the term accuracy is valued the most. A tiny error can lead to standard regulatory non-compliance, resulting in product recalls with loss of customer trust. The accuracy begins with tablet counting machines. Therefore, several healthcare fields never miss integrating this machine into the workflow. In this article, you will explore fundamental objectives related to ‘How to Ensure Counting Accuracy in Tablet Counting Machines. Let’s read!

1.Why Counting Accuracy Matters in Tablet Counting Machines?

AIPAK Tablet Counting Machine

Accuracy and precision are key aspects of the packaging process, and tablet counting machines are no exception to it. Counting accuracy is integral in ensuring that the patient receives the correct dosage while maintaining brand credibility. With accurate tablet counting, manufacturers can guarantee consistent results every time. Below are the main reasons why the precision of the tablet counter matters:

Major Objectives behind the Need For Accuracy

Compliance with GMP / FDA Regulations

Strict guidelines regarding counting accuracy are enforced by international drug regulatory authorities like the FDA or EMA. Hence, maintaining high levels of accuracy ensures pharma compliance and product quality, which in turn builds customer confidence in medications. Conversely, miscounting errors inevitably result in compliance failures that may escalate to regulatory sanctions, batch recalls, and reputational damage.

Protecting Patient Safety and Dosage Reliability

One of the most important reasons for ensuring tablet counting accuracy is to protect patient health and dose reliability. Inaccurate dosing can have serious consequences, leading to adverse reactions or even treatment failures. But by maintaining counting precision across every bottle and batch, manufacturers can safeguard patient safety and health and ensure that individuals consistently get the exact dose needed for treatment.

Cost Reduction by Minimizing Underfill/Overfill

Besides patient safety, accurate tablet counting is also vital to preventing financial losses. Even little miscounts can accumulate overtime, increasing overfilling rates and needless product giveaways. Whereas underfilling may invite regulatory scrutiny, legal actions, and financial penalties. Using precise tablet counters allows manufacturers to lower product waste and reduce operational costs.

2.What are the Factors That Affect Counting Accuracy?

Optimal counting accuracy requires a combination of advanced tablet counters, regular maintenance, and the right working conditions. Deviation in the physical characteristics of pills, environmental conditions, and human handling may impact the counting accuracy. Below mentioned are some major factors that affect the counting accuracy of tablet counters.

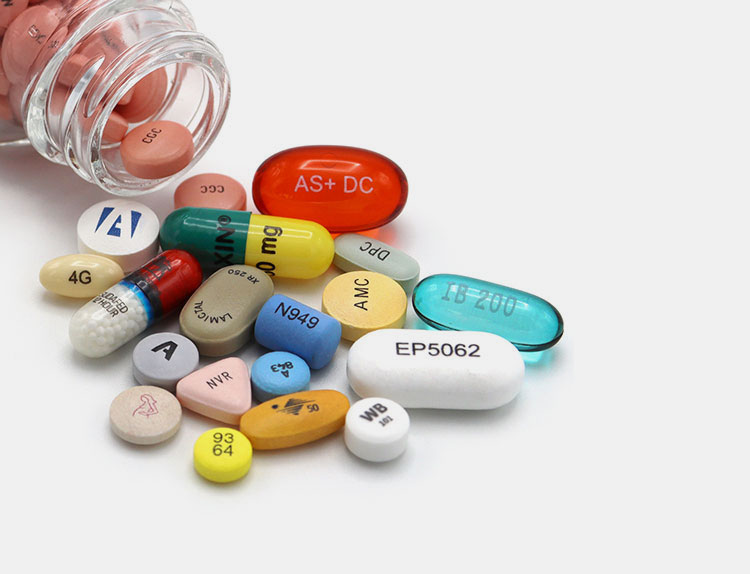

Tablet Size, Shape, and Coating

Tablet Size, Shape, and Coating- Picture courtesy: AKLEY

The sizes and shapes of pills are not always consistent. Often, pills with very small sizes and irregular forms lead to miscounts. These products have inconsistent dimensions and may overlap or jam feeding systems. Also, tablets that have rough or glossy coatings can stick to one another, resulting in their imprecise detection by the sensor.

Dust and Powder Residue

Dust and Powder Residues- Picture Courtesy: Medscape

During processing and packaging, pills may break and generate fine powder or dust. This debris settles on machine surfaces, including sensors. As a result, optical sensors are blocked and are unable to detect light, leading to reduced sensor sensitivity. Due to dust and powder residue interference with the machine vision system, tablet counter precision is decreased.

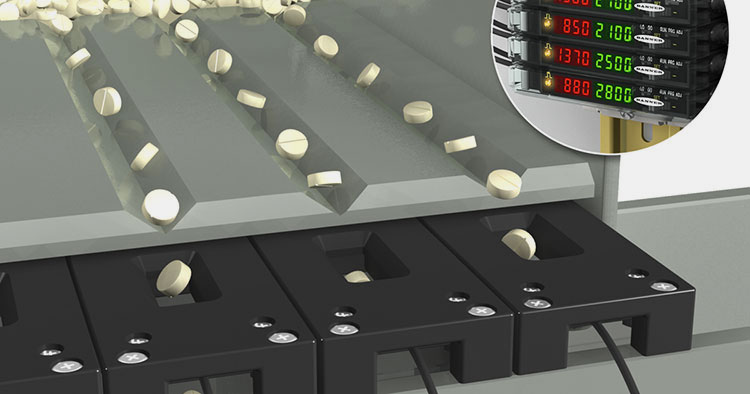

Machine Speed VS. Accuracy

Machine speed VS accuracy- Picture Courtesy: Banner Engineering

The machine speed is a great way to improve production efficiency, but it could come at the price of lower counting accuracy. High throughput vs. accuracy trade-off increases the likelihood of skipped count, tablet overlapping, or sensor misreads because pills pass in clusters through counting channels at high speeds. When this happens, sensors fail to distinguish between individual pills.

Environmental Conditions

Environmental Conditions-Picture Courtesy: BellatRX

Like other aspects of tablet counting machine performance, its counting accuracy is also influenced by environmental conditions. Factors, such as vibration, static electricity, and humidity, disrupt the smooth flow of pills and impact the sensor's performance. For instance, humidity and static charge may cause tablet stickiness, while high vibrations can disturb the sorting and feeding mechanism, ultimately leading to miscounting errors.

3.What are the Best Practices to Improve Counting Accuracy?

Pharma businesses have to ensure counting accuracy while counting tablets and capsules because miscounts can lead to financial penalties and harm the credibility of businesses. Here are some best practices that pharma and other manufacturers can follow to improve the counting accuracy:

Use of Advanced Sensor Technology

Use of Advanced Sensor Technology

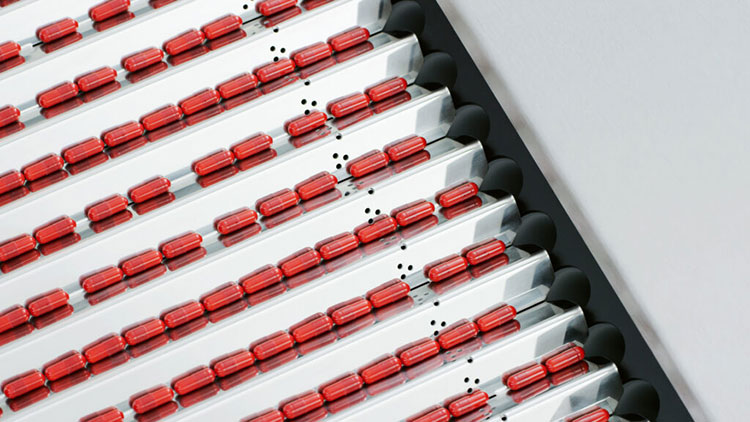

Manufacturers can increase the counting accuracy of production by using a modern tablet counting machine integrated with advanced sensor technology, such as infrared, photoelectric, laser, or camera-based vision systems. Optical sensors are commonly used in high-speed equipment and work by emitting light across a counting channel, registering the number of pills as they pass through. In contrast, vision systems employ high-definition cameras and imaging technology to examine properties of tablets, like their shape and size.

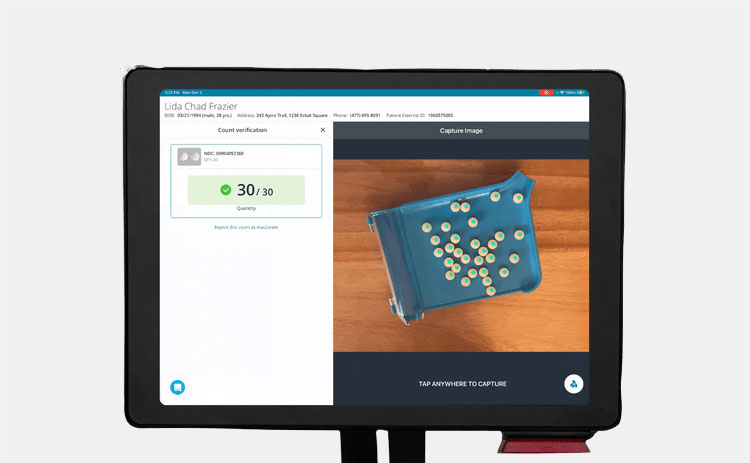

Regular Calibration and Validation

Regular Calibration-Picture Courtesy: Outcomes

The height of counting accuracy is easily attained through regularly calibrating and validating the tablet counting machine. Because if the machine is left uncalibrated, even a tiny counting error will jeopardize production quality. The calibration procedures normally check for verification of tablet count. Operators examine multiple filled bottles to confirm that the number of pills dispensed is the same as the target. In some instances, specially designed pill test batches are also used for fine-tuning equipment performance.

Proper Cleaning and Maintenance

Proper Cleaning and Maintenance-Picture Courtesy: Ruida Packing

One of the most principal measures to preserve counting accuracy is to clean and maintain equipment. After processing pill batches, the tablet counting machine experiences a buildup of dust, powders, and pill fragments, which accumulate and result in counting inaccuracies. To execute proper cleaning, it’s vital to follow the manufacturer's guidelines about the cleaning approach and cleaning substances. Also, feeding systems and sensors are more prone to residue accumulation; hence, it’s essential to pay special attention while cleaning. In this way, adequate pill movement and sensor clarity for counting are ensured.

Operator Training

Operator Training

A significant yet often ignored aspect of improving counting accuracy is the training of operators. Well-trained staff are better at dealing with and resolving everyday counting problems. For training operators, manufacturers should have comprehensive coaching programs in which operators should learn about machine settings, proper maintenance, and identifying frequent issues. This training provides tools for operating staff; thus they can do preventive maintenance to improve counting accuracy and avoid human errors.

4.How to Ensure Counting Accuracy in Tablet Counting Machines?

For pharmaceutical manufacturers, achieving precise counting accuracy is always the top priority. To attain this goal, various strategies, technologies, and tools are developed to ensure every pill is counted properly while packaging.

Comparing Single-Channel Vs. Multi-Channel Machines

Comparing Single-Channel Vs. Multi-Channel Machines

For a pharmaceutical manufacturer, the selection between a single-channel and multi-channel tablet counter directly impacts both counting accuracy and process efficiency. A single-channel tablet counter is simpler in design owing to the presence of only one counting channel; therefore, it counts only one pill at a time. In contrast, multi-channel tablet counting machines have several counting channels that work in parallel, so this allows the counting of multiple tablets in a given interval.

Due to the simple operation in a single-channel machine and the integration of synchronized sensors and control units in a multi-channel machine, counting accuracy is maintained in both of them.

Automated Reject Systems for Miscounts

Auto-Detection Ensuring Consistent Monitoring

In a tablet counting machine, automated reject systems are integrated, which serve as an integral quality control feature. With these systems, an exact, prescribed quantity of pills is ensured in every container.

Basically, these rejection systems rely on sensors, a counting tracking software, and an actuator system to ensure counting accuracy. The tracking software keeps a record of filled count. If the filled quantity is inaccurate, the control unit activates the actuator components to remove the bottle from the conveyor. Normally, either a mechanical paddle or a compressed air unit diverts a faulty bottle to the reject bin.

Integration with Bottling & Packaging Lines for Quality Consistency

Integration with Bottling & Packaging Lines

Contrary to popular belief, counting accuracy doesn’t end with a tablet counting machine. Rather, it should be maintained throughout the packaging line. For this, manufacturers integrate their counting machines with other systems in the tablet bottling & packaging line for end-to-end accuracy and quality consistency. This synchronization is vital in preventing issues of double fills, missed transfers, or product spillage.

5.What are the Troubleshooting Accuracy Issues?

Operational failures while tablet counting are very common. Both small-scale units and high-speed productions face accuracy issues every day, which leads to a loss of productivity. In the following section, we’ll explain some troubleshooting tips for accuracy issues:

Common Miscount Problems and Quick Fixes

Miscount Problems and Quick Fixes- Picture courtesy: BellatRx and Pharmaland

Even the most advanced tablet counters sometimes fail to accurately count tablets. However, by understanding the cause of miscounting problems and quick fixes, operators can maintain counting accuracy throughout operation and reduce downtime.

| Miscount Problem | Quick Fix |

| Tablet Overlapping

Sometimes tablets may stick together, resulting in double-counting or missed counts. High moisture, inadequate tablet coating, or discrepancies can be the reason for this issue. |

To rectify this issue, you can use a deduster or polishing machine before counting. Also, adjust the feeder vibration and decrease the humidity in the processing area to fix tablet clumping issues. |

| Dust Presence on Sensors

Powder dust may settle on the sensors, which prevents the sensors from detecting the light beam. Occasionally, accumulated dust may scatter light in various directions. |

An easy solution to this problem is to implement a daily cleaning schedule in your productions and wipe sensors and channels on a routine basis. The installation of dust extraction units solves the dust generation hazards. |

| High Feeder Speed

If the tablets move at very high speed from the feeder to the counting channels, the tablets go undetected by sensors. Or they may pass in clusters, making them hard to count by sensors. |

When this happens, operators are advised to modify the feeder vibration or speed to match the pill shape and size. Manufacturers can buy a multi-channel machine if they’re dealing with large product batches, which will prevent miscounting problems. |

| Sensor Misalignment

If sensors in equipment are misaligned or mispositioned, they can’t spot pills properly, resulting in miscounting errors. |

If there are counting inconsistencies, check the sensors and realign them as per the equipment manual. |

When toReplace Sensors or Upgrade Software

Replace Sensors or Upgrade Software

Damaged or defective sensors, as well as software errors, are the major reasons for miscount problems. So, knowing when to replace sensors or upgrade software is essential in troubleshooting accuracy problems.

Sensor Replacement

If the machine sensors are frequently showing miscounting errors, are slow in detecting tablets, or operators are facing difficulties in calibrating sensors, then it’s time to change the sensors. It is crucial because worn-out or faulty sensors can’t give a reliable tablet count.

Software Upgrade

This is needed when machine software is old, hasn’t been updated for quite some time, lacks new features, or isn’t compatible with the latest packaging units. Manufacturers are also required to upgrade their software if it repeatedly displays erroneous counts. With upgraded software, businesses may get enhanced tracking, smarter rejection logic, and optimized sensor integration.

Importance of OEM Support and Spare Parts Availability

OEM Support and Spare Parts Availability- Picture Courtesy: Altrimex

In addition to understanding machine issues, the support of OEM (Original Equipment Manufacturer) and quick spare parts availability also helps in rectifying miscount problems.

Importance of OEM Support

With OEM support, business owners can have technical expertise and assistance, have a specialized training program for their operators, and get instant help in case of a serious issue. Furthermore, cooperative OEM notifies its machine user if an update of software is available and supplies original spare parts.

Significance of Spare Parts Availability

As components of all systems tend to wear out with passing years, keeping an inventory of validated spare parts on hand is necessary. This allows users to prevent production interruption and also to sidestep the risks linked with using non-standard or third-party replacements.

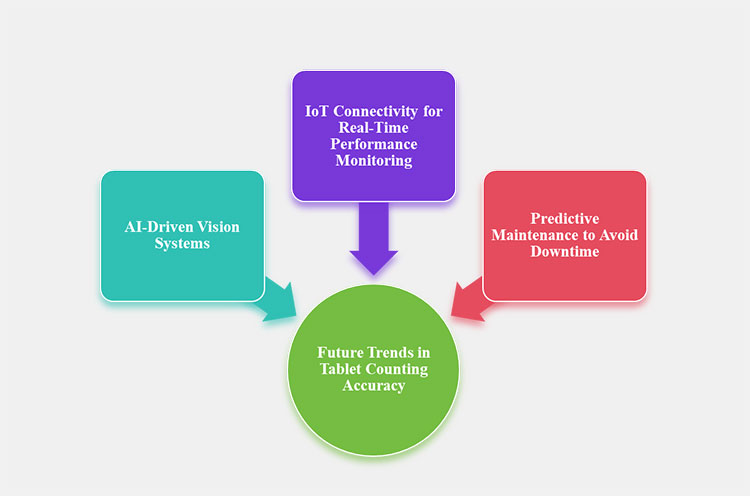

6.What are the Future Trends in Tablet Counting Accuracy?

Rapidly evolving technology has drastically improved the counting accuracy of modern tablet counting units. Here are some main futuristic innovations that manufacturers can explore to enhance quality control in their businesses:

Future Trends in Tablet Counting Accuracy

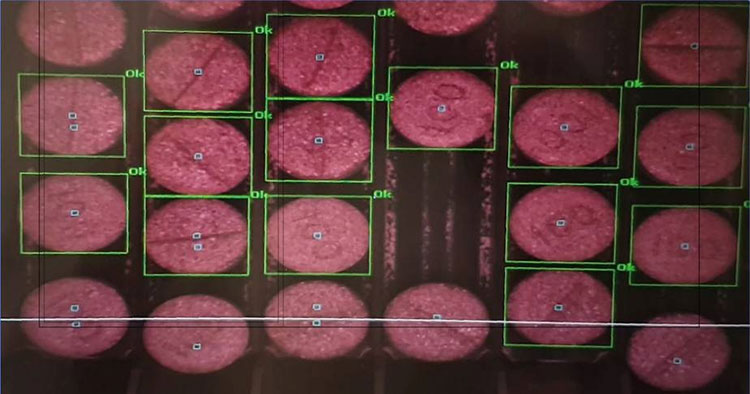

AI-Driven Vision Systems

AI-Driven Vision Systems- Picture Courtesy: Founding Minds

The analytics and precision in tablet counting systems are being transformed by the use of AI-driven vision systems. Deep learning approaches and superior performance cameras are incorporated in these components to carry out various steps, such as object detection, segmentation, tracking, and counting. This leads to faster counting and higher accuracy rates.

IoT Connectivity for Real-Time Performance Monitoring

Real-Time Performance Monitoring- Picture Courtesy: IMA Group

The integration of IoT (Internet of Things) connectivity has augmented the tablet counting accuracy. By creating a machine network with a central processor, manufacturers can view the real-time performance statistics like counting speed, sensor detection rate, and temperature and humidity of the environment. In this way, they receive immediate alerts for counting errors, facilitating them to implement instant corrective measures.

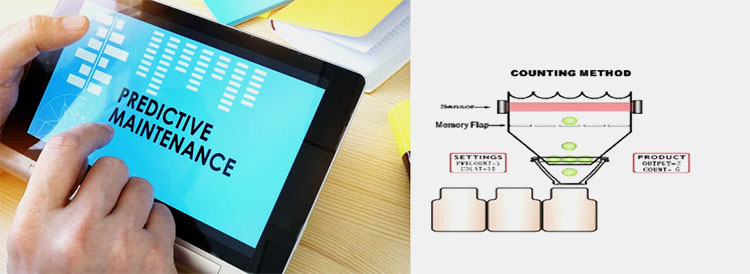

Predictive Maintenance to Avoid Downtime

Predictive Maintenance to Avoid Downtime- Picture courtesy: Llumin CCMS

With the advancement in automated data processing and expert systems, predictive maintenance is implemented to proactively identify and address potential issues before they result in a breakdown or complete machine failure. Automated dashboard provides clear insights into conditions and wear of components, enabling swift repair, cleaning, lubrication, and replacement.

Conclusion

In short, the counting accuracy of the tablet counting machines is the cornerstone of any production. It safeguards pharma compliance, patient safety, and manufacturing quality. Inaccuracy, whether overfilling or underfilling, not only impacts batch consistency but also leads to financial losses, regulatory non-compliance, costly product recalls, and reduced customer trust. To ensure tablet counting accuracy, manufacturers must invest in advanced sensors, vision technology, and reject systems, and regular machine maintenance, calibration, and cleaning. Have more questions about counting accuracy or are you interested in placing an order? Connect with AIPAK today, and our team will promptly assist you.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine