About AIPAK PHARMA

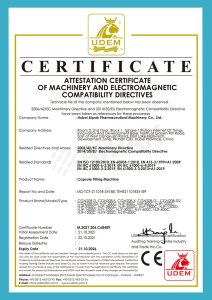

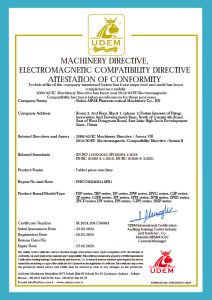

AIPAK PHARMA has been a trusted supplier of pharmaceutical processing & packaging machinery for over 10 years, serving the pharmaceutical, nutraceutical, biopharmaceutical, and biotechnology industries worldwide. We are committed to delivering technologically advanced, high-quality equipment that helps our customers optimize their production lines with greater efficiency and reliability. With continuous dedication to innovation, design, and manufacturing excellence, AIPAK PHARMA strives to be one of the world’s leading providers of fully automated and reliable pharmaceutical processing & packaging solutions.

Application

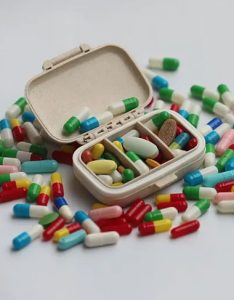

AIPAK PHARMA’s pharmaceutical equipment & packaging machinery is widely applied across multiple industries, enabling the efficient production of capsules, tablets, softgels, gummy candy, liquid ampoules, vials, and powder packaging solutions.

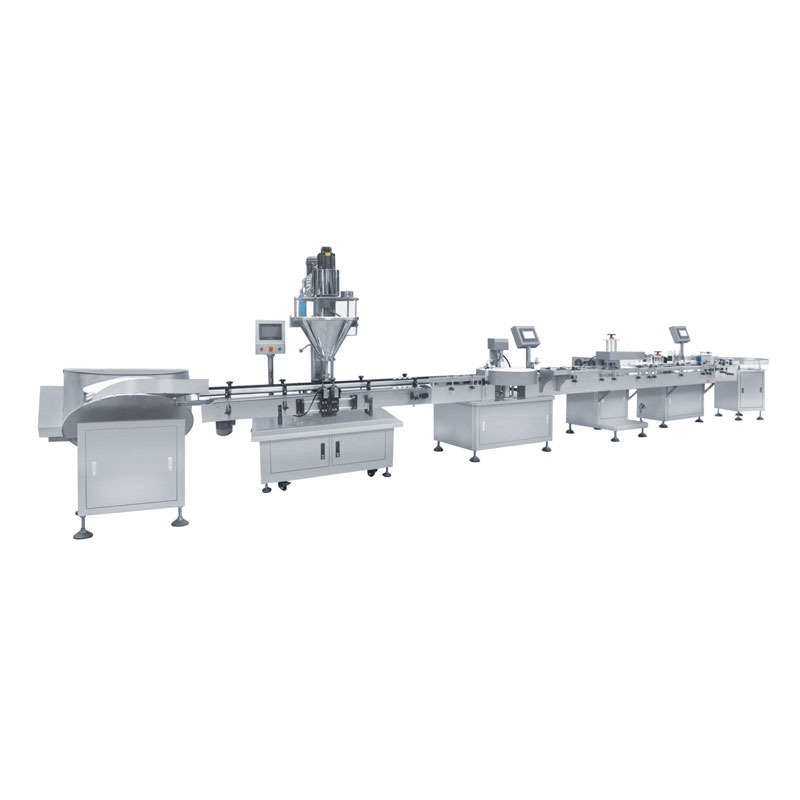

Powder Filling

Ampoule Filling

Blister Packaging

Suppository Filling

Tube Filling

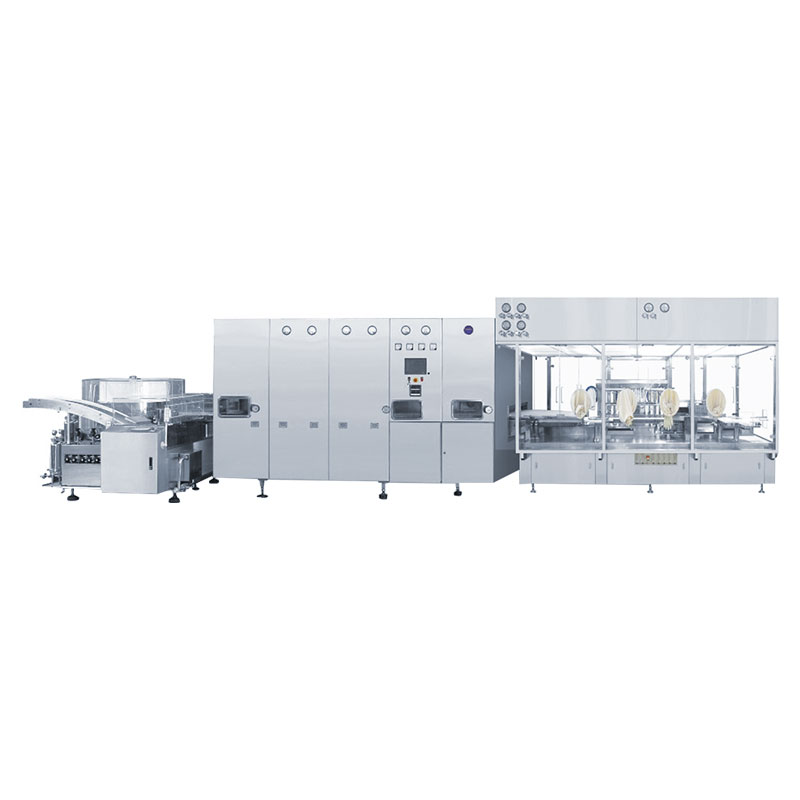

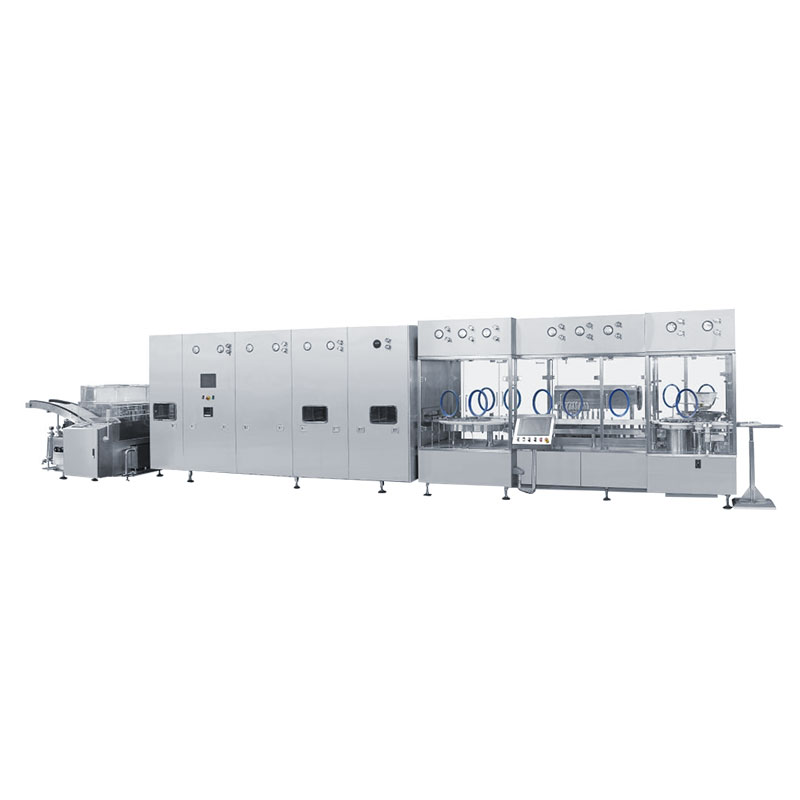

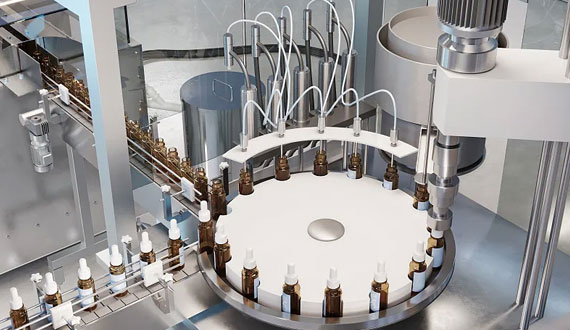

Vial Filling

Effervescent Tablets

Gummy Making

Liquid Filling

Softgel Making

Pharmaceutical Cartoning

Pharmaceutical Capsules

Pharmaceutical Tablets

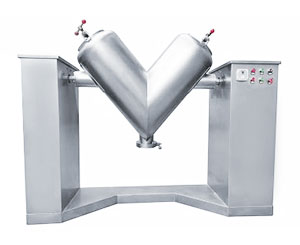

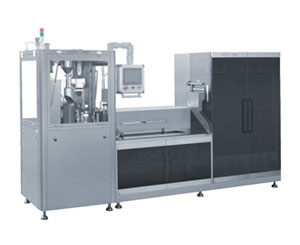

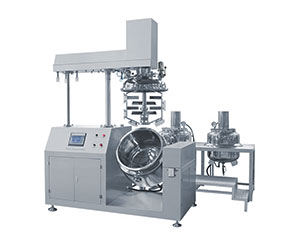

AIPAK PHARMA Processing & Packaging Machineries

One-stop Solution Line

Ensuring High Precision in Pharmaceutical Manufacturing

Scalable Solutions for Growing Production Demands

Maximizing Efficiency in Production Processes

Enhancing Product Safety and Quality

Pharma Processing & Packaging Machinery Projects

- All

- Capsule Project

- Tablet Project

- Softgel Project

- Liquid Project

- Gummy Project

Secure & Reliable Pharma Processing & Packaging Solutions

In pharmaceutical manufacturing, processing & packaging solutions play a vital role in ensuring product integrity, quality, and patient safety. Advanced processing systems guarantee precise formulation and contamination-free production, while reliable packaging solutions protect medications with tamper-proof security and compliance to global standards. By integrating automation, robust barrier technologies, and track-and-trace systems, manufacturers can streamline production, safeguard quality, and maintain trust throughout the entire supply chain.