PROJECT STORY

1

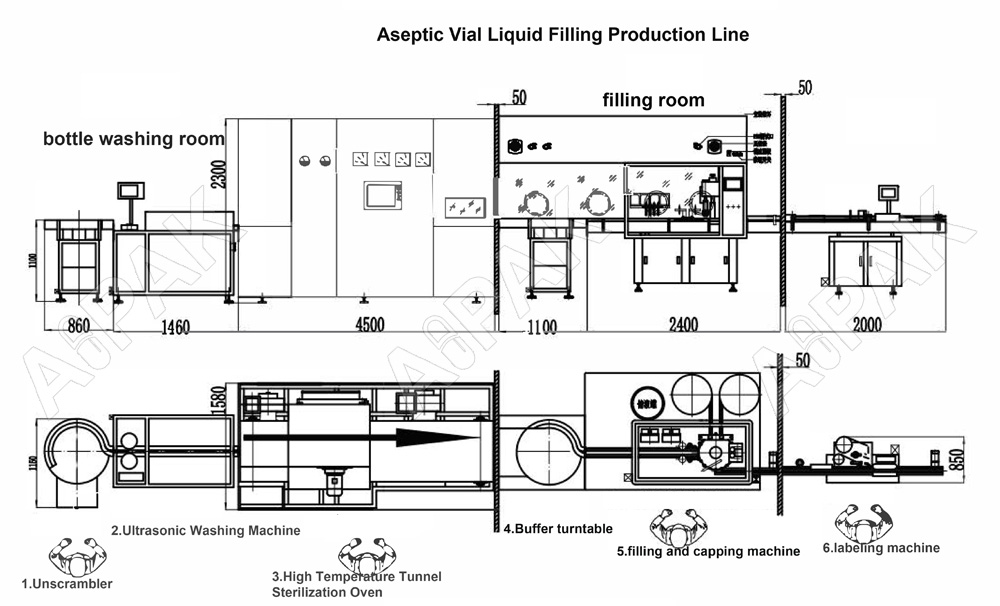

This large aseptic liquid filling production line project is for one manufacturer of hemodialysis machine in Iran and the Middle East,the customer Mr.Brian is the general manager,for long time manufacturing hemodialysis machine that served to the public or private sector,he wanted to transfer to liquid production,manufacture one kind of nasal drops with medicinal and health effects.

So he searched online and found us,after several times’ discussion,we got well known Mr.Brian’s requirement.They will set up a new factory to launch the new production line and they required on efficient production capacity as well as effective cost upon their budget.We precisely draw the 3D photos for him,and through several times’ negotitaion,finally,the whole large aseptic liquid filling production line was ordered.It was a long productsion line that will have several months’ delivery time,but Mr.Brian’s company agreed that.

PROJECT LAYOUT

1

Project Details

1

As the final products was to manufacturing nose drops,so it has requirement to the water that must be treated before filling.We designed the water treatment system for him,all water after treating fulfills the international pharmacopoeia meet with FDA requirement.

Purified water storage tanks

Purified water distribution and treatment system

RO and EDI system

When the water being treated,it will transport for filling,we designed the aseptic vial filling production line which is made of composed of ultrasonic bottle washing machine, dryer sterilizer, filling and stoppering machine, and capping machine. It can complete spraying water, ultrasonic cleaning, flushing of inner and outer wall of bottle, preheating, drying and sterilization, heat source removing, cooling, bottle unscrambling, filling, plug unscrambling, stopper pressing, cap unscrambling, capping and other complex functions, realizing automatic production of the whole process.

VIEW MORE PROJECTS

Related Products

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951