You Can Now Get Complete Guide For Suppository Filling Machine

For Suppositories Filling Machines influenced by traditional ideas, most people may not accept such products enough.

However, according to data analysis, roving sales have been increasing rapidly in the past few years.

As we have noticed that market is growing up and up, customers are more updated with the latest trends in the business of pharmacy.

Experts in the field are still accepting the suppository as a treatment tool because they know the effectiveness of the work.

Today I will utilize this suppository filling machine's definitive purchasing manual to present the low-rivalry, quickly developing suppository filling machine.

This suppository filling machine article will be explaining the latest news of the market, a bit of the introduction, components, working principle, features, a material used, quality control, quality standards, and much more related to the suppository filling machine.

Reading this guide will assist you in choosing the right suppository filling machine.

It’s time to move on.

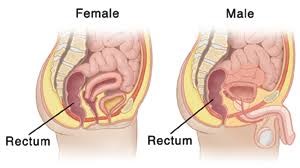

1. What Is A Suppository?

Suppositories-Photo Credit: Healthline

There are many different ways of giving drugs to the patient suppository is one of them. Most of the cases it is cone shaped, very small and round in the look and taken into the bottom by the patient or one who wants to use it.

Suppositories also perform in a different way like dissolving, melting and then start there function as drugs. Though, it is not considered one of the best of the experiences.

2. How To Put In A Suppository Without Tools?

Mostly, a suppository is inserted in the body using an applicator, but in case you don’t have that, you can also insert the drug without it. Since there are different types of suppositories, their insertion methods differ too. Following is the proper way to insert them in each case:

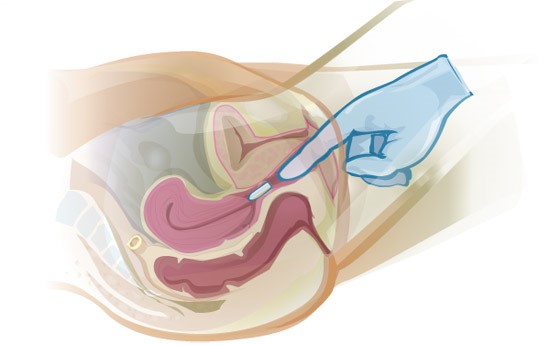

1.Rectum insertion

- The right time to insert a suppository in the rectum is when your colon is empty.

- Sanitize or wash your hands properly with a sanitizer, hand-wash, or soap. Use warm water.

- Unwrap the suppository and, if possible, lubricate it with a lubricant. You can also use water.

- Position your body. The most common position is to lie on the bed on your left side. But you can also insert a suppository while standing, but make sure your one leg is bent, and the other is straight.

- Now hold the drug in your hands, keeping the tapered end towards the rectum, and slightly insert it.

- The insertion depth should be about one inch.

- Wait for fifteen minutes. It is better to lay still until the drug melts and dissolves in the body.

- Lastly, wash your hands again or sanitize them with a sanitizer.

Rectum Insertion in Female & Male-Photo Credit: fair view Health Services

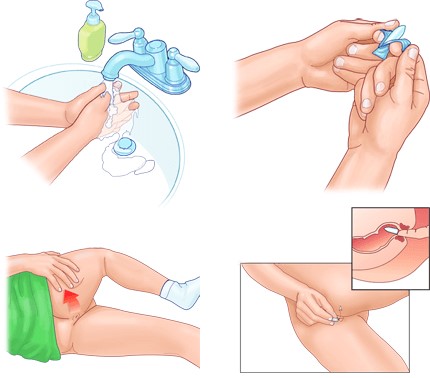

2.Vaginal insertion

- Sanitize or wash your hands properly with a sanitizer, hand-wash, or soap. Use warm water.

- Unwrap the suppository and, if possible, lubricate it with a lubricant. You can also use water.

- Sit on your back and open your legs. You can also lie on your back, but your legs should be open.

- Now hold the drug in your hands, keeping the edge towards the vagina, and slightly insert it.

- The insertion depth should be about one inch.

- Wait for a few minutes. It is better to lay still until the drug melts and dissolves in the body.

- Lastly, wash your hands again or sanitize them with a sanitizer.

Vaginal Insertion-Photo Credit: Nursing Crib

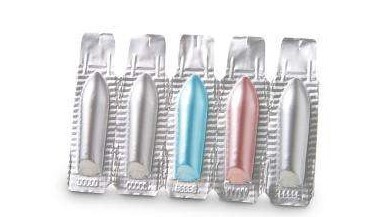

3.Urethral insertion

- The right time to insert a suppository in the rectum is when your bladder is empty.

- Sanitize or wash your hands properly with a sanitizer, hand-wash, or soap. Use warm water.

- Unwrap the suppository and, if possible, lubricate it with a lubricant. You can also use water.

- Sit in a comfortable position with your legs open.

- Now hold the drug in your hands, keeping the edge towards the urethra, and slightly insert it.

- Wait for a few minutes. It is better to lay still until the drug melts and dissolves in the body.

- Lastly, wash your hands again or sanitize them with a sanitizer.

Insertion Of Suppository-Photo Credit: fitoleum

3. Which Industries are Suppository Filling Machine widely Used?

Now that you have very well understood all the maths behind suppositories and their manufacturing machines, it is time to dig more into the topic and learn where in the world these machines can be successfully used.

- Pharmaceutical industries

Suppositories In Pharmaceutical Industry

Of course, the drugs have their greatest application for medical purposes. But even in that, there are different areas of interest. Firstly, the suppositories are greatly welcomed by pharmaceutical industries worldwide because of their efficient working better than oral dosages.

Next, since suppository filling machines produce drugs that can treat a wide range of illnesses without causing any severe side-affects, they are highly adopted in the medical industries. For example, rectal suppositories are beneficial in treating different types of allergies, anxieties, motion sicknesses, seizures, hemorrhoids, as well as itching, fever, and nausea.

One noteworthy thing is the effective use of suppositories in treating psychological disorders, including schizophrenia and bipolar disorders. Thus along with medical areas, psychogenic industries are also benefitting from suppository machines.

When it comes to vaginal suppository drugs, they are extremely effective in the areas regarding vaginal infections and vaginal dryness. What boosts up the use of suppository machines here is that they have opened up a whole new world of birth control intakes, which is another reason why pharmaceutical industries are showing great interest in them.

Last but not least, another area where the use of a suppository filling machine can be highly demanding in the production of dosages for erection problems in men. Especially when it comes to such sensitive conditions, oral dosages are not appreciated, which, again, paves the way for suppository machines!

- Food industry

Suppositories in food industry-Photo Credit: The Bold Italic

That’s right. Suppository machines are highly appreciated in the food industry too. But the question is how! To find the answer, it is important to keep in mind that not all nutrients or vitamin supplements are healthy enough to be taken orally.

In other words, recent research has shown that the bottom part of the body, that is, the rectum, is the main gateway into the body's central blood circulatory system. Thus by inserting the drug through the rectum and not swallowing or drinking it from the mouth will help circulate the nutrients directly throughout the body.

As it is mentioned again and again that suppository filling medicines are extremely safe than their hazardous counterparts. Thus they offer a safe absorbent of nutrients in the body. This not only reduces the after-effects of highly-rich minerals in the system but also saves you from the imbalance of hormones that you may get with an oral drug.

Apart from that, many herbal medicines intended to help regulate the normal functioning of the body also come under this category which adds the applications of suppository machines. In such a case, the important point is the neutral pH level in the rectum area, which makes the suppositories an excellent approach to take herbal products.

Furthermore, the mineral industry is filled with supplements, which sometimes are too concentrated that taking them orally is highly contagious. Thus, suppository machines save the world from all this hectic since their dosages have easy insertion along with no reactions.

- Cosmetic industry

Suppositories in food industry-Photo Credit: Valmatic srl

Not to be surprised, suppository machines also play well in the game of cosmetics. There is a wide range of areas where these machines come in handy. In the modern world, when lots of stress is put on the freshness of the outer body, why not the same should be applied to the inside of the body. While keeping up with such a statement begins the worldwide demand for suppository filling machines.

One thing to note here is that urethral suppositories are mostly rare in this industry, and more interests are towards vaginal and rectum suppositories. Now you may ask the use of such drugs, and for that, they serve almost the same function as a cosmetic for the skin: to keep up the balance of the inner system.

Now, what does that mean? It means that the use of suppositories in the cosmetics industry mostly concerns with the health and fitness of the feminine internal system. Thus they are manufactured to cleanse, freshen, and deodorize the vaginal area.

In addition to that, vaginal suppositories under the cosmetic sector are also formulated to cleanse, moisturize, and deodorize the body. However, when it comes to rectum cosmetics are mostly related to the prevention of constipation. The main component in these suppositories is glycerine which helps drain all the stool stuck in the body to clear the bowel, and thus letting the patient get rid of constipation.

The application is the same, and though for cosmetic use, they are manufactured in solid form harder than the usual suppositories, they also tend to break, melt and dissolve more quickly than the other suppositories.

Notably, the drugs should be made with extreme care if they are to be inserted inside the body for cleansing or deodorizing purposes, and that is why suppository filling machines are speedily conquering the industrial world.

4. What Are The Advantage Of The Suppository Filling Machine?

There is a long list of benefits that you can get with these machines as they are very efficient in their working and providing the world with profitable dosages. Though older machines were capable of producing only the specific drugs, with time, the technology has improved them a lot, and now they are highly in demand!

Following are some of the advantages of the suppository filling machines:

1. Modern suppository machines are automated and come with PLC programming.

As mentioned above, modern machines come with modern solutions. And one of them is their automated nature. Unlike other machines that are manual or semi-automatic in their working - which also makes the manufacturers prone to dangerous situations – suppository filling machines are fully automated.

This means there will be no self-working, and the whole process will be controlled through a control panel. In the case of suppository machines, they are programmed with PLC (Programmable Logic Controller). This not only has advanced features but also enables the user to monitor every step carefully.

Last but not least, another trait of suppository machines is the incorporation of alarm sounds which are also self-automated. This goes highly well with modern requirements as even a minor error can destroy all the manufacturing processes.

2. They feature easy installation and smooth working

Installation and Working

No doubt, their automatic nature makes them the easiest machines to operate. They are the best because they come with a built-in touch-screen panel to control the process. Since all you have to do is to have a good understanding of the controlling program, there is nothing that remains complex.

Also, contrary to other pharmaceutical drug formulation machines, which involve both time-taking procedures and dangerous risks, suppository filling machines offer both safety and excellent production at the same time.

The installation of the machine is an important step here. As otherwise, there would be multiple complications. For that, you can either assist someone or follow the instructions written on the machine manual.

3. Suppository machines offer a wide range of applications in the industrial world.

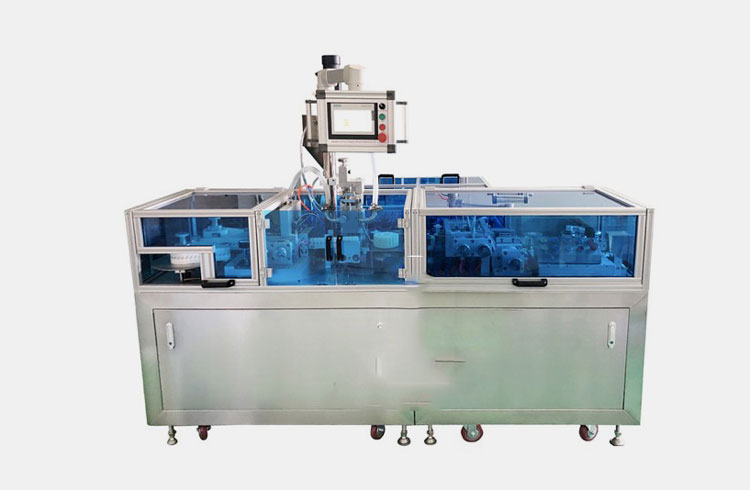

AIPAK High Speed Suppository Production Line

Now, this point is self-explanatory since the list of applications where suppository machines excel doesn't end. What makes them prominent in the industrial world is that their usage is not limited to only pharmacies. Rather a bunch of industries is profiting from them all across the globe.

If I talk about the psychological industries, then surely suppository filling machines have the greatest influence. Since the patients having psychological disorders often make it impossible to take any drug, especially in paranoid, bipolar, and schizophrenic disorders, a suppository drug helps the psychiatrists treat them well.

Other than that, food industries are flourishing under the suppository filling machines since they offer the best way to produce minerals and supplements that are not highly concentrated to damage the body. Furthermore, cosmetic industries take great advantage of suppository machines and especially when it comes to the care of the feminine body.

It is worth noting once again that the sector of childbirth control is now more secure and productive; all thanks goes to advanced suppository filling machines.

4. Their automated nature ensures fast production

Production-Photo Credit: China Sinopharm

Now you don't need to wait for days and weeks to finish a batch of drugs and medications. Neither do their production would require any hand labor. With the invention of automated suppository machines, all the problems regarding the production of drugs have been successfully solved.

Along with the manufacturing rates, time consumption is also improved since the programmed suppository filling machines now can do in hours what traditional alternatives took days to complete. This also ensures the safety of workers as now they don’t have to engage in working with sharp, dangerous machinery.

5. Modern suppository machines promise effective precision and accuracy

This feature of suppository filling machines is what out-dated all the other counterparts since it’s the preciseness that makes a drug effective. In the case of manual or semi-automatic machines, the possibility of rough and approximate dosages is very high. This not only leads to improper treatment but often puts in danger the health of patients.

With the PLC program in modern suppository filling machines, you can set all the quantities once in the control panel, and the automatic system software will handle the rest. With such high preciseness, there is no way the medicines will be inaccurately manufactured.

Another point that must be noted here is that the suppositories are inserted in the bottom area of the body, which comprises the central circulatory system. This means that any inaccurate dosage will adversely affect the normal functioning of the body. Thus, it is important that the drugs are formulated with the right quantity, and suppository machines make sure of that!

6. They don’t require careful maintenance

Now, this doesn’t mean that they don’t require any maintenance at all. Instead, it means that their automatic nature will do much of the work that would have never possible in the case of a manual or semi-automatic machine.

Also, since the machine is capable of producing a larger amount of drugs in lesser time, the process of cleansing all the chambers before preparing for the next batch would have been very exhausting. And that’s exactly what you would never experience with a suppository filling machine because their programmed software will get all the job done on its own.

That was the supervision part that usually comes after the successful production of a batch. However, you will still need to check up your machine for any impaired or damaged parts every week or month, depending on your usage.

7. Suppository machines solve all the spacious problems

Yes, absolutely! There was a time when machines used to come with a very small vessel that produces significantly below the quantity of medication. Not only that, but their small area also wasted a lot of product mixture, which in the end would add up the whole work.

But now, there is no need to be worried. Today’s suppository filling machines are capable of taking in high volumes of drug mixtures without creating a mess. Their large tanks save you from all the hectic of refilling the machine after the production of each batch.

And what better can it be to have a piece of equipment that not only takes in large fluid volumes but also doesn't waste the mixture! This makes these machines a must-have for industries.

8. They don’t take up much space!

What does the word ‘factory’ bring to your mind? A huge place with big, massive machines. Right? But what if I tell you that the modern suppository filling machines take only the half-floor space of their traditional counterparts? How satisfying!

You wouldn’t need to worry about space at all. Since these machines are made to go well with modern requirements, they can do more in less room. This goes side by side with the large tanks of suppository filling machines as they are designed in such a way that though they use massive parts, they don’t take much space at all!

Other than that, if the processing activity around the machine itself is concerned, there is no limitation either. You can leave only 1 meter of the distance around the gear, and everything is good to go!

9. Advanced suppository machines don't require time-taking certifications.

In case if you are anxious about the certification, keep in mind that a suppository machine is not any mere apparatus. They are premium quality machines that offer excellent functioning. This also positively affects their credentials since they come with all the necessary documents.

Some many different authorizations and organizations keep in check the proper credentials of suppository filling machines, and thus you can easily look for CPGP (Certified Pharmaceutical GMP Professional), CA (Certificate Authority), FDA (Food and Drug Administration), and ISO (International Organization for Standardization).

While purchasing a suppository machine, you will get all the necessary documents ensuring the proper credentials of the equipment. This makes all the procedures easier since traditional machines require long processes of certifications.

5. What Are The Disadvantages Of The Suppository Filling Machine?

Suppositories-Photo credit: Vetmedicas

First of all, there are very few disadvantages of suppository filling machines, especially if you compare them with a huge, never-ending list of their profits. Secondly, the negative points are not of suppository machines but the medication itself.

So here are some of the factors that lead to the drawbacks of a suppository machine:

The high cost of suppository medication

As mentioned again and again, on one side of the industries are showing great interest in suppositories, they are still unknown to many people.

This makes them expensive as the more common a drug is, the lesser price it will have. Though such a thing can benefit the manufacturers as they can sell their drugs at high prices, on the other side, it can also lower the chance of a massive formulation of suppository drugs.

6. What Are the Different Sort Of Suppository Filling Machines In The Market?

At the beginning of the guide, I gave a brief introduction to the types of suppositories. Each suppository filling machine is designed to prepare a specific suppository type. In other words, you cannot formulate all three types of suppositories with one machinery.

AIPAK SP-2 2 Nuzzles Suppository filling Machine

As there are three types of suppositories: vaginal, rectum, and urethral, you should carefully read the following explanation of each and then decide what will be your target. It is worth noting that whatever type you choose, the structure, modification, and operation of each will be the same.

1. Vaginal suppository filling machine

Vaginal Suppository filling Machine

This type of machine will formulate medication for vaginal infections as well as for other serious fungal infections, including vaginal candidiasis. There are many reasons for using a suppository in this case instead of an oral tablet, and the top of them is the effectiveness of the drug when combined with safety.

Other than that, with a vaginal suppository filling machine, you can formulate drugs that are helpful in birth control. The production of oral contraceptives is huge, but their failure in some areas, as well as the side-effects at the end of the day, is what builds the foundation for suppository filling machines.

2. Rectal suppository filling machine

AIPAK Rectal Suppository filling Machine

Here comes another type of suppository filling machine which is used to manufacture drugs for the rectum area. The rectum provides direct contact with the blood circulatory system in the body, and thus the suppositories inserted through it will effectively treat the problems.

While it is significant to note that investing in a rectal suppository filling machine will enable you to manufacture medication for a wide range of areas, this includes different types of allergies and anxieties, which can be treated well with a rectum suppository. Other than that, constipation is a common problem for which suppositories are particularly potent.

For patients having seizures, hemorrhoids, or any type of itching benefit greatly from rectal suppositories. Even in simple health problems such as fever and nausea, rectal suppositories are an easy cure. And still, there is so much more they can do. Anal pruritus, analgesia, sedation, and also when it comes to respiratory treatments, rectal suppositories are capable of medical treatment.

Now you can see how much benefit a rectal suppository machine can do as there are so many areas where its dosages are in demand. However, the size does differ from other suppositories, and since the rectum has a narrow space than the vagina, thus the suppositories have a round shape like bullets. They are almost one inch long, and the application is the same as others.

3. Urethral suppository filling machine

Urethral Suppository Filling Machine

Urethral suppository filling machines also have great importance in the industrial world since like other suppository machines, it also tackles sensitive body problems. However, since it is to be inserted in the urethral of the male body mostly, its size is relatively smaller than the counterparts.

Such an equipment helps in preparation of medicines for erection problems in men that have usually come in grain size. The medication or the inner mixture used in these suppositories is alprostadil which is highly effective in treating erectile dysfunction. It not only relaxes the male reproductive organ but also helps to regularize its blood circulation.

Some other interesting information about these machines is that there are three different forms (250, 500, and 1000) in which they can formulate the dosages (µg). Though treatments for such sensitive conditions are prescribed by the physician only, they also provide a huge opportunity to boost up your pharmaceutical business.

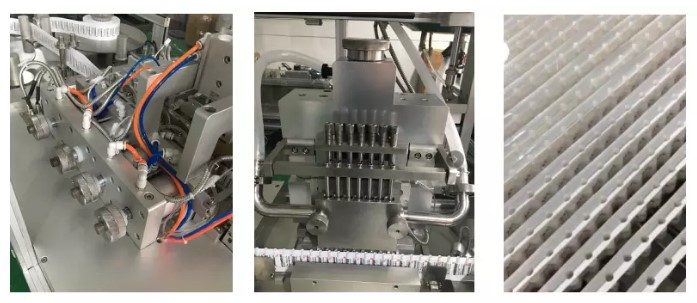

7. What Are The Different Parts Of The Suppository Filling?

After getting a thorough knowledge of different types of machines, now is the time to explore each of them and see how different parts are assembled to make up a suppository filling machine.

Parts Of Machine

Though the drugs differ in their size, formulation, and operation, the machines which make them are comprised of the same parts. This means that by understanding the major and minor components of one machine, you’ll be able to learn the operation of all sorts of suppository machines.

One thing that I should mention before moving towards the explanation is that all the parts or subunits of a suppository filling machine are equally important and play their key role in all the processing. This also means that leaving any component will adversely affect the production of the suppositories.

1. Film unwind system

Also known as the feeding part of the machine, this is the first chamber where the processing takes place. All the ingredients in their raw form are added here to be mixed to form the molds. Now it should be remembered that the film unwinds assembled in two strips.

Unwind System

Furthermore, this part also has two other subparts, which are called 'release plate,' where the film unwinds are placed, and the 'release fixture,' where it helps in the relaying of the film unwinds. It is also known as a clamp or a transmitting fixture. Now, if I talk about the different types of films, they can vary in the following rage: PE, PVC, or the combination of both.

2. The forming part

Now, this is the part where all the moulds are formed. Unlike other drug machines where first the inner mixture is formed and then the outer shell, suppository filling machines first prepare the molds and then go to the next step. A guide wheel is responsible for rolling the mixture for the shell area to be formed properly.

Forming Part

This chamber also has three clamps for different purposes. In the first one, the mold is positioned after providing enough heat, while the second clamp has the pre-heating cavity, and the third clamp is responsible for the formation of proper shapes of the molds.

Another subunit that helps a lot in the formation of the outer shell is the base finishing and the dotted line cutting gear, which forms the final shape of the shell by cutting it as instructed. Also, all the parameters or the instructions should be carefully inputted in this area because the entire success of the suppositories is based on their well-manufactured protective shell.

3. The filling system

This is a whole system designed to fill in the prepared moulds. It consists of a filling pump that pours all the inner mixture into a large bucket with the help of many plunger pumps. These pumps also take help from the ten injectors to fill the bucket with a mixture.

Filling Part

The heating system that comprises of two heaters lets the temperature rise at the desired limit, and then the agitator mixes all the ingredients with its sharp blades. The last component here is a circulating pump that is responsible for keeping all things in balance, such as providing adequate heat at a balanced mixing speed. When all the ingredients are mixed thoroughly, the moulds are filled.

4. The cooling segment

Once the molds are filled with an inner mixture, they are cooled. Now you may notice that the cooling part in a suppository filling machine takes place before the sealing step, and it is done by double cooling tunnels where a large number of prepared suppositories can be stored.

Cooling Part

As the name applies, the tunnels along with water chillers lower the temperature to let the suppositories cool down and eventually become solid. Another component that plays a significant role here is the air cooler fans which also help in regulating a low temperature.

5. The sealing segment

Now, this part is tricky so pay attention. Once the suppositories are cooled, it’s time to seal them. But since they are coming from a cold temperature in solid form, it is not possible to seal them without first ‘heating’ them.

Sealing Segment-Photo Credit: Pharmaceutical Blister

So, the sealing system is responsible for them to first re-heat them, but not at a very high temperature since it will lose all the progress made, rather at a temperature suitable to melt them enough to seal them with a sealing box element.

6. Marking / Printing System

Traditional suppository filling machines lacked in this part, but thanks to advanced technology, now you can customize your suppositories as per your likings. You can mark on your suppositories their expiry date (which is a must, though), their manufacturing date, and also assign them a batch number to keep them separated from other suppositories. All this is done through an inkjet printer that is capable of marking each suppository with a maximum of four lines.

7. Trimming/cutting segment

Till now, the suppositories are made successfully. But there is still one step missing, and that is to cut them into applicable sizes. Also, they should have a top edge to ease the insertion process. This is done by first through a sharp cutting component that ‘trims’ the suppositories to form a nice edge, and then another sharp blade takes the responsibility to cut them into desirable suppositories. This step is also affected by what type of suppository machine you are using since the size of each suppository differs according to its use in the vagina, urethra, or rectum.

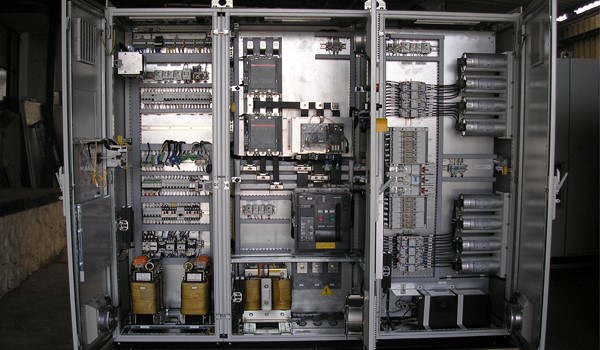

8. Electrical control system and Cabinet segment

Till now, all the parts of the machine engage primarily in the manufacturing of suppository drugs, but there is also another section that plays its role in making all that happen. This is the overall control system that keeps in check even the little details in each step. A well-structured electrical control system will comprise of the following subparts:

- PLC communication module: this subunit keeps in check the relaying and synchronizing of all the input data for successful processing of information to receive a desirable output in the end.

- Human-computer interface: Of course, the machine is automated, which means it is capable of doing all its work, but even before that, it is the user that gives instructions to the machine. This is done through the control panel, which has a built-in touch system and uses multiple features such as voicing and graphics to enhance the workflow.

- Sensors and transducers: now, these little devices are installed in the machinery to keep track of required inputs such as temperature, pressure, and ultrasonic sensitivity. Their main job is to transform one mode of energy into another form as per the requirement.

- The other minor components in this area are display panels, automated electronic switches, electromagnetic valve apparatus for air processing, warning electrical device in case anything goes wrong, thermo-regulators with thermoforming devices, different sensors, and Siemens components.

There are also some other parts of a suppository filling machine which though they do not comprise the main parts, but affect the smooth working of the machine if removed. These include dotted cutters, resistance heating rods, different types of cables, belts, and bearings, sealing rings, and also suppository molds.

8. How Does A Suppository Filling Machine Works?

Now that you have learned all the major and minor parts of a suppository machine, this section would be easy to grasp. All the functioning steps are the same and can be classified into:

- Film Unwind Stage: This stage is the beginning point of all the procedure and comprises unwind films which can be either made of PVC or PE or a combination of both. The release plate and release fixture both work together to process the materials.

- The formation stage: The guide wheels take the film strips in the forming section, where different processes take place to prepare the molds. This includes pre-heating the material, then rising the temperature to achieve the required heal level, and processing the material in it to 'form' the desired mold shape. The blowing casts or different clamps help in the molding process. In last, a triangle side knife along with dotted line blades give the prepared moulds a final shape.

- The filling stage: The moulds are now ready to be filled with material. The inner mixture is prepared beforehand, and the automatic nature of suppository filling machines fills in all the empty moulds. What's more relaxing is that both the heating of the mixture and the filling of molds take place at once. So, if there are any raw materials left, they will be in the heating process to the filling stage with the help of an agitator and the electric heater.

- The cooling stage: This stage cools the heated material into a solid form. The double cooling units have a vast space to store a large number of prepared suppositories while the cooling fans and water chillers provide them with enough cold.

- The sealing stage: Once the suppositories are cooled, they are sealed properly. They are first pre-heated, but the temperature is mild enough to not melt them fully and then re-heated to seal them in the sealing tails with a sealing element.

- The printing stage: Now that the suppositories are fully prepared, they are customized using an inkjet printer which usually marks them with their manufacturing date, expiry date, and batch number. Sometimes, they are also marked with the name of the manufacturing company to make the information even more precise.

- The cutting stage: This stage includes the cutting of suppositories in desired shapes. For vaginal suppositories, it will be an oval shape, while for rectum suppositories, the size will be round. In the case of urethral suppositories, the size will be even smaller and will be no more than the size of a grain. You can adjust all these parameters in the built-in display panel.

When the final product is made, they are packaged with the help of a cartooning machine which packs them in packets ready to dispatch.

9. What Are The Features Of The Suppository Filling Machine?

A suppository machine has worldwide applications. You can use it in pharmacies, food industries, and even in cosmetics ones. But the features are the same everywhere since the machine is designed to beat the alternatives with its advanced peculiarities. So here are some of the significant features of a suppository filling machine:

AIPAK Medium Speed Suppository Machine

Automatic nature

Modern suppository filling machines are automatic, which makes them an outstanding choice to go for. This simply means no in-depth understanding of complex machinery since everything will be done by just giving instructions. An automatic machine also excels in other areas because no human labor is needed, and thus you will save so much time!

PLC control panel

A display panel is pre-attached in the suppository filling machine to make all the complicated working a piece of cake. The software installed takes input data and processes it accordingly. It uses different functions such as graphics, voicing and comes with all the necessary options to manufacture suppositories.

PLC Control Panel-Photo Credit: Newtech System

Precision and accuracy

Another significant feature of a suppository filling machine is its ability to precisely measure all the material and then formulate the drugs accurately. Since the dosage is to be inserted in the most central part of the body, the active ingredient should be carefully measured. And with such a machine, the chances of error in the functioning fall to the lowest levels.

Large capacity

A large capacity tank or vessel ensures the production of a bigger batch. It saves the user from the hectic of filling the machine again and again, which, in traditional cases, would have required a lot of time as well as labor. Thus today’s suppository machines feature a large volume of materials and are even faster in their production rate.

Less floor space

With large volume comes a bigger floor space as well, but this is not the case with modern suppository machines. They take up a very reasonable floor area and even require no more than a meter of space for their surroundings!

No wastage

Another important feature of suppository filling machines is that they don’t waste excessive material, rather are designed to utilize in other ways. This also makes them one of the best choices to invest in!

Easy installation and maintenance

Suppository machines also feature an easy installation process along with less maintenance that makes them an easy approach even to those who have no understanding of complex mechanical structures. In addition to that, they also are easy to maintain, which was the biggest con of traditional counterparts.

10. What Are The Basic Quality Requirement For Suppository Filling Machine?

Though all the machinery of a suppository machine should comprise equipment that is of premium quality, there are some basic quality requirements for the overall machine that you should keep in mind when purchasing one. Here they are:

- Temperature: the suppository machine should be capable of melting the ingredients as well as mixing them thoroughly. This area also involves the cooling temperature since both heating and cooling are essential elements in the successful production of suppositories.

- Weight: this means that a suppository machine should be able to produce suppositories as per the weight and size requirements since different drugs have different insertion areas.

- Microbial limit: lastly, there are microbial limits that are confirmed by a microbial test. It is necessary because it ensures the authentication of the drugs to be formulated.

11.How Do You Fix Common Issues In Suppository Filling Machine?

Even if you are a professional or assist one in the installation process of your suppository machine, there can still be times when your machine can show unusual behavior. Common errors and minor problems are a part of the working environment, and especially if the machine is automatic, there can be situations like these.

However, you don’t need to consult professionals every time your machine doesn’t work. Rather, you should learn how to cope with certain signs because, in most of the case, the solution doesn’t require any complex fixation.

When it comes to a suppository filling machine, you may encounter errors that either belong to the system or the mechanical body of the machinery. In either case, the following is a list of all the possible problems with their solutions to help you confront them without wasting any money as well as time.

Problem 1: The machine isn’t starting

In many cases, the reason behind such a problem is the disconnection of machinery. Check all the equipment and ensure all of them are properly connected. Next comes the wires, and their connection should also be proper and accurate. Lastly, check if the emergency stop switch is strongly fixed.

Hopefully, this will help, and the machine will start. But if, after checking all the connections, the machine shows any unusual data on the touch panel, then you should consult a professional immediately.

Problem 2: The machine isn’t resetting

There are two things that you can do here: Stop and restart the emergency stop button. Ensure the proper functioning of the sensors.

Problem 3: The machine isn’t starting in the automatic mode

Again, here the problem can be caused by an emergency stop switch which can get lose with time. Thus, if that's the case, fix it properly. Next, ensure the proper functioning of all the sensors since their impaired signals can affect the working of the machine. You should reset the machine if that doesn't work or configure it into its programmed state. And in last, if the display panel shown unfamiliar data, consult a professional.

Problem 4: The display panel is not working properly / not showing proper communications

The power cables are to be checked if such a problem occurs. All the cables should be connected properly, and the communicator should be properly linked with the power control.

Problem 5: The temperature isn’t rising for the preparation of shell/mould

The main reason can be a short-circuited heater so check that. If not, reset the thermostat and carefully observe its proper functioning. Next, check the hearing wires. In case if they are broken, replace them immediately. Also, the terminals of heaters should be sturdily connecting the mold.

Problem 6: The processing speed is not stable/slow down

The three components/elements responsible for this problem can be the seal ring, pneumatic pipe, and air pressure. The first one should be firmly attached to the piston and replace if it is broken. The second one shouldn't be leaking or have any blockage in it. At the same time, the last one should be stable and sufficient enough to aid smooth processing.

12. What is the Recent Technological Advancement in Suppository Filling?

Traditional suppository filling machines were capable of doing just the basics, while the modern ones are built with advanced technology to boost the overall processing. They save time, money, and even maintenance problems. But other than that, there are also so many things that are being improved daily to help manufacturers get the best of it!

Human-friendly display panel

The world is advancing fast, and know that every person has a touch screen mobile, working on buttons and switches feels troublesome. And that is why modern suppository filling machines are designed with a built-in display panel that allows you to control all the processing by just setting the parameters on the screen. You can alter temperature, pressure, and even speed with the help of the control panel.

Thermostat

Another brilliant addition to modern machines, the thermostat takes the responsibility to maintain the desired temperature during the processing. Thus with such technology, you can easily alter between different settings by giving commands on the display panel.

However, what makes it exceptional is its ability to use alarms to warn the user whenever the level of temperature rises or lowers than what was required. Thus it not only saves the material from getting over-heated but also protects the machinery.

Optical fiber

The innovation of optical fiber has changed all the game. The power that keeps all the processing going is handled through the sensors and photocells, which use induction lamps to ensure the successful transmission and reception of the information through the fiber cables. With such a sensitive job, they also require proper maintenance and careful checking daily. Another thing to note down is that the sensors and photocells should be correctly fixed to ensure their best performance.

13.Is CGMP Compliance Important For Suppository Filling Machine?

The answer to this question is Yes, and the reason behind this is that CGMP (Current Goods Manufacturing Parties) checks all the requirements that a machine needs to fulfill to maintain premium style working according to modern needs of formulation of suppositories.

14. How To Maintain Suppository Filling Machine?

Maintaining the suppository machine is a must not only because it is a huge investment but also because a sound machine will ensure the excellent quality of your products. Thus you must take great care of your suppository filling machine on a daily, weekly, and monthly basis. As previously mentioned, a suppository machine is divided into four main parts or chambers. Following is the list of all the parts you should carefully examine:

- The main unit: the films should be reviewed daily. Both the release plate and the release fixture should be working in a flow.

- The filler unit: Ensure that the guide wheel works properly and the heating gear is not damaged. The dotted cutting gear shouldn’t be prone to rust which otherwise would cause great loss.

- The chiller unit: Here, you should focus more since the double cooling tunnels may have residue left of heated suppositories. The water chillers and the air cooler fans should not be unstable as their correspondence during the cooling part ensures a quality product.

- The ultimate unit: Like the double cooling tunnels, the sealing box can also have residue stick to it since it seals the heated suppositories. Carefully examine all the sharp edges of the gears since they shouldn’t be damaged. Also, the inkjet printer should be saved from clogged nozzles.

15. How Much Room Space Required To Place The Suppository Machine?

It should be clear by now that a modern suppository filling machine doesn't take much space. But the factor of size, at the same time, is also affected by the difference of models. Other factors include the weight of the machine, the heights, as well as the length and width of the machine since all of these combine to form the room space.

16. Any Suggestions For Room Temperature And Humidity Control?

There are no specific requirements when it comes to the temperature since the machine is specifically designed to cool itself with its built-in cooling system. However, the general room temperature should be a must since a high temperature can affect the working.

17. How Does Suppository Dissolving Time In Anus?

It depends on what ingredients are used. The average time is 15-20 minutes, but it is recommended to stay still for half an hour to maximize the effectiveness of the drug.

Suppository Filling Machine Related Products

Suppository Filling Machine Related Posts

Suppository Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine