6 Important Things You Need To Know About The Tablet Coating Machine

Have you ever seen or known the tablet coating machine before?

If you know something about the machine, this article will help you get more information about the tablet machine that you didn’t know before, especially the aspect of operation steps.

If you don’t know anything about this machine, you’d better not miss this article. Because it can help you know 6 important things about the tablet coating machine.

Do not hesitate, let’s get started!

Before we understand these two aspects of knowledge.

We must first understand the subject of this knowledge- the tablet coating machine.

Maybe you will have the same questions as me.

What is tablet coating? What is a tablet coating machine?

Tablet coating is an important machine widely used in the pharmaceutical industry.

It is used for the application of non-functional or functional coatings (polymer films that play an aesthetic, protective role or control the reaction speed), as well as the precipitation of active pharmaceutical ingredients (API) onto multi-particle preparations.

Tablet Coating applications include masking taste, modifying color, physically protecting, and/or making improved release forms.

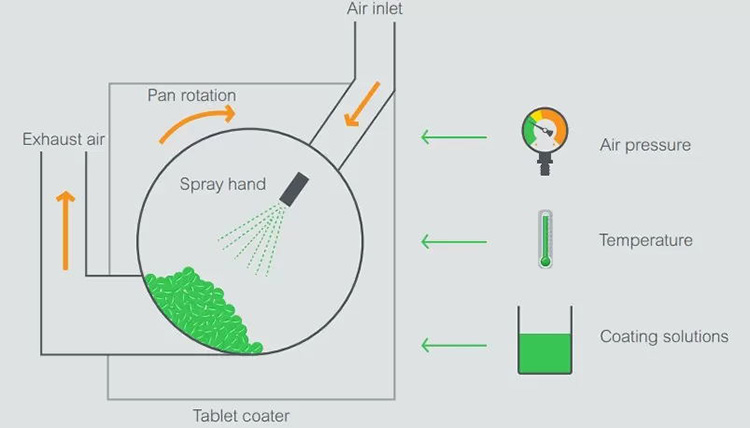

The table coating machine is mainly composed of the main machine, the controllable normal temperature hot air system, the automatic liquid and gas supply spray system, etc.

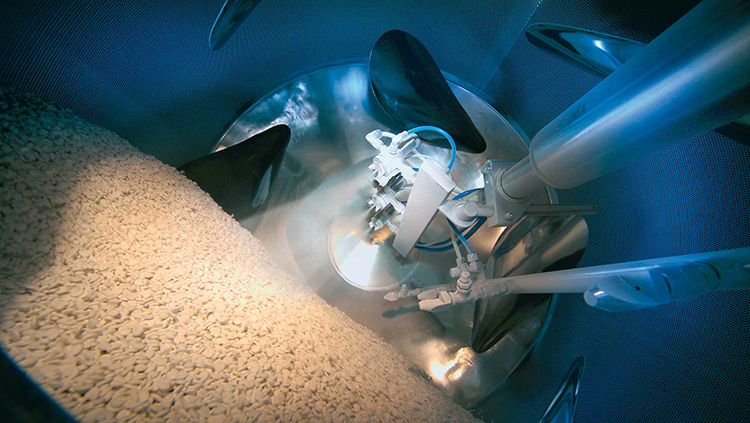

The main motor in a tablet coating machine can be controlled by frequency conversion, and the coating excipients are sprayed onto the tablet surface with a high atomization spray gun through the automatic control of electrical appliances.

At the same time, the tablets move in a continuous and complex trajectory in the coating pot of the tablet coating machine, so that the coating liquid is evenly wrapped on the tablet core.

There is a controllable room temperature hot air in the tablet coating machine’s pot to dry the tablets at the same time, so that the surface of the tablets can quickly form a solid, fine, complete and smooth surface film.

After having a fundamental understanding about the table coating machine.

You need to start in the first direction.

Five operation steps of the tablet coating machine.

Installation of the tablet coating machine

First, turn on the tablet coating machine’s power. What you need to pay attention to is that the phase line and zero line cannot be connected incorrectly.

Second, you need to pass the air source through Φ 8pu pipe, which should be connected with the connector of the air pipe at the lower side of the machine body.

Third, you should add coating liquid into the tablet coating machine’s liquid cylinder.

Fourth, start the tablet coating machine’s power switch and turn on the power.

Fifth, you must adjust the speed of the main engine according to the operating instructions of the main engine governor.

Sixth, you need to turn on the inlet air regulation switch and let the inlet air machine begin to work.

Seventh, to adjust the temperature controller, you need to adjust the temperature to the temperature value you need.

At this time, if the actual temperature is lower than the set value, you need to turn on the heater to start heating. If the actual temperature is higher than the set value, you need to disconnect the power supply of the heater to stop heating.

Eighth, you should turn on the spray gun switch and the spray gun starts to work. Please refer to the spray gun manual for the use of the spray gun.

Ninth, after the above functions are adjusted properly, you can start the air compressor, and the air pressure is about 4-6kg / cm3.

Lubrication

You know what?

In the tablet coating machine, the use of lubricating is also very particular.

The reduction gearbox’s worm and worm gear shall be lubricated by splash lubrication.

One bearing on the top is lubricated by an oil cup, which should be filled regularly.

You need to change the oil in the gearbox every six months.

You should remember that hl20 gear oil is used in winter and hl30 gear oil is used in summer.

Debugging

First, once the tablet coating machine is in place, you should place it smoothly and steadily and

fixed it with anchor bolts.

Second, you need to open the oil filler cap, and then add lubricating oil to the reducer until it reaches the oil mark line.

Third, you should place the electrical control box of the tablet coating machine on the dry and easy to operate side. After the powder is turned on, you need to rotate the sugar coating pot clockwise.

Fourth, when you are commissioning, you need to pay attention to whether the tablet coating machine has abnormal noise, so as to stop the machine in time for inspection.’

Fifth, you should know that the inclination of the sugar coating pot is related to the loading and the exchange performance of objects. Generally, when the loading is moderate and the inclination angle of the sugar coating pot is 30o, the production efficiency and quality are good.

Operating procedures of the tablet coating machine

First, you must carefully check whether the fasteners of all parts of the tablet coating machine are loose before operation.

Second, you need to dry the inside and outside of the sugar coated pot.

Third, start the main motor of the tablet coating machine and idle the machine for 2 minutes.

Fourth, when you finish the feeding step, you should first press the main motor button, then press the blower button according to the sugar crystallization, and turn on the tablet coating machine’s heating wire switch.

Maintenance and safety techniques of the tablet coating machine

First, you need to remember that the lubricating oil in the gearbox should be replaced regularly as required.

Second, if the sugar coated pot in a tablet coating machine is not used for a long time, it should be cleaned. The copper pot should also be coated with oil on its surface to prevent toxic copper compounds from being generated after the copper material of the pot is oxidized or damp.

Third, in order to ensure the lubrication conditions of the worm gear pair transmission in the reduction box, the temperature of the box during operation shall not exceed 50 ℃.

Fourth, the sealing ring at the worm shaft end should be checked and replaced regularly, generally not more than six months.

Fifth, the machine must be reliably grounded, and its grounding resistance should be ≤ 4 Ω.

Sixth, you cannot remove the protective covers of electrical appliances and belts casually.

About these 6 important things about the tablet coating machine, you must master them very, well ,which will be helpful to you in your future use of the coating machine.

You should know that the seemingly simple five operation steps involve all aspects of the production of the coating machine.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine