PROJECT STORY

1

Mr.Boris is an OEM supplement manufacturer for natural health food & supplements from America,he has a large facory located in California that manufactues lots of supplement products,like capsule,tablets,powder,liquid,ready-to-drink,pet food,protein energy bar,etc. He is also a professional manufacturer of plant extraction use in the nutraceutical, pharmaceutical, health-food, functional beverage, and cosmetics industries.

In 2020,one of his partners recommend the good prospect of gummy candies to him,so he wanted to have a try,then he searched online and found us.

We provided 3 sets of solutions for his choice,finally,as per Mr.Boris would like to have a trial production,so he chose a small scale APK-GM80 gummy making machine and the whole production line.

PROJECT LAYOUT

1

PROJECT DETAILS

1

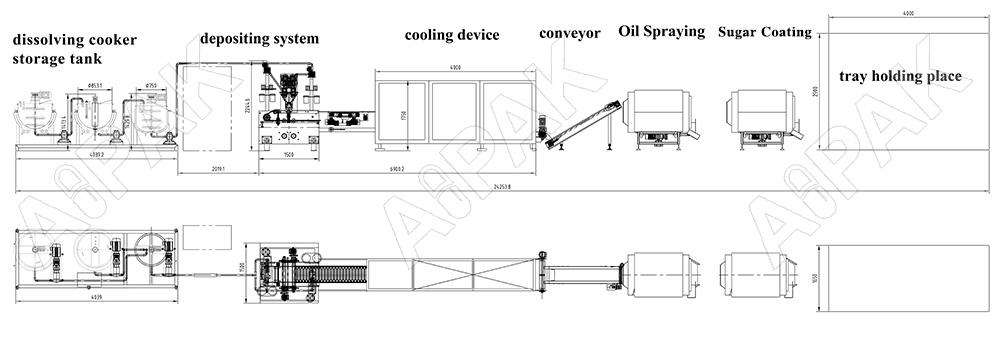

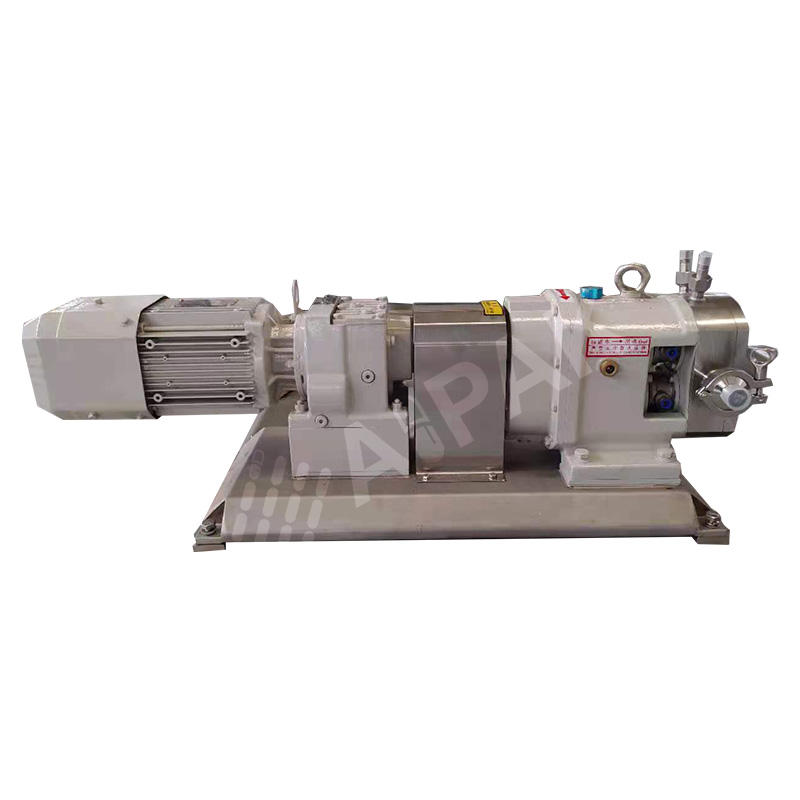

The production of gummy candies involves some axuiliary devices like the dissolving cooker storage tank,depositing system,cooling deive,conveyor,etc.

And as Mr.Boris’s requirement,he would like to try gummies coated with sugar,so we have designed a oil spray coater and sugar coater for him.

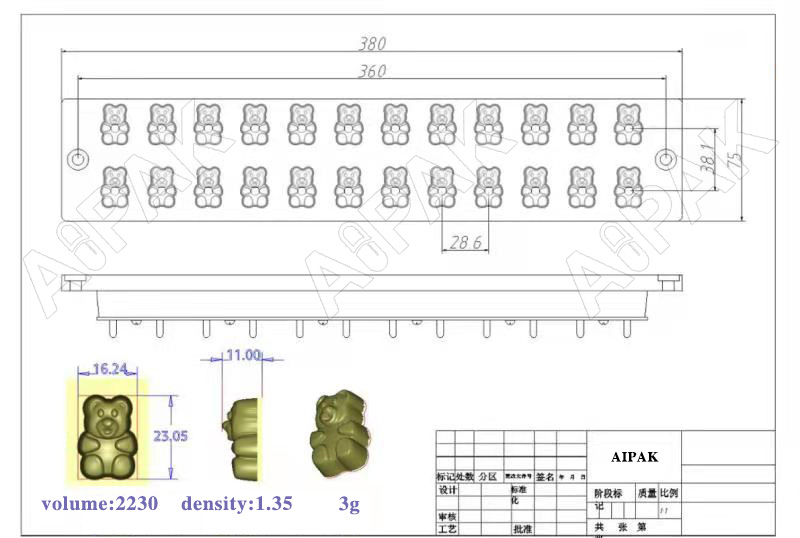

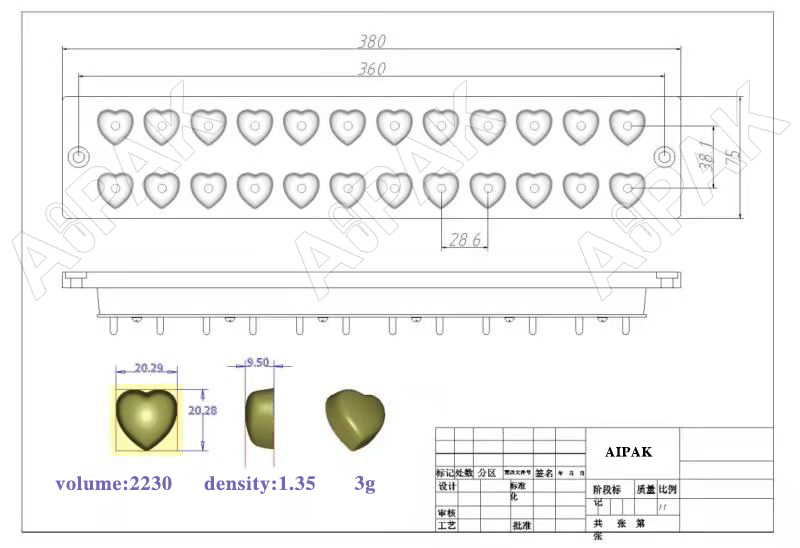

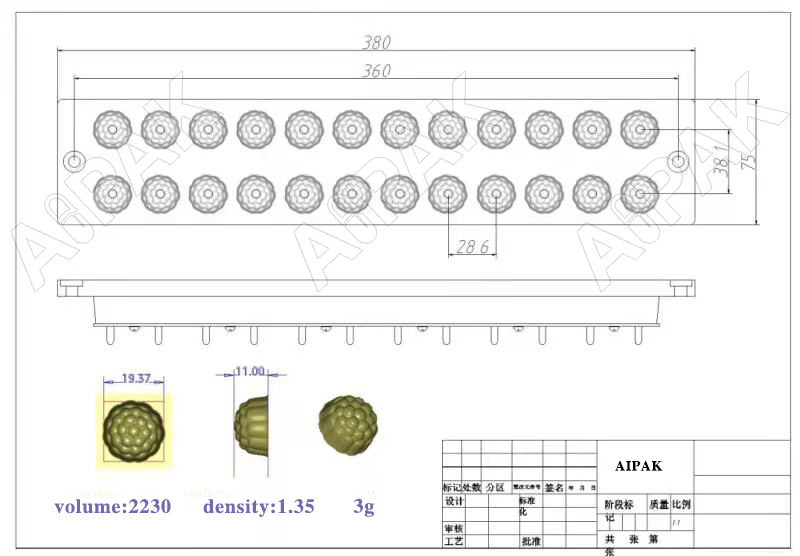

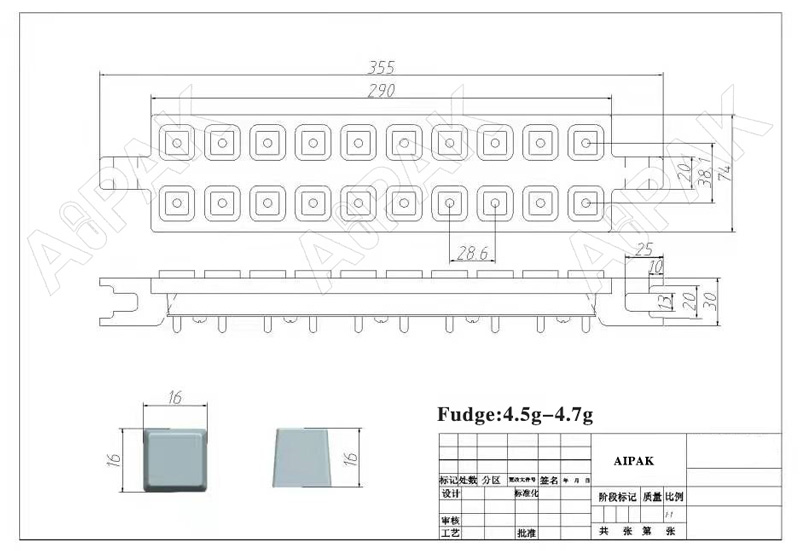

Gummy turnover tray

Gummy tray holding place

VIEW MORE PROJECTS

Related Products

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586