Film Coating Machine:the Ultimate Buying Guide in 2025

Have you ever get complain of unpleasant odor and taste of the oral pallets. Do your customers also show rejection towards oral drugs and ask you to improve the quality of the tablets. The swallowing of bitter and noxious drug is quite difficult. To overpower this problem pharmaceutical industry has come up with various solutions. There has been great development and inventions in the pharmaceutical industry. All these inventions have given a great shift to the pharmaceutical business. The demand for the latest technology for the high quality production of pharmaceutical drugs is increasing day by day. With all the new technologies one of the biggest invention is the Film Coating Machine.

Film Coating Machine has given the solution of masking the unpleasant taste and smell of tablets, pills, and capsules. Film coating machine is an ideal tool and is not the choice but the need of the modern pharmaceutical industry.

Film Coating is a process in which a thin layer of the polymer-based formulation is coated on the pills, tablets, capsules, and powder formulations. The purpose of Film Coating is to mask the unpleasant taste of the drug and to protect it from environmental harsh conditions.

All this information will help you in a better understanding of the Film Coating Machine. You will be able to make a conscious decision about the buying of film coating machine after going through this information.

1.What is Film Coating?

Film Coating is a pharmaceutical process in which thin film made up of polymer-based materials is coated over the pills, tablets, capsules, as well as on the powder formulations.

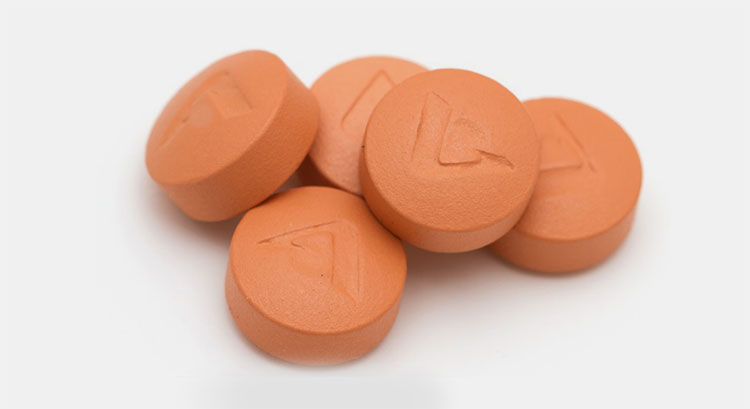

Film Coated Drugs-Image Courtesy: pharmaexcipients

It is necessary to protect the pharmaceutical drug from the harsh environmental conditions, it also makes the swallowing of drugs easy by overpowering the bitter taste of drugs.

2. Why it is beneficial for you to film coat the tablets?

Oral medication is the most common form of drug intake by people. Several pharmaceutical processes are carried out to improve the efficiency of the drugs and to ease the process of drug intake. Film coating is also one of those processes that benefit the consumer and positively impact the growth of the pharmaceutical industry.

The following points give a clear understanding of the importance of the film coating of pharmaceutical drugs.

Reasons for the Film Coating-Image Courtesy: pharmaexcipients

Aesthetic Aspects:

In the process of film coating a thin layer of special ingredients is coated on the pills, capsules, and tablets, this gives the tablet a colorful aesthetically pleasing appearance. The different colors of the film coating also help in the identification of different pills and is a smart way of branding the products.

Ease the Swallowing:

It is important to film coat the drugs to mask the unpleasant taste of the drug, as well as the odor of the pill is also compensated. In this way, the film coating makes the swallowing of the drugs easy for its consumer.

Protection of the Drug:

Film Coating is necessary for the protection of the drugs as it provides a protective layer against harsh light, heat, moisture, and oxidation. Thus, it overall improves the shelf life of the drugs.

Release of the drugs at various sites:

Film coating is important for the release of active drug ingredients at the required site. Some drugs need to be released in the intestine so film coating provides protection to the drug against the acidic PH of the stomach and ensures its action in the intestine respectively.

The film coating also works in the sustained release of the drug and positively impacts the efficiency of the drug.

3. What is a Film Coating Machine?

Film Coating Machine is a pharmaceutical device that is used to coat a thin layer of polymer-based coating on a compressed pill, tablet, or capsule for various functions.

The film coating machine has different designs and specifications available depending upon the requirements of the consumer. So, you always have a choice to customize your film coating machine depending upon your needs and market demands.

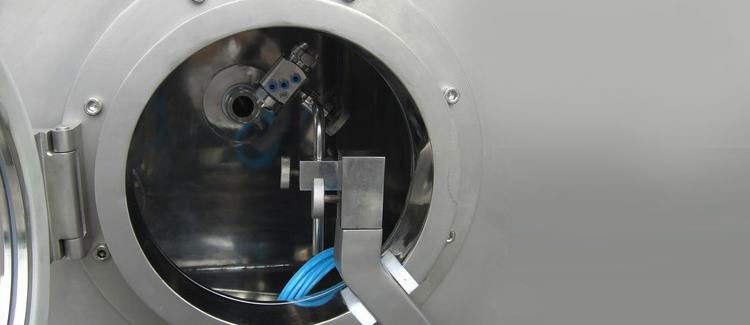

AIPAK Film Coating Machine

4. What different types of solvents can be used in the Film Coating Machine?

The choice of solvent in the film coating machine highly affects the process of film coating and the quality of the coated products. You should be very vigilant while choosing your solvent. Here I will guide you about different parameters of the solvents that must be considered before choosing it for the process of film coating in the film coating machine.

Aqueous and Non-Aqueous Solvents-Image Courtesy: alfa

A good solvent must have the following properties:

- It must be colorless, odorless, non-reactive, and non-toxic.

- It shouldn’t react with the environmental changes, and must not alter the chemical properties of the drug.

- It must be readily dissolved with a polymer-based coating.

- It must have good drying properties to reduce the defects in the drugs.

The commonly used solvents include ethanol, methanol, ethyl lactate, ethyl acetate, acetone, chloroform, and methylene chloride.

5. What materials are used in the Film Coating of the tablets?

The film coating of the drugs is done by mixing various ingredients in definite proportions. The following blend of ingredients makes a perfect polymer-based film coating for tablets, pills, granules, and capsules.

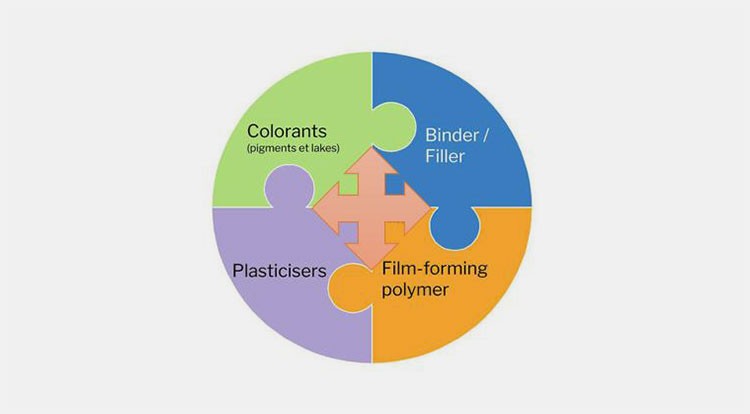

Composition of a Film Coating-Image Courtesy: seppic.com

Polymers:

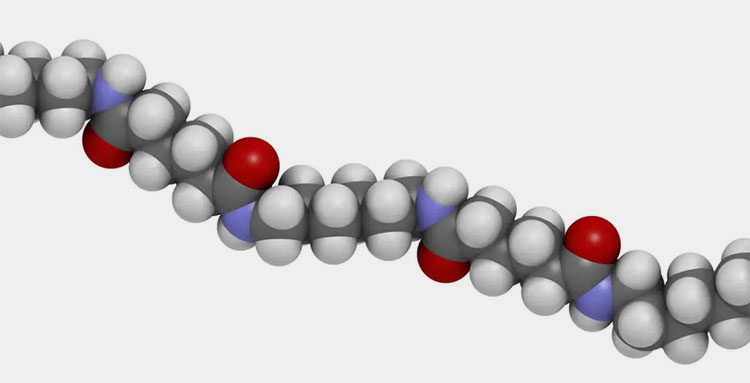

A pharmaceutical polymer makes the backbone of the film coating layer. A polymer is a substance that has the ability to form a long chain of molecules having a molar mass of millions. It gives an aesthetically appealing look to the product and makes the product stand out from the rest, thus increasing the market demands.

Polymer-Image Courtesy: sigmaaldrich

An ideal polymer has the following characteristics:

- A good polymer must be soluble with a large number of solvents.

- It must be stable against light, heat, moisture, and oxidation.

- It must not react with the drug upon which coating is being performed.

- It must not have any pharmacological properties and must be non-toxic.

- It must have high compatibility with additives other than the pharmaceutical drug.

- It must have high binding properties to form a good film in the coating process.

The most commonly used polymers include:

- Vinyls, in the form of polyvinyl alcohol

- Cellulosics, like hydroxypropyl methyl cellulose (HPMC), hydroxypropyl cellulose (HPC), and ethyl cellulose (EC).

- Acrylics, such as methacrylic acid, ethylacrylate copolymers.

- Natural derivatives including alginates and shellac.

Solvents:

Different solvents are used in the film coating machine. Solvents are preferred over water because of the poor drying properties of the water, and the adhesion of polymer with water is zero. Thus, the use of the aqueous system will make the polymer-based coating unstable.

Solvents-Image Courtesy: studiousguy

The commonly used solvents include chloroform, ethyl acetate, ethyl lactate, castor oil, coconut oil, and methylene chloride.

Colorants:

Colorants and other pigments are used to enhance the appearance of tablets and pills. They also provide protection against light and moisture. They improve the gas permeability of the tablet and increase the thickness of the tablet. They also improve elasticity by reducing tensile strength.

The following types of coloring agents can be used in the film coating machine.

Colorants-Image Courtesy: cuttothetrace

Natural Dyes:

It includes carotenoids, vegetable juices, and turmeric.

Water-insoluble colors:

It includes tartrazine, quinoline yellow, indigo carmine, and Allura red.

Water-soluble dyes:

They can also be used like FD&C, and Yellow 5.

Inorganic pigments:

It includes iron oxide, pearlescent pigments, and titanium dioxide.

Plasticizers:

Plasticizers are the low molecular weight molecules that are used along with the polymer to alter the physical properties of the polymer. They help in attracting the dispersed solvents molecules and weak the bonds between the polymer molecules. In this way, the flexibility of the film coating is improved. They also adjust the elasticity, stress, and tensile strength of the coating. There are different types of plasticizers used that have different physiochemical properties and permeability.

The list of the plasticizers that can be used include:

- Oils including vegetable oil and mineral oil.

- Glycerides like acetylated monoglycerides.

- Polyhydric Alcohols include glycerol, polyethylene glycol (PEG), propylene glycol.

- Acetate Esters such as triethyl citrate (TEC), and triacetin (glycerol triacetate).

Flavors:

These are used to improve the taste of the pill and are also good for branding the product. They are used as sweeteners that are either natural or artificial sweeteners like mint vanilla, berry, and mint.

Glidants:

They are used to make the film coating smooth and dent-free. They are in the form of waxes and talc.

Viscosity Modifiers:

They are used to improve the overall strength of the film coating and make the process more effective. They include gums and carbohydrates like starch, lactose, and polydextrose.

6. What advantages you can get from the use of the Film Coating Machine?

The uses of the film coating machine are numerous. Film coating machine has given a huge shift to the manufacturing of the pharmaceutical drugs. Following are some of the major benefits of the film coating machine.

- The film coating machine is fully automatic and it gives 100% accurate and effective results, thus reducing the cost of the labor.

- The film coating machine makes the tablets smooth and even thus ease in the swallowing of the tablets.

- The film coating machine produces tablets that are light in weight as there is only 2-3% of overall weight gain of the drug after the film coating.

- The film coating machine protects the tablets from light, heat, moisture, and environmental oxidation.

- The film coating makes the drug-resistant to the action of stomach acids.

- The film-coated tablets are safe to use for consumers of all ages.

- The film coating machine produces a thin layer of film over the tablets that masks the unpleasant taste of the tablet and made its swallowing easy.

- The absorption of the film-coated tablets is better in the body than the non-film-coated tablets.

- The film-coated tablets are more effective due to a long time of dissolution.

- The film coating machine gives an attractive, and eye-catching appearance to the drugs, thus making them aesthetically appealing as well as the film-coated tablets are identified easily.

7. Which type of drugs are used in the Film Coating Machine?

Almost all types of drugs can be film-coated as it increases the efficiency and effectiveness of the drug and also enhances the sales of the drug thus increasing the market value of the drug.

The common examples of the film-coated drugs are Zinc 30mg, Atenolol 100mg, Ondansetron 8mg, and Ibuprofen 200mg.

8. What are the different parts of a Film Coating Machine?

A Film coating Machine is made up of many parts since there are different types and models of the machine available, thus the arrangement of components also differs accordingly. As you have the choice of customization of the film coating machine so the parts of the machine can be adjusted accordingly.

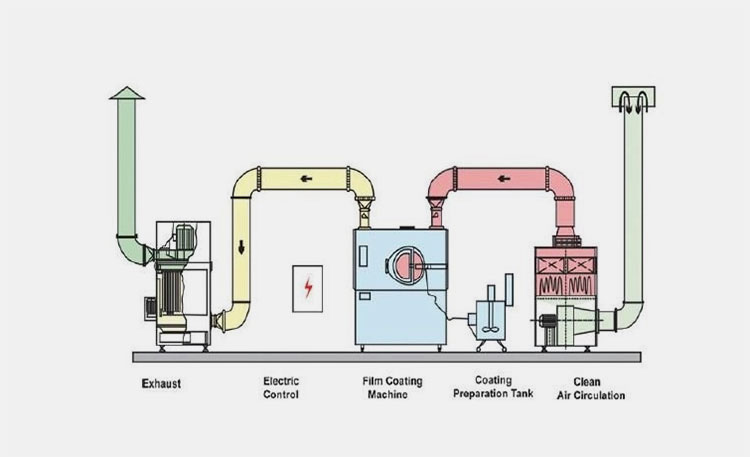

Lay out of Components of the Film Coating Machine

It is important for you to look up the different parts of the film coating machine before your final purchase. Here I am going to describe some of the common and relatively more important parts of a film coating machine.

Electric Motor:

The electric motor of the film coating machine is used for various functions as mixing the tablets, blowing the air, and creating negative pressure. There may be as many as three electric motors present in the film coating machine depending upon the capacity of the machine.

The electric motors are present in the peristaltic pump, air exhaust section, coating system, and hot air equipment.

The energy consumption and the cost of the tablet coating depend upon the type of motor being used.

Automatic Control System:

Modern technology gives you full control of the operations of the film coating machine.

Automatic Control system-Image Courtesy: bhagwatipharma

The automatic control system gives you the authority to manage the system of the machine in various ways.

- You can select the operating state of the machine.

- You can control various parameters like temperature, pressure, and speed of the process.

- You can document the whole process of film coating and print it later on.

- You can even select to display the whole data of the process.

So before buying the film coating machine always check for the latest technology and the level of the atomization.

Touch Screen Panel:

This is the most advanced function that is user-friendly and provides Human Machine Interface (HMI). This makes your work even more easy and effortless.

Touch Screen Control Panel of Film Making Machine-Image Courtesy: bhagwatipharma

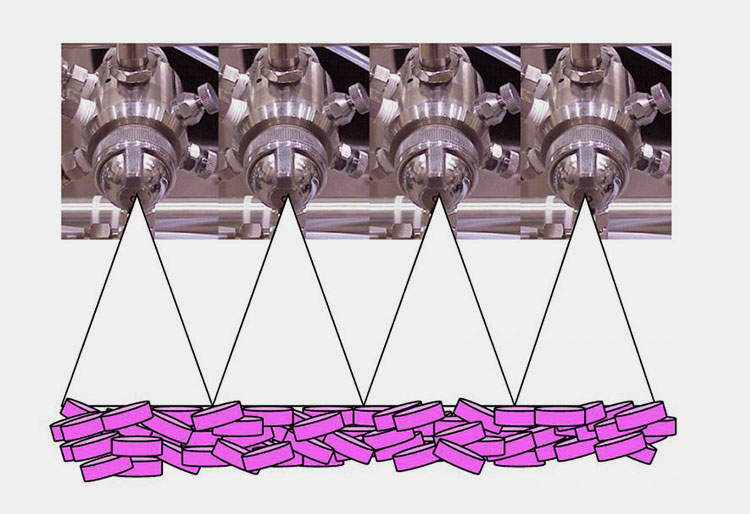

Spraying System:

This is the most important part of the film coating machine consists of a nozzle, tank, and pump. The simplicity of this component helps in stable the atomization process, ease in the cleaning of the spraying gun, as well as the coating solution doesn’t waste. The head of the spraying gun is easily adjustable and it can also help in the atomization of a large amount of coating solution.

Spraying System of the Film Coating Machine-Image Courtesy: freund-vector

Guide Plate:

There is a system of guiding plates in the film coating machine that helps the tablets to tumble smoothly in the pan during the coating process. These guiding plates also help in preventing the breakage of the tablets as they collide with the solvent from the spraying gun. The guiding plate also helps in the drying process and eases the flow of the dry air.

Guide plates of the Film Coating Machine-Image Courtesy: bhagwatipharma

Peristaltic Pump:

The peristaltic pumps help in achieving uniform atomization from the spraying system, and it also controls the pressure of the coating solution. So equal volume of solution is coated over the tablets.

Peristaltic Pump of the Film Coating Machine-Image Courtesy: bhagwatipharma

Coating Preparation Tank:

This is the component in which the coating solution is prepared and with the help of the pump, the solution is inserted into the spraying system.

Clean Air Circulation:

This part of the film coating machine helps in receiving the air from the external environment. It also functions to adjust the temperature of the air before blowing it over the coated tablets.

Exhaust:

This is used for maintaining the temperature of the system by blowing off the hot air that dries the coating tablets. Thus it is the temperature dropping system of the machine.

9. What is the working principle of a Film Coating Machine?

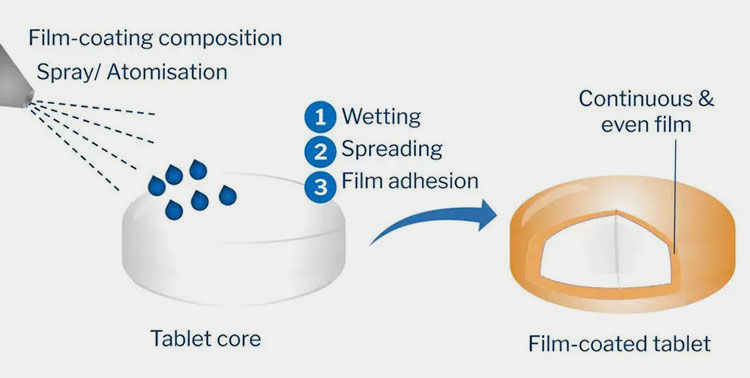

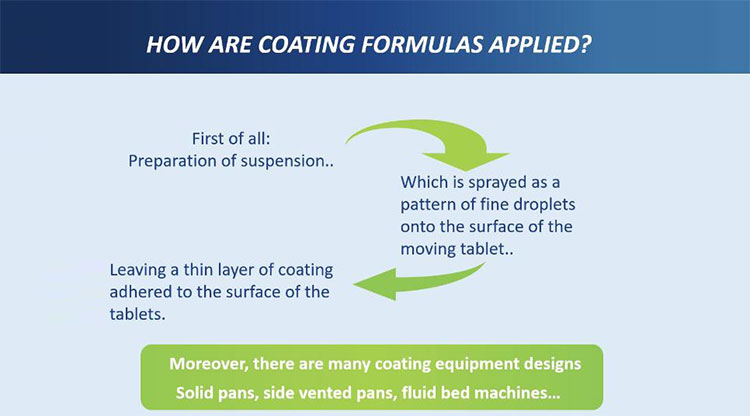

Process of the Film Coating-Image Courtesy: seppic

The working principle of the film coating machine is very simple and is completely automatic. First of all, you will prepare the coating mixture by adding the required solvent in the polymer-based solution along with other ingredients like plasticizers, colorants, flavors, and viscosity modifiers. The tablets are loaded in the pan or coating drum and the coating solution is uniformly distributed in the spraying system. The distance between the tablet's bed and the spraying gun should be accurate. The atomizer will help to achieve a uniform coating through the sprinkling of fine droplets. The droplets of the coating solution will collide with the tablet and spread in a uniform film form. There are multi-gun systems in the film coating machine.

Process of Film Coating-Image Courtesy: .pharmaexcipients

After the uniform coating of the solution, the other important step is the drying of the coated tablets. This is achieved by the pumping of hot air over the tablet bed. The temperature, speed, and pressure of the air are controlled by the automatic system of the machine.

After the drying of tablets, they are then sent for packaging.

10. What are the different types of Film Coating machines?

There are different types of film coating machines available in the market. There has been so much advancement in science and technology that you can now customize your own film coating machine based upon your requirements and demands.

Here I am going to give you an overview of the three most common types of film coating machines that are widely used by pharmaceutical manufacturers.

Standard Pan Coating System:

This is the most common type of film coating machine that is used by pharmaceutical manufacturers. This machine has a circular metal pan of almost 6 to 8 inches (15 to 200cm) in diameter that rotated with electricity. The tablets are loaded in the pan and with the rotating action of the pan, the tablets move in the pan. With the help of atomization, the coating materials are coated on the tablets. The atomizer produces fast and even distribution of the coating.

Pan Coating Machine-Image Courtesy: Indiamart

The next step is the drying of the tablets that can be done by:

- The use of immersion sword in which the dry air is sprayed through a metal sword immersed in the bed.

- The use of diffuser and baffled pan in which the dry air is equally distributed on the surface of the tablets.

- The use of the immersion tube system in which the tubes embedded in the bed sprayed heated air through the nozzle.

Perforated Pan Coating System:

In this type of coating, the system has a partial or full perforated material drum that is housed in a sealing system. The drum rotates in the horizontal direction and the tablets are sprayed with the coating material through a nozzle that is positioned on the inner side of the drum. This system has high spray rates in the shortest time period. Also, the horizontal position of the drum gives smooth and even coating results.

AIPAK Perforated Coating Machine

The drying of the tablets is achieved by bypassing the dry air through the bed of the tablets. The air leaves the system through the backside of the pan. This horizontal flow of air gives high-quality coating results.

11. Which factors affect the efficiency of the Film Coating Machine?

There are some factors that impact the process of the film coating machine. It is important to discuss these factors as they affect the quality of the film coating machine.

These factors include:

Composition of the Coating Material:

The right composition of the coating material is necessary for the high efficiency of the film-making machine. The coating material includes a mixture of polymer and other ingredients with the solvent. The solvent is removed in the process of drying through the application of the hot air. There must be a fine balance between the rate of removal of solvent and the introduction of the coating liquid.

Surface Area of the Tablet:

The size and weight of the tablet are important in determining the amount of coating material required. The area/weight ratio decreases as the size of the tablet increases. The overall surface area of the tablet describes the amount of coating material needed. It is important to select the standard size of the tablets, otherwise, it will not only affect the efficiency of the machine but also cause defects in the tablets.

The capacity of the Air:

The dry air is blown during the drying of the solvent from the tablet after is coating is done. The right amount of air is necessary during the drying process otherwise it leads to defects in the tablet.

The efficiency of the equipment:

The machine must be fully functional and all the parts of the machine must be in fully working condition, otherwise, it will affect your coating process.

12. How do the film-coated tablets differ from the non-film-coated tablets?

When we talk about the choice between the coated and non-coated tablets we compare both of them on the basis of their individual benefits and drawbacks. Let me give you a clear picture of both of the tablets.

| Characteristics | Film Coated Tablets | Non-Film Coated Tablets |

| Safety of the Drug | They have a thin plastic cover that prevents the drug from damage of heat, light, and moisture. | They don’t have any protective layer around them, thus are exposed to damage from the environment. |

| Dissolution Time | They take more time to dissolve in the acidic environment of the stomach. | They get dissolve very easily in the stomach. |

| Health Effects | They prevent you from the stomach irritation as coating layer don’t dissolve in the stomach PH. | These drugs cause stomach irritation, ulcer, and bleeding. |

| Physical Characteristics of the Drug | The film coating mask the unpleasant taste and odor of the drug thus makes it consumer friendly. | These drugs have unpleasant taste and odor that makes the swallowing of the drug difficult for the patient. |

| Cost Friendly | They are expensive as the coating increase the 2-3% weights of the drug, and the use of the modern technology makes the drug costly. | They are cost friendly and inexpensive as compared to the film coated ones. |

13. What is the difference between Aqueous Film Coating and Non-Aqueous Film Coating?

The aqueous and non-aqueous film coating has their own characteristics, and the choice between the two highly depends upon the nature of the drug. Here are the major differences between the aqueous and non-aqueous film coating.

| Characteristics | Aqueous Film Coating | Non-Aqueous Film Coating |

| Rate of Evaporation | It has high rate of evaporation and takes more time for drying. | It evaporates quickly and takes less time in drying. |

| Environmental Hazards | It doesn’t produce any chemical or side products that are dangerous for the environment. So it is environment friendly. | It produces side products that are dangerous to the environment. |

| Effect on the Drugs | It takes more time for drying thus can cause defects and dents in the drug. | It has no effect on the drug as it dries out very soon and leaves the drug unaltered except the slight change in the taste and odor of the drug. |

| Ventilation | It doesn’t have any special requirements for the ventilation. | It requires high production area for proper ventilation. |

| Maintenance of the Machine | In aqueous coating the machine can be used again and again without special cleaning and adjustment. | For non-aqueous film coating the machine needs to be cleaned each time after the process is carried out. |

14. How you can differentiate Enteric Coating from the Film Coating?

Enteric coating and the Film coating are the two different types of the coatings and can be differentiate in the following ways.

Enteric Coated Tablets-Image Courtesy:Berkeley Wellness

| Characteristics | Enteric Coating | Film Coating |

| Site of Absorption | Enteric coating is resistant to the acidic PH of the stomach and absorb in the small intestine. | Film Coating is not resistant to the acidic environment of the stomach and is readily absorbed in the stomach. |

| Time of Coating | Enteric coating takes more time as it takes more time to dry the coating. | Film coating is easy to done and it dries out quickly. |

| Cost-Effectiveness | Enteric coating is cost friendly and inexpensive. | Film coating is expensive than the enteric coating and is not cost effective. |

| Dissolution Time | The digestion time for the enteric coating is almost 120 minutes. | Film coating dissolves after the 30-60 minutes of their intake. |

15. What quality standards must be fulfilled by a Film Coating Machine?

For a Film Coating Machine, some quality standards must be fulfilled to ensure the safety of users of the machine. These standards are equally important for the safety of its users.

Quality Assurance-Image Courtesy: testbytes.net

The important quality standards include:

- cGMP

- License from the FDA

- Halal and Kosher Certification

- ISO 9001: 2000 certification

16. What are the common problems of the Film Coating Machine?

Some problems may occur in the Film Coating Machine. These problems need to be addressed and solved on an immediate basis otherwise it will affect the efficiency of the film coating machine and hence cause a delay in production.

Following are the common problems of the film coating machine.

The twinning of Tablets:

The tablets may stick to each other because of the high surface area. This problem can be overcome by having the small surface of tablets, and the other important thing in this regard is to introduce slight curvatures in the edges of the tablets rather than shaping them simply flat. In this way, the tablets will not stick together.

Twinning of the Tablets-Image Courtesy: filmcoating-troubleshooting

Breaking of Tablets:

During the pan loading and unloading of the tablets, the breakage of pills may occur. To avoid this you must observe the process of pan loading and unloading. Also, check the breakage force for the tablets.

Chipping of the Tablet-Image Courtesy: filmcoating-troubleshooting

Discoloration of Tablets:

Sometimes the color difference in the form of patches and light color may be observed in the pills. This problem occurs because of high temperature than the normally required temperature. The other reason for this problem is the improper mixing of the ingredients. So, by adjusting the temperature and proper stirring you can avoid precipitation and patches on your pill.

Discoloration of Tablets-Image Courtesy: filmcoating-troubleshooting

High Humidity in Tablets:

The main reason for the humidity in the tablets is the difference in the speed of spraying nozzle and drying out time. This problem mostly occurs with the aqueous coating. As the water-based solvents take more time to dry out than the other organic solvents. The high humidity will cause damage to the film and make uneven films.

Excessively Humid Tablet-Image Courtesy: consumerlab

This problem can be avoided by adjusting the speed of the spraying nozzle and increasing the temperature of the inlet. You can also use talcum powder and magnesium stearate to avoid this problem.

Rough Texture of Tablets:

The outer surface of the tablets may become rough and the tablets appear to look uneven. This problem occurs because of fast spray drying, the dried polymer particles stick to the surface of the tablet and cause roughness. This phenomenon is also known as the orange peel phenomenon as the texture of the tablets looks like the surface of the orange peel.

Excessive Roughness of Tablet Surface-Image Courtesy: filmcoating-troubleshooting

This problem can be solved by adjusting the spraying speed, lowering the air inlet temperature, and shortening the distance between the spray bed and tablet bed.

Logo Bridging:

When the viscosity of the coating material is high then the outer surface of the tablet becomes irregular and bridges will form. The simple solution to this problem is increasing the amount of solvent or plasticizer in the coating mixture.

Logo Bridging of Tablets-Image Courtesy: filmcoating-troubleshooting

17. How to maintain a Film Coating Machine?

For the high quality and proper functioning of the Film Coating Machine, it needs to be cleaned and maintained at regular intervals of the time.

The following steps will help you in maintaining and cleaning your film coating machine:

- Clean the coating pot and lubricate it properly.

- The machine must be positioned properly on the ground.

- The electrical connections of the machine must be well adjusted and you must not disturb these connections.

- In case of any issue in the parts or functioning always seek expert technician advice.

- Properly clean the different parts of the machine.

- To avoid any blockage in the machine pressurize the spraying gun and rinse with clean water after every use.

These small steps will help you in the long run of the machine and will save you from the hustle of loss of production because of improper functioning of the machine.

18. What are the future insights of the Film Coating Machine?

Tablet Coating Machine Related Products

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine